Discover the Advantages of Carbon Biaxial Fabric for Improved Manufacturing Processes

By:Admin

Company News & Blog

High-Quality Kevlar Cloth: Lightweight and Versatile Reinforcements for Resin Composites

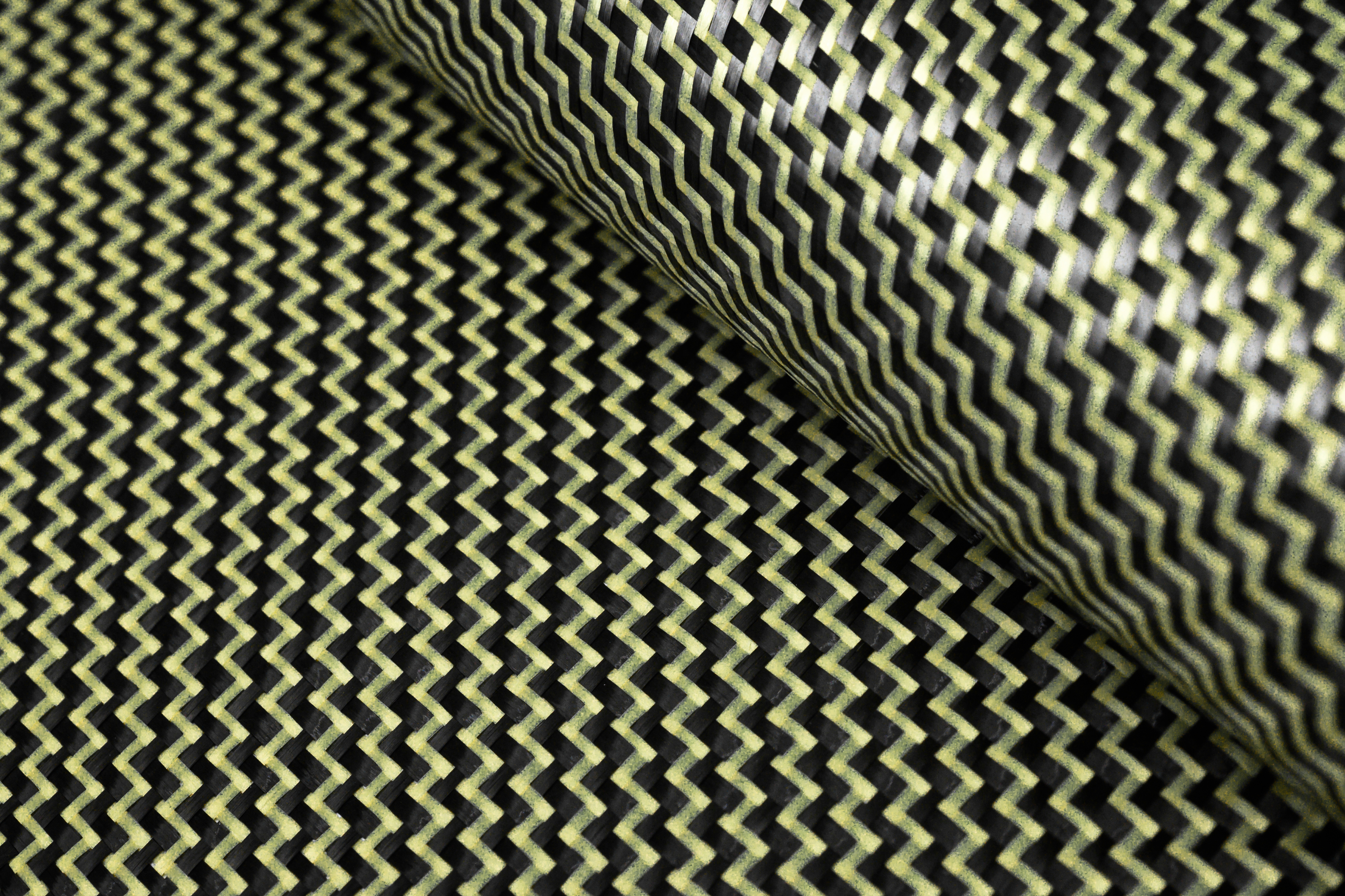

Title: The Dynamic Duo: Exploring the Versatility of Carbon Kevlar WeaveIntroduction:In the realm of materials engineering, few combinations hold as much promise as carbon and Kevlar reinforcements. The intertwining of these materials results in exceptional strength, durability, and remarkable versatility. Today, we delve into the world of carbon Kevlar weave, its various applications, and the significance it holds in several industries.Chapter 1: Understanding Carbon Kevlar Weave and its Composition1.1 Origins and Development: - A brief history of carbon Kevlar weave, its inception, and how it has evolved over the years.1.2 Composition and Characteristics: - An in-depth look at the properties of carbon Kevlar weave, including its weight options and weaving techniques. - The applications that carbon Kevlar weave is best suited for due to its specific characteristics.Chapter 2: The Exceptional Mechanical Properties of Carbon Kevlar Weave2.1 Fatigue Resistance: - Discussing the superior fatigue resistance exhibited by carbon Kevlar weave and how it contributes to its longevity and reliability.2.2 Impact Strength: - Delving into the impressive impact strength of carbon Kevlar weave and its applications in high-stress environments.2.3 Durability Under Extreme Conditions: - Analyzing the ability of carbon Kevlar weave to withstand harsh environments and extreme temperatures. - Highlighting real-world examples where carbon Kevlar weave has shown exceptional durability.Chapter 3: Applications of Carbon Kevlar Weave in Various Industries3.1 Aerospace and Aviation: - Exploring how carbon Kevlar weave is utilized in aircraft construction to enhance structural integrity and reduce weight. - Highlighting the advantages carbon Kevlar weave offers in terms of fuel efficiency and improved performance.3.2 Automotive and Motorsports: - Discussing the use of carbon Kevlar weave in high-performance vehicles and its contribution to safety and improved aerodynamics.3.3 Sports and Recreation: - Examining how carbon Kevlar weave enhances the performance and durability of sports equipment, such as bicycles, tennis rackets, and race car helmets.3.4 Marine and Defense Applications: - Analyzing the role of carbon Kevlar weave in marine vessels and military equipment, emphasizing its ability to withstand water and extreme conditions.Chapter 4: Maintaining and Protecting Carbon Kevlar Weave4.1 Sensitivity to UV Light: - Understanding the impact of prolonged UV exposure on carbon Kevlar weave and the necessary precautions to minimize damage.4.2 Compatible Resins: - Highlighting the resin options that work well with carbon Kevlar weave, including UP, VE, and EP resins.4.3 Care and Maintenance: - Offering tips and best practices for preserving the longevity and performance of carbon Kevlar weave products.Conclusion:With its exceptional mechanical properties, durability, and versatility, carbon Kevlar weave has revolutionized numerous industries. This groundbreaking composite material continues to push boundaries and set new standards for strength and performance. From aerospace to automotive, sports to defense, carbon Kevlar weave remains a game-changer, unparalleled in its ability to enhance and fortify various applications.Keywords: Carbon Kevlar Weave, Carbon and Kevlar Reinforcements, Carbon Kevlar Cloth, Carbon and Kevlar Composites, Fatigue Resistance, Impact Strength, UV Light Sensitivity, Versatility, Applications, Aerospace, Automotive, Sports, Marine, Defense.

How Sewing Fiberglass Fabric Can Enhance Your DIY Projects

Title: Innovative Sewing Fiberglass Fabric Revolutionizes the Textile IndustryIntroduction:The textile industry is witnessing a groundbreaking innovation with the introduction of a remarkable sewing fiberglass fabric. Manufactured by an industry-leading company, this fabric is set to revolutionize various sectors, including automotive, aerospace, and construction. Offering exceptional strength, durability, and versatility, this cutting-edge material is poised to transform the way fabrics are used in diverse applications.1. Overview of the Sewing Fiberglass Fabric:The sewing fiberglass fabric, developed by a renowned company, combines advanced technology and meticulous craftsmanship to create a unique textile solution. With its distinct properties, this fabric surpasses traditional materials and offers numerous advantages across multiple industries.2. Strength and Durability:One of the key attributes of this sewing fiberglass fabric is its exceptional strength. Manufactured using a high-density fiberglass material, it provides exceptional tensile strength, making it ideal for applications that require resistance to heavy loads or extreme conditions.Moreover, the fabric enjoys remarkable durability, ensuring its longevity and reliability. Its robust composition enables it to withstand wear and tear, making it superior to conventional fabrics. These qualities make the sewing fiberglass fabric an unparalleled choice, particularly in industries where performance and longevity are crucial.3. Versatility in Applications:The introduction of this revolutionary sewing fiberglass fabric has opened up new possibilities in various sectors. In the automotive industry, it is being employed for the manufacturing of lightweight yet sturdy car seats, ensuring enhanced safety and comfort for passengers. Additionally, its application in vehicle upholstery offers exceptional resistance to fire and heat, further improving safety measures.Furthermore, the aerospace sector has recognized the potential of this fabric. Its unique combination of strength and lightweight properties makes it an ideal material for constructing aircraft interiors, including cabin panels and overhead storage compartments. By utilizing this fabric, aerospace manufacturers can reduce weight and improve fuel efficiency without compromising structural integrity.The construction industry also stands to benefit significantly from this remarkable fabric. Its high resistance to corrosive substances and extreme temperatures makes it suitable for reinforcing concrete structures, ensuring enhanced durability and longevity. Additionally, its application in the production of fire-resistant curtains or protective clothing for construction workers further adds to its versatility in this sector.4. Environmental Impact and Sustainability:The manufacturing process of this sewing fiberglass fabric adheres to strict environmental regulations, making it a sustainable alternative in comparison to other materials. Its longevity and robustness also contribute to reducing waste since it requires less frequent replacement. Moreover, its potential for recycling adds further value to its sustainability.5. Future Developments and Market Potential:The sewing fiberglass fabric is expected to witness extensive demand in the coming years. As the textile industry continues to focus on sustainability and innovative materials, this fabric's unique qualities make it a sought-after choice. The market potential is promising as major industries embrace the benefits it offers while seeking more efficient and eco-friendly solutions.Furthermore, ongoing research and development efforts are aimed at enhancing the fabric's properties, making it even more durable, lightweight, and cost-effective. Collaborations with other technology companies and fabric manufacturers are being explored to expedite the adoption of this fabric and explore new applications.Conclusion:The introduction of sewing fiberglass fabric marks a significant milestone in the textile industry. Offering unparalleled strength, durability, and versatility, this fabric has the potential to transform various sectors, from automotive and aerospace to construction. As its market potential grows and further advancements are made, this innovative fabric will continue to redefine the industry's standards, making it a cornerstone of textile manufacturing in the future.

Discover the Advantages of Carbon Quadraxial Fabric for Enhanced Performance

[Assistant]Title: Revolutionary Carbon Quadraxial Fabric Redefines Composite Material IndustryIntroduction:In an exciting breakthrough, a leading company in the field of advanced materials has unveiled a revolutionary product that promises to reshape the composite material industry. Carbon Quadraxial Fabric (CQF), a game-changing innovation, is set to enhance the performance and capabilities of numerous industries, ranging from aerospace and automotive to sports and recreation. With its exceptional strength, versatility, and manufacturing flexibility, CQF is primed to become a go-to material for engineers and designers worldwide.Main Body:1. Understanding Carbon Quadraxial Fabric: Carbon Quadraxial Fabric is manufactured using advanced technologies that ingeniously weave together high-tensile carbon four-axis filament yarns. This proprietary weaving technique results in a fabric that boasts superior mechanical properties, including exceptional strength, stiffness, and fatigue resistance. Unlike traditional carbon fabrics, CQF also exhibits reduced delamination and improved impact resistance, making it an ideal choice for demanding applications.2. The Unprecedented Versatility of CQF: The unique characteristics of Carbon Quadraxial Fabric allow it to be utilized across a wide array of industries, offering benefits that surpass those of traditional materials. From lightweight structural components in the aerospace sector to high-performance body panels in the automotive industry, CQF offers heightened strength-to-weight ratios without compromising durability. Additionally, its exceptional resistance to chemicals and extreme temperatures makes it valuable in industrial settings.3. Revolutionizing Aerospace Manufacturing: The aerospace industry, in particular, stands to benefit immensely from Carbon Quadraxial Fabric. The material's exceptional strength and stiffness make it a perfect fit for designing and manufacturing aircraft components. By utilizing CQF, aerospace engineers can achieve increased fuel efficiency, reduced maintenance costs, and improved overall performance. Moreover, CQF's low thermal expansion properties make it a preferred choice for applications requiring stability at varying temperatures.4. Application in Automotive Engineering: Automotive manufacturers are eagerly embracing the potential of Carbon Quadraxial Fabric for its ability to enhance vehicle performance and fuel efficiency. Lightweight components made with CQF allow designers to reduce vehicle weight while maintaining structural integrity, leading to improved handling, reduced emissions, and increased overall energy efficiency. Additionally, CQF's impact resistance properties contribute to increased passenger safety.5. Impacting Sporting and Recreational Industries: Sports and recreational equipment manufacturers are also recognizing the tremendous advantages of Carbon Quadraxial Fabric. From high-performance bicycles and tennis rackets to skis and golf clubs, CQF's exceptional strength and stiffness provide athletes with a competitive edge. Its lightweight nature also enables enthusiasts to enjoy more comfortable and energy-efficient experiences.Conclusion:The introduction of Carbon Quadraxial Fabric onto the market represents a significant watershed moment in the composite material industry. This cutting-edge technology promises to revolutionize various sectors, offering unparalleled strength, versatility, and durability. As CQF gains widespread adoption, industries can expect to witness exponential advancements in product performance, design, and sustainability. With limitless possibilities in fields ranging from aerospace and automotive engineering to sports and recreation, Carbon Quadraxial Fabric is poised to redefine the future of advanced materials.

New Colored Carbon Fiber Fabric Now Available in the Market

Colored carbon fiber fabric takes the textile world by stormThe textile industry, like many other sectors, constantly seeks to innovate and incorporate new materials into their portfolio. One such industry that has experienced a significant shift is the carbon fiber fabric market. Carbon fiber fabrics are widely used in several industries, including aerospace, automotive, and sporting goods. They have gained popularity due to their amazing attributes, such as lightweight, high tensile strength, stiffness, and chemical resistance, making them ideal for various applications.A few years ago, colored carbon fiber fabric entered the market, marking the onset of a new era. Unlike traditional carbon fiber, which has a dark black hue, colored carbon fiber is vibrant and captivating. The new fabric has been warmly embraced as it offers a wide range of aesthetically pleasing possibilities. The fabrics are a favorite of high-end fashion designers and luxury brands who have incorporated it into their collections, giving their products a sophisticated look. One company that has excelled in producing the colored carbon fiber fabric is the {remove brand name} firm. They have made a significant impact in the market due to their unmatched flair and creativity in the production process. According to Tim Smith, the company's COO, the colored carbon fiber fabric is achieved by introducing colored films in the weaving process that gives the fiber added color. The result is a weave of colored carbon fiber textiles that match the color scheme of a customer's specification.The new fabric has found its way into numerous industries and applications, as companies seek to augment their products with a touch of elegance and class. For example, car enthusiasts can use the colored carbon fiber to indulge in their car's customization, giving it a personal flair that catches the eye. As for sports enthusiasts, brands use the carbon fiber fabric to produce superior quality sports equipment that is both lightweight and durable.One crucial benefit of this new fabric is the wide range of design options available. The carbon fiber fabric can be further enhanced with added patterns and textures to create more complex structures. This versatility in design vastly expands the range of applications the carbon fiber fabric can be used in, making it a top choice in the market. But it's not all about aesthetics; the colored carbon fiber fabric holds immense value in various applications that require durable materials. The colored carbon fiber fabric has extensive use in the aerospace industry as it is lightweight, yet strong enough to meet the high safety standards required. Since the fabric's introduction into the market, the aerospace industry has embraced it as the go-to material for a variety of applications. Another industry that has reaped the benefits of the new fabric is the marine industry. The colored carbon fiber fabric's unique properties make it the ideal material for boat-building as it offers durability and high-performance capabilities in harsh environments. Furthermore, the fabric's moisture-resistant properties prolong its lifespan, making it a sound investment for boat owners. In the medical industry, the colored carbon fiber fabric has found even more applications. The material is ideal for making prosthetics as it is lightweight and durable. It can be used in artificial limbs to provide amputees with a more comfortable and mobile life. The colored carbon fiber fabric in prosthetics has also found application in the entertainment industry, where it is used to create realistic-looking props and costumes. The colored carbon fiber fabric has created a whole new world of possibilities for the textile industry. It offers both elegance and functionality, combining aesthetics and durability. The fabric's range of applications and design options has made it a top choice in many industries, and its future only seems to shine brighter. According to {remove brand name}'s Tim Smith, with the increased focus on sustainability and eco-friendliness, they have embarked on developing eco-friendly colored carbon fiber fabric. This move is aimed at ensuring that the company conforms to the industry's sustainability guidelines and reduces its carbon footprint. The company plans to introduce this new material in the market soon, and the textile industry is eagerly waiting for it. In conclusion, the colored carbon fiber fabric is an exceptional innovation that has transformed the textile industry. Its lightweight, strong, and aesthetically appealing properties make it diverse, resulting in its extensive application in various sectors. With the development of eco-friendly materials, the colored carbon fiber industry is well-positioned to pave the way for a more sustainable future.

Innovative 3D Fabric: The Future of Fiberglass Technology

[Title]: Revolutionary Fiberglass 3D Fabric: A Breakthrough in Textile Innovation[Subtitle]: Company X Introduces a Cutting-Edge Solution to Reinforcing Materials Industry[Date][City], [State] - Company X is proud to present its revolutionary Fiberglass 3D Fabric, a breakthrough textile innovation set to transform the reinforcing materials industry. With its unique construction and superior performance, this fabric is primed to revolutionize various sectors, from aerospace and automotive to construction and marine.Fiberglass 3D Fabric serves as a game-changer in the realm of textile-based solutions. Adhering to the company's dedication to quality and innovation, this fabric sets new standards by combining strength, durability, and versatility. With its unmatched ability to reinforce numerous materials, Fiberglass 3D Fabric is spurring a paradigm shift in industries worldwide.At the core of this cutting-edge fabric is its three-dimensional structure. Through an intricate weaving process, the fabric gains exceptional strength, resilience, and adaptability. The precise interlacing of fiberglass strands forms a matrix-like composition, allowing it to withstand significant forces while maintaining its integrity.With this unique construction, the Fiberglass 3D Fabric boasts exceptional mechanical properties, allowing it to be used as a superior reinforcement material. Compared to traditional textiles, this fabric offers significantly higher tensile strength, tear resistance, and dimensional stability, making it ideal for applications that require exceptional structural integrity.But the benefits of Fiberglass 3D Fabric go beyond strength alone. Its innovative design enables efficient resin impregnation, ensuring maximum saturation and adhesion. This feature enhances composite bonding and results in improved resilience against environmental factors such as moisture, temperature fluctuations, and chemical exposure.The versatility of Fiberglass 3D Fabric is another asset that sets it apart from other reinforcement materials. Irrespective of the shape or form of the object, this fabric effortlessly molds itself to the desired contours, ensuring consistent reinforcement throughout the structure. This adaptability opens up novel avenues for its application, such as complex geometric shapes and intricate designs, empowering designers and engineers to explore uncharted territories.As a testament to its remarkable qualities, Fiberglass 3D Fabric has already found applications in various industries. In the aerospace sector, it is enhancing structural components in aircraft, increasing strength while reducing weight. Automotive manufacturers are incorporating the fabric into vehicle bodies, providing additional safety and rigidity. In construction, Fiberglass 3D Fabric is reinforcing concrete elements, ranging from bridges to buildings, ensuring longevity and resilience. Marine applications see its extensive use in boat hulls and other watercraft components, providing unmatched durability in challenging environments.Moreover, the sustainability aspect of Fiberglass 3D Fabric adds to its appeal. This fabric is manufactured using environmentally friendly techniques, ensuring minimal carbon footprint throughout its production process. Its long-lasting properties further contribute to the reduction of waste generated by material replacement, making it a sustainable choice in the long run.Company X, in collaboration with leading research institutions, continually expands the application possibilities of Fiberglass 3D Fabric. Ongoing research focuses on further optimizing the fabric's properties, exploring additional industries for its application, and enhancing manufacturing processes to meet increasing demands.With the introduction of Fiberglass 3D Fabric, Company X solidifies its position as a pioneer in textile innovation. The company's commitment to pushing boundaries and reimagining possibilities has resulted in a fabric that combines strength, versatility, and sustainability. As industries across the globe embrace this revolutionary solution, the future of reinforcement materials has never looked more promising.

Discover the Incredible Potential of Camouflage Carbon Fiber Fabric

Title: Revolutionizing Camouflage: Introducing Advanced Carbon Fiber FabricIntroduction:Carbon fiber fabric has found several applications in various industries due to its exceptional strength-to-weight ratio and durability. However, recent advancements have taken this material to new heights, particularly in the field of camouflage. This has given birth to an innovative product - Camouflage Carbon Fiber Fabric (CCFF), developed by a leading company in the industry. This fabric offers a range of benefits and has the potential to revolutionize the way camouflage is used in military, outdoor, and fashion sectors.1. The Science Behind Camouflage Carbon Fiber Fabric:Camouflage Carbon Fiber Fabric combines the cutting-edge technology of carbon fiber with advanced camouflage patterns. The result is a lightweight, flexible, and highly effective camouflage solution. The carbon fiber material provides the fabric with superior strength and durability, making it ideal for use in challenging environments. Moreover, the camo patterns are strategically designed to mimic natural surroundings, ensuring optimal concealment in different terrains.2. Versatility in Military Applications:One of the key applications of CCFF is in the military sector. The fabric's strong and lightweight nature makes it ideal for use in combat uniforms, tactical gear, and equipment. Its high resistance to abrasion and punctures ensures durability, even in extreme conditions. The advanced camouflage patterns enable soldiers to blend seamlessly into their surroundings, thereby increasing their chances of mission success and personal safety. Additionally, the fabric's quick-drying properties offer enhanced comfort, crucial during prolonged deployments.3. Outdoor Enthusiasts and Hunting Apparel:CCFF holds immense potential for outdoor enthusiasts, particularly hunters. The fabric's lightweight and flexible characteristics make it perfect for hunting apparel, allowing for ease of movement and reducing fatigue during extended periods in the field. Moreover, the advanced camouflage patterns aid in concealing hunters from wildlife, increasing the likelihood of a successful hunt. The fabric's durability ensures longevity, catering to the rugged nature of outdoor activities.4. Commercial and Fashion Applications:Apart from its military and outdoor uses, CCFF also has exciting potential in the fashion industry. The unique properties of the carbon fiber material make it an appealing choice for fashion designers seeking innovation and durability. Combining the lightweight and flexible attributes of the fabric with the advanced camouflage patterns allows for the creation of cutting-edge apparel and accessories. From jackets to backpacks, this fabric opens up a world of possibilities for trendy and functional designs.5. Environmental Impact and Sustainability:Furthermore, the production of CCFF takes into account the importance of environmental sustainability. The company behind the fabric prioritizes minimizing their carbon footprint and reducing waste. By utilizing recycled carbon fibers, they ensure that the fabric is both strong and eco-friendly. This commitment to sustainability demonstrates the company's dedication to preserving the environment and offering responsible products.Conclusion:Camouflage Carbon Fiber Fabric represents the convergence of advanced technology and practicality. With its exceptional strength, lightweight nature, and advanced camouflage patterns, this fabric has the potential to redefine the concept of camouflage across various sectors. Whether in military applications, outdoor endeavors, or fashion, CCFF offers unmatched durability, versatility, and efficiency. Additionally, the fabric's environmentally friendly production process aligns with the growing emphasis on sustainability. As this innovative material gains wider recognition, it paves the way for a future marked by groundbreaking applications and advancements.

Key Benefits of Carbon Fiber Fiberglass Cloth

Carbon Fiber Fiberglass Cloth Revolutionizes the Automotive Industry: A Product of Innovation and Dedication to ExcellenceInnovation, quality, and customer satisfaction are the core values of {Company Name}. With years of experience and expertise in the manufacturing and supply of advanced materials and composites, {Company Name} has been at the forefront of industry-transforming technologies.Carbon fiber fiberglass cloth is the latest addition to the range of premium quality products from {Company Name}. This advanced material has been making waves in the automotive industry due to its exceptional strength, durability, and versatility.The ever-growing demand for lightweight and high-performance materials in the automotive sector has led to the rise of carbon fiber composites. Carbon fiber fiberglass cloth is a hybrid composite made up of carbon fibers and fiberglass threads woven together. This combination of materials produces a high-strength cloth that is lightweight, flexible, and resistant to corrosion.One of the primary advantages of carbon fiber fiberglass cloth is its ability to withstand high-temperature environments. This feature makes it ideal for use in the manufacture of engine parts and other components that are exposed to high heat and pressure. Furthermore, carbon fiber fiberglass cloth has excellent stiffness and tensile strength, which makes it ideal for applications that require high mechanical performance.Another benefit of carbon fiber fiberglass cloth is its aesthetic appeal. The unique texture and patterns of the woven carbon fibers offer a distinctive and luxurious look that enhances the overall aesthetics of the automobile. Many luxury car makers have adopted carbon fiber composites for their cars, as it provides a sleek and modern feel to the design.{Company Name} understands the importance of quality and performance for our customers. That is why our carbon fiber fiberglass cloth undergoes a rigorous testing process to ensure it meets high industry standards. Our manufacturing processes use only the highest quality raw materials with strict quality control measures. This ensures that every order we send out is of the highest quality possible.In addition to the automotive industry, carbon fiber composites are also used in the aerospace, marine, and sporting goods industries. These industries demand materials that can withstand extreme conditions, yet still provide optimal performance. It is worth noting that carbon fiber composites are also being used in newer industries, such as medical and construction.The benefits of carbon fiber composites are enormous, and there is no doubt that they will continue to revolutionize all areas they have been applied. At {Company Name}, we are committed to providing our customers with innovative products that offer the best in class performance. Our dedication to quality, innovation, and customer satisfaction sets us apart from our competitors, and our carbon fiber fiberglass cloth product is a testimony to this.We have a team of experienced and dedicated professionals who strive to ensure that our customers receive the best products and services we can offer. We have established ourselves as a trusted and reputable supplier of advanced materials and composites. We are always looking for ways to innovate and improve our product offerings to keep up with ever-evolving industry demands.In conclusion, carbon fiber fiberglass cloth is a game-changing material that is transforming the automotive industry. It provides unmatched strength, durability, and lightweight properties that make it ideal for a wide range of applications. At {Company Name}, we are proud to offer high-quality carbon fiber fiberglass cloth that is backed by our commitment to excellence. Our customers can be assured that every purchase they make from us is a sound investment in quality and performance.

Discover the Versatility and Strength of Carbon Fiberglass Cloth

Title: Innovative Carbon Fiberglass Cloth Revolutionizes Industrial ApplicationsIntroduction:In an era where sustainable materials and innovative technologies are reshaping industries, {Company Name} has introduced a groundbreaking carbon fiberglass cloth, poised to revolutionize various industrial applications. This cutting-edge material combines the lightweight and high-tensile strength properties of carbon fiber with the exceptional durability and heat resistance of fiberglass. Through this integration, {Company Name} aims to provide enhanced solutions for the automotive, aerospace, construction, and renewable energy sectors, while advancing the boundaries of modern manufacturing.Body:1. Carbon Fiberglass Cloth: The Future of Advanced Materials (100 words){Company Name}'s carbon fiberglass cloth represents a major leap forward in material science. By combining the best attributes of two highly regarded materials, this innovative cloth offers outstanding mechanical properties such as high strength, rigidity, and thermal stability. The carbon fiber aspect provides exceptional tensile strength and lightweight characteristics, while the fiberglass component enhances toughness, impact resistance, and thermal insulation abilities. This unique composition enables the carbon fiberglass cloth to surpass traditional materials commonly used in industrial applications, opening up new possibilities for a wide range of industries.2. Automotive Industry: Transformative Lightweight Solutions (150 words)The automotive industry has long pursued lightweight materials to improve fuel efficiency and reduce emissions. With the introduction of {Company Name}'s carbon fiberglass cloth, car manufacturers now have access to a game-changing solution. The integration of carbon fiber and fiberglass brings exceptional strength-to-weight ratio, enabling the development of lighter yet extremely strong components. This revolutionary cloth can be used to manufacture structural parts, doors, hoods, and chassis, enhancing both vehicle performance and safety. Additionally, the enhanced thermal resistance of the material reduces heat transfer, improving the overall efficiency and lifespan of automotive components.3. Aerospace Sector: Pushing the Boundaries of Design (150 words)In the aerospace sector, weight reduction and reliability are paramount concerns. {Company Name}'s carbon fiberglass cloth offers an unprecedented opportunity to create aircraft components that are not only lighter but also possess higher resistance to extreme temperatures and impacts. By incorporating the cloth into the manufacturing process, aircraft designers can optimize fuel efficiency, increase payload capacity, and enhance overall performance. The material's exceptional strength, stiffness, and fire resistance properties make it suitable for various applications, including aircraft outer panels, interior structures, and engine components, thus enabling aerospace manufacturers to push the boundaries of design and engineering.4. Construction Industry: Matching Strength with Sustainability (150 words)The construction industry is embracing sustainable practices and seeking materials that combine strength, durability, and environmental responsibility. With {Company Name}'s carbon fiberglass cloth, builders gain access to a material that surpasses conventional construction materials on multiple fronts. The cloth's remarkable mechanical characteristics enable the creation of structures that require reduced maintenance and possess superior impact and damage resistance. Moreover, the lightweight nature of the cloth facilitates easier transportation and installation, streamlining construction processes and reducing costs. By adopting this innovative material, the construction sector can make significant progress towards achieving sustainable and high-performance buildings, reinforcing their commitment to greener practices.5. Contribution to Renewable Energy: Enhancing Efficiency and Longevity (150 words)Renewable energy technologies, such as wind turbines, demand materials that can withstand extreme conditions while maximizing energy output. By integrating {Company Name}'s carbon fiberglass cloth in the production of wind turbine blades, the renewable energy sector can achieve game-changing results. The cloth's unique combination of high strength, lightweight, and thermal stability improves the overall performance and longevity of wind turbine blades, enabling them to withstand harsh environmental factors and generate more energy. This advancement supports the transition to clean and sustainable energy sources, contributing towards a greener future.Conclusion:{Company Name}'s introduction of this groundbreaking carbon fiberglass cloth marks a milestone in material innovation. With its powerful combination of carbon fiber and fiberglass properties, this cloth is set to revolutionize various industrial sectors including automotive, aerospace, construction, and renewable energy. By enhancing strength, reducing weight, improving thermal resistance, and offering exceptional durability, this innovative cloth expands the possibilities of design and manufacturing. As industries embrace the potential of this material, {Company Name} continues to lead the charge in developing cutting-edge solutions that address the evolving needs of a sustainable future.

Get to Know Fiberglass: The Common Fiber-Reinforced Plastic

Fiberglass – A Breakthrough in Reinforced PlasticsFiberglass, also known as fibreglass in the UK, is a type of fiber-reinforced plastic that uses glass fiber as its primary reinforcement material. It is one of the most popular and widely used engineering materials in various industries, including aerospace, construction, automotive, marine, and many more. In this blog, we will dive deep into the world of fiberglass, its properties, applications, and various forms, including woven fiberglass sheets.What is Fiberglass?Fiberglass is composed of fine glass fibers that are woven or randomly arranged and held together by a plastic resin matrix. The glass fibers are made up of silicon dioxide and other additives and can be manufactured in a range of diameters and lengths. The plastic resin matrix can be a thermosetting polymer matrix, such as epoxy, polyester resin, or vinylester, or a thermoplastic.Fiberglass is available in several different forms, including chopped strand mat, woven fiberglass sheets, rovings, and continuous strand mat. Unlike metal, fiberglass is a lightweight and strong material that is resistant to corrosion, rot, and mildew. The glass fibers provide superior tensile strength, while the plastic matrix offers excellent compressive strength and durability.What are the Properties of Fiberglass?Fiberglass has numerous properties that make it an ideal material for various applications.1. Light Weight: Fiberglass is a lightweight material that offers excellent strength-to-weight ratio.2. High Strength: Fiberglass is a high-strength material that can withstand high loads and stresses.3. Chemical Resistance: Fiberglass is resistant to many chemicals, including acids, alkalis, and salts.4. Heat Resistance: Fiberglass can withstand high temperatures without deformation, making it ideal for high-temperature applications.5. Electrical Insulation: Fiberglass is an excellent electrical insulator, making it suitable for electrical applications.6. Weather Resistance: Fiberglass is resistant to UV radiation, wind, and rain, making it durable in outdoor applications.What are the Applications of Fiberglass?Fiberglass has a wide range of applications across various industries.1. Aerospace: Fiberglass is widely used in the aerospace industry to manufacture aircraft components, such as wings, fuselage, and nose cones.2. Construction: Fiberglass is commonly used in construction applications, such as insulation, roofing, and cladding.3. Automotive: Fiberglass is used to manufacture auto body panels, bumpers, and fenders for vehicles.4. Marine: Fiberglass is commonly used in the marine industry to manufacture boats, yachts, and other watercraft.5. Sports and Recreation: Fiberglass is used to manufacture sports equipment, such as fishing rods, surfboards, and golf club shafts.What are Woven Fiberglass Sheets?One of the most common forms of fiberglass is woven fiberglass sheets. Woven fiberglass is composed of glass fibers that are woven into a fabric-like material. The weaving process arranges the fibers into a criss-cross pattern, providing multidirectional strength. The woven fiberglass sheets are then coated with a plastic resin matrix to provide additional strength and durability.Woven fiberglass sheets are used in various applications, including:1. Mold Making: Woven fiberglass sheets are used to make molds for various applications, including automotive parts, bathtubs, and countertops.2. Reinforcement: Woven fiberglass is used to reinforce concrete, making it stronger and more durable.3. Electrical Insulation: Woven fiberglass is an excellent electrical insulator, making it suitable for electrical applications.4. Soundproofing: Woven fiberglass sheets are used as a soundproofing material in walls and ceilings.ConclusionFiberglass is a versatile and widely used material that offers numerous benefits, including high strength, light weight, and chemical resistance. The various forms of fiberglass, including woven fiberglass sheets, make it suitable for various applications across various industries. As technology continues to improve, the use of fiberglass is only set to increase, offering new and exciting solutions for engineering and manufacturing needs.

Nonwoven Activated Carbon Filter Cotton for Functional Fabric Applications

New Fabric Technology: Nonwoven Activated Carbon Filter CottonFabric technology has come a long way from being just a means to cover the body. Today, it has evolved to include functional fabrics that provide additional benefits to the wearer. One such fabric technology is nonwoven activated carbon filter cotton, which is quickly gaining popularity in the market for its ability to filter harmful substances and protect the wearer from pollution.Ruibang, a leading brand in the industry, has introduced a new product called the AC05-01 nonwoven activated carbon filter cotton. This product is made of a combination of activated carbon cloth, melt-blown nonwoven fabric, and carbon fiber cloth. The activated carbon cloth has a strong adsorption capacity, which effectively filters out harmful substances such as odors and gases. The melt-blown nonwoven fabric is highly efficient at filtering out particles, including PM2.5, dust, and bacteria. The carbon fiber cloth is durable and adds structural support to the fabric.The AC05-01 nonwoven activated carbon filter cotton has a weight of 250g per square meter and is available in various colors. The fabric has excellent air permeability, making it comfortable to wear for extended periods. It is also washable and reusable, making it an eco-friendly option compared to disposable alternatives.One of the main applications of this fabric technology is in the production of respiratory masks. The AC05-01 nonwoven activated carbon filter cotton can be used as the filter layer of masks to help protect the wearer from harmful substances in the air. With the rise of air pollution in many cities around the world, this technology offers a solution to help people breathe cleaner air.Besides masks, this fabric technology has other applications in various industries. It can be used in the production of air purifiers, car air filters, and even insoles for shoes. The ability to filter out harmful substances makes it a valuable addition to products that aim to improve indoor air quality.In conclusion, the introduction of nonwoven activated carbon filter cotton has opened up new possibilities in the fabric industry. Ruibang's AC05-01 product offers a high-quality solution to help protect people from the harmful effects of pollution. With its excellent filtering abilities and comfortable wear, it is sure to become a popular choice for those looking for functional fabrics.