Durable Fiberglass Cloth: A Must-Have for Industrial Applications

By:Admin

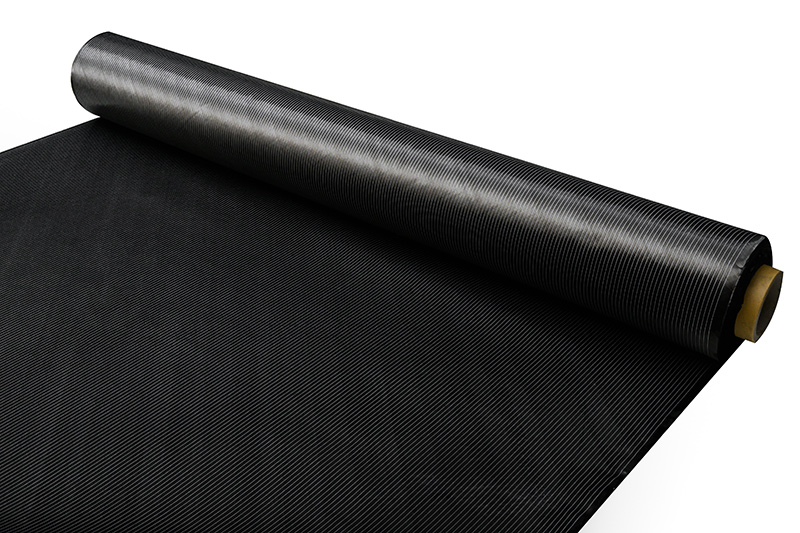

[Company Name], a leading manufacturer of high-quality fiberglass products, has recently announced the introduction of a new product line to meet the increasing demand for fiberglass cloth in various industries. The new product, named 120 Fiberglass Cloth, is designed to provide enhanced strength and durability for a wide range of applications.

120 Fiberglass Cloth is made from high-quality fiberglass yarns woven into a tight and uniform pattern, resulting in a fabric that is strong, lightweight, and resistant to heat and chemicals. The cloth is available in various widths and thicknesses to cater to different requirements, making it suitable for a wide range of applications such as insulation, filtration, reinforcement, and composite materials.

With the growing demand for fiberglass cloth in industries such as aerospace, automotive, marine, construction, and manufacturing, the introduction of 120 Fiberglass Cloth comes at a time when companies are seeking reliable and high-performance materials to meet their specific needs. The new product line is expected to provide customers with a cost-effective solution that offers superior performance and durability compared to traditional materials.

[Company Name] has established a strong reputation for delivering high-quality fiberglass products that meet the most stringent industry standards. The company's state-of-the-art manufacturing facility is equipped with advanced technology and a team of skilled professionals who are dedicated to ensuring the highest level of quality and performance in every product they produce.

In addition to 120 Fiberglass Cloth, [Company Name] offers a wide range of fiberglass products including woven rovings, chopped strands, yarns, mats, and tapes, as well as custom-made products to meet specific customer requirements. The company's commitment to innovation and continuous improvement has made it a trusted partner for businesses seeking reliable and high-performance fiberglass solutions.

Speaking about the new product line, [Company Name] President stated, "We are excited to introduce 120 Fiberglass Cloth to the market, as we believe it will address the growing demand for high-quality fiberglass materials in various industries. Our team has worked tirelessly to develop a product that offers exceptional strength, durability, and versatility, and we are confident that it will exceed our customers' expectations."

The introduction of 120 Fiberglass Cloth reinforces [Company Name]'s position as a leading manufacturer of fiberglass products, committed to meeting the evolving needs of its customers and the industry. The company's dedication to delivering top-quality products and exceptional customer service has made it a trusted partner for businesses seeking reliable and high-performance fiberglass solutions.

As the demand for fiberglass materials continues to grow across various industries, [Company Name] remains committed to developing innovative products that offer superior performance, durability, and value. The introduction of 120 Fiberglass Cloth is a testament to the company's ongoing commitment to meeting the needs of its customers and providing them with the highest quality fiberglass solutions.

Company News & Blog

Fiberglass Cloth Roll: A Comprehensive Overview of 1708 Material

Title: Revolutionizing Reinforcements: Introduction of 1708 Fiberglass Cloth Roll in the Composites IndustryIntroduction (100 words):The composites industry has witnessed a game-changing development with the introduction of the innovative 1708 Fiberglass Cloth Roll. This groundbreaking product, manufactured by a leading company in the field, promises to revolutionize composites manufacturing with its exceptional properties and unmatched versatility. With a strong commitment to producing high-quality reinforcements, this company has once again proven its dedication to delivering cutting-edge solutions that exceed industry expectations. This article will delve into the details of the 1708 Fiberglass Cloth Roll, highlighting its remarkable features, benefits, and the significant impact it will have on various sectors that rely on composites for their operations.I. Overview of the 1708 Fiberglass Cloth Roll (200 words):The 1708 Fiberglass Cloth Roll represents a significant advancement in the field of composites reinforcements. It is a non-woven fabric made from continuous fiberglass roving that is laid flat and held together with a light binder. This unique manufacturing process ensures optimal conformity, durability, and strength.One of the most distinguishing features of the 1708 Fiberglass Cloth Roll is its combined axial and biaxial fabric orientation. This means that it consists of one layer of fiberglass roving aligned in the 0° (axial) direction and another layer placed at a 90° angle (biaxial). This configuration provides exceptional load-bearing capabilities in both direction orientations simultaneously, resulting in superior strength and stiffness for the composites it reinforces.Additionally, the 1708 Fiberglass Cloth Roll is compatible with a wide range of resin systems, making it adaptable to diverse manufacturing processes. Whether being utilized in wet lay-up, vacuum infusion, or hand lay-up techniques, this versatile reinforcement excels in enhancing the mechanical properties of various composite structures.Furthermore, the unique non-woven construction of the 1708 Fiberglass Cloth Roll offers improved wet-out characteristics, which ensures better resin distribution and ultimately enhances the bond between fibers and resin. This results in an optimal fiber-to-resin ratio, maximizing the performance and longevity of the composite product.II. Advantages and Applications (300 words):The introduction of the 1708 Fiberglass Cloth Roll carries numerous advantages, making it a highly sought-after reinforcement material in the composites industry. Some key benefits include:1. Superior strength and stiffness: The 1708 Fiberglass Cloth Roll ensures exceptional load-bearing capabilities, enhancing the overall strength and stiffness of composite structures. This makes it an ideal choice for various applications that require durable, lightweight materials.2. Versatility: The compatibility of the 1708 Fiberglass Cloth Roll with different resin systems and manufacturing processes allows for its use in diverse applications. It is widely employed in industries such as automotive, marine, aerospace, construction, and sporting goods.3. Improved wet-out characteristics: The non-woven construction of the 1708 Fiberglass Cloth Roll facilitates better resin distribution and adhesion, resulting in an optimal fiber-to-resin ratio. This significantly improves the performance and durability of composite products.4. Cost-effectiveness: By enhancing the mechanical properties of composites, the 1708 Fiberglass Cloth Roll helps manufacturers produce lightweight and durable products. This cost-effective solution reduces material waste and overall production costs.The application possibilities of the 1708 Fiberglass Cloth Roll are vast. In automotive manufacturing, it can be utilized in the fabrication of lightweight body panels, interior components, and structural parts, contributing to improved fuel efficiency and overall vehicle performance. In the marine industry, this innovation finds application in the production of hulls, decks, and bulkheads, ensuring superior integrity and longevity. The aerospace sector can benefit from the 1708 Fiberglass Cloth Roll in the construction of aircraft components, reducing weight while maintaining high strength and stiffness. In the construction industry, it finds use in building materials like structural panels, reinforcing beams, and columns, providing durability and resistance to environmental factors. Finally, the sporting goods industry can make use of this reinforcement material in the production of lightweight yet robust sporting equipment, enabling better performance for athletes.Conclusion (100 words):The introduction of the 1708 Fiberglass Cloth Roll marks a significant milestone in the composites industry. Its unique properties, versatility, and exceptional performance open up a world of possibilities for manufacturers across various sectors. With its superior strength, stiffness, and compatibility with different manufacturing processes, this reinforcement material has the potential to revolutionize composite manufacturing, enabling the production of lightweight, durable, and cost-effective products. As this innovative solution continues to gain momentum, it is clear that the 1708 Fiberglass Cloth Roll is set to become an indispensable tool for composites manufacturers in the years to come.

Discover the Benefits of Fiberglass Matting Cloth in Various Applications

Fiberglass Matting Cloth: The Resilient Solution for Diverse Applications[Company name], a leading manufacturer in the domain of innovative materials, has recently launched its groundbreaking Fiberglass Matting Cloth. Renowned for its exceptional strength, durability, and versatility, this cutting-edge product promises to revolutionize various industries worldwide.Fiberglass Matting Cloth, an advanced composite material, is fabricated using high-quality glass fibers that are woven together to create a sturdy yet flexible cloth. This unique combination ensures enhanced mechanical performance, making it suitable for a wide range of applications across different sectors. From construction and automotive to aerospace and marine industries, this product is designed to meet the demands of modern-day engineering.One of the significant advantages of Fiberglass Matting Cloth lies in its exceptional strength-to-weight ratio. This lightweight yet robust material offers superior mechanical properties, making it an ideal choice for structural reinforcements. Its high tensile strength and resistance to corrosion and chemicals make it suitable for applications requiring long-lasting durability. Whether used as reinforcement in composite structures like fiberglass composites or as insulation in thermal and acoustic systems, this product ensures optimal performance under extreme conditions.In the construction industry, Fiberglass Matting Cloth has gained significant traction due to its excellent structural and insulating properties. It is widely used in reinforced concrete structures to enhance their load-carrying capacity and resistance to cracking. Moreover, its anti-alkali and alkali-resistant properties make it ideal for applications where exposure to moisture and harsh chemicals is inevitable. Furthermore, this cloth serves as an effective thermal and acoustic insulation material, improving energy efficiency and ensuring a comfortable living environment.The automotive sector has also recognized the tremendous potential of Fiberglass Matting Cloth. Given its exceptional mechanical strength and heat resistance, it is used in manufacturing lightweight yet robust components for automobiles. From reinforcing bumpers and body panels to fabrication of exhaust system components, this cloth contributes to increased fuel efficiency and overall vehicle safety.Aerospace and aviation industries have also embraced the benefits of Fiberglass Matting Cloth. The lightweight nature of this material makes it an excellent choice for manufacturing aircraft components, including wings, engine housings, and interior furnishings. In addition, its temperature resistance and low thermal conductivity ensure safe operation even under the most extreme conditions, making it an invaluable asset in this demanding sector.The marine industry, too, has greatly benefited from the utilization of Fiberglass Matting Cloth. Its resistance to saltwater corrosion and dimensional stability make it an ideal material for boat building. Fiberglass reinforced hulls, decks, and interior structures ensure longevity and durability, even in challenging marine environments. Furthermore, its exceptional strength-to-weight ratio contributes to enhanced fuel efficiency and increased speed, thereby offering a competitive edge to boat manufacturers.[Company name] has not only excelled in offering top-quality Fiberglass Matting Cloth but has also emphasized sustainable manufacturing practices. The production process adheres to global environmental standards, ensuring minimal waste and carbon footprint. By implementing this eco-friendly approach, [Company name] aims to contribute towards a greener future for generations to come.As industries evolve and seek advanced materials to meet their diverse needs, Fiberglass Matting Cloth stands tall as a reliable and versatile solution. Its exceptional strength, durability, and resistance to various environmental factors make it a top choice for numerous sectors. With [Company name]'s unwavering commitment to innovation and sustainable manufacturing, Fiberglass Matting Cloth is set to shape the future of engineering and design across the globe.

Fiberglass Cloth Roll and Resin: The Ultimate Guide for High-Quality Materials

Title: Advanced Fiberglass Cloth Roll and Resin for Enhanced Manufacturing ProcessesIntroduction:In the realm of manufacturing, the demand for reliable and high-quality materials is ever-increasing. Fiberglass has emerged as a crucial component in several industries, owing to its exceptional strength, durability, and versatility. Combining the robust properties of fiberglass cloth roll and resin, one company has emerged as a leading provider, delivering innovative solutions to meet the evolving needs of various sectors.Company Background:With over two decades of experience in the industry, {Company Name} has become a reputable and reliable supplier of fiberglass cloth roll and resin. Based on the principles of quality, innovation, and customer satisfaction, they have consistently proven their commitment to excellence. Their extensive range of top-notch fiberglass products has garnered them a loyal customer base.Advanced Fiberglass Cloth Roll:Fiberglass cloth roll is an integral component in manufacturing processes that require strength and flexibility. {Company Name}, through its relentless research and development efforts, has successfully developed an advanced fiberglass cloth roll that offers enhanced performance. The new fiberglass cloth roll boasts higher tensile strength, improved flame resistance, and increased resistance to chemical degradation.The company understands the significance of diverse application requirements, and hence, offers a wide range of options in terms of thickness, weave patterns, and styles, ensuring compatibility with various manufacturing processes. Industries such as automotive, aerospace, construction, and marine extensively benefit from the utilization of this advanced fiberglass cloth roll.High-Quality Resin:When it comes to ensuring the integrity and longevity of fiberglass-based products, the role of resin cannot be undermined. {Company Name} has strived to overcome the limitations of conventional resins by formulating a high-quality resin that complements their advanced fiberglass cloth roll. This resin excels in its ability to bond with the fiberglass cloth, providing excellent adhesion and increasing structural integrity.The improved resin combines ease of handling with rapid curing, thereby reducing production time and costs. Furthermore, its compatibility with various manufacturing processes, such as hand lay-up, vacuum infusion, and resin transfer molding, makes it a versatile choice for a multitude of industries.Applications and Benefits:The combination of advanced fiberglass cloth roll and high-quality resin has revolutionized manufacturing in numerous sectors. Some key applications and benefits of this innovation include:1. Automotive Industry: Fiberglass cloth roll and resin find applications in the production of lightweight body panels, reducing overall vehicle weight and enhancing fuel efficiency.2. Aerospace Industry: Utilizing advanced fiberglass cloth roll and resin in the fabrication of aircraft components results in improved strength-to-weight ratios, leading to enhanced performance and reduced maintenance costs.3. Construction Industry: The combination of these materials enables the production of durable and weather-resistant construction panels, ensuring longevity and reduced repair and replacement expenses.4. Marine Industry: Fiberglass cloth roll and resin allow the construction of robust boat hulls, resistant to water penetration and damage from UV radiation, contributing to extended vessel lifespans.Conclusion:Driven by their commitment to quality and innovation, {Company Name} has successfully produced advanced fiberglass cloth roll and resin, catering to diverse industry requirements. Their state-of-the-art materials offer improved strength, durability, and compatibility with a range of manufacturing processes. As various sectors continue to rely on fiberglass-based products, the combination of advanced fiberglass cloth roll and high-quality resin remains indispensable in achieving superior manufacturing outcomes.

High-Quality Fiberglass 1708 Cloth: Everything You Need to Know

[Company Name] Introduces New Fiberglass 1708 Cloth for Enhanced Strength and Durability[City, State] – [Company Name], a leading manufacturer of advanced fiberglass products, is proud to introduce its latest innovation, the Fiberglass 1708 Cloth. This new product is specially designed to provide superior strength and durability for a wide range of applications in industries such as marine, automotive, aerospace, and construction.The Fiberglass 1708 Cloth is composed of two layers of fiberglass fabric stitched together using a complex weave pattern. This unique construction results in a high-strength, multidirectional reinforcement that enhances the mechanical properties of composite materials. The cloth is specifically engineered to provide excellent stiffness, impact resistance, and fatigue performance, making it an ideal choice for demanding structural applications."We are thrilled to introduce the Fiberglass 1708 Cloth to the market," said [Company Name] spokesperson. "Our team of experts has worked tirelessly to develop a product that not only meets but exceeds the performance expectations of our customers. This new cloth represents our commitment to providing innovative solutions that help our clients achieve their goals."In addition to its exceptional mechanical properties, the Fiberglass 1708 Cloth is also compatible with a variety of resin systems, including epoxy, polyester, and vinyl ester. This versatility allows for seamless integration into different manufacturing processes, giving designers and engineers the freedom to explore new possibilities in product development.The introduction of the Fiberglass 1708 Cloth is a testament to [Company Name]'s dedication to pushing the boundaries of material science and engineering. With a strong focus on research and development, the company continues to invest in cutting-edge technologies and production methods to deliver high-quality, high-performance products to the market."Our goal is to empower our customers with the tools they need to succeed in their respective industries," said [Company Name] spokesperson. "The Fiberglass 1708 Cloth is a prime example of how we leverage our expertise and resources to create value for our clients. We are excited to see the impact this product will have in the market."The Fiberglass 1708 Cloth is now available for purchase and can be customized to meet specific requirements based on application needs. With its advanced features and proven performance, this new product is poised to set a new standard for composite reinforcement materials.For more information about the Fiberglass 1708 Cloth and other innovative products from [Company Name], please visit [company website].About [Company Name]:[Company Name] is a leading manufacturer of advanced fiberglass products for various industries. With a strong emphasis on research, innovation, and customer satisfaction, the company has established itself as a trusted partner for businesses seeking high-performance materials. Using state-of-the-art manufacturing processes and a team of highly skilled professionals, [Company Name] is committed to delivering cutting-edge solutions that drive success for its clients.

High-Quality Fireproof Fiberglass Fabric for Ultimate Protection

Fireproof Fiberglass Fabric a Game Changer in Fire Safety In a world where fire safety is of utmost importance, the need for innovative and reliable fireproof materials has become increasingly evident. One company has stepped up to the challenge, introducing a groundbreaking product that is set to revolutionize the fire safety industry. {Remove brand name}, a leading manufacturer of advanced textiles, has unveiled its latest creation - Fireproof Fiberglass Fabric. This cutting-edge material boasts exceptional fire-resistant properties, making it an ideal choice for a wide range of applications where fire safety is paramount. The Fireproof Fiberglass Fabric is specially engineered using state-of-the-art technology and high-quality materials, ensuring maximum protection against the spread of flames and heat. Its unique composition allows it to withstand extreme temperatures, making it an invaluable asset in fire prevention and containment. One of the key features of {Remove brand name}'s Fireproof Fiberglass Fabric is its versatility. This innovative material can be used in various industries, including construction, automotive, aerospace, and manufacturing. Its ability to provide a reliable barrier against fire makes it an essential component in the design and production of fire-resistant structures, vehicles, and equipment. Furthermore, the Fireproof Fiberglass Fabric is designed to be lightweight and flexible, allowing for easy integration into existing products and systems. Its non-toxic and environmentally friendly nature also makes it a sustainable choice for companies looking to enhance their fire safety protocols. In addition to its exceptional fire-resistant properties, {Remove brand name}'s Fireproof Fiberglass Fabric also offers thermal insulation and chemical resistance, further solidifying its position as a game changer in fire safety. Its durability and reliability make it an invaluable asset for companies and industries looking to elevate their fire safety standards. {Remove brand name} has a longstanding reputation for excellence in the production of advanced textiles, with a commitment to delivering products that surpass industry standards. The introduction of the Fireproof Fiberglass Fabric further reinforces the company's dedication to innovation and quality, setting a new benchmark for fire safety materials. With its proven track record of delivering high-performance textiles to a global customer base, {Remove brand name} is well positioned to make a significant impact with its Fireproof Fiberglass Fabric. This revolutionary material is poised to set a new standard in fire safety, offering unprecedented protection against the threat of fire in various industries and applications. The launch of {Remove brand name}'s Fireproof Fiberglass Fabric is a significant milestone in the company's journey towards advancing fire safety solutions. It is a testament to their commitment to research and development, as well as their unwavering dedication to providing innovative, high-quality products to the market. As the demand for reliable fire safety materials continues to grow, {Remove brand name}'s Fireproof Fiberglass Fabric is set to play a pivotal role in shaping the future of fire prevention and containment. Its exceptional performance, versatility, and sustainability make it a compelling choice for companies and industries looking to enhance their fire safety measures. In conclusion, {Remove brand name}'s Fireproof Fiberglass Fabric is a groundbreaking development that has the potential to revolutionize the fire safety industry. Its exceptional fire-resistant properties, versatility, and sustainability make it a game changer in the quest for reliable and effective fire safety materials. With this innovative product, {Remove brand name} is setting a new standard for fire protection, and paving the way for a safer and more secure future.

High-Quality Fiberglass Matting Roll for Various Applications

Fiberglass Matting Roll is a crucial component in the construction and manufacturing industries. It is a versatile material that is used for reinforcing materials such as plastics, concrete, and even insulation. The fiberglass matting is made from extremely fine glass fibers which are carefully woven together to form a strong and flexible material. One of the leading suppliers of fiberglass matting roll is {}, a company that has been at the forefront of providing high-quality fiberglass products for various industries. With over 20 years of experience in the industry, {} has established itself as a reliable and trusted supplier of fiberglass materials.The fiberglass matting roll offered by {} is known for its exceptional strength and durability. It is designed to provide reinforcement and support to a wide range of materials, making it an essential component in many construction and manufacturing processes. The company's fiberglass matting roll is available in various widths and thickness, making it suitable for a diverse range of applications.{} takes pride in its commitment to quality and innovation. The company constantly invests in research and development to ensure that its products are of the highest standard. This dedication to excellence has earned {} a solid reputation in the industry, with many clients relying on their fiberglass matting roll for their critical projects.In addition to its focus on quality, {} also places a strong emphasis on customer service. The company works closely with its clients to understand their specific needs and requirements, and then provides tailored solutions to meet those needs. This personalized approach has helped {} build strong and long-lasting relationships with its clients, who trust the company to deliver top-notch fiberglass products consistently.One of the key advantages of {}'s fiberglass matting roll is its versatility. It can be used in a diverse range of applications, from reinforcing plastic components in the automotive industry to providing insulation in construction projects. The strength and flexibility of the fiberglass matting make it an ideal choice for manufacturers and builders who require a reliable and durable reinforcement material.Furthermore, {} ensures that its fiberglass matting roll is manufactured in compliance with the highest industry standards. The company adheres to strict quality control measures throughout the production process, guaranteeing that its products meet all relevant safety and performance regulations. This gives clients peace of mind, knowing that they are receiving fiberglass matting roll that is not only effective but also safe to use.As the demand for high-quality fiberglass matting roll continues to grow, {} remains committed to staying at the forefront of the industry. The company is continuously exploring new opportunities for growth and expansion, while also keeping a strong focus on maintaining its reputation for excellence and reliability.In conclusion, {} is a leading supplier of fiberglass matting roll, offering a product that is renowned for its strength, durability, and versatility. With a strong commitment to quality and customer service, {} has become a trusted partner for clients in a wide range of industries. As the company continues to innovate and expand, it is well-positioned to meet the evolving needs of the market and maintain its status as a top provider of fiberglass materials.

Discover the Benefits of Biaxial Fiberglass Tape in Industrial Applications

Biaxial Fiberglass Tape: The Ultimate Solution for Strong and Durable StructuresBiaxial Fiberglass Tape is a type of reinforced adhesive tape that has been gaining popularity in recent years for its superior strength and durability. It is specially designed for applications where a high level of strength and flexibility is required, making it ideal for use in a variety of industries, including construction, automotive, aerospace, and marine. This article will explore the features and benefits of Biaxial Fiberglass Tape and how it is revolutionizing the way we build structures.Biaxial Fiberglass Tape is made up of several layers of fiberglass fabric, which are coated with a high-performance adhesive. The tape is then biaxially oriented, meaning that it is stretched in two different directions to create a cross-hatch pattern. This process creates a tape that is strong and flexible, capable of withstanding high loads and stresses while also allowing for expansion and contraction due to temperature changes.One of the most significant advantages of Biaxial Fiberglass Tape is its outstanding strength-to-weight ratio. This means that it is much stronger than traditional materials while being much lighter in weight. This property makes it an excellent choice for applications where weight is a critical factor, such as in aerospace and automotive industries. Biaxial Fiberglass Tape is also highly resistant to corrosion, making it ideal for use in harsh environments, such as marine structures.Another benefit of Biaxial Fiberglass Tape is its ease of use. It can be applied to a variety of surfaces, including metal, plastic, and composite materials, using standard application techniques. This makes it a versatile solution that can be used in a wide range of applications, from simple repairs to complex structural projects.Biaxial Fiberglass Tape is also highly customizable, with different combinations of fiberglass fabrics, adhesive types, and tape widths available to suit specific project requirements. This can help to reduce waste and increase efficiency, as only the necessary amount of tape is used. The tape can also be pre-cut to specific lengths, making it quick and easy to apply.One of the most significant advantages of Biaxial Fiberglass Tape is its ability to provide long-lasting protection against wear and tear. Unlike traditional materials like steel, which can corrode and weaken over time, Biaxial Fiberglass Tape is highly resistant to damage, making it an excellent choice for applications where long-term structural integrity is essential.At () (remove brand name), we have been at the forefront of Biaxial Fiberglass Tape innovation for over a decade. Our team of experts has developed a range of high-quality tapes that are designed to meet the needs of our customers in a variety of industries. We use only the highest quality materials and manufacturing processes, ensuring that our tapes are of the highest quality and built to last.Our Biaxial Fiberglass Tape products are highly versatile, with a range of widths, thicknesses, and adhesive types available to suit a wide variety of applications. We also offer custom tape cutting services, allowing our customers to get the exact amount of tape they need for their project.In addition to our tape products, we also offer a range of technical support services, including consultations, training, and on-site support. Our team of experts can help you to select the best tape product for your project, as well as provide guidance on application techniques and best practices.With its superior strength, durability, and ease of use, Biaxial Fiberglass Tape is quickly becoming the go-to solution for a wide range of industries. Whether you are repairing a boat, building a new structure, or designing the next generation of aerospace components, Biaxial Fiberglass Tape can help you to achieve outstanding results. Contact us () remove brand name) today to learn more about our Biaxial Fiberglass Tape products and how we can help you to build a stronger future.

High-Quality Fire-Resistant Fiberglass Fabric at Affordable Prices

Fire Resistant Fiberglass Fabric - The Key to Safety in Industrial SettingsThe potential for fire outbreaks in industrial settings is high due to the presence of flammable materials, chemicals, and machinery. In such situations, the safety of employees and equipment is of utmost importance. Fortunately, advancements in technology have led to the development of fire-resistant materials that can prevent and contain fires. One such material that has garnered a lot of attention is Fire Resistant Fiberglass Fabric.What is Fire Resistant Fiberglass Fabric?Fire-resistant fiberglass fabric is a specialized textile comprised of glass fibers that have been woven together and treated with a fire-resistant coating. The fabric is designed to be durable, lightweight, and able to withstand extreme temperatures without deteriorating. It is used primarily in industrial settings, where there is a high risk of fire outbreaks.Some of the key features of Fire Resistant Fiberglass Fabric include:1. Non-combustible - The fabric does not ignite when exposed to flames.2. Heat Resistant - The fabric can withstand high temperatures without melting or burning.3. Insulating - The fabric can be used as insulation to protect people and equipment from heat.4. Durable - The fabric is resistant to wear and tear, and can withstand exposure to chemicals and moisture.Uses of Fire Resistant Fiberglass Fabric1. Protective clothing - Fire-resistant fiberglass fabric is used to make protective clothing for workers in industries such as welding, firefighting, and oil and gas. The fabric's heat-resistant and non-combustible properties make it an ideal material for clothing that can withstand high temperatures and prevent injuries.2. Insulation - Fiberglass fabric is used as insulation to protect electrical equipment from heat. It can also be used in boilers, furnaces, and power plants to contain heat and prevent fires.3. Curtains and blankets - Fiberglass fabric can be used to make curtains and blankets to contain fires and prevent them from spreading.4. Tents and shelters - Fiberglass fabric is used to make tents and shelters for emergency situations. The fabric's heat-resistant and non-combustible properties make it an ideal material for these applications.Advantages of Fire Resistant Fiberglass Fabric1. Safety - Fire-resistant fiberglass fabric can prevent and contain fires, ensuring the safety of employees and equipment.2. Durability - The fabric's resistance to wear and tear, chemicals, and moisture make it a durable and long-lasting material.3. Lightweight - Fiberglass fabric is lightweight, making it easy to handle and transport.4. Cost-effective - Fiberglass fabric is an affordable material that offers long-term benefits in terms of durability and safety.ConclusionFire Resistant Fiberglass Fabric is the key to safety in industrial settings. Its non-combustible, heat-resistant, insulating, and durable properties make it an ideal material for protective clothing, insulation, curtains and blankets, and tents and shelters. It is also a cost-effective solution that offers long-term benefits in terms of safety and durability. Businesses that prioritize safety should invest in Fire Resistant Fiberglass Fabric to ensure the protection of their employees, equipment, and facilities.

Discover the Numerous Uses and Benefits of Glass Fabric Cloth

Title: Cutting-Edge Glass Fabric Cloth Revolutionizing Industries: A Closer Look at Innovative MaterialIntroduction:In today's rapidly evolving world, technological advancements continue to be at the forefront of innovation. One such breakthrough is the development of Glass Fabric Cloth by an industry-leading company. This revolutionary material is set to transform multiple industries, thanks to its exceptional properties and versatile applications. Let's delve deeper into the capabilities of Glass Fabric Cloth and explore how it is poised to revolutionize various sectors.I. Understanding Glass Fabric Cloth:Glass Fabric Cloth is a cutting-edge composite material that combines the excellent mechanical properties of glass fibers with the flexibility and durability of fabric. This hybrid fabric is engineered to deliver superior strength, thermal resistance, and remarkable electrical insulation. The specialized manufacturing process ensures the uniform distribution of glass fibers throughout the cloth, resulting in a product that exhibits exceptional dimensional stability and resistance to heat, chemicals, and abrasions.II. Applications in Aeronautics and Aerospace:The aeronautics and aerospace industries are set to benefit immensely from the breakthrough advancements facilitated by Glass Fabric Cloth. Its high strength-to-weight ratio makes it ideal for manufacturing components such as aircraft wings, fuselage, and tail structures. The exceptional thermal resistance of the cloth ensures that it can withstand extreme temperature variations encountered during flights. Additionally, the electrical insulation properties of Glass Fabric Cloth set it apart, making it a crucial material for wiring and insulation in aircraft.III. Automotive Industry Integration:Glass Fabric Cloth is revolutionizing the automotive industry, with applications in both electric and conventional vehicles. The material's lightweight properties prove beneficial in increasing fuel efficiency while maintaining the structural integrity of various components. The cloth's thermal insulation capability also aids in development, ensuring protection against engine heat while allowing optimal performance. Furthermore, Glass Fabric Cloth provides electrical insulation, making it ideal for use in wiring harnesses, batteries, and interior components.IV. Industrial and Infrastructure Applications:Glass Fabric Cloth is poised to redefine industrial and infrastructure applications due to its exceptional strength and endurance. Its resistance to heat and chemicals makes it an excellent choice for the construction of furnaces, pipelines, tanks, and other high-temperature environments. Furthermore, Glass Fabric Cloth finds widespread use in reinforcement layers for composites, providing structural stability in applications such as wind turbine blades, bridges, and pipelines.V. Advancements in Consumer Goods and Sporting Equipment:The versatility of Glass Fabric Cloth extends to the consumer goods and sporting equipment industries. The material's lightness and durability make it a preferred choice for developing luggage, backpacks, and durable accessories. Moreover, Glass Fabric Cloth's resistance to moisture and abrasion enhances the longevity of outdoor gear such as tents, backpacks, and clothing. Its widespread adoption ensures that consumers can enjoy reliable and long-lasting products that can withstand demanding outdoor conditions.Conclusion:The advent of Glass Fabric Cloth marks a significant milestone in material innovation. With its exceptional mechanical properties, outstanding thermal resistance, and remarkable electrical insulation, this cutting-edge material is poised to revolutionize industries across the board. From aeronautics and automotive to industrial applications and consumer goods, Glass Fabric Cloth is transforming the way products are designed, manufactured, and utilized. As technology continues to progress, Glass Fabric Cloth presents limitless possibilities in enhancing performance, improving fuel efficiency, and creating durable and sustainable solutions for the future.

The Evolution of Carbon Fibers in Structural Materials

Carbon fiber is a highly versatile material that has revolutionized the manufacturing industry. It is lightweight and strong, making it the perfect material for a range of structural applications. Carbon fibers have come a long way since their invention by Thomas Edison in 1879. Today, they are used in everything from aerospace to sports equipment. In this blog post, we will explore the history and applications of carbon fiber.Carbon Fiber HistoryCarbon fibers were first invented to create filaments for incandescent light bulbs. Lewis Latimer, a Black inventor, patented the process for carbonizing cotton threads and bamboo slivers to create filaments that were longer lasting than their predecessors. It wasn't until the end of World War II that engineers started to develop carbon fibers for use in structural materials.The first carbon fiber was created by Robert H. Wentorf Jr., who was working at General Electric in 1958. Wentorf heated a mixture of carbon and graphite powders to extreme temperatures and pressures, creating a new material that was incredibly strong and lightweight. It wasn't until the 1960s that the use of carbon fiber expanded outside of the aerospace industry. Today, carbon fibers are used in everything from bicycles to wind turbine blades.Carbon Fiber ApplicationsOne of the most common applications of carbon fiber is in the aerospace industry. Carbon fibers are lightweight and strong, making them perfect for use in aircraft components. Carbon fiber composites are used in the fuselage, wings, and other structural components of airplanes, reducing the weight of the aircraft and improving its fuel efficiency.Another application of carbon fiber is in the automotive industry. Automakers use carbon fiber to create lightweight body panels and components that improve fuel efficiency and performance. Carbon fiber is also used in sports equipment like tennis rackets, golf clubs, and bicycles. The material is strong and lightweight, making it ideal for athletes who need to perform at the highest level.Carbon fiber is not the only material used in manufacturing. Fiberglass cloth is another popular material used to create everything from boat hulls to shower enclosures. Fiberglass cloth is strong and resistant to water, making it ideal for use in marine applications. It is also used to create automotive body panels and insulation for buildings.ConclusionCarbon fiber and fiberglass cloth are two of the most popular materials used in manufacturing today. Carbon fiber was first invented to create filaments for incandescent light bulbs. Today, it is used in everything from aerospace to sports equipment. Fiberglass cloth is another popular material used to create boat hulls, automotive body panels, and insulation for buildings. Both materials offer a range of benefits, including strength, lightweight, and resistance to water. As technology continues to advance, we can expect to see even more applications for these versatile materials.