Discover the Advantages of Lightweight Fiberglass Cloth for Various Applications

By:Admin

Introduction:

Fiberglass, a versatile material known for its exceptional strength and durability, has been an integral part of various industries, from construction to automotive, aerospace to marine. A leading player in the industry, renowned for its commitment to innovation, has revolutionized the fiberglass landscape with its groundbreaking product line - Lightweight Fiberglass Cloth.

Company Introduction:

With roots dating back to the 1960s, {Company Name} has emerged as a global leader in the manufacture and development of fiberglass-based products. Their cutting-edge solutions have cemented their reputation as a pioneer in the industry, constantly pushing the boundaries of what is possible with fiberglass. The company's unwavering focus on research and development, combined with a commitment to sustainability, has made them a trusted partner for businesses across the globe.

Unveiling Lightweight Fiberglass Cloth:

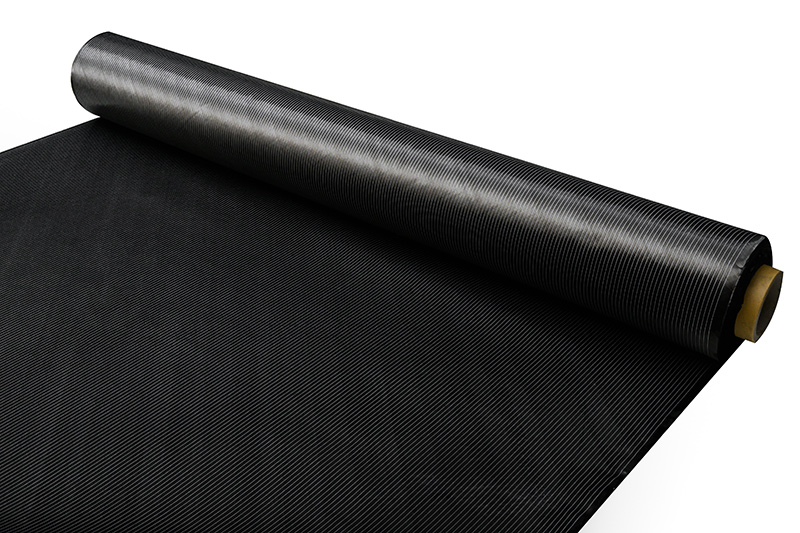

In their latest game-changing development, {Company Name} unveiled their revolutionary product - Lightweight Fiberglass Cloth. This groundbreaking fabric combines the inherent strength of fiberglass with an unprecedented lightweight composition, offering a range of benefits that will significantly impact various industries.

Innovative Composition:

The secret lies in the meticulous engineering of the fiberglass strands. By incorporating advanced manufacturing techniques and proprietary materials, {Company Name} has been able to create a fiberglass cloth that boasts an incredibly low weight without compromising on quality. This innovation opens up a world of possibilities across a multitude of applications.

Advantages in Construction:

The construction industry has embraced Lightweight Fiberglass Cloth wholeheartedly. Contractors and architects are now able to create lightweight, yet incredibly strong structures, reducing both material costs and labor requirements. Moreover, the cloth's exceptional corrosion resistance makes it an ideal choice for infrastructure projects in harsh environments, ensuring longevity and sustainability.

Automotive and Aerospace Applications:

The automotive and aerospace sectors have also seen an immediate impact from this breakthrough technology. The lightweight nature of the cloth finds extensive use in manufacturing vehicle components and aircraft parts, delivering increased fuel efficiency without compromising on safety. Furthermore, the exceptional thermal insulation properties of Lightweight Fiberglass Cloth make it suitable for use in engines and exhaust systems.

Marine and Sports Industries:

In the marine and sports industries, Lightweight Fiberglass Cloth has transformed design possibilities and performance levels. Boat manufacturers can now create vessels that effortlessly glide through the water, thanks to the reduced weight and increased strength offered by the cloth. Similarly, sports equipment, such as bicycles, tennis rackets, and surfboards, have become lighter and more aerodynamic, elevating athletes' performance to new heights.

Environmental Sustainability:

Beyond its versatility and durability, Lightweight Fiberglass Cloth also proves beneficial for the environment. Due to its lightweight nature, it allows for reduced fuel consumption in transportation and decreases carbon emissions. Additionally, its remarkable longevity minimizes waste generation, as structures, vehicles, and equipment crafted with the cloth require fewer replacements.

Conclusion:

With the introduction of Lightweight Fiberglass Cloth, {Company Name} has redefined the possibilities and applications of fiberglass. Their innovative approach to engineering has revolutionized multiple industries by providing lightweight, yet incredibly durable solutions. From construction to automotive, aerospace to marine, this game-changing product has left an indelible mark on the world of materials. As the demand for sustainable, high-performance solutions continues to rise, the future looks promising for both {Company Name} and industries looking to leverage the unmatched strength and versatility of Lightweight Fiberglass Cloth.

Company News & Blog

Discover the Advantages of Lightweight Fiberglass Cloth for Various Applications

Title: Lightweight Fiberglass Cloth: Revolutionizing Industries with Unmatched Durability and VersatilityIntroduction:Fiberglass, a versatile material known for its exceptional strength and durability, has been an integral part of various industries, from construction to automotive, aerospace to marine. A leading player in the industry, renowned for its commitment to innovation, has revolutionized the fiberglass landscape with its groundbreaking product line - Lightweight Fiberglass Cloth.Company Introduction:With roots dating back to the 1960s, {Company Name} has emerged as a global leader in the manufacture and development of fiberglass-based products. Their cutting-edge solutions have cemented their reputation as a pioneer in the industry, constantly pushing the boundaries of what is possible with fiberglass. The company's unwavering focus on research and development, combined with a commitment to sustainability, has made them a trusted partner for businesses across the globe.Unveiling Lightweight Fiberglass Cloth:In their latest game-changing development, {Company Name} unveiled their revolutionary product - Lightweight Fiberglass Cloth. This groundbreaking fabric combines the inherent strength of fiberglass with an unprecedented lightweight composition, offering a range of benefits that will significantly impact various industries.Innovative Composition:The secret lies in the meticulous engineering of the fiberglass strands. By incorporating advanced manufacturing techniques and proprietary materials, {Company Name} has been able to create a fiberglass cloth that boasts an incredibly low weight without compromising on quality. This innovation opens up a world of possibilities across a multitude of applications.Advantages in Construction:The construction industry has embraced Lightweight Fiberglass Cloth wholeheartedly. Contractors and architects are now able to create lightweight, yet incredibly strong structures, reducing both material costs and labor requirements. Moreover, the cloth's exceptional corrosion resistance makes it an ideal choice for infrastructure projects in harsh environments, ensuring longevity and sustainability.Automotive and Aerospace Applications:The automotive and aerospace sectors have also seen an immediate impact from this breakthrough technology. The lightweight nature of the cloth finds extensive use in manufacturing vehicle components and aircraft parts, delivering increased fuel efficiency without compromising on safety. Furthermore, the exceptional thermal insulation properties of Lightweight Fiberglass Cloth make it suitable for use in engines and exhaust systems.Marine and Sports Industries:In the marine and sports industries, Lightweight Fiberglass Cloth has transformed design possibilities and performance levels. Boat manufacturers can now create vessels that effortlessly glide through the water, thanks to the reduced weight and increased strength offered by the cloth. Similarly, sports equipment, such as bicycles, tennis rackets, and surfboards, have become lighter and more aerodynamic, elevating athletes' performance to new heights.Environmental Sustainability:Beyond its versatility and durability, Lightweight Fiberglass Cloth also proves beneficial for the environment. Due to its lightweight nature, it allows for reduced fuel consumption in transportation and decreases carbon emissions. Additionally, its remarkable longevity minimizes waste generation, as structures, vehicles, and equipment crafted with the cloth require fewer replacements.Conclusion:With the introduction of Lightweight Fiberglass Cloth, {Company Name} has redefined the possibilities and applications of fiberglass. Their innovative approach to engineering has revolutionized multiple industries by providing lightweight, yet incredibly durable solutions. From construction to automotive, aerospace to marine, this game-changing product has left an indelible mark on the world of materials. As the demand for sustainable, high-performance solutions continues to rise, the future looks promising for both {Company Name} and industries looking to leverage the unmatched strength and versatility of Lightweight Fiberglass Cloth.

Shop for Fiberglass Fabric, Weave & Cloth in Various Lengths, Sizes & Styles - In Stock & Ready to Ship.

Fiberglass Fabric: A Versatile Solution for a Variety of ApplicationsFiberglass fabric is a woven material that is often used in applications that require high strength and durability. This versatile material is made by combining glass fibers with a polymer resin, resulting in a material that is strong, lightweight, and heat-resistant. Fiberglass fabric is available in a variety of styles, sizes, and lengths, making it an ideal solution for a wide range of applications in industries such as aerospace, automotive, marine, and construction.One of the key benefits of fiberglass fabric is its excellent strength-to-weight ratio. This property makes it an ideal material for applications where weight is a concern, such as aerospace and automotive engineering. Fiberglass fabric is also highly resistant to heat, making it a popular choice for applications that involve high temperatures, such as insulation for furnaces and ovens.In addition to its strength and heat resistance, fiberglass fabric is also highly resistant to chemicals and moisture. This makes it an ideal material for use in the marine industry, where it can be used to fabricate components such as boat hulls, decks, and bulkheads. Fiberglass fabric can also be used in a variety of construction applications, from reinforcing concrete to creating lightweight composite panels.At (brand name removed), we offer a wide selection of fiberglass fabrics, weaves, and cloths to meet the needs of our customers. Our fiberglass fabrics are available in a range of styles and sizes, including plain weave, twill weave, and satin weave options. We carry both E-glass and S-glass fabrics, allowing our customers to choose the material that is best suited for their specific application.Our fiberglass fabrics are available in a variety of lengths, ranging from small rolls to large bolts, and we can also custom cut our fabrics to meet our customers' specific needs. All of our fiberglass fabrics are of the highest quality, and we take great care to ensure that they meet the strictest industry standards for strength, durability, and performance.In addition to our selection of fiberglass fabrics, we also offer aluminized fiberglass fabrics, which are coated with a layer of aluminum to provide additional heat resistance and reflectivity. Aluminized fiberglass fabrics are often used in applications such as furnace curtains, welding blankets, and fire barriers.At (brand name removed), we pride ourselves on our commitment to providing our customers with the highest-quality fiberglass fabrics, weaves, and cloths in the industry. We understand that every application is unique, and we work closely with our customers to ensure that they have the right materials to meet their specific needs. With our extensive selection, competitive pricing, and unparalleled customer service, we are the go-to source for fiberglass fabrics for customers across a wide range of industries.In conclusion, fiberglass fabric is a versatile material that offers a range of benefits for a variety of applications. At (brand name removed), we are proud to offer a wide selection of fiberglass fabrics, weaves, and cloths to meet the needs of our customers. Whether you are working on an aerospace project, automotive application, marine fabrication, or construction project, we have the right materials to meet your needs. Contact us today to learn more about our fiberglass fabrics and how they can benefit your application.

Discover the Advantages of Carbon Quadraxial Fabric for Enhanced Performance

[Assistant]Title: Revolutionary Carbon Quadraxial Fabric Redefines Composite Material IndustryIntroduction:In an exciting breakthrough, a leading company in the field of advanced materials has unveiled a revolutionary product that promises to reshape the composite material industry. Carbon Quadraxial Fabric (CQF), a game-changing innovation, is set to enhance the performance and capabilities of numerous industries, ranging from aerospace and automotive to sports and recreation. With its exceptional strength, versatility, and manufacturing flexibility, CQF is primed to become a go-to material for engineers and designers worldwide.Main Body:1. Understanding Carbon Quadraxial Fabric: Carbon Quadraxial Fabric is manufactured using advanced technologies that ingeniously weave together high-tensile carbon four-axis filament yarns. This proprietary weaving technique results in a fabric that boasts superior mechanical properties, including exceptional strength, stiffness, and fatigue resistance. Unlike traditional carbon fabrics, CQF also exhibits reduced delamination and improved impact resistance, making it an ideal choice for demanding applications.2. The Unprecedented Versatility of CQF: The unique characteristics of Carbon Quadraxial Fabric allow it to be utilized across a wide array of industries, offering benefits that surpass those of traditional materials. From lightweight structural components in the aerospace sector to high-performance body panels in the automotive industry, CQF offers heightened strength-to-weight ratios without compromising durability. Additionally, its exceptional resistance to chemicals and extreme temperatures makes it valuable in industrial settings.3. Revolutionizing Aerospace Manufacturing: The aerospace industry, in particular, stands to benefit immensely from Carbon Quadraxial Fabric. The material's exceptional strength and stiffness make it a perfect fit for designing and manufacturing aircraft components. By utilizing CQF, aerospace engineers can achieve increased fuel efficiency, reduced maintenance costs, and improved overall performance. Moreover, CQF's low thermal expansion properties make it a preferred choice for applications requiring stability at varying temperatures.4. Application in Automotive Engineering: Automotive manufacturers are eagerly embracing the potential of Carbon Quadraxial Fabric for its ability to enhance vehicle performance and fuel efficiency. Lightweight components made with CQF allow designers to reduce vehicle weight while maintaining structural integrity, leading to improved handling, reduced emissions, and increased overall energy efficiency. Additionally, CQF's impact resistance properties contribute to increased passenger safety.5. Impacting Sporting and Recreational Industries: Sports and recreational equipment manufacturers are also recognizing the tremendous advantages of Carbon Quadraxial Fabric. From high-performance bicycles and tennis rackets to skis and golf clubs, CQF's exceptional strength and stiffness provide athletes with a competitive edge. Its lightweight nature also enables enthusiasts to enjoy more comfortable and energy-efficient experiences.Conclusion:The introduction of Carbon Quadraxial Fabric onto the market represents a significant watershed moment in the composite material industry. This cutting-edge technology promises to revolutionize various sectors, offering unparalleled strength, versatility, and durability. As CQF gains widespread adoption, industries can expect to witness exponential advancements in product performance, design, and sustainability. With limitless possibilities in fields ranging from aerospace and automotive engineering to sports and recreation, Carbon Quadraxial Fabric is poised to redefine the future of advanced materials.

Understanding the Characteristics of Carbon-fiber Composites

Title: Exploring the Marvels of Fiber Carbon Cloth: Revolutionizing the World of CompositesIntroduction (70 words):Welcome to our extensive guide on the revolutionary material that is fiber carbon cloth. In this blog, we will delve deep into the world of this incredible composite, exploring its various applications and highlighting its remarkable traits. From its woven fibrous construction to its resiliency, versatility, and strength, fiber carbon cloth has emerged as a game-changer in multiple industries. So, without further ado, let's unravel the secrets behind this remarkable material!Understanding Fiber Carbon Cloth (100 words):Fiber carbon cloth is a fibrous carbon composite that has revolutionized countless industries in recent years. It begins with individual strands woven into a rough cloth, which is then carefully impregnated with epoxy resin after molding it into desired shapes. This combination produces a material boasting exceptional strength-to-weight ratio, rigidity, and high tensile strength. Fiber carbon cloth owes its incredible properties to the unique arrangement of carbon fibers that form its core structure. Now, let's explore the remarkable benefits and applications of this cutting-edge material.Applications and Advantages (250 words):1. Aerospace Industry:In the aerospace industry, fiber carbon cloth finds extensive use due to its lightweight, high strength, and excellent resistance to high temperatures and impacts. It enhances fuel efficiency in aircraft, reduces structural weight, and improves overall performance. From aircraft frames to wings, fiber carbon cloth has become an integral component in the manufacturing process.2. Automotive Industry:In the automotive sector, fiber carbon cloth is employed in the production of high-performance vehicles. By utilizing this material in car manufacturing, automotive companies can reduce weight, enhance fuel efficiency, and improve structural integrity. Carbon fiber components, such as hoods, fenders, and body panels, are gaining popularity due to their striking aesthetics and outstanding performance.3. Sports and Recreation:From professional sports equipment to recreational products, the sports industry has embraced fiber carbon cloth for its durability and lightness. Tennis rackets, bicycles, golf clubs, helmets, and ski poles are just a few examples of sporting goods that utilize carbon fiber composites for superior performance and reduced weight.4. Construction and Infrastructure:In the construction field, fiber carbon cloth helps strengthen existing structures by acting as reinforcement in concrete and other building materials. Its lightweight nature and high strength allow for efficient and long-lasting construction projects while reducing material usage. Additionally, fiber carbon cloth is increasingly used in earthquake-resistant building designs and bridge construction.5. Renewable Energy:The renewable energy sector has also recognized fiber carbon cloth as an ideal material for producing enhanced wind turbine blades. Its low weight and high strength characteristics enable turbines to convert wind energy more efficiently, contributing to the sustainable energy movement.Keywords: Fiber Carbon Cloth, carbon fiber composite, woven carbon fibers, strength-to-weight ratio, aerospace industry, automotive industry, sports and recreation, construction, infrastructure, renewable energyConclusion (80 words):Fiber carbon cloth has revolutionized various sectors, thanks to its exceptional strength, lightweight nature, and versatility. Industries such as aerospace, automotive, sports, construction, and renewable energy have witnessed significant advancements thanks to this game-changing material. As technology continues to advance, we can expect further innovations in the field of fiber carbon cloth, leading to new breakthroughs and applications across different industries. This remarkable composite will undoubtedly play a crucial role in shaping our future.

High-Quality Biaxial Fiberglass Cloth Revolutionizes Manufacturing Processes

———New Product Launch: 1708 Biaxial Fiberglass Cloth Debuts from [Company Name][City, State] - [Company Name], a leading manufacturer of high-quality fiberglass materials for industrial and commercial use, has unveiled its latest product: 1708 biaxial fiberglass cloth. The new material is designed to meet the growing demand for lightweight, durable, and cost-effective reinforcements for various applications in the marine, transportation, construction, and aerospace industries.According to [Company Name], the 1708 biaxial fiberglass cloth is made of high-strength E-glass fibers that are woven in two directions - 0 and 90 degrees - which provide excellent tensile, flexural, and impact strength in both axial and transverse directions. The fabric is also impregnated with a special resin that provides good bonding properties, high adhesion, and superior wet-out characteristics, ensuring that the fabric conforms to complex shapes and surfaces without delaminating or wrinkling.Moreover, the 1708 biaxial fiberglass cloth is compatible with various resin systems, including polyester, vinyl ester, and epoxy, and can be used in various manufacturing processes, such as hand lay-up, vacuum bagging, infusion, and pultrusion. The fabric is available in various widths, lengths, and weights, depending on the specific needs and requirements of the customers."The 1708 biaxial fiberglass cloth is a game-changer in the fiberglass industry, as it offers superior performance, versatility, and affordability compared to other traditional materials," said [Company Name]'s CEO [Name]. "Our R&D team has worked hard to develop this innovative product, and we are confident that it will exceed our customers' expectations and open new opportunities for growth and expansion."The 1708 biaxial fiberglass cloth has already attracted interest from several leading companies in the marine, transportation, and construction sectors, who have tested and approved the material for their applications. For example, a boat builder has used the 1708 biaxial fiberglass cloth to reinforce the hull and deck of a 25-foot center console boat, resulting in a lighter, stronger, and more fuel-efficient vessel. A trucking company has used the fabric to repair and reinforce damaged cargo boxes and trailers, saving time and money compared to traditional metal or wood repairs. A construction firm has used the material to strengthen and waterproof concrete structures, such as bridges, tunnels, and dams, improving their durability and longevity."We are impressed with the quality and performance of the 1708 biaxial fiberglass cloth, and we appreciate [Company Name]'s commitment to innovation and customer service," said a spokesperson from one of the customers. "We have been using fiberglass materials for many years, but this product stands out for its ease of use, strength, and cost-effectiveness. We look forward to partnering with [Company Name] to explore new applications and markets for this product."[Company Name] is a leading fiberglass manufacturing company with more than 20 years of experience in the industry. The company offers a wide range of fiberglass products, including chopped strand mat, woven roving, stitched mat, multiaxial fabrics, surfacing veil, and specialty fabrics, as well as custom-made solutions for specific applications. [Company Name] prides itself on its superior quality, reliability, and customer service, and has a global network of distributors and partners who provide local support and expertise."We are committed to providing our customers with the best possible solutions for their fiberglass needs, and the 1708 biaxial fiberglass cloth is a testament to that commitment," said [Name]. "We are excited about the opportunities that this product brings to our company and our customers, and we will continue to invest in R&D and innovation to stay at the forefront of the industry."The 1708 biaxial fiberglass cloth is now available for ordering through [Company Name]'s website or authorized distributors. The company offers competitive pricing, fast delivery, and technical support to ensure a smooth and successful implementation of the product. For more information about 1708 biaxial fiberglass cloth and other products, please visit [Company Name]'s website or contact their sales team.

The Evolution of Carbon Fibers in Structural Materials

Carbon fiber is a highly versatile material that has revolutionized the manufacturing industry. It is lightweight and strong, making it the perfect material for a range of structural applications. Carbon fibers have come a long way since their invention by Thomas Edison in 1879. Today, they are used in everything from aerospace to sports equipment. In this blog post, we will explore the history and applications of carbon fiber.Carbon Fiber HistoryCarbon fibers were first invented to create filaments for incandescent light bulbs. Lewis Latimer, a Black inventor, patented the process for carbonizing cotton threads and bamboo slivers to create filaments that were longer lasting than their predecessors. It wasn't until the end of World War II that engineers started to develop carbon fibers for use in structural materials.The first carbon fiber was created by Robert H. Wentorf Jr., who was working at General Electric in 1958. Wentorf heated a mixture of carbon and graphite powders to extreme temperatures and pressures, creating a new material that was incredibly strong and lightweight. It wasn't until the 1960s that the use of carbon fiber expanded outside of the aerospace industry. Today, carbon fibers are used in everything from bicycles to wind turbine blades.Carbon Fiber ApplicationsOne of the most common applications of carbon fiber is in the aerospace industry. Carbon fibers are lightweight and strong, making them perfect for use in aircraft components. Carbon fiber composites are used in the fuselage, wings, and other structural components of airplanes, reducing the weight of the aircraft and improving its fuel efficiency.Another application of carbon fiber is in the automotive industry. Automakers use carbon fiber to create lightweight body panels and components that improve fuel efficiency and performance. Carbon fiber is also used in sports equipment like tennis rackets, golf clubs, and bicycles. The material is strong and lightweight, making it ideal for athletes who need to perform at the highest level.Carbon fiber is not the only material used in manufacturing. Fiberglass cloth is another popular material used to create everything from boat hulls to shower enclosures. Fiberglass cloth is strong and resistant to water, making it ideal for use in marine applications. It is also used to create automotive body panels and insulation for buildings.ConclusionCarbon fiber and fiberglass cloth are two of the most popular materials used in manufacturing today. Carbon fiber was first invented to create filaments for incandescent light bulbs. Today, it is used in everything from aerospace to sports equipment. Fiberglass cloth is another popular material used to create boat hulls, automotive body panels, and insulation for buildings. Both materials offer a range of benefits, including strength, lightweight, and resistance to water. As technology continues to advance, we can expect to see even more applications for these versatile materials.

Fiberglass Scrim Cloth: A Comprehensive Guide to Understanding its Applications and Benefits

Fiberglass Scrim Cloth (need remove brand name) – Durable and VersatileFiberglass Scrim Cloth (need remove brand name) is a versatile product that has been widely used across various industries. This product is made from fiberglass yarns, which are woven into a lightweight and durable fabric. The fabric is then treated to increase its strength and stability, making it an ideal material for a wide range of applications.The uses of Fiberglass Scrim Cloth (need remove brand name) are vast, from reinforcing plaster walls to providing structural support for roofs and walls. It is commonly used in the construction industry due to its high strength-to-weight ratio, fire resistance, and insect resistance. This material is also used in the automotive industry as a reinforcing material for plastic parts.Fiberglass Scrim Cloth (need remove brand name) is highly durable and can withstand exposure to extreme weather conditions. It is resistant to rot, mildew, and corrosion, making it an ideal material for outdoor applications. Additionally, the fabric is highly flexible and can be easily cut and shaped to fit a wide range of shapes and surfaces.Fiberglass Scrim Cloth (need remove brand name) is also water-resistant, making it an ideal material for use in damp environments. It can be used to reinforce areas prone to water damage, such as around windows, doors, and roofs. The fabric is also highly breathable, allowing moisture to escape, further reducing the risk of mold and mildew growth.Moreover, the product is easy to install and does not require any specialized tools or equipment. It can be easily cut to fit around corners and other obstructions. Additionally, the fabric can be easily painted or coated to match the surrounding material, making it an attractive and practical option for use in both residential and commercial applications.About the CompanyThe company is a leading manufacturer of Fiberglass Scrim Cloth (need remove brand name) in China. It has been producing high-quality fiberglass products for over 20 years, using state-of-the-art technology and advanced manufacturing processes. The company prides itself on its commitment to quality, professionalism, and customer satisfaction.The company's production facilities are equipped with advanced machinery and testing equipment to ensure that each product meets the highest standards of quality. Its team of experienced engineers and technicians is dedicated to developing innovative products that meet the unique needs of its customers.The company is committed to sustainability and operates with a strong sense of social responsibility. It follows strict environmental standards and uses only high-quality, eco-friendly materials in its production processes. The company's commitment to sustainability is reflected in its products, which are designed to be long-lasting, durable, and environmentally friendly.ConclusionFiberglass Scrim Cloth (need remove brand name) is a highly versatile and durable product that has become a staple in the construction, automotive, and other industries. It is a lightweight, flexible, and easy-to-install material that offers exceptional strength, stability, and resistance to weather and other environmental factors. The product is produced by a top manufacturer that is committed to quality, professionalism, and social responsibility. If you're looking for a high-quality and affordable option for your next project, Fiberglass Scrim Cloth (need remove brand name) is an excellent choice.

Discover the Incredible Potential of Camouflage Carbon Fiber Fabric

Title: Revolutionizing Camouflage: Introducing Advanced Carbon Fiber FabricIntroduction:Carbon fiber fabric has found several applications in various industries due to its exceptional strength-to-weight ratio and durability. However, recent advancements have taken this material to new heights, particularly in the field of camouflage. This has given birth to an innovative product - Camouflage Carbon Fiber Fabric (CCFF), developed by a leading company in the industry. This fabric offers a range of benefits and has the potential to revolutionize the way camouflage is used in military, outdoor, and fashion sectors.1. The Science Behind Camouflage Carbon Fiber Fabric:Camouflage Carbon Fiber Fabric combines the cutting-edge technology of carbon fiber with advanced camouflage patterns. The result is a lightweight, flexible, and highly effective camouflage solution. The carbon fiber material provides the fabric with superior strength and durability, making it ideal for use in challenging environments. Moreover, the camo patterns are strategically designed to mimic natural surroundings, ensuring optimal concealment in different terrains.2. Versatility in Military Applications:One of the key applications of CCFF is in the military sector. The fabric's strong and lightweight nature makes it ideal for use in combat uniforms, tactical gear, and equipment. Its high resistance to abrasion and punctures ensures durability, even in extreme conditions. The advanced camouflage patterns enable soldiers to blend seamlessly into their surroundings, thereby increasing their chances of mission success and personal safety. Additionally, the fabric's quick-drying properties offer enhanced comfort, crucial during prolonged deployments.3. Outdoor Enthusiasts and Hunting Apparel:CCFF holds immense potential for outdoor enthusiasts, particularly hunters. The fabric's lightweight and flexible characteristics make it perfect for hunting apparel, allowing for ease of movement and reducing fatigue during extended periods in the field. Moreover, the advanced camouflage patterns aid in concealing hunters from wildlife, increasing the likelihood of a successful hunt. The fabric's durability ensures longevity, catering to the rugged nature of outdoor activities.4. Commercial and Fashion Applications:Apart from its military and outdoor uses, CCFF also has exciting potential in the fashion industry. The unique properties of the carbon fiber material make it an appealing choice for fashion designers seeking innovation and durability. Combining the lightweight and flexible attributes of the fabric with the advanced camouflage patterns allows for the creation of cutting-edge apparel and accessories. From jackets to backpacks, this fabric opens up a world of possibilities for trendy and functional designs.5. Environmental Impact and Sustainability:Furthermore, the production of CCFF takes into account the importance of environmental sustainability. The company behind the fabric prioritizes minimizing their carbon footprint and reducing waste. By utilizing recycled carbon fibers, they ensure that the fabric is both strong and eco-friendly. This commitment to sustainability demonstrates the company's dedication to preserving the environment and offering responsible products.Conclusion:Camouflage Carbon Fiber Fabric represents the convergence of advanced technology and practicality. With its exceptional strength, lightweight nature, and advanced camouflage patterns, this fabric has the potential to redefine the concept of camouflage across various sectors. Whether in military applications, outdoor endeavors, or fashion, CCFF offers unmatched durability, versatility, and efficiency. Additionally, the fabric's environmentally friendly production process aligns with the growing emphasis on sustainability. As this innovative material gains wider recognition, it paves the way for a future marked by groundbreaking applications and advancements.

Fiber, USA-made Carbon Fiber, Benefits of Plain Weave Carbon FiberCarbon fiber is a popular material that has become a staple in various industries. It possesses excellent properties, such as high strength-to-weight ratio, corrosion resistance, and fatigue resistance, among others. Manufacturers often use carbon fiber to produce lightweight and durable products, including automotive parts, aerospace components, sports equipment, and more. One type of carbon fiber that manufacturers commonly use is plain weave carbon fiber.Plain weave carbon fiber is a type of carbon fiber that uses a basic over-and-under weaving pattern to produce a tight, symmetric weave. This weaving pattern results in a checkerboard-like appearance on the surface of the carbon fiber. Compared to other weaving patterns, such as twill and satin, plain weave carbon fiber is less expensive, has a lower profile, and has a more uniform surface texture.One of the benefits of using plain weave carbon fiber is its improved mechanical properties. Its tightly woven pattern gives it increased tensile strength, stiffness, and resistance to deformation. Plain weave carbon fiber also has better fatigue resistance than other weaving patterns, making it ideal for applications that undergo repeated stress and strain.Another benefit of using plain weave carbon fiber is its ability to create a smooth and uniform surface finish. Its tight weave pattern produces a more consistent surface texture, which is especially useful for aesthetic applications. Manufacturers often use plain weave carbon fiber for parts that require painting, as it provides a smooth and even surface for paint to adhere to.Plain weave carbon fiber is also compatible with various resin systems, such as epoxy, polyester, and vinyl ester. This compatibility allows manufacturers to tailor the mechanical properties of plain weave carbon fiber to specific applications. They can adjust the resin-to-fiber ratio, curing temperature, and curing time to achieve the desired properties.At Elevated Materials, we take pride in producing USA-made carbon fiber products, including our plain weave carbon fiber sheets. We use high-quality materials and state-of-the-art equipment to manufacture our carbon fiber products. Our plain weave carbon fiber sheets are available in various thicknesses and sizes to accommodate different applications. Whether you need carbon fiber sheets for automotive, aerospace, or industrial use, we have the right product for you.In conclusion, plain weave carbon fiber is an excellent choice for lightweight and durable applications that require improved mechanical properties and uniform surface finish. Its basic over-and-under weaving pattern results in a more affordable and uniform surface texture, making it ideal for aesthetic applications. If your project requires high-quality, USA-made plain weave carbon fiber sheets, look no further than Elevated Materials.