Guide to Layering Fiberglass Cloth for Reinforcement

By:Admin

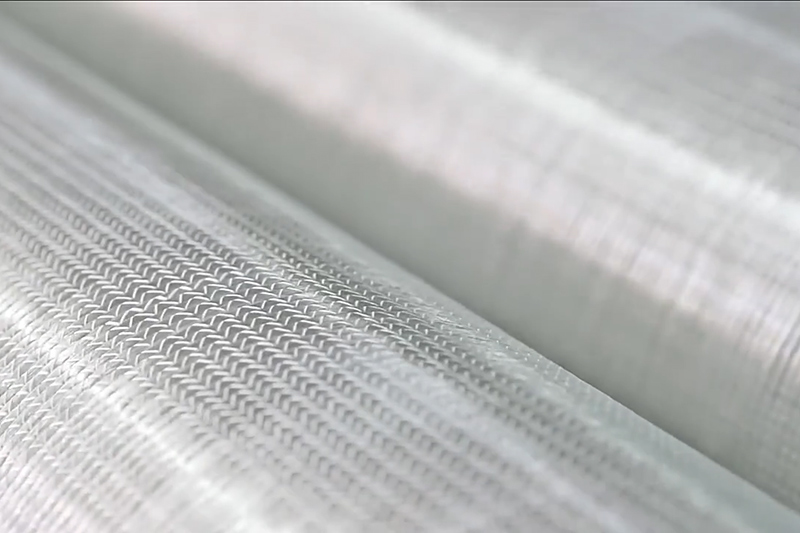

Fiberglass cloth is a versatile and widely used material in various industries due to its excellent strength, durability, and resistance to heat and chemicals. One company that has been at the forefront of providing high-quality fiberglass cloth is {}. With a strong focus on innovation and technological advancement, {} has been consistently delivering top-notch fiberglass cloth products to meet the diverse needs of its customers.

{} offers a wide range of fiberglass cloth products, including woven roving, chopped strand mat, and stitched fabric. These products are widely used in the manufacturing of composites, laminates, and other reinforced materials across industries such as automotive, aerospace, construction, marine, and sports equipment.

The process of layering fiberglass cloth is a critical step in the manufacturing of composite materials. It involves strategically placing multiple layers of fiberglass cloth and impregnating them with resin to create a strong and durable composite structure. The quality of the fiberglass cloth and the precision of the layering process are crucial in determining the mechanical properties and performance of the final composite material.

{} takes great pride in its commitment to quality and excellence in the production of fiberglass cloth. The company uses advanced manufacturing techniques and state-of-the-art equipment to ensure that its products meet the highest standards of quality and performance. By maintaining strict quality control measures and adhering to international standards, {} has earned a reputation for being a reliable and trusted supplier of fiberglass cloth.

In addition to its focus on quality, {} also places a strong emphasis on customer satisfaction. The company works closely with its customers to understand their specific requirements and provides customized solutions to meet their needs. Whether it is a small-scale project or a large industrial application, {} is dedicated to delivering fiberglass cloth products that exceed customer expectations.

One of the key advantages of using fiberglass cloth from {} is its versatility and compatibility with different resin systems. This allows manufacturers to tailor the mechanical and chemical properties of the composite material to suit their specific application requirements. With {}'s extensive experience and expertise in fiberglass cloth technology, customers can be assured of receiving the right product for their unique needs.

Furthermore, {} is committed to environmental sustainability and responsible manufacturing practices. The company ensures that its production processes minimize waste and energy consumption, while also investing in research and development to explore eco-friendly alternatives in fiberglass cloth production. By prioritizing environmental stewardship, {} aims to contribute to a greener and more sustainable future for the industry.

In conclusion, {} has established itself as a leading provider of high-quality fiberglass cloth, known for its commitment to excellence, customer satisfaction, and environmental responsibility. With a strong focus on innovation and quality, the company continues to be a preferred choice for manufacturers across industries looking for reliable and high-performance fiberglass cloth solutions. As the demand for advanced composite materials grows, {} remains dedicated to meeting the evolving needs of its customers and setting new standards in the fiberglass cloth industry.

Company News & Blog

Revolutionary 3D Fiberglass Fabric Takes the Textile Industry by Storm" becomes "Innovative 3D Fiberglass Fabric Disrupts the Textile Industry

text:3D Fiberglass Fabric: The Latest Innovation in the Textile IndustryThe textile industry has undergone several drastic changes in the past decade, with new and innovative products making their way into the market. One of the latest entrants is 3D fiberglass fabric, which is quickly being adopted worldwide for its numerous benefits. Let us take a closer look at this revolutionary product.What is 3D Fiberglass Fabric?3D fiberglass fabric is a textile material that is woven using state-of-the-art machinery and technology. The fabric consists of multiple layers of fiberglass, which are interwoven to form a three-dimensional structure. The result is a highly flexible and versatile material that can be used in a variety of applications.The Benefits of 3D Fiberglass Fabric3D fiberglass fabric has several unique benefits that make it the perfect choice for many industries. These include:1. High Strength: 3D fiberglass fabric has a much higher strength-to-weight ratio than traditional woven fiberglass fabric. This makes it the ideal choice for applications that require high strength and durability.2. Easy to Shape: The three-dimensional structure of the fabric makes it easier to shape and mold into complex shapes. This means that it can be used to create intricate parts and components for a range of industries.3. Lightweight: Despite its high strength, 3D fiberglass fabric is lightweight and does not add significant weight to a structure or component. This makes it the preferred choice for applications where weight is a critical factor.4. Corrosion-resistant: The fiberglass material used in the fabric is highly resistant to corrosion and degradation from exposure to the elements. This makes it ideal for use in harsh environments, such as marine applications.5. Thermal stability: 3D fiberglass fabric is also highly resistant to and able to withstand high temperatures. This makes it suitable for application in industrial processes where heat is a significant factor.Industry Adoption and Applications3D fiberglass fabric has already been adopted by several industries worldwide. Its unique properties make it ideal for a range of applications, including:- Aerospace: 3D fiberglass fabric is being used in the production of lightweight and durable components for aircraft. Its high strength and lightweight properties make it ideal for use in the aerospace industry.- Automotive: The automotive industry is using 3D fiberglass fabric to produce lightweight and durable components for cars, trucks, and other vehicles. This helps improve fuel efficiency and reduce emissions.- Marine: 3D fiberglass fabric is being used to produce corrosion-resistant components for boats and ships. Its ability to withstand exposure to saltwater and harsh environments makes it a preferred choice for marine applications.- Construction: The material is used in the production of lightweight and durable composite structures such as beams, columns, slabs, and walls.- Sports and leisure: 3D fiberglass fabric has become popular in the production of sports equipment, such as helmets, paddles, boats, and bicycles.- Oil and Gas: The ability of the material to withstand high temperatures makes it ideal for use in the oil and gas industry.Company IntroductionThe leading 3D fiberglass fabric manufacturer under the brand name (name) is a trusted and reputable supplier of high-quality 3D fiberglass fabric. Our products are manufactured using state-of-the-art technology and the highest quality materials. Our team of experienced technicians is dedicated to providing our clients with personalized service and support to ensure that their specific needs are met.ConclusionThe textile industry is continually evolving, with new and innovative products entering the market. 3D Fiberglass Fabric is the latest innovative product, and it has already proven invaluable to many industries due to its unique properties. We can expect to see further applications for this material in the future as industries continue to explore its potential. If you are looking for high-quality 3D fiberglass fabric, contact us today to learn more about our products and services.

Understanding the Benefits and Uses of Woven Fiberglass Sheets

[Company Name] Revolutionizes the Textile Industry with Woven Fiberglass Sheets[City], [Date] - The textile industry has witnessed a groundbreaking development with the introduction of [Company Name]'s innovative Woven Fiberglass Sheets. These sheets, made from high-quality fiberglass materials, are now poised to revolutionize multiple sectors that rely on textiles, including construction, automotive, aerospace, and more. With unique properties and exceptional performance, these products are set to redefine the standards of strength, durability, and versatility.[Company Name] is a visionary leader in textile manufacturing, known for its commitment to innovation and excellence. Leveraging years of experience and expertise in the industry, they have successfully developed Woven Fiberglass Sheets that offer unparalleled strength and stability. Designed for a wide range of applications, these sheets are engineered to withstand extreme conditions and provide long-lasting performance.One of the key advantages of [Company Name]'s Woven Fiberglass Sheets is their incredible strength-to-weight ratio. The inherent strength of fiberglass combined with the advanced weaving technique used by [Company Name] ensures that these sheets can withstand high loads and pressures while remaining lightweight. This makes them an ideal choice for industries where strength and durability are of utmost importance.Moreover, the woven pattern of these fiberglass sheets adds an extra layer of reinforcement, enhancing their structural integrity. This unique construction allows for better load distribution and increased resistance to impacts, making them highly sought after in the construction and transportation industries. From reinforcing concrete structures to replacing traditional metal components, [Company Name]'s Woven Fiberglass Sheets offer endless possibilities for architects, engineers, and designers.In addition to their strength, these sheets also possess exceptional thermal and electrical insulation properties. Fiberglass is known for its low thermal conductivity, which means that [Company Name]'s Woven Fiberglass Sheets can effectively reduce heat transfer. This makes them an excellent choice for insulation applications in buildings and industrial equipment. Furthermore, their electrical insulation properties make them suitable for various electrical and electronic applications, where safety and reliability are paramount.Another remarkable feature of [Company Name]'s Woven Fiberglass Sheets is their resistance to corrosion and chemicals. Unlike traditional textile materials that may deteriorate when exposed to harsh environments, these sheets exhibit excellent chemical resistance, allowing them to withstand acids, alkalis, and solvents. This durability makes them invaluable in industries such as chemical processing, oil and gas, and marine, where exposure to corrosive substances is common.Furthermore, the versatility of [Company Name]'s Woven Fiberglass Sheets makes them suitable for a wide range of applications. They can be easily molded, cut, and shaped according to specific requirements, providing endless design possibilities and customization options. Architects can create unique structures, engineers can develop complex components, and manufacturers can optimize production processes, all thanks to the flexibility and adaptability of these innovative sheets.The introduction of [Company Name]'s Woven Fiberglass Sheets signifies a significant milestone in the textile industry. With their exceptional strength, durability, and versatility, these products are set to disrupt multiple sectors and enhance the performance of various applications. As a pioneer in textile manufacturing, [Company Name] continues to drive innovation to meet the evolving needs of industries globally.

New Colored Carbon Fiber Fabric Now Available in the Market

Colored carbon fiber fabric takes the textile world by stormThe textile industry, like many other sectors, constantly seeks to innovate and incorporate new materials into their portfolio. One such industry that has experienced a significant shift is the carbon fiber fabric market. Carbon fiber fabrics are widely used in several industries, including aerospace, automotive, and sporting goods. They have gained popularity due to their amazing attributes, such as lightweight, high tensile strength, stiffness, and chemical resistance, making them ideal for various applications.A few years ago, colored carbon fiber fabric entered the market, marking the onset of a new era. Unlike traditional carbon fiber, which has a dark black hue, colored carbon fiber is vibrant and captivating. The new fabric has been warmly embraced as it offers a wide range of aesthetically pleasing possibilities. The fabrics are a favorite of high-end fashion designers and luxury brands who have incorporated it into their collections, giving their products a sophisticated look. One company that has excelled in producing the colored carbon fiber fabric is the {remove brand name} firm. They have made a significant impact in the market due to their unmatched flair and creativity in the production process. According to Tim Smith, the company's COO, the colored carbon fiber fabric is achieved by introducing colored films in the weaving process that gives the fiber added color. The result is a weave of colored carbon fiber textiles that match the color scheme of a customer's specification.The new fabric has found its way into numerous industries and applications, as companies seek to augment their products with a touch of elegance and class. For example, car enthusiasts can use the colored carbon fiber to indulge in their car's customization, giving it a personal flair that catches the eye. As for sports enthusiasts, brands use the carbon fiber fabric to produce superior quality sports equipment that is both lightweight and durable.One crucial benefit of this new fabric is the wide range of design options available. The carbon fiber fabric can be further enhanced with added patterns and textures to create more complex structures. This versatility in design vastly expands the range of applications the carbon fiber fabric can be used in, making it a top choice in the market. But it's not all about aesthetics; the colored carbon fiber fabric holds immense value in various applications that require durable materials. The colored carbon fiber fabric has extensive use in the aerospace industry as it is lightweight, yet strong enough to meet the high safety standards required. Since the fabric's introduction into the market, the aerospace industry has embraced it as the go-to material for a variety of applications. Another industry that has reaped the benefits of the new fabric is the marine industry. The colored carbon fiber fabric's unique properties make it the ideal material for boat-building as it offers durability and high-performance capabilities in harsh environments. Furthermore, the fabric's moisture-resistant properties prolong its lifespan, making it a sound investment for boat owners. In the medical industry, the colored carbon fiber fabric has found even more applications. The material is ideal for making prosthetics as it is lightweight and durable. It can be used in artificial limbs to provide amputees with a more comfortable and mobile life. The colored carbon fiber fabric in prosthetics has also found application in the entertainment industry, where it is used to create realistic-looking props and costumes. The colored carbon fiber fabric has created a whole new world of possibilities for the textile industry. It offers both elegance and functionality, combining aesthetics and durability. The fabric's range of applications and design options has made it a top choice in many industries, and its future only seems to shine brighter. According to {remove brand name}'s Tim Smith, with the increased focus on sustainability and eco-friendliness, they have embarked on developing eco-friendly colored carbon fiber fabric. This move is aimed at ensuring that the company conforms to the industry's sustainability guidelines and reduces its carbon footprint. The company plans to introduce this new material in the market soon, and the textile industry is eagerly waiting for it. In conclusion, the colored carbon fiber fabric is an exceptional innovation that has transformed the textile industry. Its lightweight, strong, and aesthetically appealing properties make it diverse, resulting in its extensive application in various sectors. With the development of eco-friendly materials, the colored carbon fiber industry is well-positioned to pave the way for a more sustainable future.

New Carbon Cloth Technology: A Breakthrough in Sustainable Materials

Carbon Cloth, also known as carbon fiber fabric, is a high-tech, advanced material that is gaining popularity for its lightweight and durable properties. It is made from carbon fiber, which is known for its high tensile strength, low weight, high temperature tolerance, and low thermal expansion. The use of carbon cloth is diverse, ranging from aerospace and automotive applications to sports equipment and consumer electronics.[Company Name] is a leading manufacturer and supplier of carbon cloth, specializing in producing high-quality carbon fiber fabric for various industrial and commercial uses. The company has a team of experienced professionals and state-of-the-art facilities that allow them to produce carbon cloth in different weaves, weights, and finishes to meet the specific needs of their customers.The carbon cloth produced by [Company Name] is used in a wide range of applications. In the aerospace industry, it is used to manufacture lightweight, high-strength parts for aircraft and spacecraft. The automotive industry employs carbon cloth to create body panels, interior components, and other structural parts to reduce vehicle weight and improve fuel efficiency. In the sports and leisure sector, carbon cloth is used to make high-performance bicycles, tennis rackets, and golf clubs, as well as in the construction of sailing yachts and racing boats. Additionally, carbon cloth is used in the production of consumer electronics, such as laptop cases, phone cases, and other products that benefit from its lightweight and durable nature.The carbon cloth produced by [Company Name] undergoes a rigorous quality control process to ensure that it meets the highest industry standards. The company uses advanced manufacturing techniques and cutting-edge technology to create carbon cloth with consistent quality and performance. They also work closely with their customers to understand their specific requirements and provide tailored solutions to meet their needs.In addition to their commitment to quality, [Company Name] also prioritizes sustainability and environmental responsibility in their production processes. The company invests in eco-friendly production methods and continuously seeks to minimize their carbon footprint. Their dedication to sustainability has earned them a reputation as a responsible and ethical supplier of carbon cloth.One of the key advantages of carbon cloth is its exceptional strength-to-weight ratio, which makes it an ideal material for lightweight, high-performance applications. Compared to other traditional materials like steel and aluminum, carbon cloth offers superior strength and durability while being significantly lighter. This makes it a popular choice in industries that require strong yet lightweight components, such as aerospace and automotive manufacturing.Another advantage of carbon cloth is its versatility. It can be manufactured in a variety of weaves and finishes to meet the specific requirements of different applications. Whether the application demands a plain weave for a smooth surface finish or a twill weave for a more decorative appearance, carbon cloth can be tailored to meet these needs. It can also be combined with other materials, such as resin, to create composite materials that offer even greater performance and functionality.The demand for carbon cloth is expected to continue growing as industries increasingly seek lightweight, durable, and high-performance materials for their products. With their expertise and commitment to quality, [Company Name] is well-positioned to meet this demand and provide customers with the high-quality carbon cloth they need.In conclusion, carbon cloth is a valuable and versatile material that offers a wide range of benefits in various industries. As a leading manufacturer and supplier of carbon cloth, [Company Name] plays a crucial role in meeting the growing demand for this advanced material. With their dedication to quality, sustainability, and customer satisfaction, [Company Name] is poised to remain a key player in the carbon cloth industry for years to come.

Top Lightweight Fiberglass Cloth for Versatile Use

[Company Name], Leading Provider of Lightweight Fiberglass Cloth, Revolutionizes the Industry with its Cutting-Edge Solution[CITY], [DATE] - [Company Name], a dynamic and innovative leader in the production of advanced materials, has recently launched its latest product – a game-changing Lightweight Fiberglass Cloth. This revolutionary solution is set to transform multiple industries, including aerospace, automotive, and construction.[Company Name] has always been at the forefront of research and development to provide the market with high-performance materials. Their new Lightweight Fiberglass Cloth is a testament to their commitment to innovation and pushing boundaries. This cutting-edge product offers a wide range of advantages that make it a superior choice over traditional cloth options.One of the standout features of [Company Name]'s Lightweight Fiberglass Cloth is its exceptional strength-to-weight ratio. The cloth is engineered using an advanced manufacturing process that ensures it remains lightweight while offering unparalleled strength and durability. This characteristic makes it a preferred choice in industries where weight reduction is essential, such as aerospace and automotive manufacturing.Moreover, [Company Name]'s Lightweight Fiberglass Cloth boasts excellent thermal and electrical insulation properties. This feature makes it highly desirable for applications in the construction industry, where insulation is crucial for energy efficiency and comfort. The cloth's ability to resist heat penetration ensures optimum thermal regulation, leading to reduced energy consumption and lower carbon footprints.The manufacturing process of the Lightweight Fiberglass Cloth also ensures its exceptional corrosion resistance. Traditional cloth materials often succumb to the harmful effects of corrosion over time, compromising their structural integrity. However, the specialized manufacturing techniques employed by [Company Name] provide the cloth with a powerful shield against corrosion, prolonging its lifespan and reducing maintenance costs significantly.[Company Name]'s commitment to sustainability is also evident in the production of their Lightweight Fiberglass Cloth. The cloth is crafted using eco-friendly materials and adheres to strict environmental standards throughout the manufacturing process. By reducing the carbon footprint associated with traditional cloth manufacturing, [Company Name] is positioning itself as a responsible and forward-thinking company.Furthermore, [Company Name] aims to ensure that their customers experience a seamless integration of the Lightweight Fiberglass Cloth into their manufacturing processes. To achieve this, the company offers comprehensive support services, including technical guidance, training seminars, and even customized solutions to suit specific applications. Regardless of the size or complexity of the project, [Company Name] ensures that their customers receive the necessary assistance to maximize the benefits of the Lightweight Fiberglass Cloth.With the introduction of their Lightweight Fiberglass Cloth, [Company Name] has set the benchmark for excellence in the industry. Its exceptional attributes and numerous applications have garnered attention from major players across various sectors. Customers are already witnessing significant improvements in product performance and cost savings by replacing their traditional cloths with [Company Name]'s groundbreaking solution.By continuously investing in research and development, [Company Name] demonstrates its commitment to pioneering the next generation of high-performance materials. The company's Lightweight Fiberglass Cloth exemplifies its relentless pursuit of innovation and the desire to provide customers with superior products that drive efficiency and sustainability.As the industry continues to applaud [Company Name]'s groundbreaking solutions, it is clear that the Lightweight Fiberglass Cloth is transforming the landscape of materials used in multiple sectors. The future of lightweight materials is in the hands of [Company Name], and they are gearing up to revolutionize industries, one fiber at a time.About [Company Name]:[Company Name], founded in [YEAR], is a leading provider of advanced materials, specializing in the production of high-performance fibers and fabrics. With a strong focus on innovation and customer satisfaction, [Company Name] has established itself as a renowned name in the industry. Their products are known for their exceptional quality, durability, and cutting-edge technology. Through extensive research and development, [Company Name] continues to redefine industry standards and provide market-leading solutions. For more information, please visit [www.companywebsite.com].

Ultimate Guide to Plain Weave Carbon Fiber: Benefits, Applications, and Uses

Plain Weave Carbon Fiber is a high-performance material that is increasingly being used in a variety of industries for its strength, lightweight properties, and resistance to corrosion. This advanced material is manufactured by the company (need remove brand name), a leader in the production of carbon fiber products.The company (need remove brand name) has been at the forefront of carbon fiber technology for over a decade, continually innovating and pushing the boundaries of what is possible with this remarkable material. Their expertise in creating Plain Weave Carbon Fiber has made them a trusted supplier to industries such as aerospace, automotive, marine, and sports equipment. The superior strength-to-weight ratio of Plain Weave Carbon Fiber makes it an ideal choice for applications where durability and performance are paramount. In the aerospace industry, this material is used to produce aircraft components that need to withstand extreme conditions while still being as lightweight as possible. The automotive industry also benefits from the use of Plain Weave Carbon Fiber in the manufacturing of body panels, trim pieces, and even entire vehicle chassis to improve fuel efficiency and performance. Moreover, the marine industry utilizes Plain Weave Carbon Fiber in the construction of boat hulls and other structural components to provide increased strength and reduce weight, allowing for faster and more fuel-efficient vessels. Additionally, in the sports equipment industry, Plain Weave Carbon Fiber is utilized in the production of high-performance bicycle frames, tennis rackets, golf club shafts, and more, providing athletes with a competitive edge.The unique properties of Plain Weave Carbon Fiber, coupled with the expertise and precision of the company (need remove brand name) have made this material an essential choice for numerous applications. By utilizing the latest manufacturing techniques and technology, (need remove brand name) consistently produces Plain Weave Carbon Fiber products that exceed industry standards and customer expectations.In addition to their advanced manufacturing capabilities, (need remove brand name) provides comprehensive customer support throughout the entire production process. From initial concept and design to final product delivery, their team works closely with clients to ensure that their specific needs and requirements are met. This commitment to excellence has earned the company (need remove brand name) a strong reputation as a reliable and trusted partner in the carbon fiber industry.With a focus on sustainability and environmental responsibility, the company (need remove brand name) is also dedicated to reducing their carbon footprint and minimizing waste during the manufacturing process. By investing in eco-friendly practices and using cutting-edge technology, (need remove brand name) strives to be a leader in environmentally conscious manufacturing within the carbon fiber industry.Looking ahead, (need remove brand name) is committed to further expanding their product offerings and capabilities to meet the evolving needs of their customers. With ongoing research and development, the company continues to explore new applications and uses for Plain Weave Carbon Fiber, ensuring that they remain at the forefront of innovation in the industry.In conclusion, Plain Weave Carbon Fiber, manufactured by (need remove brand name), is a high-performance material that is revolutionizing numerous industries with its exceptional strength, lightweight properties, and durability. With a track record of excellence and a commitment to innovation, the company (need remove brand name) is poised to continue leading the way in the production of advanced carbon fiber products for years to come.

Understanding the Characteristics of Carbon-fiber Composites

Title: Exploring the Marvels of Fiber Carbon Cloth: Revolutionizing the World of CompositesIntroduction (70 words):Welcome to our extensive guide on the revolutionary material that is fiber carbon cloth. In this blog, we will delve deep into the world of this incredible composite, exploring its various applications and highlighting its remarkable traits. From its woven fibrous construction to its resiliency, versatility, and strength, fiber carbon cloth has emerged as a game-changer in multiple industries. So, without further ado, let's unravel the secrets behind this remarkable material!Understanding Fiber Carbon Cloth (100 words):Fiber carbon cloth is a fibrous carbon composite that has revolutionized countless industries in recent years. It begins with individual strands woven into a rough cloth, which is then carefully impregnated with epoxy resin after molding it into desired shapes. This combination produces a material boasting exceptional strength-to-weight ratio, rigidity, and high tensile strength. Fiber carbon cloth owes its incredible properties to the unique arrangement of carbon fibers that form its core structure. Now, let's explore the remarkable benefits and applications of this cutting-edge material.Applications and Advantages (250 words):1. Aerospace Industry:In the aerospace industry, fiber carbon cloth finds extensive use due to its lightweight, high strength, and excellent resistance to high temperatures and impacts. It enhances fuel efficiency in aircraft, reduces structural weight, and improves overall performance. From aircraft frames to wings, fiber carbon cloth has become an integral component in the manufacturing process.2. Automotive Industry:In the automotive sector, fiber carbon cloth is employed in the production of high-performance vehicles. By utilizing this material in car manufacturing, automotive companies can reduce weight, enhance fuel efficiency, and improve structural integrity. Carbon fiber components, such as hoods, fenders, and body panels, are gaining popularity due to their striking aesthetics and outstanding performance.3. Sports and Recreation:From professional sports equipment to recreational products, the sports industry has embraced fiber carbon cloth for its durability and lightness. Tennis rackets, bicycles, golf clubs, helmets, and ski poles are just a few examples of sporting goods that utilize carbon fiber composites for superior performance and reduced weight.4. Construction and Infrastructure:In the construction field, fiber carbon cloth helps strengthen existing structures by acting as reinforcement in concrete and other building materials. Its lightweight nature and high strength allow for efficient and long-lasting construction projects while reducing material usage. Additionally, fiber carbon cloth is increasingly used in earthquake-resistant building designs and bridge construction.5. Renewable Energy:The renewable energy sector has also recognized fiber carbon cloth as an ideal material for producing enhanced wind turbine blades. Its low weight and high strength characteristics enable turbines to convert wind energy more efficiently, contributing to the sustainable energy movement.Keywords: Fiber Carbon Cloth, carbon fiber composite, woven carbon fibers, strength-to-weight ratio, aerospace industry, automotive industry, sports and recreation, construction, infrastructure, renewable energyConclusion (80 words):Fiber carbon cloth has revolutionized various sectors, thanks to its exceptional strength, lightweight nature, and versatility. Industries such as aerospace, automotive, sports, construction, and renewable energy have witnessed significant advancements thanks to this game-changing material. As technology continues to advance, we can expect further innovations in the field of fiber carbon cloth, leading to new breakthroughs and applications across different industries. This remarkable composite will undoubtedly play a crucial role in shaping our future.

High-quality fiberglass cloth for various applications on the market

E Glass Fiberglass Cloth, a high-quality material used in a variety of industries, is making waves in the manufacturing world. From automotive to aerospace, this durable and versatile material has become a staple in many production processes. One company that has been at the forefront of this innovation is {Company Name}.{Company Name} is a leading producer of E Glass Fiberglass Cloth, providing top-notch quality and innovative solutions for a wide range of applications. With a focus on research and development, {Company Name} has been able to stay ahead of the competition and provide cutting-edge products to its customers.E Glass Fiberglass Cloth is known for its strength, durability, and resistance to heat and chemicals. This makes it an ideal material for industries such as automotive, aerospace, construction, and marine. It is widely used in the production of composites, insulation, and reinforcement materials.One of the key advantages of E Glass Fiberglass Cloth is its versatility. It can be used in a variety of forms, including woven, knitted, and coated, to suit different manufacturing needs. This flexibility makes it an attractive choice for many companies looking for reliable and high-performing materials.{Company Name} has a strong focus on quality control and testing, ensuring that their E Glass Fiberglass Cloth meets the highest standards in terms of performance and reliability. Their state-of-the-art manufacturing facilities and experienced team of engineers and technicians enable them to produce consistent and top-quality products.In addition to their commitment to quality, {Company Name} also emphasizes sustainability in their production processes. They have implemented eco-friendly practices to minimize their environmental impact and promote a more sustainable future for the industry.One of the recent developments from {Company Name} is their introduction of advanced coatings for E Glass Fiberglass Cloth. These coatings provide additional properties such as fire resistance, water repellency, and improved adhesion for specific applications. This innovation has expanded the potential uses of E Glass Fiberglass Cloth and opened up new opportunities for their customers.Another area where {Company Name} has excelled is in their customer service and technical support. Their team of experts is dedicated to providing tailored solutions and assisting their clients in finding the most suitable products for their needs. This personalized approach has earned them a strong reputation in the industry and has led to long-lasting partnerships with their customers.Looking ahead, {Company Name} is poised to continue its leadership in the E Glass Fiberglass Cloth market. With a focus on innovation, sustainability, and customer satisfaction, they are well-positioned to meet the evolving needs of the manufacturing industry and drive further advancements in the field.In conclusion, E Glass Fiberglass Cloth is a vital component in various industries, and {Company Name} has established itself as a leading provider in this market. With a strong commitment to quality, innovation, and customer service, they are well-equipped to meet the demands of the industry and drive future developments in the field of E Glass Fiberglass Cloth.

24oz Vermiculite Coated Fiberglass Cloth: A Fire and Chemical Resistant Solution for High Temperature Insulation and Welding Applications

Acmetex Inc Launches Revolutionary 24oz Vermiculite Coated Fiberglass ClothAcmetex Inc, a leading manufacturer of high-performance fiberglass cloth and textile products, has announced the launch of its latest innovation, the 24oz Vermiculite Coated Fiberglass Cloth. This new product brings cutting-edge technology and design to the market, providing customers with an advanced and reliable solution for their high-temperature insulation and fire-resistant needs.Acmetex's 24oz Vermiculite Coated Fiberglass Cloth is made from continuous texturized E-fiberglass yarns, which offer exceptional strength and durability. These yarns are woven together to create a tight, dense fabric that can withstand high temperatures and harsh conditions. Vermiculite coating is added to the cloth to improve abrasion resistance and add an extra layer of protection against direct flame.Heat travels across the fabric, not through it, making this product an excellent choice for high-temperature insulation and heat shield applications. It provides superior thermal insulation, keeping heat from escaping and cold from seeping in, making it ideal for use in welding blankets, curtains, and expansion joints. The vermiculite coating also improves the cloth's strength and resistance to tearing, making it a great option for high-stress applications.Acmetex Inc has been a leading manufacturer of fiberglass cloth and textile products for over 20 years. The company has a proven track record of providing high-quality solutions to customers across a wide range of industries, including automotive, aerospace, marine, and construction. Acmetex's commitment to innovation and quality has made it a trusted partner for many leading companies in these industries."We are excited to launch our latest innovation, the 24oz Vermiculite Coated Fiberglass Cloth," said a spokesperson for Acmetex Inc. "This new product is a testament to our commitment to providing our customers with the highest quality solutions for their needs. We believe that this product will be a game-changer in the market, and we are confident that it will be very well received by our customers."Acmetex's 24oz Vermiculite Coated Fiberglass Cloth is available in a variety of widths and lengths, making it suitable for a wide range of applications. It is also customizable, allowing customers to tailor the fabric to meet their specific needs. The product is expected to be available for purchase on Acmetex's website and through its authorized distributors in the coming weeks.In conclusion, Acmetex Inc's 24oz Vermiculite Coated Fiberglass Cloth is a breakthrough product that offers exceptional strength, durability, and fire-resistant properties. It is a testament to the company's commitment to innovation and quality and a clear demonstration of its ability to bring cutting-edge solutions to the market. This product is sure to be a game-changer and a valuable asset for customers across a wide range of industries.