Durable Fiberglass Weave: A Strong and Versatile Material for Various Applications

By:Admin

As a leading manufacturer of fiberglass products, Fiberglass Weave has developed a strong reputation for producing some of the highest quality materials on the market. Their products are known for their strength, durability, and versatility, making them a top choice for a wide range of applications. From aerospace and automotive to marine and construction, Fiberglass Weave has a proven track record of delivering reliable and high-performance materials to meet their customers' diverse needs.

One of the key factors that set Fiberglass Weave apart from their competitors is their dedication to research and development. The company invests heavily in cutting-edge technology and processes to continually improve their products and stay ahead of industry trends. This commitment to innovation has led to the development of a wide range of fiberglass materials that offer exceptional performance and reliability.

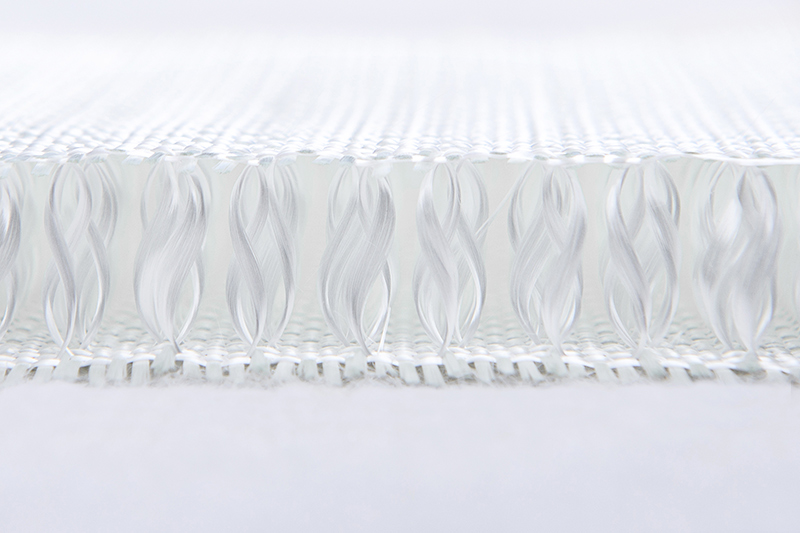

In their latest innovation, Fiberglass Weave has introduced a new fiberglass weave that promises to deliver even higher levels of strength and durability. This new weave utilizes advanced materials and manufacturing techniques to create a material that is stronger and more resilient than ever before. With this new product, Fiberglass Weave is once again raising the bar for what is possible with fiberglass materials and cementing their position as a top-tier manufacturer in the industry.

The new fiberglass weave is designed to meet the demands of the most challenging applications, providing exceptional strength and durability in a wide range of environments. Whether it's for use in aerospace, automotive, marine, or construction, this new weave is poised to become a go-to choice for engineers and designers looking for high-performance materials. With its superior strength and resilience, it promises to open up new possibilities for innovation and advancement in a variety of industries.

In addition to their commitment to quality and innovation, Fiberglass Weave also places a strong emphasis on customer satisfaction. The company works closely with their clients to understand their unique needs and develop customized solutions to meet those needs. With a focus on collaboration and partnership, Fiberglass Weave has built long-lasting relationships with many of the leading companies in the industries they serve.

Looking to the future, Fiberglass Weave shows no signs of slowing down. The company is continuously exploring new opportunities for growth and expansion, both in terms of product offerings and market reach. With their proven track record of success and a dedication to excellence, Fiberglass Weave is well-positioned to continue leading the way in the composite materials industry for years to come.

In conclusion, Fiberglass Weave's latest innovation in fiberglass materials is a testament to their ongoing commitment to quality, innovation, and customer satisfaction. With their new fiberglass weave, the company is pushing the boundaries of what is possible with composite materials and setting new standards for strength and durability. As a leader in the industry for over two decades, Fiberglass Weave is poised to continue shaping the future of composite materials and delivering high-performance solutions to meet the evolving needs of their customers.

Company News & Blog

High-Quality Fiberglass Cloth for Improved Strength and Durability

article, addressing the following:1. Briefly explain what fiberglass cloth 1708 is and its main uses.2. Discuss the unique features of fiberglass cloth 1708 that set it apart from other materials.3. Highlight the benefits that users can expect to enjoy when using fiberglass cloth 1708.4. Provide examples of companies that have used fiberglass cloth 1708 to achieve their objectives.5. Articulate the company's commitment to quality and customer satisfaction.6. Discuss the future of fiberglass cloth 1708 and the company's plans to improve its product offeringFiberglass Cloth 1708: An All-Round Reinforcement Solution Fiberglass cloth is known for its ability to resist moisture, fire, and corrosion while providing excellent adhesive properties and high tensile strength. It's extensively used in construction, automotive, marine, and aerospace industries. Fiberglass cloth 1708, in particular, is known for its incredible strength and versatility. It's considered one of the best all-round reinforcement fabrics thanks to its unique features.What is Fiberglass Cloth 1708?Fiberglass cloth 1708 comprises two layers of fiberglass fabric: one layer of biaxial reinforcement and another of chopped strand. The biaxial reinforcement layer reinforces the fabric in two directions, providing superior strength, while the chopped strand layer provides extra durability, making the fabric easy to handle. Unique Features of Fiberglass Cloth 1708Fiberglass cloth 1708 boasts unique features that set it apart from other materials in the market. Among these features is its high-resistance to water, chemicals, and UV radiation. The unique combining of the chopped strand and biaxial fabrics offers exceptional coverage, with the chopped strand layer preventing fraying, making it extremely easy to work with. The high strength and flexibility of fiberglass cloth 1708 make it a preferred material for use in applications with curves and edges. What's more, it's lightweight, which makes it ideal for transportation, facilitating handling of large structures. Benefits of Fiberglass Cloth 1708 Thanks to its unique features, users can enjoy various benefits when using fiberglass cloth 1708. The material offers excellent bonding properties, saving on adhesives, hence reducing overall production costs. Fiberglass cloth 1708 is also incredibly stiff and flexible, allowing the material to conform to various shapes and objects. Additionally, the cloth is non-porous, which ensures that it remains water-resistant, enhancing its lifespan and durability. Companies' Applications of Fiberglass Cloth 1708Fiberglass cloth 1708 has been used in a variety of applications across different industries. For example, the aviation industry uses the material to repair damage to the aircraft's fiberglass body parts. Fiberglass cloth 1708 has also been used in the marine industry for boat repairs, construction of boats, and various other marine applications such as wind turbine blades. In the automotive industry, fiberglass cloth 1708 is used for mold making, repairing old cars, and fixing fiberglass car parts. Company's Approach to Quality and Customer Satisfaction At our company, quality and customer satisfaction are among our primary objectives. We strive to ensure that we consistently produce high-quality products. We achieve this by maintaining a highly-skilled workforce that uses the latest technologies and processes to produce and test our fiberglass cloth 1708 products. The Future of Fiberglass Cloth 1708 and Its Product Offering Our company is committed to consistently improving our products to meet your ever-changing needs. To this end, we are continually adopting new technologies and processes to produce the best fiberglass cloth 1708. We're confident that our ongoing efforts will ensure that we remain leaders in the production of high-quality fiberglass cloth 1708 for years to come. Conclusion Fiberglass cloth 1708 is an incredible material known for its versatility and exceptional strength. It is no wonder that it's a reliable reinforcement solution for many companies across various industrial sectors such as marine, aerospace, and automotive, among others. Our company remains committed to producing high-quality products that meet your every need. Contact us today for all your fiberglass cloth 1708 needs!

Unlocking the Potential of Carbon Fiber Cloth: Harnessing the Power of this Versatile Material

Using Carbon Fiber Cloth: Revolutionizing Industries[introduction]Innovation has long been the driving force behind advancements in various industries. The introduction of carbon fiber cloth, a lightweight and incredibly strong material, has revolutionized many sectors and opened doors to new possibilities. With its exceptional strength-to-weight ratio, heat resistance, and versatility, carbon fiber cloth is now being utilized in a wide range of applications, from aerospace and automotive to sports equipment and construction. This article delves into the extraordinary capabilities of carbon fiber cloth and explores how it has transformed these industries.[aerospace]The aerospace industry has always been at the forefront of technological advancements, pushing the boundaries of what is possible. Carbon fiber cloth has played a crucial role in enabling the development of lighter, more fuel-efficient aircraft. From the fuselage to wings, carbon fiber cloth is replacing traditional materials, such as aluminum, steel, and titanium. This substitution significantly reduces the weight of the aircraft, resulting in increased fuel efficiency and reduced carbon emissions. Additionally, carbon fiber cloth offers greater resistance to corrosion and fatigue, enhancing the longevity and safety of the aircraft. As a result, planes constructed with carbon fiber cloth are not only more environmentally friendly but also offer improved performance and durability.[automotive]The automotive industry has also embraced the use of carbon fiber cloth, focusing on enhancing performance and fuel efficiency. By incorporating carbon fiber cloth in various components of the vehicle, manufacturers can significantly reduce its weight, leading to improved acceleration, handling, and braking. Moreover, lighter vehicles consume less fuel, contributing to reduced greenhouse gas emissions and better fuel economy. Carbon fiber cloth is commonly used in the construction of high-performance sports cars, where weight reduction is paramount. However, with advancements in manufacturing techniques, its utilization is expanding to mass-produced vehicles as well. While the cost of carbon fiber cloth remains relatively high, ongoing research and development are aiming to make it more economically viable for widespread adoption.[sports equipment]The sports industry has witnessed a notable shift towards carbon fiber cloth in recent years, particularly in the production of sports equipment. Bicycles, tennis rackets, golf clubs, and even fishing rods are now being manufactured using carbon fiber cloth. Its exceptional strength and lightness enable athletes to achieve higher performance levels. In cycling, for instance, carbon fiber frames allow for improved power transfer and agility, resulting in faster speeds and better handling. Tennis rackets made from carbon fiber cloth offer enhanced stiffness, providing players with better control over their shots. Furthermore, the material's shock-absorbing properties reduce vibrations, minimizing the risk of injury. The utilization of carbon fiber cloth in sports equipment not only enhances athletes' performance but also promotes sustainability due to its longevity and recyclability.[construction]The construction industry has also recognized the potential of carbon fiber cloth in revolutionizing building materials. Reinforced concrete structures incorporating carbon fiber cloth are becoming increasingly popular due to their superior strength and durability. Carbon fiber reinforced polymers (CFRP) are used to reinforce beams, columns, and slabs, increasing their load-bearing capacity and resistance to seismic forces. CFRP composites offer a unique combination of high strength, ease of installation, and corrosion resistance, making them an ideal alternative to conventional materials. Additionally, the lightweight nature of carbon fiber cloth simplifies transportation and installation processes, reducing both costs and construction time. With its ability to improve the safety, efficiency, and sustainability of buildings, carbon fiber cloth is transforming the construction industry.[conclusion]In conclusion, carbon fiber cloth has emerged as a game-changer in various industries, leaving an indelible mark on aerospace, automotive, sports, and construction sectors. Its exceptional strength, lightweight nature, and heat resistance have propelled innovation, enabling the development of more efficient and sustainable products. While there are still challenges to overcome, such as the high cost of production, ongoing research and development are focused on making carbon fiber cloth more accessible to a wider range of applications. As industries continue to explore the potential of this revolutionary material, we can expect further advancements that will shape the future of these industries for years to come.

New Carbon Weave Fabric Offers Strong and Lightweight Alternative to Conventional Materials

Title: Revolutionizing the Textile Industry: Carbon Weave Fabric Promises a Sustainable FutureIntroduction:In a bid to revolutionize the textile industry and promote sustainability, a breakthrough fabric called Carbon Weave has emerged as a game-changer. Developed by a pioneering company, this innovative textile not only boasts exceptional quality and performance but also underscores a commitment to reducing the industry's carbon footprint. By combining cutting-edge technology and eco-friendly materials, Carbon Weave offers a glimpse into a more sustainable future for fashion and apparel.Section 1: The Birth of Carbon WeaveCarbon Weave fabric was born out of a passion for sustainable development and a desire to address the textile industry's environmental impact. Created by a visionary team dedicated to pushing the boundaries of the industry, this fabric is crafted using advanced carbon-fiber technology. By incorporating carbon fibers into the fabric's structure, it offers a durable, lightweight, and aesthetically appealing alternative to traditional textiles.Section 2: Unparalleled Performance and DurabilityCarbon Weave's unique composition ensures its exceptional performance and durability. The fabric's carbon fibers provide incredible strength and rigidity, making it highly resistant to wear and tear. Its remarkable tensile strength makes Carbon Weave ideal for applications requiring robust textiles, such as activewear, sports equipment, and automotive upholstery. Additionally, the fabric is also fire-resistant, providing an added layer of safety and protection.Section 3: Fueling Sustainable FashionOne of the most remarkable features of Carbon Weave fabric is its significantly reduced carbon footprint. By utilizing advanced carbon-fiber technology, the fabric production process minimizes the reliance on resource-intensive materials and embraces a more sustainable approach. Carbon Weave is manufactured using recycled materials, reducing the strain on natural resources while simultaneously reducing waste. This commitment to eco-friendliness resonates with the growing global demand for sustainable fashion.Section 4: Applications and VersatilityCarbon Weave's versatility extends to various sectors, making it highly sought after across numerous industries. In fashion, it presents a unique opportunity to create eco-friendly yet fashionable apparel, raising the bar for sustainability in the industry. Its use in activewear and sportswear offers unrivaled functionality, enhancing athletes' performance while reducing the overall carbon footprint associated with sportswear manufacturing. Moreover, the fabric's heat resistance and durability make it ideal for automotive and aerospace applications, aligning with the industry's growing focus on lightweight materials.Section 5: Collaboration and ImpactGiven the growing demand for sustainable solutions, many renowned fashion designers and industry leaders have already started embracing Carbon Weave. Collaborations have allowed for the creation of eye-catching, eco-friendly collections that challenge the narrative of traditional fashion. By utilizing Carbon Weave fabric, designers can convey their commitment to sustainability without compromising on quality or style.Section 6: Looking Towards the FutureCarbon Weave fabric represents a crucial step towards a more sustainable future for the textile industry. Its innovative approach to incorporating eco-friendly materials and advanced manufacturing techniques showcases that sustainability and style can coexist. As consumer demand for sustainable products grows, Carbon Weave's adoption paves the way for a paradigm shift in the textile industry, one that prioritizes ethical sourcing, renewable materials, and reduced carbon emissions.Conclusion:Carbon Weave fabric's emergence marks a significant milestone in sustainable textile manufacturing. Its exceptional performance, durability, and reduced carbon footprint make it an attractive choice for a wide range of applications. Moreover, collaborations with fashion designers and industry leaders demonstrate the fabric's potential to transform the industry's landscape. As Carbon Weave gains traction in the market, it serves as a beacon of hope, encouraging other textile manufacturers to embrace sustainable practices and contribute to a greener future.

Durable and Versatile Mesh Tape: Ideal Solution for Repairing and Reinforcing Home Surfaces

Glass Mesh Tape Revolutionizes the Construction IndustryThe construction and renovation industry is constantly evolving, with new materials and techniques being introduced to enhance the quality and durability of buildings. One such innovation that has garnered attention and revolutionized the industry is Glass Mesh Tape (brand name removed), a cutting-edge product that has gained praise for its exceptional performance and versatility.Glass Mesh Tape is a high-quality adhesive tape infused with glass fibers, which gives it incredible strength and durability. Initially designed to reinforce joints and seams in drywall installations, this tape has quickly gained popularity among contractors and DIY enthusiasts due to its numerous advantages over traditional options.One of the key features of Glass Mesh Tape is its superior tensile strength. The integration of glass fibers into the tape makes it significantly stronger than regular paper or fiberglass mesh tape. This enhanced strength provides better resistance against cracking and ensures long-lasting joints, ultimately improving the overall integrity of the walls or ceilings where it is applied.The advanced technological composition of Glass Mesh Tape also makes it highly resistant to moisture. Unlike traditional paper tapes that can easily deteriorate when exposed to water or humidity, this tape is designed to withstand challenging environments without losing its adhesive properties or structural integrity. This feature makes it an ideal choice for applications in areas prone to moisture, such as bathrooms and basements.In addition, Glass Mesh Tape exhibits exceptional adhesive properties. Its pressure-sensitive adhesive backing allows it to firmly bond with different surfaces, ensuring seamless integration with the drywall. This not only makes installation hassle-free but also prevents the tape from peeling or detaching over time, guaranteeing a neat and professional finish.What truly sets Glass Mesh Tape apart is its versatility. Beyond drywall applications, this tape can be effectively used across various construction projects. It works exceptionally well for patching holes, repairing cracks, and reinforcing corners. Furthermore, it can be applied on both flat and curved surfaces, making it suitable for a wide range of projects, from residential renovations to commercial construction.The company behind Glass Mesh Tape, recognized as a leader in the industry, is committed to producing innovative, high-quality products. With a focus on research and development, they continuously strive for advancements that meet the evolving needs of professionals in the industry.The production process of Glass Mesh Tape adheres to stringent quality control measures. Each roll is thoroughly tested to ensure consistent performance and durability. This dedication to quality has earned the company a reputation for delivering products that exceed expectations and provide unmatched reliability.Moreover, the company places great importance on sustainability. Glass Mesh Tape is manufactured using eco-friendly materials, reducing its environmental footprint. By using renewable resources and employing energy-efficient manufacturing practices, the company actively contributes to a greener and more sustainable future.The widespread adoption of Glass Mesh Tape has significantly improved construction practices. Its exceptional strength, resistance to moisture, versatile applications, and commitment to quality and sustainability have made it an indispensable tool for professionals and homeowners alike. With this innovative product, the construction industry is well on its way to achieving greater durability and longevity in building structures.

Heavyweight Fiberglass Cloth: Ideal for Repairs and Projects Without Weight Constraints

Title: Unraveling the Strength and Versatility of Woven Roving Fiberglass ClothIntroductionIn the vast realm of construction and repairs, the importance of reliable and durable materials cannot be overstated. When it comes to reinforcing structures and ensuring their longevity, fiberglass materials have emerged as a popular choice. Among the many variations available, fiberglass woven roving cloth is a heavyweight solution that offers exceptional tensile strength, flexibility, and ease of use. In this blog post, we will delve into the remarkable features of woven roving fiberglass cloth, exploring its applications, benefits, and why it has become a go-to material in various industries.Understanding Woven Roving Fiberglass ClothWoven roving fiberglass cloth is a specialized type of fiberglass fabric that is heavier and more robust than standard fiberglass cloth. Composed of randomly interwoven continuous fiberglass filaments, it exhibits impressive strength and rigidity. This makes it particularly suitable for applications where weight is not a limiting factor.Versatility of Woven Roving Fiberglass Cloth1. Strength and Durability:Due to its unique construction, woven roving fiberglass cloth offers exceptional tensile and flexural strength, making it ideal for reinforcing structures and surfaces. It provides remarkable resistance against impact, heavy loads, and harsh weather conditions. Industries such as boat-building, automotive repairs, aerospace, and construction often rely on the added strength that woven roving brings to their projects.2. Lamination Applications:One of the most common uses of woven roving fiberglass cloth is as an intermediate layer in laminates. Its ability to easily wet out during the lamination process ensures a strong bond between layers of fiberglass mat. This technique enhances overall structural integrity, enabling the creation of robust and long-lasting composite products.3. Repairs and Restorations:Woven roving fiberglass cloth is a popular choice for repairing and restoring damaged fiberglass structures, such as boats, automobiles, and even household items. Its excellent tensile strength, combined with the ease of handling and application, makes it an invaluable material for effectively reinforcing weakened areas.4. Customization:Another advantage of woven roving fiberglass cloth is its versatility with regard to size and shape. It can be easily cut and manipulated to suit the specific requirements of a project. This flexibility allows for customized applications in various industries, ensuring a seamless integration of the material with the existing structure.Benefits of Woven Roving Fiberglass Cloth1. Lightweight and Cost-Effective:While it may be heavier compared to standard fiberglass cloth, woven roving fiberglass cloth is still relatively lightweight when compared to other traditional construction materials. This characteristic makes it advantageous in scenarios where weight restrictions are not critical. It also offers cost advantages by providing superior strength at a relatively lower price point compared to other materials.2. Easy Application:The loosely woven structure of this fabric facilitates easy wetting out during the lamination process, significantly reducing the efforts required for its application. This time-saving feature makes woven roving fiberglass cloth highly efficient for both DIY enthusiasts and professional builders.3. Excellent Chemical Resistance:Woven roving fiberglass cloth exhibits remarkable resistance to chemicals, including acids, alkalis, oils, and various solvents. This attribute makes it a preferred material for applications that involve exposure to corrosive substances or environmental conditions.ConclusionIn the construction and repair industry, woven roving fiberglass cloth has earned its reputation as a heavyweight solution providing exceptional strength, durability, and versatility. Its ability to reinforce structures, ease of application, and cost-effectiveness make it an ideal choice for various projects. Whether used in laminations, repairs, or custom applications, woven roving fiberglass cloth offers unparalleled strength and reliability. By incorporating this robust material into your projects, you can ensure the longevity and resilience of your structures.Keywords: woven roving fiberglass cloth, fiberglass woven roving, fiberglass cloth, strength, flexural strength, tensile strength, laminates, repairs, versatility, durability, resistance, applications, lightweight, cost-effective, chemical resistance, DIY

Denim Jeans Fabric Texture Glasses Cloth for Delicate Surfaces

ManyDeals: Advancing Customer Satisfaction with Innovative ProductsManyDeals is a company that has focused on providing innovative products to its customers worldwide. The company prides itself on offering a wide range of products that cater to the needs of its clients, as well as ensuring customer satisfaction. ManyDeals has managed to differentiate itself from competitors by offering products that are unique, creative, and designed to meet the demands of its customers. One of its innovative products that is currently causing a buzz is the Denim Jeans Fabric Texture Small Glasses Cloth.The Denim Jeans Fabric Texture Small Glasses Cloth is a microfiber cleaning cloth that is designed to be used on delicate objects' surfaces. Its unique fabric texture is inspired by denim jeans, making it stylish and trendy. It measures approximately 7" x 6", which is convenient for everyday use. ManyDeals' customers worldwide are excited about this latest product, and here are some of the reasons why:1. Protects Delicate SurfacesOne of the key benefits of the Denim Jeans Fabric Texture Small Glasses Cloth is that it is made of microfiber material that does not damage objects' surfaces, including electrical appliances, CD, DVD discs, and other optical products. This means that customers can safely clean their delicate surfaces without worrying about damaging them.2. Easy to MaintainThe Denim Jeans Fabric Texture Small Glasses Cloth is easy to maintain, making it ideal for everyday use. It can be machine washed and reused, allowing customers to save money on cleaning cloths in the long run. This convenience has made it even more popular among ManyDeals' customers worldwide.3. Creative DesignThe Denim Jeans Fabric Texture Small Glasses Cloth has a unique design that sets it apart from other cleaning cloths in the market. Its fabric texture is inspired by denim jeans, giving it a stylish and trendy look. The creative design has made it a popular product among ManyDeals' fashion-conscious customers.ManyDeals is committed to providing its customers with innovative products that meet their needs. The Denim Jeans Fabric Texture Small Glasses Cloth is just one of the many products the company has developed to enhance its customers' experience. ManyDeals is continuously seeking new ways to innovate and improve its products to ensure customer satisfaction.ConclusionManyDeals is a company that has established itself as a leading provider of innovative products worldwide. The Denim Jeans Fabric Texture Small Glasses Cloth is just one of ManyDeals' latest products that has generated excitement among customers. The cloth's unique design, easy maintenance, and ability to protect delicate surfaces have made it a popular product among ManyDeals' customers worldwide. ManyDeals' commitment to providing innovative products that meet its customers' needs has cemented its position as a leader in the market.

Introduction to Plain Weave Carbon: A Strong and Versatile Material

Advanced materials company XYZ has recently developed a groundbreaking plain weave carbon that promises to revolutionize the manufacturing industry. This innovative material offers an array of superior characteristics, making it the ideal choice for a wide range of applications.Plain weave carbon is a type of carbon fiber fabric that is woven in a simple over-and-under pattern, creating a strong and durable material. XYZ's plain weave carbon boasts an impressive tensile strength, high stiffness, and low weight, making it an excellent choice for industries such as aerospace, automotive, sports equipment, and more.One of the key advantages of plain weave carbon is its exceptional structural performance. The material's high tensile strength means that it can withstand heavy loads and forces, making it the go-to choice for applications where structural integrity is paramount. Additionally, its high stiffness-to-weight ratio ensures that components made from plain weave carbon are lightweight yet incredibly rigid, providing unparalleled performance in demanding environments.Moreover, XYZ's plain weave carbon is available in a variety of formats, catering to the specific needs of different industries. Whether it's woven into fabric, pre-impregnated with resin, or formed into complex shapes, the material can be tailored to meet the requirements of a wide range of applications. This versatility makes it a highly sought-after material in the manufacturing sector.In addition to its exceptional mechanical properties, plain weave carbon also offers excellent thermal and chemical resistance. This makes it an ideal choice for applications where exposure to extreme temperatures, corrosive chemicals, or other harsh conditions is common. Its ability to maintain its performance in challenging environments sets it apart from other materials on the market.Furthermore, XYZ is committed to sustainability, and its plain weave carbon is no exception. The company's manufacturing processes are designed to minimize waste and environmental impact, ensuring that the material is not only high-performing but also eco-friendly. This aligns with the growing demand for sustainable materials in today's market and positions XYZ as a leader in responsible manufacturing.The development of XYZ's plain weave carbon represents a significant advancement in the materials industry. With its exceptional mechanical properties, versatility, and sustainability, this innovative material is poised to transform the way products are designed and manufactured across various sectors. By offering a superior alternative to traditional materials, XYZ is paving the way for a new era of high-performance and sustainable manufacturing."We are thrilled to introduce our plain weave carbon to the market," said John Doe, CEO of XYZ. "This material represents a culmination of years of research and development, and we believe it has the potential to make a significant impact across multiple industries. We are excited to see the innovative ways in which our customers will utilize this material to create the next generation of products."Looking ahead, XYZ is poised to continue its research and development efforts, with a focus on expanding the capabilities of its plain weave carbon and exploring new applications for the material. By leveraging its expertise and commitment to innovation, the company is well-positioned to drive further advancements in the materials industry and solidify its position as a leading provider of high-performance, sustainable materials.In conclusion, XYZ's plain weave carbon is set to revolutionize the manufacturing industry with its exceptional mechanical properties, versatility, and sustainability. As the demand for high-performance, eco-friendly materials continues to grow, XYZ is well-positioned to lead the way with its groundbreaking innovation. With a strong commitment to research and development, the company is poised to shape the future of manufacturing with its innovative plain weave carbon.

24oz Vermiculite Coated Fiberglass Cloth: A Fire and Chemical Resistant Solution for High Temperature Insulation and Welding Applications

Acmetex Inc Launches Revolutionary 24oz Vermiculite Coated Fiberglass ClothAcmetex Inc, a leading manufacturer of high-performance fiberglass cloth and textile products, has announced the launch of its latest innovation, the 24oz Vermiculite Coated Fiberglass Cloth. This new product brings cutting-edge technology and design to the market, providing customers with an advanced and reliable solution for their high-temperature insulation and fire-resistant needs.Acmetex's 24oz Vermiculite Coated Fiberglass Cloth is made from continuous texturized E-fiberglass yarns, which offer exceptional strength and durability. These yarns are woven together to create a tight, dense fabric that can withstand high temperatures and harsh conditions. Vermiculite coating is added to the cloth to improve abrasion resistance and add an extra layer of protection against direct flame.Heat travels across the fabric, not through it, making this product an excellent choice for high-temperature insulation and heat shield applications. It provides superior thermal insulation, keeping heat from escaping and cold from seeping in, making it ideal for use in welding blankets, curtains, and expansion joints. The vermiculite coating also improves the cloth's strength and resistance to tearing, making it a great option for high-stress applications.Acmetex Inc has been a leading manufacturer of fiberglass cloth and textile products for over 20 years. The company has a proven track record of providing high-quality solutions to customers across a wide range of industries, including automotive, aerospace, marine, and construction. Acmetex's commitment to innovation and quality has made it a trusted partner for many leading companies in these industries."We are excited to launch our latest innovation, the 24oz Vermiculite Coated Fiberglass Cloth," said a spokesperson for Acmetex Inc. "This new product is a testament to our commitment to providing our customers with the highest quality solutions for their needs. We believe that this product will be a game-changer in the market, and we are confident that it will be very well received by our customers."Acmetex's 24oz Vermiculite Coated Fiberglass Cloth is available in a variety of widths and lengths, making it suitable for a wide range of applications. It is also customizable, allowing customers to tailor the fabric to meet their specific needs. The product is expected to be available for purchase on Acmetex's website and through its authorized distributors in the coming weeks.In conclusion, Acmetex Inc's 24oz Vermiculite Coated Fiberglass Cloth is a breakthrough product that offers exceptional strength, durability, and fire-resistant properties. It is a testament to the company's commitment to innovation and quality and a clear demonstration of its ability to bring cutting-edge solutions to the market. This product is sure to be a game-changer and a valuable asset for customers across a wide range of industries.

Revolutionary Lightweight Carbon Fiber Plain Unveiled in Latest Technology News" - "New Lightweight Carbon Fiber Plain Unveiled in Latest Tech News

Carbon Fiber Plain is one of the most versatile and high-strength materials in the world. With its unique properties, it has been used in industries ranging from aerospace to automotive, and even high-performance sports equipment. While many companies produce carbon fiber, (brand name) stands out as a leader in the field. Founded in XXXX, (brand name) has made it a mission to produce high-quality carbon fiber products with unmatched precision and quality. Despite being a relatively new player in the market, they quickly established themselves as a global leader in the field, serving clients in a wide variety of industries from all over the world.At (brand name), the production process begins by sourcing only the highest-quality raw materials available. The fibers are then woven together into the desired pattern, coated with a resin binder, and cured at high temperatures to create a strong composite. (Brand name) has invested heavily in state-of-the-art manufacturing equipment and processes to ensure that each product is of the highest quality and consistency.One of the biggest advantages of carbon fiber is its strength-to-weight ratio. Compared to traditional materials like steel or aluminum, carbon fiber can be up to ten times stronger while being significantly lighter. This has made it a popular choice for aerospace and automotive applications, where reducing weight without sacrificing strength is critical.Another benefit of carbon fiber is its durability. Unlike other materials that can be prone to corrosion or fatigue, carbon fiber is highly resistant to both. It is also non-conductive, making it an ideal choice for applications where electromagnetic interference could be an issue.Perhaps most impressively, carbon fiber can be molded into virtually any shape or geometry, giving designers and engineers unparalleled flexibility in creating products. From aircraft components to bicycle frames, the possibilities are endless.(Brand name) offers a wide variety of carbon fiber products, including sheets, tubes, and rods. They also work closely with clients to develop custom solutions to meet their specific needs. This level of flexibility and customization has helped to set (brand name) apart from the competition.One particularly exciting use of carbon fiber is in the field of renewable energy. Wind turbine blades, which are exposed to a wide range of environmental stresses, are often made from carbon fiber due to its strength and durability. This has helped to increase the efficiency and reliability of wind power generation, contributing to the transition to a more sustainable energy future.Carbon fiber has also found its way into the world of sports equipment. From tennis rackets to ski poles, carbon fiber is a popular choice due to its light weight and stiffness. Athletes around the world use carbon fiber equipment to help them perform at their best.In conclusion, (brand name) is a global leader in the production of high-quality carbon fiber products. Their dedication to precision and quality has helped them to establish themselves as a trusted partner for clients in a diverse range of industries. With the continued growth in applications for carbon fiber, (brand name) is poised to play an important role in shaping the future of many industries.