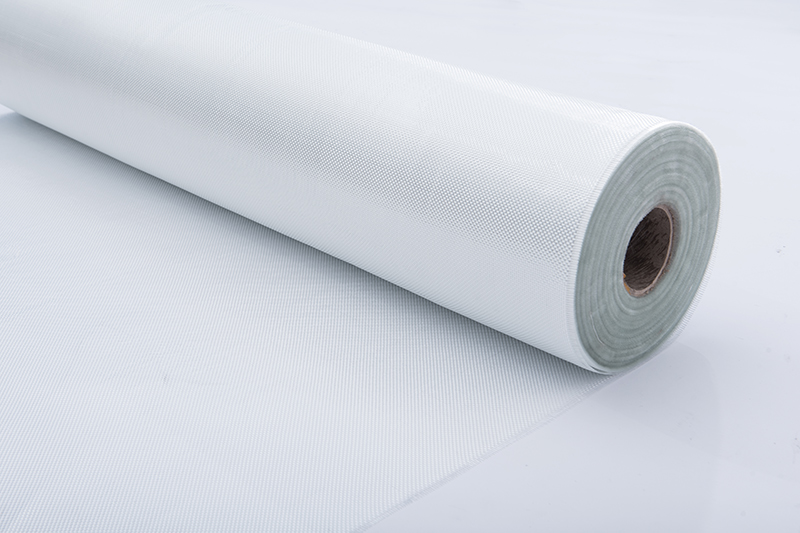

High-Quality 1/2 oz Fiberglass Cloth - 38 Inches Wide - 3m Long

Read More

Revolutionary Lightweight Carbon Fiber Plain Unveiled in Latest Technology News" - "New Lightweight Carbon Fiber Plain Unveiled in Latest Tech News

Carbon Fiber Plain is one of the most versatile and high-strength materials in the world. With its unique properties, it has been used in industries ranging from aerospace to automotive, and even high-performance sports equipment. While many companies produce carbon fiber, (brand name) stands out as a leader in the field. Founded in XXXX, (brand name) has made it a mission to produce high-quality carbon fiber products with unmatched precision and quality. Despite being a relatively new player in the market, they quickly established themselves as a global leader in the field, serving clients in a wide variety of industries from all over the world.At (brand name), the production process begins by sourcing only the highest-quality raw materials available. The fibers are then woven together into the desired pattern, coated with a resin binder, and cured at high temperatures to create a strong composite. (Brand name) has invested heavily in state-of-the-art manufacturing equipment and processes to ensure that each product is of the highest quality and consistency.One of the biggest advantages of carbon fiber is its strength-to-weight ratio. Compared to traditional materials like steel or aluminum, carbon fiber can be up to ten times stronger while being significantly lighter. This has made it a popular choice for aerospace and automotive applications, where reducing weight without sacrificing strength is critical.Another benefit of carbon fiber is its durability. Unlike other materials that can be prone to corrosion or fatigue, carbon fiber is highly resistant to both. It is also non-conductive, making it an ideal choice for applications where electromagnetic interference could be an issue.Perhaps most impressively, carbon fiber can be molded into virtually any shape or geometry, giving designers and engineers unparalleled flexibility in creating products. From aircraft components to bicycle frames, the possibilities are endless.(Brand name) offers a wide variety of carbon fiber products, including sheets, tubes, and rods. They also work closely with clients to develop custom solutions to meet their specific needs. This level of flexibility and customization has helped to set (brand name) apart from the competition.One particularly exciting use of carbon fiber is in the field of renewable energy. Wind turbine blades, which are exposed to a wide range of environmental stresses, are often made from carbon fiber due to its strength and durability. This has helped to increase the efficiency and reliability of wind power generation, contributing to the transition to a more sustainable energy future.Carbon fiber has also found its way into the world of sports equipment. From tennis rackets to ski poles, carbon fiber is a popular choice due to its light weight and stiffness. Athletes around the world use carbon fiber equipment to help them perform at their best.In conclusion, (brand name) is a global leader in the production of high-quality carbon fiber products. Their dedication to precision and quality has helped them to establish themselves as a trusted partner for clients in a diverse range of industries. With the continued growth in applications for carbon fiber, (brand name) is poised to play an important role in shaping the future of many industries.

Read More

Fiber-reinforced plastic made with glass fibers

Woven Fiberglass Sheets: The Secret to a Strong and Durable StructureWhen it comes to building structures that are both durable and visually appealing, fiberglass is a popular choice among architects and builders alike. Its unique properties make it an ideal material for a wide range of applications, from aircraft and automobile parts to boats and piping systems.One of the most common forms of fiberglass is woven fiberglass sheets. These sheets are made by weaving glass fibers together to create a strong, lightweight fabric that is used in a variety of construction and industrial applications.The Advantages of Woven Fiberglass SheetsCompared to other materials, woven fiberglass sheets offer many advantages. Here are just a few:1. Strength: Woven fiberglass sheets are incredibly strong and can withstand a lot of force without breaking or deforming. This makes them ideal for structures that need to withstand heavy loads or external pressure.2. Durability: Thanks to their resistance to moisture, heat, and chemicals, woven fiberglass sheets are incredibly durable and long-lasting. They can withstand years of wear and tear without weakening or deteriorating.3. Flexibility: Woven fiberglass sheets are flexible and can be molded into virtually any shape or size. This makes them ideal for creating curved or irregular shapes that would be difficult to create with other materials.4. Lightweight: Woven fiberglass sheets are lightweight, making them easy to work with and transport. This also makes them an economical choice, as they can be used to create structures that are both strong and lightweight.5. Cost-effective: Compared to other building materials, woven fiberglass sheets are relatively inexpensive. This makes them an affordable option for builders who want to create high-quality structures without breaking the bank.Applications of Woven Fiberglass SheetsWoven fiberglass sheets are used in a variety of applications, including:1. Aerospace: Woven fiberglass sheets are used to make aircraft parts, where their strength and durability are crucial for safety and performance.2. Automotive: Woven fiberglass sheets are used to make parts for cars and trucks, where their lightweight and durable properties make them an ideal choice for efficiency and performance.3. Marine: Woven fiberglass sheets are used to make boats and other watercraft, where their resistance to moisture makes them an ideal choice for durability and longevity.4. Building: Woven fiberglass sheets are used to reinforce concrete, making it stronger and more durable. They are also used to create exterior features, such as facades and cladding.ConclusionWoven fiberglass sheets are a versatile and durable material that offer a wide range of benefits for builders and architects. Whether you are building an airplane, a boat, or a building, woven fiberglass sheets can help you create a strong, durable structure that will last for years to come. So if you are looking for a material that combines strength, durability, and affordability, be sure to consider woven fiberglass sheets for your next project.

Read More

High-Density 4.3 oz Prepreg Unidirectional Carbon Fiber Fabric for Marine Applications

Title: Harnessing the Power of 12k Carbon Fiber Fabric: The Versatile Solution for Marine ApplicationsIntroduction:Carbon fiber has revolutionized numerous industries with its exceptional strength, lightweight nature, and durability. In marine applications, where strength and performance are paramount, the utilization of carbon fiber becomes even more critical. Among various options, the 12k Carbon Fiber Fabric stands out due to its high density and unidirectional nature, ensuring maximum strength in a specific direction. This blog aims to explore the versatility and benefits of utilizing 12k Carbon Fiber Fabric in marine applications while highlighting its key features and addressing the importance of obtaining a high-density, non-woven fabric for optimal results.Understanding 12k Carbon Fiber Fabric:12k Carbon Fiber Fabric is a type of prepreg unidirectional fabric that boasts an incredibly high-density carbon fiber arrangement. The term '12k' represents the number of carbon filaments bundled together within a tow. Higher values indicate increased density, resulting in enhanced mechanical properties and strength. This fabric possesses the ideal characteristics to meet the demanding requirements of marine applications.Enhanced Strength & Durability:The primary goal of employing 12k Carbon Fiber Fabric in marine applications is to achieve maximum strength in a specific direction. The unidirectional nature of the fabric ensures that the fibers are aligned parallelly, allowing for exceptional stiffness and strength along that axis. This specific characteristic allows boat manufacturers to reinforce weaker sections and critical load-bearing structures effectively. The lightweight properties of carbon fiber minimize weight while maximizing structural integrity, further improving overall vessel performance.Corrosion Resistance and Longevity:One of the significant challenges faced by marine structures is corrosion due to constant exposure to harsh seawater environments. Traditional materials such as steel or aluminum are prone to corrosion and require regular maintenance. However, 12k Carbon Fiber Fabric possesses remarkable resistance to corrosion, making it an ideal choice for marine applications. With superior resistance to the elements, carbon fiber extends the longevity of marine structures, reducing maintenance requirements and ensuring prolonged performance.Applications in Marine Engineering:1. Hull Construction and Reinforcement:12k Carbon Fiber Fabric plays a crucial role in reinforcing and strengthening hull structures, offering unparalleled stiffness and rigidity. By integrating this fabric into the laminate or composite layers, boat manufacturers can enhance the overall structural integrity, ensuring exceptional performance, and reducing potential stress fractures in rough sea conditions.2. Masts, Booms, and Other Rigging Equipment:The unidirectional nature and strength of 12k Carbon Fiber Fabric make it an ideal material for building masts, booms, and rigging components. These critical structural elements require lightweight, yet rigid materials to withstand the forces exerted by wind and waves. Carbon fiber offers the perfect balance, allowing for reliable and high-performance rigging equipment.3. Bulb Keel Construction:When it comes to constructing bulb keels, 12k Carbon Fiber Fabric is the go-to option due to its remarkable stiffness and strength. Bulb keels significantly enhance the vessel's stability and maneuverability, and integrating carbon fiber fabric ensures maximum efficiency without adding unnecessary weight.Conclusion:The utilization of 12k Carbon Fiber Fabric in marine applications has opened up a world of possibilities for boat manufacturers, designers, and engineers. Its superior strength, lightness, corrosion resistance, and longevity make it an ideal choice for reinforcing various marine structures, including hulls, masts, booms, and bulb keels. With the ability to achieve maximum strength in one direction, 12k Carbon Fiber Fabric addresses the specific needs of marine engineering, ensuring exceptional performance even in challenging sea conditions. By leveraging the remarkable properties of this non-woven fabric, marine vessels are now capable of achieving new levels of strength, durability, and efficiency, contributing to the advancement of the industry as a whole.Keywords: 12k Carbon Fiber Fabric, prepreg unidirectional fabric, marine applications, maximum strength, high density, unidirectional nature, versatility, lightweight, durability, corrosion resistance, boat manufacturers, stiffness, rigidity, hull construction, masts, booms, bulb keel construction.

Read More

Sewing Fiberglass Fabric: A Comprehensive Guide to Working with this Versatile Material

Title: Cutting-Edge Sewing Fiberglass Fabric Revolutionizes Manufacturing IndustryIntroduction:In an era where technological advancements are shaping industries across the globe, one company is leading the charge with its innovative sewing fiberglass fabric. The fabric, produced by an industry player (need to remove brand name) is designed to transform traditional manufacturing processes, enhancing durability, strength, and efficiency. With a commitment to meeting the evolving needs of various sectors, the company aims to revolutionize the way fiberglass composites are utilized, leaving a lasting impact on the manufacturing industry.Body:1. A Game-Changing Sewing Fiberglass Fabric:The sewing fiberglass fabric developed by (company name) presents a breakthrough in the manufacturing realm. Engineered to deliver exceptional performance, the fabric boasts unique properties such as high tensile strength, heat resistance, and corrosion resistance. These characteristics make it an ideal material for applications ranging from aerospace and automotive to marine and construction.2. Durability Meets Flexibility:One of the key advantages of (company name)'s sewing fiberglass fabric is its impressive durability paired with flexibility. Unlike conventional fiberglass composites, this fabric offers a higher degree of flexibility, ensuring a perfect fit for intricate shapes and contours. This quality significantly reduces waste materials and simplifies manufacturing processes, resulting in improved efficiency and cost-effectiveness.3. Enhanced Strength and Safety:With safety being a paramount concern for manufacturers in various industries, the sewing fiberglass fabric provides an added layer of security. Its exceptional strength surpasses conventional alternatives, offering enhanced load-bearing capacity and impact resistance. This translates into safer products, whether it be in the form of aircraft components, automotive parts, or structural reinforcements.4. Versatility Across Industries:Recognizing the diverse needs of different sectors, (company name) has engineered its sewing fiberglass fabric to be highly versatile. From lightweight components in the aviation industry to durable panels and structures in the construction sector, this material can be tailored to suit a wide range of applications. Its adaptability paves the way for increased efficiency and innovation across various manufacturing domains.5. Streamlined Manufacturing Processes:Capitalizing on the unique properties of the sewing fiberglass fabric, (company name) aims to streamline and simplify manufacturing processes. By leveraging its flexibility, easier handling, and improved weave patterns, the fabric can be seamlessly integrated into existing production lines. This eliminates the need for complex molds and reduces overall production time, thereby boosting productivity for manufacturers around the globe.6. Environmental Sustainability:In addition to its performance capabilities, (company name)'s sewing fiberglass fabric aligns with growing environmental concerns. With a focus on sustainable development, the fabric is produced using eco-friendly materials and manufacturing processes, minimizing the carbon footprint. Its longevity and resistance to degradation also contribute to reducing waste in the long run, highlighting the company's commitment to environmental stewardship.Conclusion:With the introduction of their revolutionary sewing fiberglass fabric, (company name) has set the stage for a manufacturing revolution. Combining durability, flexibility, and strength, this innovative material is poised to reshape various industries. From increased efficiency and cost-effectiveness to enhanced safety and sustainability, the potential of this sewing fiberglass fabric is vast. As the company continues to push the boundaries of innovation, it is paving the way for a future where manufacturing is redefined by cutting-edge materials and technologies.

Read More

Discover the Numerous Uses and Benefits of Glass Fabric Cloth

Title: Cutting-Edge Glass Fabric Cloth Revolutionizing Industries: A Closer Look at Innovative MaterialIntroduction:In today's rapidly evolving world, technological advancements continue to be at the forefront of innovation. One such breakthrough is the development of Glass Fabric Cloth by an industry-leading company. This revolutionary material is set to transform multiple industries, thanks to its exceptional properties and versatile applications. Let's delve deeper into the capabilities of Glass Fabric Cloth and explore how it is poised to revolutionize various sectors.I. Understanding Glass Fabric Cloth:Glass Fabric Cloth is a cutting-edge composite material that combines the excellent mechanical properties of glass fibers with the flexibility and durability of fabric. This hybrid fabric is engineered to deliver superior strength, thermal resistance, and remarkable electrical insulation. The specialized manufacturing process ensures the uniform distribution of glass fibers throughout the cloth, resulting in a product that exhibits exceptional dimensional stability and resistance to heat, chemicals, and abrasions.II. Applications in Aeronautics and Aerospace:The aeronautics and aerospace industries are set to benefit immensely from the breakthrough advancements facilitated by Glass Fabric Cloth. Its high strength-to-weight ratio makes it ideal for manufacturing components such as aircraft wings, fuselage, and tail structures. The exceptional thermal resistance of the cloth ensures that it can withstand extreme temperature variations encountered during flights. Additionally, the electrical insulation properties of Glass Fabric Cloth set it apart, making it a crucial material for wiring and insulation in aircraft.III. Automotive Industry Integration:Glass Fabric Cloth is revolutionizing the automotive industry, with applications in both electric and conventional vehicles. The material's lightweight properties prove beneficial in increasing fuel efficiency while maintaining the structural integrity of various components. The cloth's thermal insulation capability also aids in development, ensuring protection against engine heat while allowing optimal performance. Furthermore, Glass Fabric Cloth provides electrical insulation, making it ideal for use in wiring harnesses, batteries, and interior components.IV. Industrial and Infrastructure Applications:Glass Fabric Cloth is poised to redefine industrial and infrastructure applications due to its exceptional strength and endurance. Its resistance to heat and chemicals makes it an excellent choice for the construction of furnaces, pipelines, tanks, and other high-temperature environments. Furthermore, Glass Fabric Cloth finds widespread use in reinforcement layers for composites, providing structural stability in applications such as wind turbine blades, bridges, and pipelines.V. Advancements in Consumer Goods and Sporting Equipment:The versatility of Glass Fabric Cloth extends to the consumer goods and sporting equipment industries. The material's lightness and durability make it a preferred choice for developing luggage, backpacks, and durable accessories. Moreover, Glass Fabric Cloth's resistance to moisture and abrasion enhances the longevity of outdoor gear such as tents, backpacks, and clothing. Its widespread adoption ensures that consumers can enjoy reliable and long-lasting products that can withstand demanding outdoor conditions.Conclusion:The advent of Glass Fabric Cloth marks a significant milestone in material innovation. With its exceptional mechanical properties, outstanding thermal resistance, and remarkable electrical insulation, this cutting-edge material is poised to revolutionize industries across the board. From aeronautics and automotive to industrial applications and consumer goods, Glass Fabric Cloth is transforming the way products are designed, manufactured, and utilized. As technology continues to progress, Glass Fabric Cloth presents limitless possibilities in enhancing performance, improving fuel efficiency, and creating durable and sustainable solutions for the future.

Read More

High-Quality Kevlar Cloth: Lightweight and Versatile Reinforcements for Resin Composites

Title: The Dynamic Duo: Exploring the Versatility of Carbon Kevlar WeaveIntroduction:In the realm of materials engineering, few combinations hold as much promise as carbon and Kevlar reinforcements. The intertwining of these materials results in exceptional strength, durability, and remarkable versatility. Today, we delve into the world of carbon Kevlar weave, its various applications, and the significance it holds in several industries.Chapter 1: Understanding Carbon Kevlar Weave and its Composition1.1 Origins and Development: - A brief history of carbon Kevlar weave, its inception, and how it has evolved over the years.1.2 Composition and Characteristics: - An in-depth look at the properties of carbon Kevlar weave, including its weight options and weaving techniques. - The applications that carbon Kevlar weave is best suited for due to its specific characteristics.Chapter 2: The Exceptional Mechanical Properties of Carbon Kevlar Weave2.1 Fatigue Resistance: - Discussing the superior fatigue resistance exhibited by carbon Kevlar weave and how it contributes to its longevity and reliability.2.2 Impact Strength: - Delving into the impressive impact strength of carbon Kevlar weave and its applications in high-stress environments.2.3 Durability Under Extreme Conditions: - Analyzing the ability of carbon Kevlar weave to withstand harsh environments and extreme temperatures. - Highlighting real-world examples where carbon Kevlar weave has shown exceptional durability.Chapter 3: Applications of Carbon Kevlar Weave in Various Industries3.1 Aerospace and Aviation: - Exploring how carbon Kevlar weave is utilized in aircraft construction to enhance structural integrity and reduce weight. - Highlighting the advantages carbon Kevlar weave offers in terms of fuel efficiency and improved performance.3.2 Automotive and Motorsports: - Discussing the use of carbon Kevlar weave in high-performance vehicles and its contribution to safety and improved aerodynamics.3.3 Sports and Recreation: - Examining how carbon Kevlar weave enhances the performance and durability of sports equipment, such as bicycles, tennis rackets, and race car helmets.3.4 Marine and Defense Applications: - Analyzing the role of carbon Kevlar weave in marine vessels and military equipment, emphasizing its ability to withstand water and extreme conditions.Chapter 4: Maintaining and Protecting Carbon Kevlar Weave4.1 Sensitivity to UV Light: - Understanding the impact of prolonged UV exposure on carbon Kevlar weave and the necessary precautions to minimize damage.4.2 Compatible Resins: - Highlighting the resin options that work well with carbon Kevlar weave, including UP, VE, and EP resins.4.3 Care and Maintenance: - Offering tips and best practices for preserving the longevity and performance of carbon Kevlar weave products.Conclusion:With its exceptional mechanical properties, durability, and versatility, carbon Kevlar weave has revolutionized numerous industries. This groundbreaking composite material continues to push boundaries and set new standards for strength and performance. From aerospace to automotive, sports to defense, carbon Kevlar weave remains a game-changer, unparalleled in its ability to enhance and fortify various applications.Keywords: Carbon Kevlar Weave, Carbon and Kevlar Reinforcements, Carbon Kevlar Cloth, Carbon and Kevlar Composites, Fatigue Resistance, Impact Strength, UV Light Sensitivity, Versatility, Applications, Aerospace, Automotive, Sports, Marine, Defense.

Read More

High-Quality Quick Change Fiberglass Laminating Rollers for Efficient and Smooth Fiberglass Applications

ers, Quick Change Fiberglass Rollers, Pure Bristle Fiberglass Rollers, and Bodi Company, Inc.Bodi Company, Inc. is a well-known and trusted manufacturer of fiberglass laminating rollers. Their products have been favored by many professionals in the industry for their efficiency and durability. The latest addition to their line of fiberglass laminating rollers is the Bristle Roller Quick Change Fiberglass Laminating Roller. This innovative product has quickly gained popularity among professionals due to its unique features and benefits.The Bristle Roller Quick Change Fiberglass Laminating Roller is made of pure bristle fiberglass rollers that are spirally wound. This construction method results in a strong fiberglass lamination while also allowing for smooth application of the fiberglass matting. The roller is designed to produce consistent results and can even be used in tight places where traditional rollers may be unable to reach.One of the most significant advantages of this roller is that you can hear the bubbles popping as you apply it to the fiberglass matting. This sound indicates that the air pockets are being removed from the lamination, ensuring that a uniform and strong bond is formed. This feature is especially useful for those who are new to working with fiberglass and may be unsure of the proper lamination techniques.The Bristle Roller Quick Change Fiberglass Laminating Roller is also very easy to use. Its quick change mechanism allows you to replace the rollers quickly and easily, which saves you time and effort. Additionally, the roller is designed to work efficiently with different types of fiberglass matting, making it a versatile tool for any fiberglass laminating project.In conclusion, the Bristle Roller Quick Change Fiberglass Laminating Roller by Bodi Company, Inc. is an excellent choice for professionals and beginners alike. Its innovative features and benefits make it stand out among other fiberglass laminating rollers on the market. Whether you are working on small or large projects, this roller is sure to provide you with consistent and reliable results. So, if you're looking for a high-quality fiberglass laminating roller, the Bristle Roller Quick Change Fiberglass Laminating Roller is definitely worth considering.

Read More

24oz Vermiculite Coated Fiberglass Cloth: A Fire and Chemical Resistant Solution for High Temperature Insulation and Welding Applications

Acmetex Inc Launches Revolutionary 24oz Vermiculite Coated Fiberglass ClothAcmetex Inc, a leading manufacturer of high-performance fiberglass cloth and textile products, has announced the launch of its latest innovation, the 24oz Vermiculite Coated Fiberglass Cloth. This new product brings cutting-edge technology and design to the market, providing customers with an advanced and reliable solution for their high-temperature insulation and fire-resistant needs.Acmetex's 24oz Vermiculite Coated Fiberglass Cloth is made from continuous texturized E-fiberglass yarns, which offer exceptional strength and durability. These yarns are woven together to create a tight, dense fabric that can withstand high temperatures and harsh conditions. Vermiculite coating is added to the cloth to improve abrasion resistance and add an extra layer of protection against direct flame.Heat travels across the fabric, not through it, making this product an excellent choice for high-temperature insulation and heat shield applications. It provides superior thermal insulation, keeping heat from escaping and cold from seeping in, making it ideal for use in welding blankets, curtains, and expansion joints. The vermiculite coating also improves the cloth's strength and resistance to tearing, making it a great option for high-stress applications.Acmetex Inc has been a leading manufacturer of fiberglass cloth and textile products for over 20 years. The company has a proven track record of providing high-quality solutions to customers across a wide range of industries, including automotive, aerospace, marine, and construction. Acmetex's commitment to innovation and quality has made it a trusted partner for many leading companies in these industries."We are excited to launch our latest innovation, the 24oz Vermiculite Coated Fiberglass Cloth," said a spokesperson for Acmetex Inc. "This new product is a testament to our commitment to providing our customers with the highest quality solutions for their needs. We believe that this product will be a game-changer in the market, and we are confident that it will be very well received by our customers."Acmetex's 24oz Vermiculite Coated Fiberglass Cloth is available in a variety of widths and lengths, making it suitable for a wide range of applications. It is also customizable, allowing customers to tailor the fabric to meet their specific needs. The product is expected to be available for purchase on Acmetex's website and through its authorized distributors in the coming weeks.In conclusion, Acmetex Inc's 24oz Vermiculite Coated Fiberglass Cloth is a breakthrough product that offers exceptional strength, durability, and fire-resistant properties. It is a testament to the company's commitment to innovation and quality and a clear demonstration of its ability to bring cutting-edge solutions to the market. This product is sure to be a game-changer and a valuable asset for customers across a wide range of industries.

Read More