Discover the Benefits of Woven Fiberglass Mesh for Strong and Durable Applications

By:Admin

[Company Introduction:]

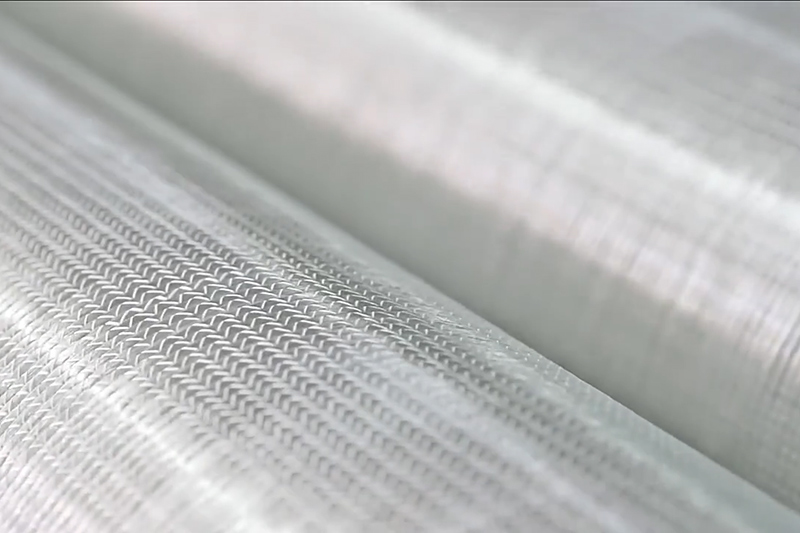

In the fast-evolving world of construction, innovation is key to staying ahead of the curve. One company that embodies this philosophy is XYZ Corporation, a renowned industry leader in the development and manufacturing of high-performance construction materials. With a strong commitment to revolutionizing conventional practices, XYZ Corporation has introduced a groundbreaking product that is set to transform the way construction projects are executed – Woven Fiberglass Mesh.

Woven Fiberglass Mesh, developed and manufactured by XYZ Corporation, is a versatile construction material that offers unmatched durability and efficiency. By blending advanced technology with meticulous craftsmanship, XYZ Corporation has created a product that meets the ever-increasing demands of modern construction projects.

[News Content:]

The construction industry is witnessing a paradigm shift as new-age materials like Woven Fiberglass Mesh redefine conventional practices. As an essential component for reinforcing and stabilizing structures, this innovative product provides a higher level of structural integrity, making it a game-changer in the industry.

The inherent strength of fiberglass and the unique weaving pattern of the Woven Fiberglass Mesh make it a reliable and long-lasting solution for a wide range of construction applications. From plastering to exterior insulation and finishing systems, the versatility of this material knows no bounds. Its ability to prevent cracking and provide superior tensile strength makes it an ideal choice for enhancing the overall durability of buildings and structures.

However, its benefits don't end there. Woven Fiberglass Mesh is also incredibly lightweight, which simplifies installation and reduces the strain on construction workers. Unlike traditional reinforcement materials, such as metal mesh, Woven Fiberglass Mesh can be effortlessly cut to size without the need for specialized tools, resulting in increased efficiency and saved time on the job site.

Moreover, this innovative product also boasts excellent resistance to chemicals and corrosion, further extending its lifespan and ensuring optimal performance under harsh environmental conditions. Woven Fiberglass Mesh is designed to withstand the test of time, offering peace of mind to both contractors and property owners.

Emphasizing its commitment to sustainability, XYZ Corporation has ensured that Woven Fiberglass Mesh is environmentally friendly. By utilizing fiberglass, a material known for its low carbon footprint and minimal environmental impact, XYZ Corporation aligns with the growing demand for eco-conscious products in the construction industry. This sustainability aspect adds another layer of appeal to Woven Fiberglass Mesh, making it a viable choice for environmentally responsible construction projects.

To ensure the highest level of quality, XYZ Corporation adheres to stringent manufacturing processes. Each roll of Woven Fiberglass Mesh undergoes meticulous testing to guarantee consistent levels of strength, durability, and performance. This dedication to excellence has earned XYZ Corporation a stellar reputation among industry professionals, further solidifying their position as a leader in the market.

As the construction industry continues to evolve, the demand for innovative materials that provide enhanced durability and efficiency is rapidly increasing. Woven Fiberglass Mesh, developed and manufactured by XYZ Corporation, is at the forefront of this revolution. With its exceptional strength, easy installation, and environmental sustainability, it is set to become an indispensable material in the construction sector.

In conclusion, XYZ Corporation's Woven Fiberglass Mesh represents a significant advancement in construction materials. Its unique properties and versatile application make it a formidable contender in an ever-competitive industry. As construction projects become more complex and demanding, this innovative product is poised to redefine the standards of durability and efficiency, ensuring a brighter and more resilient future for the construction sector.

Company News & Blog

New Carbon Weave Fabric Offers Strong and Lightweight Alternative to Conventional Materials

Title: Revolutionizing the Textile Industry: Carbon Weave Fabric Promises a Sustainable FutureIntroduction:In a bid to revolutionize the textile industry and promote sustainability, a breakthrough fabric called Carbon Weave has emerged as a game-changer. Developed by a pioneering company, this innovative textile not only boasts exceptional quality and performance but also underscores a commitment to reducing the industry's carbon footprint. By combining cutting-edge technology and eco-friendly materials, Carbon Weave offers a glimpse into a more sustainable future for fashion and apparel.Section 1: The Birth of Carbon WeaveCarbon Weave fabric was born out of a passion for sustainable development and a desire to address the textile industry's environmental impact. Created by a visionary team dedicated to pushing the boundaries of the industry, this fabric is crafted using advanced carbon-fiber technology. By incorporating carbon fibers into the fabric's structure, it offers a durable, lightweight, and aesthetically appealing alternative to traditional textiles.Section 2: Unparalleled Performance and DurabilityCarbon Weave's unique composition ensures its exceptional performance and durability. The fabric's carbon fibers provide incredible strength and rigidity, making it highly resistant to wear and tear. Its remarkable tensile strength makes Carbon Weave ideal for applications requiring robust textiles, such as activewear, sports equipment, and automotive upholstery. Additionally, the fabric is also fire-resistant, providing an added layer of safety and protection.Section 3: Fueling Sustainable FashionOne of the most remarkable features of Carbon Weave fabric is its significantly reduced carbon footprint. By utilizing advanced carbon-fiber technology, the fabric production process minimizes the reliance on resource-intensive materials and embraces a more sustainable approach. Carbon Weave is manufactured using recycled materials, reducing the strain on natural resources while simultaneously reducing waste. This commitment to eco-friendliness resonates with the growing global demand for sustainable fashion.Section 4: Applications and VersatilityCarbon Weave's versatility extends to various sectors, making it highly sought after across numerous industries. In fashion, it presents a unique opportunity to create eco-friendly yet fashionable apparel, raising the bar for sustainability in the industry. Its use in activewear and sportswear offers unrivaled functionality, enhancing athletes' performance while reducing the overall carbon footprint associated with sportswear manufacturing. Moreover, the fabric's heat resistance and durability make it ideal for automotive and aerospace applications, aligning with the industry's growing focus on lightweight materials.Section 5: Collaboration and ImpactGiven the growing demand for sustainable solutions, many renowned fashion designers and industry leaders have already started embracing Carbon Weave. Collaborations have allowed for the creation of eye-catching, eco-friendly collections that challenge the narrative of traditional fashion. By utilizing Carbon Weave fabric, designers can convey their commitment to sustainability without compromising on quality or style.Section 6: Looking Towards the FutureCarbon Weave fabric represents a crucial step towards a more sustainable future for the textile industry. Its innovative approach to incorporating eco-friendly materials and advanced manufacturing techniques showcases that sustainability and style can coexist. As consumer demand for sustainable products grows, Carbon Weave's adoption paves the way for a paradigm shift in the textile industry, one that prioritizes ethical sourcing, renewable materials, and reduced carbon emissions.Conclusion:Carbon Weave fabric's emergence marks a significant milestone in sustainable textile manufacturing. Its exceptional performance, durability, and reduced carbon footprint make it an attractive choice for a wide range of applications. Moreover, collaborations with fashion designers and industry leaders demonstrate the fabric's potential to transform the industry's landscape. As Carbon Weave gains traction in the market, it serves as a beacon of hope, encouraging other textile manufacturers to embrace sustainable practices and contribute to a greener future.

High-Quality Fiberglass Woven Fabrics for Marine and Industrial Use

Fiberglass Release Fabric: The Key to Easy Release of Composite MaterialsIn the world of composites, fiberglass fabrics play a crucial role. Fiberglass fabrics are widely used for their outstanding temperature and strength properties, as well as their resistance to rot and mildew. Fiberglass fabrics are commonly used in applications such as marine, aerospace, automotive, and industrial processes.However, the biggest challenge that comes with using fiberglass fabrics is the issue of release. Fiberglass fabrics tend to stick to the composite materials, making it difficult to separate them. This issue can lead to increased production time and waste of materials, which can ultimately affect the profitability of your business.The solution to this problem is the use of fiberglass release fabric. Fiberglass release fabric is designed to prevent fiberglass fabrics from sticking to composite materials. The fabric is coated with a special release agent that prevents adhesion, making it easy to release the composite part from the mold.Fiberglass release fabric is an essential tool for manufacturers who need to produce high-quality composite parts efficiently. Using fiberglass release fabric not only saves time and materials but also ensures the integrity of the finished product.At (need remove brand name), we offer a wide range of fiberglass release fabrics designed to meet the needs of different industries. Our high-quality release fabrics are made from premium fiberglass materials that are asbestos-free and do not harm health. Our products provide an excellent release effect, reduce cycle time and increase productivity; this will help your business improve profitability!Our fiberglass release fabrics are available in various sizes, widths, and thicknesses, and we can customize our fabrics to meet our customer's specific needs. We also offer various coatings to suit different production processes and part geometries.In summary, fiberglass release fabric is a game-changer for manufacturers who use fiberglass fabrics in composite production processes. The use of fiberglass release fabric reduces production time, reduces material waste, and ensures high-quality finished products. At (need remove brand name), we offer high-quality fiberglass release fabrics that will improve production efficiency and ultimately improve your bottom line! So, try our products today and experience the difference!

Red Carbon Fiber Embossed Faux Leather Vinyl Upholstery Fabric for Various Projects

for Automotive, RV, Boat, Healthcare, Hospitality, Home decor, Fashion, and Commercial Projects.Are you looking for a versatile, stylish, and durable fabric for your next project? Look no further than our Red Carbon Fiber Embossed Faux Leather Vinyl, a top-quality upholstery fabric available at FabulessFabrics.com.Featuring an embossed cross weave pattern of carbon fibers, this fabric is perfect for adding a touch of sophistication and modern style to any project. Whether upholstering a car, RV, or boat, or creating custom home decor or fashion accessories, this fabric is sure to impress.But this fabric isn't just stylish – it's also incredibly functional. Thanks to its antibacterial properties and protective UV coating, it's perfect for healthcare, hospitality, and commercial projects. And with its water and stain-resistant properties, it's easy to clean and maintain, making it ideal for high-traffic areas.So why wait? Visit FabulessFabrics.com today to shop our wide selection of Red Carbon Fiber Embossed Faux Leather Vinyl and other top-quality upholstery fabrics. Whether you're a professional upholsterer or a DIY enthusiast, we have everything you need to bring your vision to life.

Discover the Benefits of Using 24oz Fiberglass Cloth for Your Projects

[Company Introduction][Company Name], a leading manufacturer in the fiberglass industry, is proud to announce the launch of their new 24 Oz Fiberglass Cloth. With years of experience in providing high-quality fiberglass materials, [Company Name] continues to innovate and meet the growing demands of various industries. Known for their commitment to excellence, durability, and customer satisfaction, [Company Name] has become a trusted name in the field.[News Content][City Name], [Date] - [Company Name] is excited to introduce their latest product, the 24 Oz Fiberglass Cloth, targeting industries that require superior strength and durability. This new addition to their extensive line of fiberglass materials further solidifies [Company Name]'s commitment to providing solutions that meet their customers' evolving needs.Fiberglass cloth is widely used in various industries, including construction, aerospace, automotive, marine, and many others. With its exceptional resistance to harsh environments, high strength-to-weight ratio, and excellent insulation properties, fiberglass cloth has become a staple material for multiple applications. [Company Name]'s 24 Oz Fiberglass Cloth takes these attributes to the next level, making it the go-to choice for professionals seeking top-quality materials.One of the key features of [Company Name]'s 24 Oz Fiberglass Cloth is its superior strength. Designed to withstand heavy loads and extreme conditions, this cloth offers exceptional resistance to tearing, impact, and abrasion. Its robust construction makes it perfect for applications that require structural reinforcement, such as the production of high-strength composites or repairs on existing structures.The 24 Oz Fiberglass Cloth also offers excellent thermal insulation properties, making it ideal for applications that require temperature regulation. It can withstand extreme heat or cold, making it suitable for applications in the automotive industry, where it can be used to insulate exhaust systems or engine components. Its effectiveness in temperature control also makes it a preferred choice in the aerospace industry, where it can be used for insulating aircraft components or engines.Furthermore, the cloth is chemically resistant, meaning it can withstand exposure to various chemicals, acids, and alkaline substances without deteriorating or losing its integrity. This feature proves invaluable in industries such as manufacturing and construction, where contact with corrosive materials is common.In addition to its strength and durability, [Company Name]'s 24 Oz Fiberglass Cloth is flexible and easy to work with. It can be cut, shaped, and molded to fit specific applications, making it a versatile material suitable for various purposes.[Company Name]'s commitment to quality extends beyond its products. They also ensure an environmentally friendly manufacturing process, using sustainable materials and minimizing waste. By continuously investing in research and development, [Company Name] strives to improve their products' performance while reducing their impact on the environment.The introduction of the 24 Oz Fiberglass Cloth reaffirms [Company Name]'s position as a market leader, providing solutions that meet the high expectations of industries worldwide. With their focus on innovation, quality, and customer satisfaction, [Company Name] continues to offer top-notch fiberglass materials that drive progress and excellence.For more information on [Company Name] and their 24 Oz Fiberglass Cloth, please visit their official website or contact their sales team directly.

High-Quality Fire-Resistant Fiberglass Fabric at Affordable Prices

Fire Resistant Fiberglass Fabric - The Key to Safety in Industrial SettingsThe potential for fire outbreaks in industrial settings is high due to the presence of flammable materials, chemicals, and machinery. In such situations, the safety of employees and equipment is of utmost importance. Fortunately, advancements in technology have led to the development of fire-resistant materials that can prevent and contain fires. One such material that has garnered a lot of attention is Fire Resistant Fiberglass Fabric.What is Fire Resistant Fiberglass Fabric?Fire-resistant fiberglass fabric is a specialized textile comprised of glass fibers that have been woven together and treated with a fire-resistant coating. The fabric is designed to be durable, lightweight, and able to withstand extreme temperatures without deteriorating. It is used primarily in industrial settings, where there is a high risk of fire outbreaks.Some of the key features of Fire Resistant Fiberglass Fabric include:1. Non-combustible - The fabric does not ignite when exposed to flames.2. Heat Resistant - The fabric can withstand high temperatures without melting or burning.3. Insulating - The fabric can be used as insulation to protect people and equipment from heat.4. Durable - The fabric is resistant to wear and tear, and can withstand exposure to chemicals and moisture.Uses of Fire Resistant Fiberglass Fabric1. Protective clothing - Fire-resistant fiberglass fabric is used to make protective clothing for workers in industries such as welding, firefighting, and oil and gas. The fabric's heat-resistant and non-combustible properties make it an ideal material for clothing that can withstand high temperatures and prevent injuries.2. Insulation - Fiberglass fabric is used as insulation to protect electrical equipment from heat. It can also be used in boilers, furnaces, and power plants to contain heat and prevent fires.3. Curtains and blankets - Fiberglass fabric can be used to make curtains and blankets to contain fires and prevent them from spreading.4. Tents and shelters - Fiberglass fabric is used to make tents and shelters for emergency situations. The fabric's heat-resistant and non-combustible properties make it an ideal material for these applications.Advantages of Fire Resistant Fiberglass Fabric1. Safety - Fire-resistant fiberglass fabric can prevent and contain fires, ensuring the safety of employees and equipment.2. Durability - The fabric's resistance to wear and tear, chemicals, and moisture make it a durable and long-lasting material.3. Lightweight - Fiberglass fabric is lightweight, making it easy to handle and transport.4. Cost-effective - Fiberglass fabric is an affordable material that offers long-term benefits in terms of durability and safety.ConclusionFire Resistant Fiberglass Fabric is the key to safety in industrial settings. Its non-combustible, heat-resistant, insulating, and durable properties make it an ideal material for protective clothing, insulation, curtains and blankets, and tents and shelters. It is also a cost-effective solution that offers long-term benefits in terms of safety and durability. Businesses that prioritize safety should invest in Fire Resistant Fiberglass Fabric to ensure the protection of their employees, equipment, and facilities.

Fiberglass Cloth: The Top Choice for Strengthening Materials

Title: Cloth for Fiberglass: A Revolutionary Innovation in the Composite IndustryIntroduction:In an era driven by innovation, the integration of advanced materials and revolutionary techniques is crucial in various sectors. In the field of composites, a recent breakthrough has been achieved with the development of Cloth for Fiberglass. This cutting-edge product has revolutionized the composite industry, enabling enhanced strength and durability across a wide range of applications. This news article aims to explore the features, benefits, and applications of Cloth for Fiberglass, while shedding light on the pioneering company behind this game-changing invention.Company Introduction:Owned and operated by a team of dedicated professionals, the company behind the development of Cloth for Fiberglass is committed to pushing the boundaries of composite materials. With decades of experience in the industry, their expertise has allowed them to engineer an innovative product that surpasses traditional fiberglass cloth. Leveraging their state-of-the-art facilities, the company has successfully manufactured Cloth for Fiberglass, catering to the growing demands and requirements of various sectors.Features of Cloth for Fiberglass:Cloth for Fiberglass boasts several key features that differentiate it from conventional materials. Firstly, its molecular structure has been meticulously designed to offer exceptional strength and sturdiness, making it resistant to impact and external forces. This remarkable strength not only improves the lifespan of the end products but also enhances their structural integrity. Additionally, Cloth for Fiberglass is lightweight and flexible, facilitating ease of use during manufacturing processes. Furthermore, it exhibits exceptional resistance to corrosion, chemicals, and extreme temperatures, making it an ideal choice for harsh environments.Benefits of Cloth for Fiberglass:The introduction of Cloth for Fiberglass provides numerous benefits across various industries. One of its primary advantages is its versatility, allowing its application in numerous sectors, including aerospace, automotive, marine, and construction. By using this innovative material, manufacturers can achieve the perfect balance between strength, weight reduction, and cost-effectiveness. Moreover, the inherent dimensional stability of Cloth for Fiberglass ensures that the end products retain their shape even under extreme conditions. This stability further contributes to the longevity of the final product, reducing maintenance and replacement costs.Applications of Cloth for Fiberglass:The revolutionary Cloth for Fiberglass has found applications across a wide range of sectors, with its unparalleled benefits making it an ideal choice for composite manufacturers. In the aerospace industry, it is utilized for the construction of aircraft components, providing lightweight and durable alternatives. In the automotive sector, it offers solutions for high-performance vehicles, allowing manufacturers to enhance fuel efficiency while maintaining safety standards. Furthermore, Cloth for Fiberglass finds extensive use in the marine industry, contributing to the design and production of sturdy and seaworthy vessels. Its resistance to corrosion and moisture make it particularly suitable for marine applications. Finally, in the construction industry, the cloth is extensively employed to produce durable and strong composite materials for infrastructure projects.Conclusion:The development of Cloth for Fiberglass marks a significant milestone in the composite industry, bringing forth a groundbreaking material that surpasses traditional alternatives. The company behind this innovative product continues to drive the industry forward by harnessing the endless potential of composites. With its remarkable strength, versatility, and resistance to various environmental factors, Cloth for Fiberglass is revolutionizing the way industries design and manufacture their products. As manufacturers increasingly adopt this game-changing cloth, we can expect a paradigm shift in the utilization of composites, opening avenues for enhanced performance, sustainability, and cost-effectiveness.

Fiberglass Cloth Roll: A Comprehensive Overview of 1708 Material

Title: Revolutionizing Reinforcements: Introduction of 1708 Fiberglass Cloth Roll in the Composites IndustryIntroduction (100 words):The composites industry has witnessed a game-changing development with the introduction of the innovative 1708 Fiberglass Cloth Roll. This groundbreaking product, manufactured by a leading company in the field, promises to revolutionize composites manufacturing with its exceptional properties and unmatched versatility. With a strong commitment to producing high-quality reinforcements, this company has once again proven its dedication to delivering cutting-edge solutions that exceed industry expectations. This article will delve into the details of the 1708 Fiberglass Cloth Roll, highlighting its remarkable features, benefits, and the significant impact it will have on various sectors that rely on composites for their operations.I. Overview of the 1708 Fiberglass Cloth Roll (200 words):The 1708 Fiberglass Cloth Roll represents a significant advancement in the field of composites reinforcements. It is a non-woven fabric made from continuous fiberglass roving that is laid flat and held together with a light binder. This unique manufacturing process ensures optimal conformity, durability, and strength.One of the most distinguishing features of the 1708 Fiberglass Cloth Roll is its combined axial and biaxial fabric orientation. This means that it consists of one layer of fiberglass roving aligned in the 0° (axial) direction and another layer placed at a 90° angle (biaxial). This configuration provides exceptional load-bearing capabilities in both direction orientations simultaneously, resulting in superior strength and stiffness for the composites it reinforces.Additionally, the 1708 Fiberglass Cloth Roll is compatible with a wide range of resin systems, making it adaptable to diverse manufacturing processes. Whether being utilized in wet lay-up, vacuum infusion, or hand lay-up techniques, this versatile reinforcement excels in enhancing the mechanical properties of various composite structures.Furthermore, the unique non-woven construction of the 1708 Fiberglass Cloth Roll offers improved wet-out characteristics, which ensures better resin distribution and ultimately enhances the bond between fibers and resin. This results in an optimal fiber-to-resin ratio, maximizing the performance and longevity of the composite product.II. Advantages and Applications (300 words):The introduction of the 1708 Fiberglass Cloth Roll carries numerous advantages, making it a highly sought-after reinforcement material in the composites industry. Some key benefits include:1. Superior strength and stiffness: The 1708 Fiberglass Cloth Roll ensures exceptional load-bearing capabilities, enhancing the overall strength and stiffness of composite structures. This makes it an ideal choice for various applications that require durable, lightweight materials.2. Versatility: The compatibility of the 1708 Fiberglass Cloth Roll with different resin systems and manufacturing processes allows for its use in diverse applications. It is widely employed in industries such as automotive, marine, aerospace, construction, and sporting goods.3. Improved wet-out characteristics: The non-woven construction of the 1708 Fiberglass Cloth Roll facilitates better resin distribution and adhesion, resulting in an optimal fiber-to-resin ratio. This significantly improves the performance and durability of composite products.4. Cost-effectiveness: By enhancing the mechanical properties of composites, the 1708 Fiberglass Cloth Roll helps manufacturers produce lightweight and durable products. This cost-effective solution reduces material waste and overall production costs.The application possibilities of the 1708 Fiberglass Cloth Roll are vast. In automotive manufacturing, it can be utilized in the fabrication of lightweight body panels, interior components, and structural parts, contributing to improved fuel efficiency and overall vehicle performance. In the marine industry, this innovation finds application in the production of hulls, decks, and bulkheads, ensuring superior integrity and longevity. The aerospace sector can benefit from the 1708 Fiberglass Cloth Roll in the construction of aircraft components, reducing weight while maintaining high strength and stiffness. In the construction industry, it finds use in building materials like structural panels, reinforcing beams, and columns, providing durability and resistance to environmental factors. Finally, the sporting goods industry can make use of this reinforcement material in the production of lightweight yet robust sporting equipment, enabling better performance for athletes.Conclusion (100 words):The introduction of the 1708 Fiberglass Cloth Roll marks a significant milestone in the composites industry. Its unique properties, versatility, and exceptional performance open up a world of possibilities for manufacturers across various sectors. With its superior strength, stiffness, and compatibility with different manufacturing processes, this reinforcement material has the potential to revolutionize composite manufacturing, enabling the production of lightweight, durable, and cost-effective products. As this innovative solution continues to gain momentum, it is clear that the 1708 Fiberglass Cloth Roll is set to become an indispensable tool for composites manufacturers in the years to come.

Revolutionize Your Car's Appearance with Carbon Fiber Cloth Wrap

Carbon Fiber Cloth Wrap Offers a Revolutionary Solution to Improve Performance of Automotive IndustryCarbon fiber cloth wrap is a revolutionary technology that has transformed the automotive industry by offering improved performance, efficiency, and strength in high-demanding applications. This innovative solution has gained popularity due to its unique properties that give it a competitive edge compared to traditional materials such as steel, aluminum, and plastic.One of the main benefits of carbon fiber cloth wrap is has a high strength-to-weight ratio, which makes it ideal for applications that require strength and durability. Automotive manufacturers have found that this advantage provides a significant reduction in vehicle weight, contributing to improved fuel efficiency, and reduced carbon emissions.The use of carbon fiber cloth wrap has also allowed automakers to introduce new designs with complex shapes that were previously impossible to achieve with traditional materials. This technology enables them to create lightweight, high-performance components that contribute to better handling, reduced noise, and vibration, making the driving experience more enjoyable and comfortable.Another advantage of carbon fiber cloth wrap is its resistance to corrosion, heat, and chemicals. This quality makes it an ideal material for components that are exposed to harsh environments such as engines, exhaust systems, and suspension components.Companies such as XXXX have been at the forefront of the development and production of carbon fiber cloth wrap. The company has built a reputation as a leading manufacturer, offering a diverse range of products that cater to different industries, including aerospace, marine, and automotive.XXXX Company was founded in XXXX and has grown to be a global leader in advanced composite solutions, producing carbon fiber cloth wrap that is renowned for its quality, consistency, and performance. The company has invested heavily in research and development to keep up with the rapidly evolving needs of the market and to offer innovative solutions that meet and exceed customer expectations.The carbon fiber cloth wrap produced by XXXX is manufactured using state-of-the-art equipment and high-quality raw materials, ensuring consistent quality and maximum performance. The company's products have been used by major automotive manufacturers such as XXXX, XXXX and XXXX, contributing to the production of fast and high-performance cars.The company's Director of Sales and Marketing, Mr. XXXX, stated that "the use of carbon fiber cloth wrap has significantly revolutionized the automotive industry, and we are proud to be at the forefront of this transformation. Our products have been designed to meet the needs of our customers and provide an outstanding performance that exceeds their expectations. We are committed to innovation, quality, and customer satisfaction, and we will continue to invest in new technologies to stay ahead of the competition."Carbon fiber cloth wrap has become a game-changer in the automotive industry, offering a revolutionary solution that contributes to improved performance, efficiency, and durability. As the demand for lighter, stronger, and more efficient vehicles continues to grow, the use of this innovative technology is expected to become even more popular in the years to come.In conclusion, the use of carbon fiber cloth wrap has transformed the automotive industry and offers an array of advantages, including lightweight, high strength-to-weight ratio, resistance to corrosion and heat, and improved design flexibility. Companies such as XXXX have played a significant role in the development and production of this innovative technology, providing high-quality products that exceed customer expectations. As the market for lightweight and high-performance vehicles continues to grow, the use of carbon fiber cloth wrap is expected to become even more significant in shaping the future of the automotive industry.

Fiberglass Cloth Rolls, Mat & Fabrics for Composite Construction Needs

article that introduces fiberglass cloth and its uses in various industries.Fiberglass Cloth: A Versatile and Essential Material for Various IndustriesFiberglass cloth has been one of the most versatile and essential materials used in various industries worldwide for many years now. It is made up of thin glass fibers woven together to form a cloth that is tough, durable, and resistant to heat, chemicals, and other environmental factors.The reason why fiberglass cloth is extremely popular in various fields such as construction, marine, automotive, and aerospace is that it offers an extensive range of benefits that are unmatched by other materials. Fiberglass cloth is a lightweight yet robust fabric that has high strength-to-weight ratios, making it an excellent option for strengthening and reinforcing various structures.Uses of Fiberglass ClothFiberglass cloth is used in a wide range of applications and industries due to its diverse properties. Some of its applications include:Construction Industry: Fiberglass cloth is used to reinforce concrete and other building materials, making them more durable, weather-resistant, and long-lasting.Marine and Automotive Industry: Fiberglass cloth is used to reinforce hulls, decks, and other components of boats and ships, as well as cars and trucks. The material is perfect for reducing the weight of these structures while increasing their strength and durability.Aerospace Industry: The aerospace industry uses fiberglass cloth to create lightweight materials that are strong and resistant to high temperature and extreme environments.Other Uses: Fiberglass cloth is also used in the electrical industry to make insulators, in the sports industry for various equipment, and in the medical field for prosthetics and orthotic devices.Benefits of Fiberglass ClothFiberglass cloth offers numerous benefits to the industries that use it. Here are some of the advantages of fiberglass cloth:Strength: Fiberglass cloth is stronger than many other materials, including steel. The material’s strength can be attributed to the glass fibers that make up the cloth, which are incredibly strong and resistant to impact.Durability: Fiberglass cloth is resistant to heat, chemicals, water, and other environmental factors. It also does not corrode or rust, making it last longer than other materials.Lightweight: Compared to metals and other materials, fiberglass cloth is lightweight, making it an ideal choice for reducing the weight of various structures.Easy to Work with: Fiberglass cloth is easy to cut, shape, and mold, making it easy to work with, even for those without specialized skills or tools.Cost-effective: Fiberglass cloth is relatively inexpensive compared to other materials with similar properties. This makes it a cost-effective option for various projects and industries.ConclusionFiberglass cloth is a versatile and essential material used in various industries worldwide. Its strength, durability, lightweight, and easy to work with properties make it an ideal choice for a range of applications and structures.If you’re in the market for fiberglass cloth, it is essential to source your materials from a trusted and reputable supplier. Jamestown Distributors offers top-quality fiberglass cloth, mat, fabrics, and more for all your composite construction needs.Whether you’re in the marine, automotive, aerospace, or any other industry, Jamestown Distributors has the right materials for you. Get in touch today to find out more about their products and services!