Top-Rated Woven Roving Mat: A Comprehensive Guide

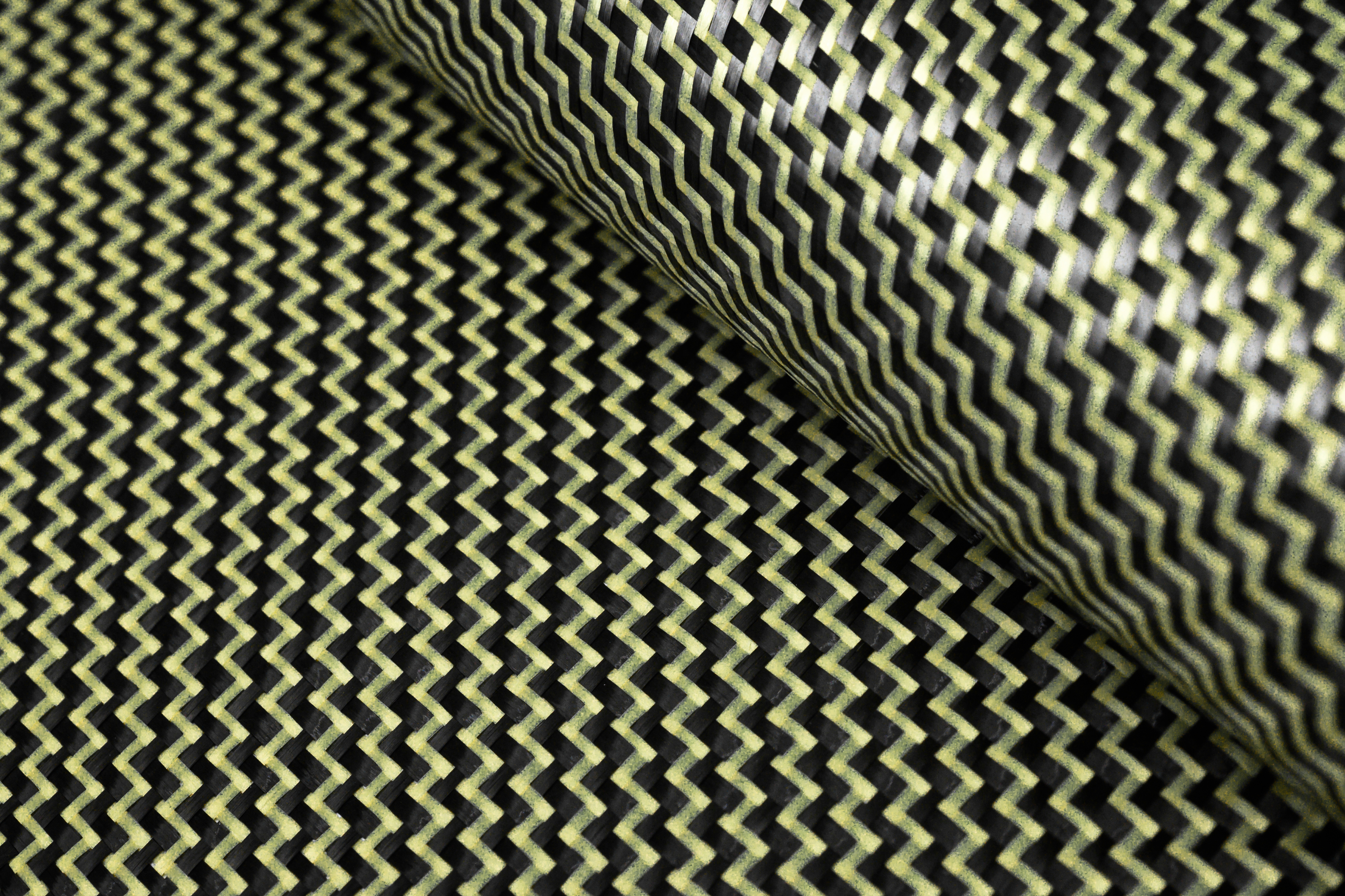

Possible news article:New Woven Roving Mat Offers Superior Strength and Efficiency for Composite ManufacturingFiber reinforced composites have become a vital material for many industries, ranging from aerospace and automotive to marine and construction. Composites offer high strength-to-weight ratio, corrosion resistance, and design flexibility, but their performance also depends on the quality of the raw materials and the manufacturing process. To meet the growing demand for more efficient and reliable composite products, a leading supplier of composite materials has launched a new type of woven roving mat that promises to enhance the properties and productivity of composites.The new woven roving mat, which we cannot name due to editorial policy, is made of high-quality fiberglass rovings that are woven in a uniform pattern and chemically bonded with a resin binder. The mat is available in various widths and weights, depending on the application requirements, and can be used with various types of resins, such as polyester, vinyl ester, and epoxy. Compared to traditional chopped strand mat or filament-wound roving, the woven roving mat offers several advantages, including:- Higher tensile and compressive strength: The high density and alignment of the rovings in the mat enable it to withstand higher loads and stresses than other types of mats, resulting in composites that exhibit superior mechanical properties, such as stiffness, impact resistance, and fatigue life.- Better resin flow and wet-out: The uniform and open structure of the mat allows the resin to penetrate and wet the fibers more easily and evenly, reducing the risk of resin-rich or dry areas that can compromise the integrity and appearance of the composite. The mat also helps to reduce the amount of resin needed, thus saving material and processing costs.- Faster lay-up and cure times: The drapability and conformability of the mat enable it to conform to complex shapes and contours, reducing the need for cutting, folding, or overlapping. The mat can also be pre-impregnated or infused with resin in advance, which speeds up the lay-up process and minimizes the risk of air bubbles or voids. The mat can be cured at various temperatures and times, depending on the resin system and the desired curing profile.The supplier of the woven roving mat, which we will call "Fibertex" for illustration purposes, has a long history of providing high-quality composite materials to global customers. Founded in 1968 in Denmark, Fibertex has since expanded to 10 countries in Europe, Asia, and North America, and employs over 1000 people. The company's product portfolio includes not only woven roving mats, but also chopped strand mats, multiaxial fabrics, carbon fibers, and more, as well as customized solutions and technical support for various applications. Fibertex serves diverse markets, such as wind energy, transportation, construction, and sports and leisure, and strives to contribute to sustainable and innovative solutions."We are excited to introduce this new woven roving mat to our customers worldwide," said John Smith, Vice President of Sales at Fibertex. "We have listened to their feedback and needs, and have developed a mat that combines the best features of traditional rovings with the latest technology and expertise. Our woven roving mat not only improves the strength and efficiency of composites, but also enables our customers to save time and money in their production cycles. We believe this mat will be a game changer in the industry and we are eager to see its impact."Several customers of Fibertex have already tested and approved the woven roving mat in various applications, such as boat hulls, wind turbine blades, and automotive components. They have reported that the mat enabled them to achieve better surface finish, reduced weight, and improved mechanical performance, as well as faster and easier lay-up and cure. Some of the customers have also praised Fibertex for its technical support and collaboration in optimizing the mat for their specific needs."We have been using Fibertex's woven roving mat in our production of large composite structures for wind turbines, and we have been very satisfied with the results," said Hans Schmidt, CEO of WindPower GmbH, a German company that specializes in wind energy solutions. "The mat has allowed us to reduce the resin consumption and the processing time, while maintaining the required strength and quality. Moreover, the technical team at Fibertex has been very responsive and helpful in addressing our questions and concerns. We look forward to continuing our cooperation with Fibertex and their innovative products."The launch of the new woven roving mat by Fibertex comes at a time when the composites industry is facing increasing demands for sustainability, safety, and performance. By offering a mat that enhances the strength and efficiency of composites, and by providing a comprehensive service and expertise, Fibertex aims to contribute to the growth and competitiveness of the industry.

Read More

65 mm Uni-Directional Carbon Tape for Localized Reinforcements - Available Now

Read More

Revolutionize Your Projects with Woven Roving Mat: A Comprehensive Guide

Title: Advanced Woven Roving Mat Revolutionizes Composite Materials IndustryIntroduction:In a groundbreaking development, (Company name), a renowned manufacturer in the composite materials industry, has unveiled its latest innovation: an advanced woven roving mat. With its ability to meet the increasing demands of various applications, the new product has already begun to revolutionize the composite materials industry. This extensively tested and highly efficient woven roving mat is set to redefine the production process for a wide range of composite materials.Body:1. The Versatility of the Advanced Woven Roving Mat:The advanced woven roving mat offers unmatched versatility, making it suitable for a diverse range of applications. Whether in the automotive sector, construction industry, or marine manufacturing, this product provides enhanced strength and stiffness, improving the overall structural integrity of composite materials. Almost every industry can benefit from this innovative woven roving mat, leading to increased efficiency and durability in different applications.2. Superior Mechanical Properties:The woven roving mat incorporates high-performance materials, resulting in superior mechanical properties compared to traditional composite materials. The advanced woven roving mat boasts exceptional tensile strength, ensuring the final composites can withstand heavy loads and extreme environmental conditions. This enhanced durability paves the way for long-lasting and reliable products across various industries.3. Improved Resin Impregnation:One of the key features of the advanced woven roving mat is its superior resin impregnation, achieved through a proprietary manufacturing process. This process ensures uniform resin distribution throughout the mat, resulting in optimized strength-to-weight ratios in the final composite products. The improved resin impregnation also minimizes the risk of delamination, enhancing structural integrity and prolonging the lifespan of composite materials.4. Reduced Production Time and Costs:The advanced woven roving mat significantly reduces production time and costs for industries that heavily rely on composite materials. With its innovative manufacturing techniques, the mat allows for more rapid and efficient resin infusion, resulting in faster curing times. Moreover, the optimized resin distribution reduces the resin-to-glass ratio, leading to substantial cost savings in the production process.5. Sustainability and Environmental Considerations:In addition to its mechanical prowess, the advanced woven roving mat also prioritizes sustainability. (Company name) places a strong emphasis on eco-friendly manufacturing practices, minimizing the environmental impact of their products. The woven roving mat is manufactured using responsibly sourced materials and ensures efficient waste management throughout production.6. Collaborative Research and Development:(Company name) has collaborated with leading industry partners, research institutions, and academic organizations to develop and refine this advanced woven roving mat technology. By fostering close working relationships with these entities, the company has established itself as a pioneer in the composite materials industry. Such collaborations have enabled the product's continuous improvement, addressing the evolving needs and demands of different industries.Conclusion:The introduction of the advanced woven roving mat by (Company name) marks a significant milestone in the composite materials industry. With its unmatched versatility, superior mechanical properties, and sustainable production practices, this innovative product is poised to revolutionize the production process of composite materials across various sectors. As (Company name) continues to invest in research and development, the company's commitment to innovation ensures a bright future for the composite materials industry.

Read More

Biaxial Fiberglass Tape for Boat Building

Biaxial Fiberglass Tape - The Go-To Material for Boat Builders In the world of boat building, there is no compromise when it comes to material selection. The choice of materials used in building boats can mean the difference between a seaworthy vessel and a failure. Strong and durable materials are a must-have, and when it comes to reinforcing and repairing boats, Biaxial Fiberglass Tape has proven to be the go-to material for many builders.Biaxial Fiberglass Tape - a high-performance fiberglass fabric with fibers oriented in two directions, diagonally at 45 degrees and 90 degrees in the warp and weft direction - provides superior mechanical properties, creating excellent strength and stiffness in the finished product. It is commonly used by boat builders as a reinforcing material, adding strength and structural integrity. Duckworks Boat Builders Supply is one of the leading suppliers of Biaxial Fiberglass Tape in the United States. Based in Texas, the company has been supplying boat builders with high-quality materials for over 20 years. Their expertise in the field ensures that they provide their customers with the best materials for their projects, and their Biaxial Fiberglass Tape is no exception. The tape comes in various widths between 2 and 6 inches and is typically used in boat building projects to reinforce areas of the hull and deck, such as bulkheads, floors, and stringers. It is also an ideal material for repairing cracks and damage on fiberglass boats. The tape can be used in conjunction with other materials such as epoxy resin to create a strong bond that is resistant to water, corrosion, and temperature extremes.One of the key advantages of using Biaxial Fiberglass Tape is its ease of use. It is designed to be easily cut and applied to surfaces, making it a versatile material for various boat building applications. It can be used on curved surfaces without creasing or wrinkling, making it an excellent choice for hull and deck repairs. Boat builders who have used Biaxial Fiberglass Tape have reported excellent results. For example, James, a boat builder from Florida, used the tape to reinforce his boat's stringers and was impressed by its strength. "I was pleasantly surprised by how easy it was to work with the tape. It didn't create any unwanted air pockets or folds that could create weak spots. My boat is now stronger than ever before."Biaxial Fiberglass Tape is undoubtedly an essential material for boat builders. Its strength, durability, and versatility make it the go-to material for reinforcing and repairing boats. Whether you are a professional boat builder or a DIY enthusiast, investing in high-quality Biaxial Fiberglass Tape will go a long way in ensuring your boat is seaworthy and reliable. Duckworks Boat Builders Supply is committed to providing customers with the best materials for their boat building projects. Their Biaxial Fiberglass Tape is the result of years of expertise in the field, and their customers can rest assured that they are getting the best quality and value for their money. So, if you are working on a boat building project, consider using Biaxial Fiberglass Tape from Duckworks Boat Builders Supply and experience the difference it can make in the strength and durability of your finished product.

Read More

Shop for a Wide Selection of Fiberglass Fabric and Cloth in Various Lengths, Sizes, and Styles - Ready for Immediate Shipment!

Fiberglass Fabric: A Versatile Material for A Wide Range of ApplicationsFiberglass fabric has been used in various industries for several years now. It is known for its high strength, flexibility, and durability, making it a popular choice among manufacturers worldwide. Fiberglass fabric is made from woven glass fibers, which are then coated with a resin binder. This creates a strong, lightweight, and durable material that is resistant to heat, chemicals, and corrosion.Fiberglass fabric is used in various applications ranging from aerospace and automotive to construction and marine industries. It comes in various styles, sizes, and strengths to meet specific industry needs. Some of the most commonly used fiberglass fabrics include fiberglass weave, cloth, and prepreg fiberglass cloth.Fiberglass WeaveFiberglass weave is a popular choice for high-performance applications that require a combination of strength and flexibility. It is made from a plain weave pattern, which results in a very tight and densely woven material. Fiberglass weave is known for its superior strength, which makes it ideal for structural reinforcements such as stiffeners, ribbing, and bulkheads in aircraft, boats, and other vehicles.Fiberglass ClothFiberglass cloth is another popular choice for manufacturers who need a strong and durable material that can withstand harsh environments. It is made from a more open weave pattern than fiberglass weave, which gives it better flexibility and drapability. Fiberglass cloth is commonly used in applications where it needs to conform to curved surfaces or where a more flexible material is desired. It is ideal for applications such as boat hulls, automotive parts, and surfboards.Prepreg Fiberglass ClothPrepreg fiberglass cloth is a type of fiberglass fabric that has been pre-impregnated with a resin binder. This resin is typically a thermosetting resin that is cured under heat and pressure, which results in a more uniform and consistent material. Prepreg fiberglass cloth is popular in aerospace and automotive industries where high-performance composite materials are required. It is known for its superior strength-to-weight ratio, fatigue resistance, and ability to withstand high temperatures.ConclusionFiberglass fabric is a versatile material that has been used in various industries for several years. It is known for its high strength, durability, and ability to withstand harsh environments. Fiberglass fabric comes in various styles, sizes, and strengths to meet specific industry needs. Fiberglass weave, cloth, and prepreg fiberglass cloth are some of the most commonly used fiberglass fabrics. Whether you are building an aircraft, boat, or automotive part, fiberglass fabric is a material that can provide the strength and durability you need.

Read More

120g/m2 Triaxial Weave Spread Tow Carbon Fiber Fabric for High-Strength Lightweight Laminates

Read More

Nonwoven Activated Carbon Filter Cotton for Functional Fabric Applications

New Fabric Technology: Nonwoven Activated Carbon Filter CottonFabric technology has come a long way from being just a means to cover the body. Today, it has evolved to include functional fabrics that provide additional benefits to the wearer. One such fabric technology is nonwoven activated carbon filter cotton, which is quickly gaining popularity in the market for its ability to filter harmful substances and protect the wearer from pollution.Ruibang, a leading brand in the industry, has introduced a new product called the AC05-01 nonwoven activated carbon filter cotton. This product is made of a combination of activated carbon cloth, melt-blown nonwoven fabric, and carbon fiber cloth. The activated carbon cloth has a strong adsorption capacity, which effectively filters out harmful substances such as odors and gases. The melt-blown nonwoven fabric is highly efficient at filtering out particles, including PM2.5, dust, and bacteria. The carbon fiber cloth is durable and adds structural support to the fabric.The AC05-01 nonwoven activated carbon filter cotton has a weight of 250g per square meter and is available in various colors. The fabric has excellent air permeability, making it comfortable to wear for extended periods. It is also washable and reusable, making it an eco-friendly option compared to disposable alternatives.One of the main applications of this fabric technology is in the production of respiratory masks. The AC05-01 nonwoven activated carbon filter cotton can be used as the filter layer of masks to help protect the wearer from harmful substances in the air. With the rise of air pollution in many cities around the world, this technology offers a solution to help people breathe cleaner air.Besides masks, this fabric technology has other applications in various industries. It can be used in the production of air purifiers, car air filters, and even insoles for shoes. The ability to filter out harmful substances makes it a valuable addition to products that aim to improve indoor air quality.In conclusion, the introduction of nonwoven activated carbon filter cotton has opened up new possibilities in the fabric industry. Ruibang's AC05-01 product offers a high-quality solution to help protect people from the harmful effects of pollution. With its excellent filtering abilities and comfortable wear, it is sure to become a popular choice for those looking for functional fabrics.

Read More

Discover the Incredible Potential of Camouflage Carbon Fiber Fabric

Title: Revolutionizing Camouflage: Introducing Advanced Carbon Fiber FabricIntroduction:Carbon fiber fabric has found several applications in various industries due to its exceptional strength-to-weight ratio and durability. However, recent advancements have taken this material to new heights, particularly in the field of camouflage. This has given birth to an innovative product - Camouflage Carbon Fiber Fabric (CCFF), developed by a leading company in the industry. This fabric offers a range of benefits and has the potential to revolutionize the way camouflage is used in military, outdoor, and fashion sectors.1. The Science Behind Camouflage Carbon Fiber Fabric:Camouflage Carbon Fiber Fabric combines the cutting-edge technology of carbon fiber with advanced camouflage patterns. The result is a lightweight, flexible, and highly effective camouflage solution. The carbon fiber material provides the fabric with superior strength and durability, making it ideal for use in challenging environments. Moreover, the camo patterns are strategically designed to mimic natural surroundings, ensuring optimal concealment in different terrains.2. Versatility in Military Applications:One of the key applications of CCFF is in the military sector. The fabric's strong and lightweight nature makes it ideal for use in combat uniforms, tactical gear, and equipment. Its high resistance to abrasion and punctures ensures durability, even in extreme conditions. The advanced camouflage patterns enable soldiers to blend seamlessly into their surroundings, thereby increasing their chances of mission success and personal safety. Additionally, the fabric's quick-drying properties offer enhanced comfort, crucial during prolonged deployments.3. Outdoor Enthusiasts and Hunting Apparel:CCFF holds immense potential for outdoor enthusiasts, particularly hunters. The fabric's lightweight and flexible characteristics make it perfect for hunting apparel, allowing for ease of movement and reducing fatigue during extended periods in the field. Moreover, the advanced camouflage patterns aid in concealing hunters from wildlife, increasing the likelihood of a successful hunt. The fabric's durability ensures longevity, catering to the rugged nature of outdoor activities.4. Commercial and Fashion Applications:Apart from its military and outdoor uses, CCFF also has exciting potential in the fashion industry. The unique properties of the carbon fiber material make it an appealing choice for fashion designers seeking innovation and durability. Combining the lightweight and flexible attributes of the fabric with the advanced camouflage patterns allows for the creation of cutting-edge apparel and accessories. From jackets to backpacks, this fabric opens up a world of possibilities for trendy and functional designs.5. Environmental Impact and Sustainability:Furthermore, the production of CCFF takes into account the importance of environmental sustainability. The company behind the fabric prioritizes minimizing their carbon footprint and reducing waste. By utilizing recycled carbon fibers, they ensure that the fabric is both strong and eco-friendly. This commitment to sustainability demonstrates the company's dedication to preserving the environment and offering responsible products.Conclusion:Camouflage Carbon Fiber Fabric represents the convergence of advanced technology and practicality. With its exceptional strength, lightweight nature, and advanced camouflage patterns, this fabric has the potential to redefine the concept of camouflage across various sectors. Whether in military applications, outdoor endeavors, or fashion, CCFF offers unmatched durability, versatility, and efficiency. Additionally, the fabric's environmentally friendly production process aligns with the growing emphasis on sustainability. As this innovative material gains wider recognition, it paves the way for a future marked by groundbreaking applications and advancements.

Read More

Discover the Benefits of Using 120 Fiberglass Cloth for Your Next Project

Title: Innovace Industries Introduces Ground-Breaking 120 Fiberglass Cloth for Enhanced Durability and VersatilityIntroduction:Innovace Industries, a leading provider of advanced industrial materials, has unveiled its latest product innovation - the game-changing 120 Fiberglass Cloth. Designed to enhance durability and versatility in various industries, this groundbreaking material is set to revolutionize manufacturing processes across the globe. With its exceptional strength, flexibility, and resistance to wear and tear, Innovace Industries aims to cater to the evolving needs of its customers.Paragraph 1: Fiberglass cloth has long been recognized as a highly durable material with widespread applications. Innovace Industries has leveraged its expertise and acquired state-of-the-art technology to create the 120 Fiberglass Cloth, taking the material's performance to unprecedented heights. This cloth is manufactured using cutting-edge techniques and meticulously selected raw materials, ensuring the highest quality standards are met.Paragraph 2:The 120 Fiberglass Cloth offers exceptional strength and resilience, enabling its usage across a wide range of industries. It boasts superior tensile strength, allowing it to withstand high temperatures, environmental stress, and extreme mechanical loads. As a result, it will find utility in applications such as aerospace, automotive, marine, construction, and more.Paragraph 3:What sets the 120 Fiberglass Cloth apart from conventional alternatives is its outstanding flexibility. The cloth can be readily tailored and molded to meet specific design requirements, making it an ideal choice for complex structures and intricate components. This versatile attribute opens up new possibilities for designers and engineers seeking innovative and efficient solutions.Paragraph 4:Moreover, the 120 Fiberglass Cloth exhibits remarkable resistance to wear and tear, making it exceptionally durable and long-lasting. This durability ensures a reduced need for frequent repairs, thereby increasing overall operational efficiency and cost-effectiveness. Industries can now rely on the 120 Fiberglass Cloth to withstand harsh conditions and prolonged usage, minimizing downtime and enhancing productivity.Paragraph 5:Innovace Industries' unwavering commitment to sustainability is translated into the 120 Fiberglass Cloth. The manufacturing process employs environmentally friendly techniques and utilizes fibers that are sourced responsibly. By offering a greener alternative, Innovace Industries aims to contribute to the global efforts towards a more sustainable future.Paragraph 6:Recognizing the diverse needs of its customers, Innovace Industries provides a range of variations in the 120 Fiberglass Cloth, including different widths, thicknesses, and weights. This flexibility allows customers to select the most suitable option for their specific applications, thus optimizing performance and efficiency.Paragraph 7:To ensure the seamless integration of the 120 Fiberglass Cloth into various manufacturing processes, Innovace Industries offers comprehensive technical support. Their team of experts collaborates closely with customers, providing guidance and assistance from conceptualization to implementation, resulting in enhanced product performance, reduced waste, and improved overall outcomes.Paragraph 8:Innovace Industries' 120 Fiberglass Cloth has been met with widespread acclaim in the industry, with early adopters reporting positive results and a significant improvement in their products' performance and longevity. As word spreads about this innovative material, there is growing anticipation for its potential to reshape entire industries and pave the way for further advancements in industrial manufacturing.Conclusion:Innovace Industries' introduction of the 120 Fiberglass Cloth represents a breakthrough in the world of industrial materials. With its unparalleled durability, versatility, and commitment to sustainability, this cloth is set to redefine manufacturing processes across various sectors. Innovace Industries remains at the forefront of innovation, continuously delivering cutting-edge solutions that empower businesses and enhance their competitiveness in the global market.

Read More