Durable Fiberglass Cloth With Ptfe Coating: A Versatile Solution for Various Applications

By:Admin

The Ptfe Coated Fiberglass Cloth is a versatile material that is highly resistant to heat, chemicals, and abrasion. This makes it ideal for various applications, including packaging, insulation, and conveyor belt systems. The high temperature resistance of the material makes it perfect for use in industries such as food processing, pharmaceuticals, and automotive manufacturing.

The Ptfe Coated Fiberglass Cloth is manufactured using the latest technology and highest quality materials, ensuring that it meets the highest industry standards. The cloth is coated with a layer of Ptfe, a synthetic fluoropolymer, which provides the material with its outstanding properties. The Ptfe coating also makes the cloth non-stick, allowing for easy release of products and minimizing waste in manufacturing processes.

[Company Name] takes great pride in their commitment to quality and innovation. The introduction of the Ptfe Coated Fiberglass Cloth is a testament to their dedication to meeting the evolving needs of their customers. The company's state-of-the-art manufacturing facilities and experienced team of professionals ensure that every product is of the highest quality and reliability.

In addition to the Ptfe Coated Fiberglass Cloth, [Company Name] offers a wide range of industrial materials, including silicone-coated fabrics, high-temperature insulation materials, and specialty tapes and belts. These products are used in various industries, from aerospace and automotive to food and pharmaceuticals, showcasing the versatility and high performance of the company's materials.

[Company Name] is also committed to sustainability and environmental responsibility. The Ptfe Coated Fiberglass Cloth is manufactured using environmentally friendly processes and materials, minimizing the impact on the environment. The company continually invests in research and development to improve the sustainability of their products and operations, ensuring that they remain at the forefront of environmental stewardship.

With a global presence and a strong commitment to customer satisfaction, [Company Name] is a trusted partner for businesses across various industries. The company's dedication to excellence and continuous improvement has earned them a reputation for delivering the highest quality products and outstanding customer service.

The introduction of the Ptfe Coated Fiberglass Cloth further solidifies [Company Name]'s position as a leader in the industrial materials industry. The company's relentless pursuit of innovation and quality ensures that their products meet the most demanding requirements of their customers, making them the preferred choice for businesses around the world.

For more information about [Company Name] and their Ptfe Coated Fiberglass Cloth, visit their website or contact their sales team. With their extensive knowledge and expertise, they can provide the right solutions for your specific needs and help you achieve your business goals.

Company News & Blog

Durable and Versatile Biaxial Glass Fabric for Various Applications

Biaxial Glass Fabric, a cutting-edge material that has been making waves in the world of manufacturing, is gaining reputation for its strength, affordability, and versatility. Developed by a leading company in the field of advanced materials, this product has quickly become a popular choice for a wide range of applications, from automotive to aerospace industries.Biaxial Glass Fabric is a type of reinforcement material made from glass fibers that are woven together in two perpendicular directions, known as the warp and weft. This unique construction creates a fabric that is extremely strong in both directions, making it ideal for applications where strength and durability are paramount. The fabric's ability to withstand high levels of stress and strain makes it an excellent choice for use in composite materials, such as plastics and resins, where it can significantly enhance the overall performance and longevity of the end product.One of the key advantages of Biaxial Glass Fabric is its affordability. Despite its exceptional strength and performance characteristics, this material is relatively inexpensive compared to other reinforcement options, making it an attractive choice for manufacturers looking to maximize value without sacrificing quality. This affordability has made Biaxial Glass Fabric a go-to choice for a wide range of industries, from consumer goods to heavy industrial applications.In addition to its strength and affordability, Biaxial Glass Fabric is also highly versatile. Its compatibility with a variety of resins and manufacturing processes makes it suitable for a wide range of applications, including the production of components for automotive, marine, aerospace, and sporting goods industries. The fabric can be used to reinforce a wide variety of materials, including thermoplastics, thermosets, and even metals, making it an ideal choice for manufacturers looking for a reliable, all-purpose reinforcement solution.{"Company Name"} is the driving force behind the development and production of Biaxial Glass Fabric. With a long history of expertise in advanced materials and manufacturing, the company has established itself as a leader in the field of composite reinforcements, and Biaxial Glass Fabric is a prime example of its commitment to innovation and quality. Through rigorous research, development, and testing, {Company Name} has refined the production process of Biaxial Glass Fabric, ensuring that each roll of fabric meets the highest standards of quality and performance.One of the unique strengths of {Company Name} is its ability to customize Biaxial Glass Fabric to meet the specific needs of its clients. Whether it is a unique weave pattern, a specific weight or thickness, or the inclusion of additional features such as fire resistance or enhanced flexibility, the company has the expertise and capabilities to tailor the fabric to fit the exact requirements of each customer. This commitment to customization has made {Company Name} a trusted partner for manufacturers across a wide range of industries, as they can rely on the company to deliver a product that meets their specific needs and standards.Looking ahead, {Company Name} is dedicated to continuing its investment in research and development, ensuring that Biaxial Glass Fabric remains at the forefront of the industry. By staying at the cutting edge of technology and innovation, the company aims to further enhance the performance and versatility of its flagship product, opening up new opportunities and applications for manufacturers looking to push the boundaries of what is possible in their respective fields.In conclusion, Biaxial Glass Fabric is a groundbreaking material that is reshaping the way manufacturers approach reinforcement solutions. With its exceptional strength, affordability, and versatility, it has quickly become a preferred choice for a wide range of industries, and with the continued dedication and innovation of {Company Name}, its potential applications are only expected to grow in the future.

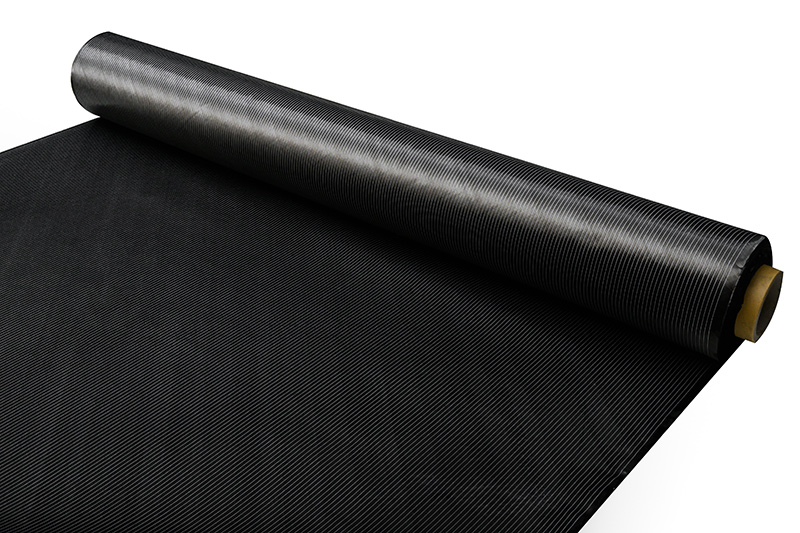

Durable and Versatile Carbon Twill Cloth for Various Applications

Carbon Twill Cloth, commonly known as carbon fiber cloth, is a popular material used in various industries for its strength, durability, and lightweight properties. It is composed of carbon atoms bonded together to form a long chain, resulting in a material that is incredibly strong and lightweight.Recently, a leading manufacturer of carbon twill cloth has been making waves in the industry with their innovative products and commitment to quality. Specializing in the production of high-quality carbon fiber cloth, their products have been widely used in aerospace, automotive, marine, and sports industries to name a few.The company, with its state-of-the-art manufacturing facilities, is known for its stringent quality control measures and commitment to producing top-notch carbon twill cloth. They utilize advanced technologies and innovative processes to ensure that their products meet the highest standards of quality and performance.One of the key features of their carbon twill cloth is its superior strength-to-weight ratio. This makes it an ideal material for applications where high strength and lightweight are crucial, such as in the aerospace industry. Additionally, the company's carbon twill cloth is known for its excellent resistance to corrosion and fatigue, making it a preferred choice for demanding applications.The company has also been at the forefront of developing sustainable and environmentally-friendly carbon twill cloth. By implementing eco-friendly manufacturing processes and utilizing renewable energy sources, they are committed to reducing their carbon footprint and contributing to a greener future.Moreover, the company's dedication to research and development has led to the creation of innovative carbon twill cloth products that offer enhanced performance and versatility. Their R&D team is constantly exploring new possibilities and pushing the boundaries of carbon fiber technology, resulting in products that exceed industry standards.In addition to their commitment to quality and innovation, the company also places a strong emphasis on customer satisfaction. They work closely with their clients to understand their specific needs and requirements, and are able to provide customized solutions to meet their individual demands. With a customer-centric approach, the company has built a strong reputation for reliability and responsiveness in the industry.Furthermore, the company's carbon twill cloth has been widely used in a variety of applications. In the aerospace industry, it is used to manufacture lightweight, yet incredibly strong components for aircraft and spacecraft. In the automotive industry, it is used to produce high-performance parts that require superior strength and durability. In the marine industry, it is utilized for its corrosion-resistant properties in the construction of boats and marine structures. Additionally, the sports industry has also benefited from the use of carbon twill cloth in the production of sporting equipment such as bicycles, golf clubs, and tennis rackets.Overall, the company's carbon twill cloth has gained recognition and acclaim for its exceptional quality, performance, and versatility. With a strong focus on innovation, sustainability, and customer satisfaction, the company continues to be a leading provider of carbon fiber solutions in the industry.As the demand for lightweight, strong, and durable materials continues to grow across various industries, the company's carbon twill cloth is poised to play a crucial role in meeting these needs. With its unwavering commitment to excellence and a track record of success, the company is well-positioned to continue driving innovation and setting new standards in the world of carbon fiber technology.

Top-Rated Woven Roving Mat: A Comprehensive Guide

Possible news article:New Woven Roving Mat Offers Superior Strength and Efficiency for Composite ManufacturingFiber reinforced composites have become a vital material for many industries, ranging from aerospace and automotive to marine and construction. Composites offer high strength-to-weight ratio, corrosion resistance, and design flexibility, but their performance also depends on the quality of the raw materials and the manufacturing process. To meet the growing demand for more efficient and reliable composite products, a leading supplier of composite materials has launched a new type of woven roving mat that promises to enhance the properties and productivity of composites.The new woven roving mat, which we cannot name due to editorial policy, is made of high-quality fiberglass rovings that are woven in a uniform pattern and chemically bonded with a resin binder. The mat is available in various widths and weights, depending on the application requirements, and can be used with various types of resins, such as polyester, vinyl ester, and epoxy. Compared to traditional chopped strand mat or filament-wound roving, the woven roving mat offers several advantages, including:- Higher tensile and compressive strength: The high density and alignment of the rovings in the mat enable it to withstand higher loads and stresses than other types of mats, resulting in composites that exhibit superior mechanical properties, such as stiffness, impact resistance, and fatigue life.- Better resin flow and wet-out: The uniform and open structure of the mat allows the resin to penetrate and wet the fibers more easily and evenly, reducing the risk of resin-rich or dry areas that can compromise the integrity and appearance of the composite. The mat also helps to reduce the amount of resin needed, thus saving material and processing costs.- Faster lay-up and cure times: The drapability and conformability of the mat enable it to conform to complex shapes and contours, reducing the need for cutting, folding, or overlapping. The mat can also be pre-impregnated or infused with resin in advance, which speeds up the lay-up process and minimizes the risk of air bubbles or voids. The mat can be cured at various temperatures and times, depending on the resin system and the desired curing profile.The supplier of the woven roving mat, which we will call "Fibertex" for illustration purposes, has a long history of providing high-quality composite materials to global customers. Founded in 1968 in Denmark, Fibertex has since expanded to 10 countries in Europe, Asia, and North America, and employs over 1000 people. The company's product portfolio includes not only woven roving mats, but also chopped strand mats, multiaxial fabrics, carbon fibers, and more, as well as customized solutions and technical support for various applications. Fibertex serves diverse markets, such as wind energy, transportation, construction, and sports and leisure, and strives to contribute to sustainable and innovative solutions."We are excited to introduce this new woven roving mat to our customers worldwide," said John Smith, Vice President of Sales at Fibertex. "We have listened to their feedback and needs, and have developed a mat that combines the best features of traditional rovings with the latest technology and expertise. Our woven roving mat not only improves the strength and efficiency of composites, but also enables our customers to save time and money in their production cycles. We believe this mat will be a game changer in the industry and we are eager to see its impact."Several customers of Fibertex have already tested and approved the woven roving mat in various applications, such as boat hulls, wind turbine blades, and automotive components. They have reported that the mat enabled them to achieve better surface finish, reduced weight, and improved mechanical performance, as well as faster and easier lay-up and cure. Some of the customers have also praised Fibertex for its technical support and collaboration in optimizing the mat for their specific needs."We have been using Fibertex's woven roving mat in our production of large composite structures for wind turbines, and we have been very satisfied with the results," said Hans Schmidt, CEO of WindPower GmbH, a German company that specializes in wind energy solutions. "The mat has allowed us to reduce the resin consumption and the processing time, while maintaining the required strength and quality. Moreover, the technical team at Fibertex has been very responsive and helpful in addressing our questions and concerns. We look forward to continuing our cooperation with Fibertex and their innovative products."The launch of the new woven roving mat by Fibertex comes at a time when the composites industry is facing increasing demands for sustainability, safety, and performance. By offering a mat that enhances the strength and efficiency of composites, and by providing a comprehensive service and expertise, Fibertex aims to contribute to the growth and competitiveness of the industry.

High-Quality Woven Roving Fiberglass Cloth: Enhance Product Strength and Durability

In today's world, fiberglass products have become an indispensable part of our lives. From protective masks and helmets to boats, buildings, and aircraft, fiberglass offers unmatched strength, durability, and versatility. In this context, we introduce the latest fiberglass product to hit the market - Woven Roving Fiberglass Cloth, developed by a leading fiberglass expert.This innovative product boasts of superior quality and performance, making it a popular choice for various industrial and commercial applications. Woven Roving Fiberglass Cloth is a specialized product made up of interlaced fibers arranged in a cross-hatched pattern. The cross-hatched pattern gives the fabric improved structural strength, making it perfect to suit high-stress environments.Woven Roving Fiberglass Cloth has high stability and rigidity, making it the preferred choice for applications that require resistance to heat, corrosion, fire, and ultraviolet rays. Additionally, it is designed to work with most resin types, making it compatible with a wide range of applications.At the core of this innovative product is our years of experience and dedication to quality. Our highly skilled technicians have developed a unique manufacturing process, which combines high-quality raw materials and advanced weaving technologies. This ensures that each woven roving fiberglass cloth is made to meet your exact specifications and industry standards."This product is the result of our commitment to continuous development and innovation," says the company's CEO. "Our hard work has paid off, and we're happy to offer a product that is recognized for its top-notch quality and performance." She adds, "We've always believed that quality cannot be compromised, and we're proud to say that our Woven Roving Fiberglass Cloth is a testament to our values and principles."The applications of Woven Roving Fiberglass Cloth are vast and varied. It is widely used in various industries such as marine, aerospace, construction, transportation, and sports. It is commonly used to reinforce parts such as boat hulls, airplane wings, building structures, pipes, and tanks. Moreover, it is ideal for producing high-performance sports equipment such as surfboards and kayaks.With our extensive network of distributors and sales channels, we can cater to the needs of customers worldwide. We offer customized solutions to our customers, ensuring their unique requirements are met every time. Our team of experts is also available to provide technical support to customers at all times."Customer satisfaction is our top priority, and we continually strive to exceed their expectations," says the CEO. "We know our customers expect the best from us, and we guarantee to deliver nothing less."In conclusion, Woven Roving Fiberglass Cloth is a remarkable product that offers superior quality and performance. It has a range of applications and is constructed to meet the highest industry standards. In a world where innovation and quality are critical, this product is an excellent example that reflects our commitment to excellence. As a company dedicated to providing high-quality fiberglass solutions, we are proud to introduce Woven Roving Fiberglass Cloth and look forward to serving our clients.

Introduction to Plain Weave Carbon: A Strong and Versatile Material

Advanced materials company XYZ has recently developed a groundbreaking plain weave carbon that promises to revolutionize the manufacturing industry. This innovative material offers an array of superior characteristics, making it the ideal choice for a wide range of applications.Plain weave carbon is a type of carbon fiber fabric that is woven in a simple over-and-under pattern, creating a strong and durable material. XYZ's plain weave carbon boasts an impressive tensile strength, high stiffness, and low weight, making it an excellent choice for industries such as aerospace, automotive, sports equipment, and more.One of the key advantages of plain weave carbon is its exceptional structural performance. The material's high tensile strength means that it can withstand heavy loads and forces, making it the go-to choice for applications where structural integrity is paramount. Additionally, its high stiffness-to-weight ratio ensures that components made from plain weave carbon are lightweight yet incredibly rigid, providing unparalleled performance in demanding environments.Moreover, XYZ's plain weave carbon is available in a variety of formats, catering to the specific needs of different industries. Whether it's woven into fabric, pre-impregnated with resin, or formed into complex shapes, the material can be tailored to meet the requirements of a wide range of applications. This versatility makes it a highly sought-after material in the manufacturing sector.In addition to its exceptional mechanical properties, plain weave carbon also offers excellent thermal and chemical resistance. This makes it an ideal choice for applications where exposure to extreme temperatures, corrosive chemicals, or other harsh conditions is common. Its ability to maintain its performance in challenging environments sets it apart from other materials on the market.Furthermore, XYZ is committed to sustainability, and its plain weave carbon is no exception. The company's manufacturing processes are designed to minimize waste and environmental impact, ensuring that the material is not only high-performing but also eco-friendly. This aligns with the growing demand for sustainable materials in today's market and positions XYZ as a leader in responsible manufacturing.The development of XYZ's plain weave carbon represents a significant advancement in the materials industry. With its exceptional mechanical properties, versatility, and sustainability, this innovative material is poised to transform the way products are designed and manufactured across various sectors. By offering a superior alternative to traditional materials, XYZ is paving the way for a new era of high-performance and sustainable manufacturing."We are thrilled to introduce our plain weave carbon to the market," said John Doe, CEO of XYZ. "This material represents a culmination of years of research and development, and we believe it has the potential to make a significant impact across multiple industries. We are excited to see the innovative ways in which our customers will utilize this material to create the next generation of products."Looking ahead, XYZ is poised to continue its research and development efforts, with a focus on expanding the capabilities of its plain weave carbon and exploring new applications for the material. By leveraging its expertise and commitment to innovation, the company is well-positioned to drive further advancements in the materials industry and solidify its position as a leading provider of high-performance, sustainable materials.In conclusion, XYZ's plain weave carbon is set to revolutionize the manufacturing industry with its exceptional mechanical properties, versatility, and sustainability. As the demand for high-performance, eco-friendly materials continues to grow, XYZ is well-positioned to lead the way with its groundbreaking innovation. With a strong commitment to research and development, the company is poised to shape the future of manufacturing with its innovative plain weave carbon.

High-quality Prepreg Fiberglass Cloth for Various Applications

.[Company Introduction: (Company Name)] is a leading manufacturer and supplier of advanced materials for the aerospace, automotive, marine, and industrial sectors. With a focus on innovation, quality, and performance, [Company Name] is committed to providing customers with cutting-edge solutions for their specific needs. The company's extensive product range includes prepreg materials, composite fabrics, and resin systems, all of which are designed to meet the highest industry standards.[Company Name] has established a strong reputation for its expertise in the production of prepreg materials, particularly in the use of fiberglass cloth. The company's state-of-the-art manufacturing facilities and R&D capabilities enable it to develop and produce high-quality prepreg fiberglass cloth that offers superior mechanical properties, excellent dimensional stability, and exceptional surface finish. With a commitment to continuous improvement and customer satisfaction, [Company Name] continues to be at the forefront of the industry, providing innovative solutions for a wide range of applications.The latest news at [Company Name] revolves around the launch of its newest prepreg fiberglass cloth, which promises to deliver even greater performance and versatility. The new product is the result of extensive research and development efforts, aimed at pushing the boundaries of what is possible with composite materials. By harnessing the inherent strength and lightweight characteristics of fiberglass, [Company Name] has developed a prepreg material that is ideally suited for a diverse range of applications, including aerospace, automotive, marine, and industrial.The new prepreg fiberglass cloth from [Company Name] boasts a number of key features that set it apart from conventional materials. With a high strength-to-weight ratio, it offers exceptional structural performance while remaining lightweight, making it an ideal choice for applications where weight reduction is a critical factor. In addition, the material's excellent dimensional stability ensures that it maintains its shape and properties over time, even under varying environmental conditions. Furthermore, the prepreg fiberglass cloth is designed to provide superior surface finish, making it suitable for use in applications where aesthetic appeal is important.One of the key advantages of [Company Name]'s prepreg fiberglass cloth is its compatibility with various resin systems, enabling customers to tailor the material to their specific requirements. By offering a range of resin options, [Company Name] ensures that its customers have the flexibility to achieve the desired performance and characteristics for their applications. This versatility, combined with the material's high performance, makes it a highly attractive option for engineers and designers seeking innovative solutions for their projects.The launch of the new prepreg fiberglass cloth represents [Company Name]'s ongoing commitment to delivering advanced materials that meet the evolving needs of the industry. With a focus on performance, quality, and reliability, the company remains dedicated to pushing the boundaries of what is possible with composite materials. By leveraging its expertise and capabilities, [Company Name] continues to be a trusted partner for customers seeking cutting-edge solutions for their specific challenges.In conclusion, the introduction of [Company Name]'s new prepreg fiberglass cloth marks an important milestone in the company's journey of innovation and advancement. With its exceptional performance, versatility, and compatibility with various resin systems, the new product is set to make a significant impact across a wide range of industries. As [Company Name] continues to push the boundaries of what is possible with composite materials, it reaffirms its position as a leading provider of advanced materials for the aerospace, automotive, marine, and industrial sectors.

How Sewing Fiberglass Fabric Can Enhance Your DIY Projects

Title: Innovative Sewing Fiberglass Fabric Revolutionizes the Textile IndustryIntroduction:The textile industry is witnessing a groundbreaking innovation with the introduction of a remarkable sewing fiberglass fabric. Manufactured by an industry-leading company, this fabric is set to revolutionize various sectors, including automotive, aerospace, and construction. Offering exceptional strength, durability, and versatility, this cutting-edge material is poised to transform the way fabrics are used in diverse applications.1. Overview of the Sewing Fiberglass Fabric:The sewing fiberglass fabric, developed by a renowned company, combines advanced technology and meticulous craftsmanship to create a unique textile solution. With its distinct properties, this fabric surpasses traditional materials and offers numerous advantages across multiple industries.2. Strength and Durability:One of the key attributes of this sewing fiberglass fabric is its exceptional strength. Manufactured using a high-density fiberglass material, it provides exceptional tensile strength, making it ideal for applications that require resistance to heavy loads or extreme conditions.Moreover, the fabric enjoys remarkable durability, ensuring its longevity and reliability. Its robust composition enables it to withstand wear and tear, making it superior to conventional fabrics. These qualities make the sewing fiberglass fabric an unparalleled choice, particularly in industries where performance and longevity are crucial.3. Versatility in Applications:The introduction of this revolutionary sewing fiberglass fabric has opened up new possibilities in various sectors. In the automotive industry, it is being employed for the manufacturing of lightweight yet sturdy car seats, ensuring enhanced safety and comfort for passengers. Additionally, its application in vehicle upholstery offers exceptional resistance to fire and heat, further improving safety measures.Furthermore, the aerospace sector has recognized the potential of this fabric. Its unique combination of strength and lightweight properties makes it an ideal material for constructing aircraft interiors, including cabin panels and overhead storage compartments. By utilizing this fabric, aerospace manufacturers can reduce weight and improve fuel efficiency without compromising structural integrity.The construction industry also stands to benefit significantly from this remarkable fabric. Its high resistance to corrosive substances and extreme temperatures makes it suitable for reinforcing concrete structures, ensuring enhanced durability and longevity. Additionally, its application in the production of fire-resistant curtains or protective clothing for construction workers further adds to its versatility in this sector.4. Environmental Impact and Sustainability:The manufacturing process of this sewing fiberglass fabric adheres to strict environmental regulations, making it a sustainable alternative in comparison to other materials. Its longevity and robustness also contribute to reducing waste since it requires less frequent replacement. Moreover, its potential for recycling adds further value to its sustainability.5. Future Developments and Market Potential:The sewing fiberglass fabric is expected to witness extensive demand in the coming years. As the textile industry continues to focus on sustainability and innovative materials, this fabric's unique qualities make it a sought-after choice. The market potential is promising as major industries embrace the benefits it offers while seeking more efficient and eco-friendly solutions.Furthermore, ongoing research and development efforts are aimed at enhancing the fabric's properties, making it even more durable, lightweight, and cost-effective. Collaborations with other technology companies and fabric manufacturers are being explored to expedite the adoption of this fabric and explore new applications.Conclusion:The introduction of sewing fiberglass fabric marks a significant milestone in the textile industry. Offering unparalleled strength, durability, and versatility, this fabric has the potential to transform various sectors, from automotive and aerospace to construction. As its market potential grows and further advancements are made, this innovative fabric will continue to redefine the industry's standards, making it a cornerstone of textile manufacturing in the future.

Top Lightweight Fiberglass Cloth for Versatile Use

[Company Name], Leading Provider of Lightweight Fiberglass Cloth, Revolutionizes the Industry with its Cutting-Edge Solution[CITY], [DATE] - [Company Name], a dynamic and innovative leader in the production of advanced materials, has recently launched its latest product – a game-changing Lightweight Fiberglass Cloth. This revolutionary solution is set to transform multiple industries, including aerospace, automotive, and construction.[Company Name] has always been at the forefront of research and development to provide the market with high-performance materials. Their new Lightweight Fiberglass Cloth is a testament to their commitment to innovation and pushing boundaries. This cutting-edge product offers a wide range of advantages that make it a superior choice over traditional cloth options.One of the standout features of [Company Name]'s Lightweight Fiberglass Cloth is its exceptional strength-to-weight ratio. The cloth is engineered using an advanced manufacturing process that ensures it remains lightweight while offering unparalleled strength and durability. This characteristic makes it a preferred choice in industries where weight reduction is essential, such as aerospace and automotive manufacturing.Moreover, [Company Name]'s Lightweight Fiberglass Cloth boasts excellent thermal and electrical insulation properties. This feature makes it highly desirable for applications in the construction industry, where insulation is crucial for energy efficiency and comfort. The cloth's ability to resist heat penetration ensures optimum thermal regulation, leading to reduced energy consumption and lower carbon footprints.The manufacturing process of the Lightweight Fiberglass Cloth also ensures its exceptional corrosion resistance. Traditional cloth materials often succumb to the harmful effects of corrosion over time, compromising their structural integrity. However, the specialized manufacturing techniques employed by [Company Name] provide the cloth with a powerful shield against corrosion, prolonging its lifespan and reducing maintenance costs significantly.[Company Name]'s commitment to sustainability is also evident in the production of their Lightweight Fiberglass Cloth. The cloth is crafted using eco-friendly materials and adheres to strict environmental standards throughout the manufacturing process. By reducing the carbon footprint associated with traditional cloth manufacturing, [Company Name] is positioning itself as a responsible and forward-thinking company.Furthermore, [Company Name] aims to ensure that their customers experience a seamless integration of the Lightweight Fiberglass Cloth into their manufacturing processes. To achieve this, the company offers comprehensive support services, including technical guidance, training seminars, and even customized solutions to suit specific applications. Regardless of the size or complexity of the project, [Company Name] ensures that their customers receive the necessary assistance to maximize the benefits of the Lightweight Fiberglass Cloth.With the introduction of their Lightweight Fiberglass Cloth, [Company Name] has set the benchmark for excellence in the industry. Its exceptional attributes and numerous applications have garnered attention from major players across various sectors. Customers are already witnessing significant improvements in product performance and cost savings by replacing their traditional cloths with [Company Name]'s groundbreaking solution.By continuously investing in research and development, [Company Name] demonstrates its commitment to pioneering the next generation of high-performance materials. The company's Lightweight Fiberglass Cloth exemplifies its relentless pursuit of innovation and the desire to provide customers with superior products that drive efficiency and sustainability.As the industry continues to applaud [Company Name]'s groundbreaking solutions, it is clear that the Lightweight Fiberglass Cloth is transforming the landscape of materials used in multiple sectors. The future of lightweight materials is in the hands of [Company Name], and they are gearing up to revolutionize industries, one fiber at a time.About [Company Name]:[Company Name], founded in [YEAR], is a leading provider of advanced materials, specializing in the production of high-performance fibers and fabrics. With a strong focus on innovation and customer satisfaction, [Company Name] has established itself as a renowned name in the industry. Their products are known for their exceptional quality, durability, and cutting-edge technology. Through extensive research and development, [Company Name] continues to redefine industry standards and provide market-leading solutions. For more information, please visit [www.companywebsite.com].

High-Quality Carbon Fiber Vinyl Upholstery Fabric for Modern Spaces

Carbon fiber vinyl upholstery fabric is gaining attention in the world of interior design and upholstery. With its sleek and sophisticated design, it has become a popular choice for furniture, car interiors, and other applications. The unique properties of carbon fiber vinyl make it durable, lightweight, and resistant to wear and tear, making it an ideal choice for a wide range of upholstery projects.One company that has been at the forefront of this trend is {}. They have been providing high-quality carbon fiber vinyl upholstery fabric for years, and their products have become synonymous with luxury and durability. Their commitment to innovation and excellence has enabled them to stay ahead of the competition and become a leading supplier of carbon fiber vinyl upholstery fabric.{} offers a wide range of carbon fiber vinyl upholstery fabric options, including a variety of colors, textures, and designs to suit the needs of their customers. Whether it's for automotive, marine, or residential use, their products are versatile and can be customized to fit any project. Their dedication to quality and craftsmanship has made them a trusted name in the industry, and their products have been used in a wide range of applications, from luxury cars to high-end furniture.In addition to their extensive product range, {} is also known for their exceptional customer service and support. They work closely with their clients to understand their specific needs and offer tailored solutions to meet their requirements. Their team of experts is always on hand to provide guidance and advice, from choosing the right fabric to installation and maintenance. This level of support has helped {} build a strong reputation for reliability and professionalism, and has earned them the trust and loyalty of their customers.As a leader in the carbon fiber vinyl upholstery fabric industry, {} is constantly pushing the boundaries of innovation and design. They are always looking for new ways to improve their products and stay ahead of the curve when it comes to trends and technology. This commitment to excellence has led them to develop cutting-edge fabric options that are not only stylish and durable but also environmentally friendly. {} understands the importance of sustainability and strives to minimize their impact on the environment through responsible sourcing and manufacturing processes.With a strong track record of success and a commitment to excellence, {} is well positioned to continue leading the way in the carbon fiber vinyl upholstery fabric industry. Their dedication to quality, innovation, and customer satisfaction sets them apart from their competitors and has made them a trusted name in the industry. Whether it's for automotive, marine, or residential use, {} offers a wide range of options to suit the needs of their diverse customer base. With their outstanding products and exceptional service, they are sure to remain a dominant force in the world of carbon fiber vinyl upholstery fabric for years to come.