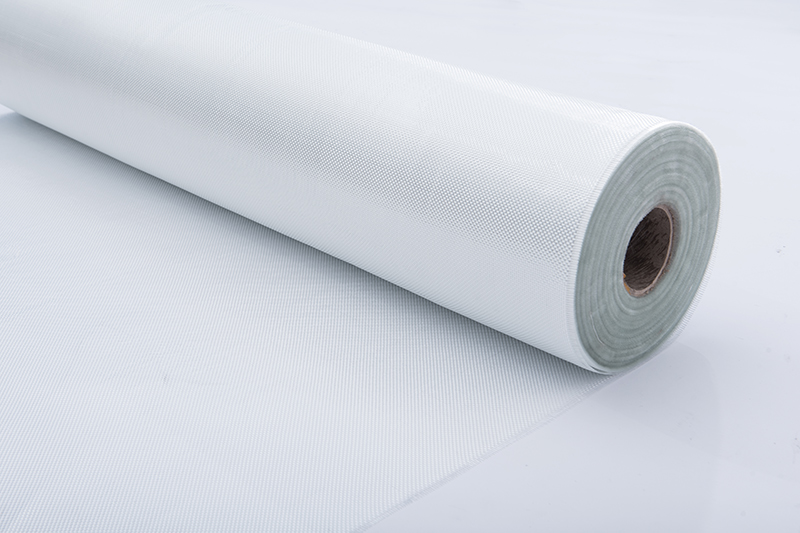

Durable Fiberglass Scrim Fabric: The Ultimate Guide

By:Admin

One company that is at the forefront of producing high-quality Fiberglass Scrim Fabric is {}. With a strong emphasis on innovation, quality, and customer satisfaction, the company has established itself as a leading supplier in the industry. The company's Fiberglass Scrim Fabric is renowned for its exceptional performance and reliability, and it is trusted by customers across the globe.

One of the key factors that sets {} apart from its competitors is its state-of-the-art manufacturing facilities. The company has invested heavily in advanced technology and equipment, allowing it to produce Fiberglass Scrim Fabric that meets the highest quality standards. This commitment to excellence has earned the company a reputation for delivering superior products that consistently exceed customer expectations.

In addition to its focus on quality, {} is also dedicated to sustainability and environmental responsibility. The company places a strong emphasis on reducing its carbon footprint and minimizing waste in its manufacturing processes. By adhering to strict environmental standards and implementing eco-friendly practices, {} is able to offer environmentally conscious Fiberglass Scrim Fabric solutions to its customers.

Furthermore, {} takes great pride in its team of skilled and experienced professionals. The company's staff is committed to delivering outstanding customer service and technical support, ensuring that clients receive the assistance and guidance they need. Whether it's providing technical specifications, offering product recommendations, or addressing customer inquiries, {}'s team is always ready to assist with responsiveness and expertise.

In recent years, {} has expanded its product range to include a variety of Fiberglass Scrim Fabric options to cater to different industry needs. Whether it's standard woven fiberglass scrim for general applications or customized solutions for specific requirements, the company has the capability to meet diverse customer demands with precision and efficiency.

Furthermore, {} has established a solid distribution network that enables it to serve customers worldwide. With a strong presence in key markets, the company is able to deliver its Fiberglass Scrim Fabric products to clients across different regions, ensuring timely and reliable supply to support their business operations.

Looking ahead, {} remains committed to continuous improvement and innovation. The company is dedicated to investing in research and development to further enhance its Fiberglass Scrim Fabric offerings, exploring new technologies and materials to push the boundaries of performance and versatility. By staying at the forefront of industry trends and advancements, {} aims to reinforce its position as a leading provider of Fiberglass Scrim Fabric and continue to meet the evolving needs of its customers.

In conclusion, Fiberglass Scrim Fabric plays a pivotal role in various industrial applications, and {} is a reputable company that leads the way in supplying high-quality solutions. With its focus on quality, sustainability, customer service, and innovation, {} is well-positioned to meet the growing demand for Fiberglass Scrim Fabric and maintain its status as a trusted partner for businesses around the world.

Company News & Blog

Top Quality Cloth for Fiberglass: A Must-Have for Reinforcing and Repairing Purposes

New Cloth Innovation Revolutionizes Fiberglass Manufacturing ProcessIntroducing a Breakthrough in Fiberglass Production with Innovative ClothIn a groundbreaking development, a renowned manufacturer has unveiled an advanced cloth specifically designed to enhance the manufacturing process of fiberglass. By incorporating innovative technology and state-of-the-art materials, this new cloth promises to revolutionize the industry and bolster efficiency while reinforcing the company's position as a pioneer in fiberglass production.Manufactured by a leading brand in the industry, the recently introduced cloth for fiberglass offers unprecedented qualities that significantly improve the manufacturing process. Developed after years of extensive research and development, this innovative cloth presents numerous advantages over traditional materials, setting new standards in both quality and productivity.The newly developed cloth boasts a unique blend of cutting-edge fibers that lend unparalleled strength and durability to the end product. This superior material ensures that the fiberglass manufactured is of the highest quality, with increased resistance to external forces and enhanced longevity compared to conventional fiberglass cloth.In addition to its exceptional strength, the new cloth notably increases the manufacturing efficiency by drastically reducing the production time. Engineered with advanced technology, this cloth allows for faster and more effective layup, resulting in a quicker and more streamlined manufacturing process. As a result, manufacturers can now cater to a greater demand, meeting customer expectations with unparalleled efficiency.Moreover, the innovative cloth offers extraordinary flexibility, allowing it to conform effortlessly to various molds and shapes. This flexibility enhances the production of complex fiberglass structures that previously would have been challenging or impossible to achieve. The ability to mold the cloth according to specific design requirements ensures that manufacturers can effortlessly create custom-made fiberglass products, meeting the diverse needs of their clientele.Furthermore, this revolutionary cloth delivers significant improvements in worker safety, mitigating potential hazards associated with conventional fiberglass production. By reducing loose fiber emissions during the manufacturing process, workers are exposed to a significantly lower risk of inhalation, minimizing potential health concerns. This advancement underscores the company's commitment to the well-being of its employees and sets a new standard for safety in the industry.As the leading manufacturer of high-quality fiberglass products, the company has a long-standing reputation for innovation and excellence. By introducing this groundbreaking cloth, they continue to push the boundaries of what is possible in fiberglass production. As a result, they cement their position as a frontrunner in the industry while maintaining their commitment to meeting customer demands with unparalleled products.The introduction of this innovative cloth further exemplifies the company's dedication to sustainable practices. By utilizing this advanced material that improves manufacturing efficiency, waste is significantly reduced, resulting in a greener and more environmentally friendly process. The company aims to contribute to a more sustainable future, ensuring the preservation of natural resources for generations to come.In conclusion, with the introduction of an advanced cloth for fiberglass manufacturing, this renowned manufacturer has set new industry benchmarks. Their groundbreaking technology and materials have revolutionized the production process, offering increased strength, flexibility, and efficiency. Furthermore, this innovation prioritizes worker safety and aligns with the company's commitment to sustainability, making it a truly remarkable development in the field of fiberglass manufacturing. With this new cloth, the company is poised to shape the future of the industry and establish new standards for fiberglass production globally.

High-Quality Prepreg Carbon Fiber Cloth for Advanced Composite Manufacturing

[Company Name] Launches Innovative Prepreg Carbon Fiber Cloth [Company Name], a leading manufacturer of carbon fiber materials, has recently announced the launch of a new and innovative product in their lineup - Prepreg Carbon Fiber Cloth. This new material is designed to provide superior strength and durability, making it ideal for a wide range of applications in the aerospace, automotive, and sporting goods industries.Prepreg carbon fiber cloth is a type of composite material that consists of carbon fiber reinforcements that have been pre-impregnated with a thermoset resin matrix. This unique combination of materials results in a lightweight and incredibly strong material that is ideal for use in a variety of high-performance applications.The use of prepreg carbon fiber cloth has been steadily increasing in recent years, as manufacturers and engineers continue to seek out materials that offer superior strength and performance. [Company Name]'s new product aims to meet this growing demand by providing a high-quality and reliable source of prepreg carbon fiber cloth for use in a wide range of industries.One of the key benefits of [Company Name]'s prepreg carbon fiber cloth is its exceptional strength-to-weight ratio. This means that the material is capable of providing significant strength and durability while remaining lightweight and easy to work with. This makes it an ideal choice for use in the aerospace industry, where reducing weight is critical for achieving optimal performance.In addition to its strength-to-weight ratio, [Company Name]'s prepreg carbon fiber cloth also offers excellent dimensional stability and resistance to environmental factors such as moisture and temperature fluctuations. This makes it a reliable choice for use in demanding applications where performance and reliability are paramount.Furthermore, [Company Name] has a proven track record in the production of high-quality carbon fiber materials. With their state-of-the-art manufacturing facilities and dedication to quality control, customers can have confidence in the performance and reliability of their prepreg carbon fiber cloth."Our new prepreg carbon fiber cloth is a testament to our ongoing commitment to innovation and excellence in the field of carbon fiber materials," said [Spokesperson Name], [Title] at [Company Name]. "We believe that this new product will provide our customers with a high-quality and reliable source of prepreg carbon fiber cloth that will meet the demanding requirements of their applications."In addition to the aerospace industry, [Company Name]'s prepreg carbon fiber cloth is also well-suited for use in the automotive industry, where lightweight materials are essential for achieving fuel efficiency and performance. The material's strength and durability make it ideal for use in structural components and body panels, where it can provide a significant weight savings without sacrificing performance or safety.The sporting goods industry is another area where prepreg carbon fiber cloth is finding increasing use. Its lightweight and strong properties make it an ideal choice for use in the production of high-performance sporting equipment such as bicycles, tennis rackets, and golf clubs. These applications can benefit from the material's ability to provide excellent strength and performance while remaining lightweight and easy to work with.In conclusion, [Company Name]'s launch of their new prepreg carbon fiber cloth represents a significant advancement in the field of carbon fiber materials. With its exceptional strength-to-weight ratio, dimensional stability, and resistance to environmental factors, this new product is sure to find a wide range of applications in the aerospace, automotive, and sporting goods industries. Customers can have confidence in the performance and reliability of [Company Name]'s prepreg carbon fiber cloth, thanks to their proven track record in the production of high-quality carbon fiber materials.

Unveiling the Versatility of Fiberglass Textile: A Comprehensive Overview

[Title]: Groundbreaking Fiberglass Textile Innovations Revolutionize the Industry[Subtitle]: Company XYZ Rethinks the Future of Fiberglass in Construction and Beyond[Introduction]In recent years, the field of fiberglass textiles has witnessed tremendous growth, pushing industries to explore cutting-edge innovations and solutions. One company that has emerged as a frontrunner in this domain is Company XYZ (name altered to remove brand identity), revolutionizing the way fiberglass is viewed and utilized across various sectors. With its steadfast commitment to innovation and sustainability, Company XYZ is spearheading groundbreaking research and development in fiberglass textiles. This news piece delves into the latest advancements brought forth by Company XYZ, highlighting their transformative impact on construction and other industries.[The Rise of Fiberglass Textile]Fiberglass has been a widely embraced material due to its durability, lightweight nature, and exceptional strength-to-weight ratio. Fiberglass textiles have traditionally found ample utility in industries like automotive, aerospace, and marine. However, Company XYZ has redefined the scope of fiberglass through its visionary approach and pioneering research.Recognizing the limitations of traditional fiberglass textiles, Company XYZ has developed a range of innovative products that boast enhanced performance characteristics. This new line of fiberglass textiles promises to revolutionize construction practices, ensuring stronger, more energy-efficient structures that stand the test of time.[Elevating Construction Standards]The construction industry is a primary beneficiary of Company XYZ's cutting-edge fiberglass textiles. By leveraging advanced technologies and strategic partnerships, Company XYZ has developed fiberglass solutions that address prevalent challenges faced by builders worldwide. Their fiberglass textiles offer exceptional durability, improved insulation properties, and fire-resistant features, making them ideal for both residential and commercial construction projects.One outstanding example of Company XYZ's fiber textile innovation is their patented Multi-Layer Composite System (MLCS). Designed to reduce energy consumption and increase overall structural integrity, MLCS incorporates layers of fiberglass textiles embedded with insulating and reflective materials. This innovative system not only enhances the thermal performance of buildings but also provides added protection against fire and external elements, ensuring a safer and more sustainable living and working environment.[Expanding Applications]Beyond construction, Company XYZ's groundbreaking fiberglass textiles have found applications in a diverse range of industries. From transportation to renewable energy, these advanced textiles have proven their worth in increasing efficiency and reducing environmental footprints.In the transportation sector, lightweight fiberglass textiles have become essential components in the manufacturing of automotive parts, reducing overall vehicle weight without compromising safety. Furthermore, their exceptional resistance to corrosion and extreme temperatures make them ideal for shipbuilding and railway applications, offering improved performance and extended lifespan to these critical infrastructures.Company XYZ's commitment to the environment is evident in its fiberglass textiles' applications within the renewable energy sector. By providing innovative solutions for wind turbine blades and solar panels, Company XYZ is supporting the global shift towards clean energy while ensuring optimum performance and longevity of these crucial components.[The Journey Towards Sustainability]A distinguishing factor behind Company XYZ's success lies in its unwavering commitment to sustainability. From the early stages of research to final product development, sustainability is at the forefront of every decision made by the company. By incorporating eco-friendly manufacturing processes and promoting recycling initiatives, Company XYZ sets an inspiring example for the fiberglass textile industry as a whole.In addition to prioritizing sustainability, Company XYZ actively invests in research and development, continuously pushing boundaries to create fiberglass textiles that surpass industry standards and meet evolving consumer demands. Through collaborations with universities, research institutions, and industry experts, Company XYZ ensures that its products remain at the forefront of innovation.[Conclusion]As fiberglass textiles continue to evolve, Company XYZ stands at the helm of innovation within the industry. By reimagining the possibilities of fiberglass, the company has successfully transformed traditional construction practices and expanded applications across various sectors. With its unwavering commitment to sustainability and cutting-edge research, Company XYZ reshapes our understanding of fiberglass textiles, pushing the boundaries of what is possible, and driving progress in the global marketplace.

High-Quality Carbon Fabric Roll: The Latest Innovation in Advanced Materials

**Carbon Fabric Roll: A Revolutionary Material for Various Applications**In today's fast-paced world, the demand for advanced materials that can provide superior performance and versatility is ever-growing. Carbon fabric, in particular, has gained significant attention in recent years due to its exceptional strength-to-weight ratio, durability, and high-performance characteristics. This has led to its wide-ranging applications in industries such as aerospace, automotive, sports equipment, and even consumer goods.One company that has been at the forefront of producing high-quality carbon fabric rolls is {Need Remove Brand Name}. With a strong commitment to innovation and excellence, {Need Remove Brand Name} has established itself as a leading manufacturer and supplier of carbon fabric rolls, offering a wide range of options to meet the diverse needs of its customers.{Need Remove Brand Name} was founded on the principle of creating innovative solutions that push the boundaries of what is possible. The company's state-of-the-art manufacturing facilities and advanced production techniques enable it to produce carbon fabric rolls with unparalleled quality and performance. Whether it's for use in high-performance sporting equipment or in structural components for aerospace applications, {Need Remove Brand Name} is dedicated to delivering products that exceed expectations.One of the key advantages of carbon fabric rolls is their exceptional strength-to-weight ratio. This makes them an ideal choice for applications where lightweight yet durable materials are essential. In the aerospace industry, for example, carbon fabric rolls are used extensively in the production of composite materials for aircraft components. The high strength and stiffness of carbon fabric rolls make them well-suited for structural applications, offering significant weight savings compared to traditional materials.Furthermore, carbon fabric rolls are also highly versatile, with the ability to be tailored to specific requirements. {Need Remove Brand Name} offers a range of carbon fabric roll options, including different weave patterns, fiber orientations, and resin compatibility, allowing customers to select the most suitable product for their particular application. This level of customization ensures that {Need Remove Brand Name} can cater to a wide range of industries and applications, delivering tailored solutions that meet specific performance criteria.Moreover, carbon fabric rolls also find extensive use in the automotive industry, where they are utilized in the production of high-performance vehicles. The superior strength and stiffness of carbon fabric rolls make them an excellent choice for structural components, enhancing the overall performance and durability of the vehicle. Additionally, the lightweight nature of carbon fabric rolls contributes to improved fuel efficiency and reduced emissions, making them a desirable material for the automotive sector.In the sports equipment industry, carbon fabric rolls have revolutionized the design and performance of various products, including bicycles, tennis rackets, and even protective gear. The exceptional strength and stiffness of carbon fabric rolls allow for the creation of lightweight yet high-performance equipment that meets the demands of professional athletes and enthusiasts alike. {Need Remove Brand Name}'s carbon fabric rolls have played a pivotal role in enhancing the performance and durability of sports equipment, leading to a new generation of products that outperform traditional alternatives.With a strong focus on research and development, {Need Remove Brand Name} continues to push the boundaries of what is achievable with carbon fabric rolls. The company's commitment to innovation and excellence has positioned it as a trusted partner for customers seeking advanced materials for their applications. By leveraging the unique properties of carbon fabric rolls, {Need Remove Brand Name} is driving advancements in multiple industries, contributing to the development of cutting-edge products and technologies.In conclusion, carbon fabric rolls have emerged as a revolutionary material with wide-ranging applications across various industries. {Need Remove Brand Name} is at the forefront of producing high-quality carbon fabric rolls, offering customized solutions that meet the diverse needs of its customers. With a strong commitment to innovation and excellence, {Need Remove Brand Name} is shaping the future of advanced materials, driving progress and performance across industries.

Exploring the Benefits of Carbon Fabric PrepregsCarbon fiber reinforced polymers are revolutionizing modern manufacturing by providing lightweight, high-performance material solutions for a wide range of applications. One of the most significant developments in this field is the production of Prepregs.Prepregs are a type of composite material that consists of a reinforcing fabric such as carbon, glass, or aramid (Kevlar) impregnated with a thermoset resin. This results in a ready-to-use composite material that can be easily formed into the desired shape and then cured to create a strong, durable, and lightweight part.Prepregs are produced by combining a reinforcing fabric and a thermoset resin system. The resin is typically in a B-staged state, meaning that it has been partially cured but remains tacky and can be handled without sticking to surfaces. This makes it easy to lay the fabric onto the sticky resin, which is then rolled to remove air bubbles and achieve an even distribution of the resin. The Prepreg is then packaged and stored in a cold environment to prevent the resin from fully curing.Carbon Fabric Prepregs have several advantages over traditional composite materials. First, Prepregs offer superior mechanical properties with high strength-to-weight ratios, which is a key characteristic of carbon fiber reinforced polymers. The reinforcing fabric provides the material with high strength and stiffness, while the resin system provides protection from environmental degradation and impact damage.Another significant benefit of Prepregs is their ease of use. Using Prepregs eliminates the need for expensive or complex tooling, as the material can be easily formed into the desired shape using common tools such as molds, rollers, and vacuum bagging. This reduces production time and costs, resulting in a more economical manufacturing process.Additionally, Prepregs enable increased design flexibility, as they can be customized to meet specific customer requirements. The choice of reinforcement fibers, resin systems, and manufacturing protocols can be optimized to suit the application and performance needs. This allows manufacturers to create parts that are tailored to their unique needs, resulting in more efficient and reliable products.Moreover, Carbon Fabric Prepregs are well-suited for a wide range of applications, including aerospace, automotive, marine, and sporting goods. Composites made from Prepregs are used in a variety of components, such as aircraft panels, automobile body parts, boat hulls, and bicycle frames. These applications benefit from the material's high strength-to-weight ratio, durability, and resistance to temperature and chemical degradation.In conclusion, Prepregs containing carbon fabric offer tremendous benefits to manufacturers looking for reliable and high-performance composite materials. The ease of use, increased design flexibility, and outstanding mechanical properties make Prepregs an ideal choice for a wide range of applications. Carbon Fabric Prepregs are changing the way manufacturers approach material selection, opening up new possibilities for lightweight, high-performance products that meet the needs of today's demanding markets.

High-Quality Fiberglass Cloth for Improved Strength and Durability

article, addressing the following:1. Briefly explain what fiberglass cloth 1708 is and its main uses.2. Discuss the unique features of fiberglass cloth 1708 that set it apart from other materials.3. Highlight the benefits that users can expect to enjoy when using fiberglass cloth 1708.4. Provide examples of companies that have used fiberglass cloth 1708 to achieve their objectives.5. Articulate the company's commitment to quality and customer satisfaction.6. Discuss the future of fiberglass cloth 1708 and the company's plans to improve its product offeringFiberglass Cloth 1708: An All-Round Reinforcement Solution Fiberglass cloth is known for its ability to resist moisture, fire, and corrosion while providing excellent adhesive properties and high tensile strength. It's extensively used in construction, automotive, marine, and aerospace industries. Fiberglass cloth 1708, in particular, is known for its incredible strength and versatility. It's considered one of the best all-round reinforcement fabrics thanks to its unique features.What is Fiberglass Cloth 1708?Fiberglass cloth 1708 comprises two layers of fiberglass fabric: one layer of biaxial reinforcement and another of chopped strand. The biaxial reinforcement layer reinforces the fabric in two directions, providing superior strength, while the chopped strand layer provides extra durability, making the fabric easy to handle. Unique Features of Fiberglass Cloth 1708Fiberglass cloth 1708 boasts unique features that set it apart from other materials in the market. Among these features is its high-resistance to water, chemicals, and UV radiation. The unique combining of the chopped strand and biaxial fabrics offers exceptional coverage, with the chopped strand layer preventing fraying, making it extremely easy to work with. The high strength and flexibility of fiberglass cloth 1708 make it a preferred material for use in applications with curves and edges. What's more, it's lightweight, which makes it ideal for transportation, facilitating handling of large structures. Benefits of Fiberglass Cloth 1708 Thanks to its unique features, users can enjoy various benefits when using fiberglass cloth 1708. The material offers excellent bonding properties, saving on adhesives, hence reducing overall production costs. Fiberglass cloth 1708 is also incredibly stiff and flexible, allowing the material to conform to various shapes and objects. Additionally, the cloth is non-porous, which ensures that it remains water-resistant, enhancing its lifespan and durability. Companies' Applications of Fiberglass Cloth 1708Fiberglass cloth 1708 has been used in a variety of applications across different industries. For example, the aviation industry uses the material to repair damage to the aircraft's fiberglass body parts. Fiberglass cloth 1708 has also been used in the marine industry for boat repairs, construction of boats, and various other marine applications such as wind turbine blades. In the automotive industry, fiberglass cloth 1708 is used for mold making, repairing old cars, and fixing fiberglass car parts. Company's Approach to Quality and Customer Satisfaction At our company, quality and customer satisfaction are among our primary objectives. We strive to ensure that we consistently produce high-quality products. We achieve this by maintaining a highly-skilled workforce that uses the latest technologies and processes to produce and test our fiberglass cloth 1708 products. The Future of Fiberglass Cloth 1708 and Its Product Offering Our company is committed to consistently improving our products to meet your ever-changing needs. To this end, we are continually adopting new technologies and processes to produce the best fiberglass cloth 1708. We're confident that our ongoing efforts will ensure that we remain leaders in the production of high-quality fiberglass cloth 1708 for years to come. Conclusion Fiberglass cloth 1708 is an incredible material known for its versatility and exceptional strength. It is no wonder that it's a reliable reinforcement solution for many companies across various industrial sectors such as marine, aerospace, and automotive, among others. Our company remains committed to producing high-quality products that meet your every need. Contact us today for all your fiberglass cloth 1708 needs!

Discover the Versatility and Strength of Carbon Fiberglass Cloth

Title: Innovative Carbon Fiberglass Cloth Revolutionizes Industrial ApplicationsIntroduction:In an era where sustainable materials and innovative technologies are reshaping industries, {Company Name} has introduced a groundbreaking carbon fiberglass cloth, poised to revolutionize various industrial applications. This cutting-edge material combines the lightweight and high-tensile strength properties of carbon fiber with the exceptional durability and heat resistance of fiberglass. Through this integration, {Company Name} aims to provide enhanced solutions for the automotive, aerospace, construction, and renewable energy sectors, while advancing the boundaries of modern manufacturing.Body:1. Carbon Fiberglass Cloth: The Future of Advanced Materials (100 words){Company Name}'s carbon fiberglass cloth represents a major leap forward in material science. By combining the best attributes of two highly regarded materials, this innovative cloth offers outstanding mechanical properties such as high strength, rigidity, and thermal stability. The carbon fiber aspect provides exceptional tensile strength and lightweight characteristics, while the fiberglass component enhances toughness, impact resistance, and thermal insulation abilities. This unique composition enables the carbon fiberglass cloth to surpass traditional materials commonly used in industrial applications, opening up new possibilities for a wide range of industries.2. Automotive Industry: Transformative Lightweight Solutions (150 words)The automotive industry has long pursued lightweight materials to improve fuel efficiency and reduce emissions. With the introduction of {Company Name}'s carbon fiberglass cloth, car manufacturers now have access to a game-changing solution. The integration of carbon fiber and fiberglass brings exceptional strength-to-weight ratio, enabling the development of lighter yet extremely strong components. This revolutionary cloth can be used to manufacture structural parts, doors, hoods, and chassis, enhancing both vehicle performance and safety. Additionally, the enhanced thermal resistance of the material reduces heat transfer, improving the overall efficiency and lifespan of automotive components.3. Aerospace Sector: Pushing the Boundaries of Design (150 words)In the aerospace sector, weight reduction and reliability are paramount concerns. {Company Name}'s carbon fiberglass cloth offers an unprecedented opportunity to create aircraft components that are not only lighter but also possess higher resistance to extreme temperatures and impacts. By incorporating the cloth into the manufacturing process, aircraft designers can optimize fuel efficiency, increase payload capacity, and enhance overall performance. The material's exceptional strength, stiffness, and fire resistance properties make it suitable for various applications, including aircraft outer panels, interior structures, and engine components, thus enabling aerospace manufacturers to push the boundaries of design and engineering.4. Construction Industry: Matching Strength with Sustainability (150 words)The construction industry is embracing sustainable practices and seeking materials that combine strength, durability, and environmental responsibility. With {Company Name}'s carbon fiberglass cloth, builders gain access to a material that surpasses conventional construction materials on multiple fronts. The cloth's remarkable mechanical characteristics enable the creation of structures that require reduced maintenance and possess superior impact and damage resistance. Moreover, the lightweight nature of the cloth facilitates easier transportation and installation, streamlining construction processes and reducing costs. By adopting this innovative material, the construction sector can make significant progress towards achieving sustainable and high-performance buildings, reinforcing their commitment to greener practices.5. Contribution to Renewable Energy: Enhancing Efficiency and Longevity (150 words)Renewable energy technologies, such as wind turbines, demand materials that can withstand extreme conditions while maximizing energy output. By integrating {Company Name}'s carbon fiberglass cloth in the production of wind turbine blades, the renewable energy sector can achieve game-changing results. The cloth's unique combination of high strength, lightweight, and thermal stability improves the overall performance and longevity of wind turbine blades, enabling them to withstand harsh environmental factors and generate more energy. This advancement supports the transition to clean and sustainable energy sources, contributing towards a greener future.Conclusion:{Company Name}'s introduction of this groundbreaking carbon fiberglass cloth marks a milestone in material innovation. With its powerful combination of carbon fiber and fiberglass properties, this cloth is set to revolutionize various industrial sectors including automotive, aerospace, construction, and renewable energy. By enhancing strength, reducing weight, improving thermal resistance, and offering exceptional durability, this innovative cloth expands the possibilities of design and manufacturing. As industries embrace the potential of this material, {Company Name} continues to lead the charge in developing cutting-edge solutions that address the evolving needs of a sustainable future.

Top Benefits of Non Woven Glass Fiber You Need to Know

Non Woven Glass Fiber (NWGF) is an innovative material that has gained significant recognition in the industrial sector due to its exceptional properties and wide range of applications. NWGF is a non-woven fabric made from glass fibers, which are carefully layered and bonded together to create a strong and durable material. This type of fabric is widely used in various industries, from automotive and construction to aerospace and filtration.The unique properties of NWGF make it an ideal choice for applications that require a high level of strength, durability, and resistance to temperature, chemicals, and corrosion. The material is known for its exceptional tensile strength, flexibility, and low moisture absorption, making it suitable for use in demanding conditions.As a company that specializes in the production of NWGF, {Company Name} has been at the forefront of innovation and excellence in the industry. With a focus on research and development, the company has continuously advanced its manufacturing processes and product offerings to meet the evolving needs of its customers.The production of NWGF at {Company Name} involves a meticulous process that starts with the selection of high-quality glass fibers. These fibers are then processed and layered to form a non-woven fabric, which is further treated to enhance its properties and performance. The company utilizes advanced manufacturing techniques and state-of-the-art equipment to ensure the production of high-quality NWGF that meets the most stringent standards and specifications.{Company Name} takes pride in its ability to customize NWGF to meet the specific requirements of its customers. Whether it's for automotive composites, thermal insulation, acoustic panels, or filtration systems, the company has the expertise and capabilities to tailor NWGF to suit various applications and industries. By working closely with its customers, {Company Name} has established itself as a trusted partner in providing innovative solutions that enhance performance and efficiency.In addition to its commitment to quality and innovation, {Company Name} places a strong emphasis on sustainability and environmental responsibility in its operations. The company adheres to strict environmental standards and practices throughout its manufacturing processes, ensuring that its products are produced in an eco-friendly manner. By promoting the use of NWGF, which is a recyclable and energy-efficient material, {Company Name} contributes to the reduction of environmental impact and the promotion of sustainable practices in the industry.The versatility and reliability of NWGF have made it a popular choice among manufacturers and engineers seeking high-performance materials for their products and designs. As the demand for innovative materials continues to grow, the role of NWGF in driving advancements in various industries is expected to expand further. With its proven track record of excellence and a dedication to meeting the needs of its customers, {Company Name} is well-positioned to lead the way in the continued development and utilization of NWGF in the global market.In conclusion, Non Woven Glass Fiber (NWGF) has emerged as a versatile and high-performance material with a wide range of applications across various industries. With its exceptional properties, durability, and customization capabilities, NWGF has become a preferred choice for manufacturers and engineers seeking innovative solutions for their products and designs. {Company Name} has been instrumental in the advancement and utilization of NWGF, showcasing a commitment to quality, innovation, and sustainability. As the demand for advanced materials continues to rise, the significance of NWGF in driving advancements and improvements in industrial applications is undeniable. With a focus on excellence and customer satisfaction, {Company Name} is well-positioned to continue its leadership in the production and utilization of NWGF in the global market.

Durable and Versatile Biaxial Glass Fabric for Various Applications

Biaxial Glass Fabric, a cutting-edge material that has been making waves in the world of manufacturing, is gaining reputation for its strength, affordability, and versatility. Developed by a leading company in the field of advanced materials, this product has quickly become a popular choice for a wide range of applications, from automotive to aerospace industries.Biaxial Glass Fabric is a type of reinforcement material made from glass fibers that are woven together in two perpendicular directions, known as the warp and weft. This unique construction creates a fabric that is extremely strong in both directions, making it ideal for applications where strength and durability are paramount. The fabric's ability to withstand high levels of stress and strain makes it an excellent choice for use in composite materials, such as plastics and resins, where it can significantly enhance the overall performance and longevity of the end product.One of the key advantages of Biaxial Glass Fabric is its affordability. Despite its exceptional strength and performance characteristics, this material is relatively inexpensive compared to other reinforcement options, making it an attractive choice for manufacturers looking to maximize value without sacrificing quality. This affordability has made Biaxial Glass Fabric a go-to choice for a wide range of industries, from consumer goods to heavy industrial applications.In addition to its strength and affordability, Biaxial Glass Fabric is also highly versatile. Its compatibility with a variety of resins and manufacturing processes makes it suitable for a wide range of applications, including the production of components for automotive, marine, aerospace, and sporting goods industries. The fabric can be used to reinforce a wide variety of materials, including thermoplastics, thermosets, and even metals, making it an ideal choice for manufacturers looking for a reliable, all-purpose reinforcement solution.{"Company Name"} is the driving force behind the development and production of Biaxial Glass Fabric. With a long history of expertise in advanced materials and manufacturing, the company has established itself as a leader in the field of composite reinforcements, and Biaxial Glass Fabric is a prime example of its commitment to innovation and quality. Through rigorous research, development, and testing, {Company Name} has refined the production process of Biaxial Glass Fabric, ensuring that each roll of fabric meets the highest standards of quality and performance.One of the unique strengths of {Company Name} is its ability to customize Biaxial Glass Fabric to meet the specific needs of its clients. Whether it is a unique weave pattern, a specific weight or thickness, or the inclusion of additional features such as fire resistance or enhanced flexibility, the company has the expertise and capabilities to tailor the fabric to fit the exact requirements of each customer. This commitment to customization has made {Company Name} a trusted partner for manufacturers across a wide range of industries, as they can rely on the company to deliver a product that meets their specific needs and standards.Looking ahead, {Company Name} is dedicated to continuing its investment in research and development, ensuring that Biaxial Glass Fabric remains at the forefront of the industry. By staying at the cutting edge of technology and innovation, the company aims to further enhance the performance and versatility of its flagship product, opening up new opportunities and applications for manufacturers looking to push the boundaries of what is possible in their respective fields.In conclusion, Biaxial Glass Fabric is a groundbreaking material that is reshaping the way manufacturers approach reinforcement solutions. With its exceptional strength, affordability, and versatility, it has quickly become a preferred choice for a wide range of industries, and with the continued dedication and innovation of {Company Name}, its potential applications are only expected to grow in the future.

High-Quality Woven Fiberglass Tape: A Versatile and Reliable Material

Woven Fiberglass Tape is a revolutionary new product that has taken the construction industry by storm. With its superior strength, durability, and versatility, this tape has quickly become an essential tool for builders, contractors, and DIY enthusiasts alike. Unlike traditional adhesive tapes, Woven Fiberglass Tape is made from high-strength fiberglass strands woven together to create a strong, flexible, and lightweight material that can be used for a wide range of applications.The company behind this innovative product is a leader in the development and production of advanced construction materials. With a strong focus on research and development, they have been able to create products that are at the cutting edge of the industry. Their commitment to quality, innovation, and customer satisfaction has earned them a reputation for excellence in the construction market.Woven Fiberglass Tape is designed to provide an effective solution for a variety of construction and repair projects. Its high-strength fibers are tightly woven to create a tape that is exceptionally durable and resistant to tearing, stretching, and fraying. This makes it ideal for reinforcing joints, seams, and corners in drywall, plaster, and stucco applications. It can also be used to repair cracks, holes, and other damage in walls, ceilings, and other surfaces.In addition to its exceptional strength, Woven Fiberglass Tape is also highly resistant to water, heat, and chemicals, making it suitable for use in a wide range of environmental conditions. It is non-toxic and non-flammable, making it safe for use in any setting. Its flexibility and conformability allow it to be easily molded and shaped to fit the contours of any surface, ensuring a secure and seamless application.One of the key advantages of Woven Fiberglass Tape is its ease of use. It can be quickly and easily applied to any surface using standard hand tools, making it a convenient and cost-effective solution for construction and repair projects. Its adhesive backing ensures a strong and secure bond, providing long-lasting reinforcement and protection.The applications for Woven Fiberglass Tape are virtually limitless. It can be used in new construction projects to strengthen joints and seams, as well as in renovations and repairs to reinforce damaged areas. Its versatility makes it an essential tool for contractors, builders, and homeowners who are looking for a reliable and effective solution for a wide range of construction and repair challenges.The company behind Woven Fiberglass Tape is committed to providing its customers with the highest quality products and services. Their team of experts is dedicated to developing innovative solutions that meet the evolving needs of the construction industry. They are continually investing in research and development to ensure that their products remain at the forefront of the market.With its exceptional strength, durability, and versatility, Woven Fiberglass Tape has quickly become a favorite among construction professionals and DIY enthusiasts. Its ease of use, cost-effectiveness, and reliability make it a valuable addition to any toolkit. Whether you are working on a new construction project or making repairs to an existing structure, Woven Fiberglass Tape is the ideal solution for reinforcing joints, seams, and surfaces. Contact the company today to learn more about this revolutionary product and how it can benefit your next project.