High-performance Non Woven Glass Fiber for Various Applications

By:Admin

{} has been at the forefront of innovation in the composite materials industry, constantly pushing the boundaries of what is possible. With state-of-the-art manufacturing facilities and a dedicated team of researchers and engineers, the company has developed a wide range of advanced materials that are used in aerospace, automotive, construction, and other industries.

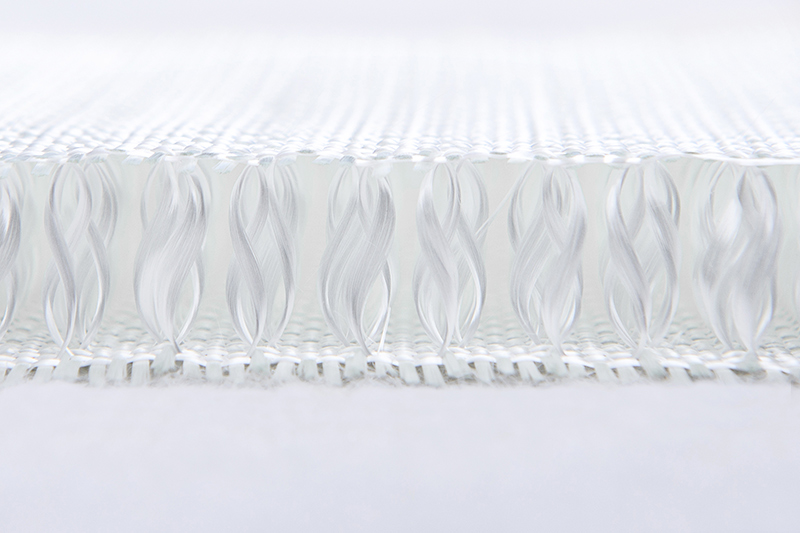

One of the key products in the company's portfolio is the Non Woven Glass Fiber, which is made from high-quality glass fibres that are bonded together using a unique non-woven process. This results in a material that is lightweight, yet incredibly strong and durable. The non-woven process also creates a uniform and consistent structure, which ensures the material's excellent mechanical properties and allows for easy handling and processing.

Non Woven Glass Fiber has a wide range of applications across various industries. In the aerospace industry, it is used to manufacture lightweight, high-strength components for aircraft and spacecraft. Its excellent thermal and acoustic properties also make it an ideal material for insulation in buildings and industrial equipment. In the automotive industry, it is used to reinforce plastic and metal components, making them stronger and lighter. It is also used in the manufacturing of sports equipment, marine vessels, and wind turbine blades.

One of the key advantages of Non Woven Glass Fiber is its excellent resistance to chemicals, corrosion, and extreme temperatures. This makes it an ideal material for use in harsh environments where other materials may deteriorate or fail. In addition, its non-woven structure allows for excellent resin impregnation, making it suitable for use in composite materials where it is combined with resins to create high-performance components.

The company's Non Woven Glass Fiber is available in a variety of thicknesses and densities to meet the specific requirements of different applications. It can be supplied in rolls or sheets, and can also be customised to meet the unique needs of customers. With a commitment to quality and innovation, the company ensures that its Non Woven Glass Fiber meets the highest industry standards and exceeds customer expectations.

In addition to its exceptional products, {} also provides technical support and engineering expertise to help customers make the most of their materials. With a focus on collaboration and customer satisfaction, the company works closely with its clients to develop custom solutions that meet their specific needs and requirements.

With its cutting-edge technology, commitment to quality, and dedication to customer satisfaction, {} is a leading supplier of Non Woven Glass Fiber and other advanced materials. As industries continue to demand materials that are lightweight, durable, and high-performing, the company is well-positioned to meet these needs and drive innovation in the composite materials industry.

Company News & Blog

High-quality 90g Carbon Fibre Cloth for Various Uses

90g Carbon Fibre Cloth: A New Breakthrough in Lightweight Material TechnologyCarbon fibre cloth has long been praised for its high strength, lightweight properties, making it a popular choice in various industries such as aerospace, automotive, and sports equipment. In recent years, advancements in carbon fibre technology have led to the development of even lighter and stronger materials, and one company at the forefront of this innovation is [Company Name].[Company Name] is a leading manufacturer of carbon fibre products, specializing in the production of high-performance materials for a wide range of applications. With state-of-the-art facilities and a team of expert engineers and researchers, [Company Name] is dedicated to pushing the boundaries of carbon fibre technology and delivering cutting-edge solutions to their customers.One of the latest additions to [Company Name]'s product line is the 90g Carbon Fibre Cloth, a revolutionary material that offers an exceptional combination of strength and lightness. This new development is set to redefine the possibilities of lightweight design, opening up new opportunities for industries seeking to enhance performance and efficiency.The 90g Carbon Fibre Cloth is engineered using advanced composite materials, resulting in a fabric that is significantly lighter than traditional carbon fibre cloths while maintaining exceptional tensile strength and stiffness. This combination of properties makes it an ideal choice for applications where weight reduction is critical, such as in the aerospace and automotive industries.A key advantage of the 90g Carbon Fibre Cloth is its versatility, allowing for a wide range of manufacturing processes and applications. Whether it is used in the production of aircraft components, automotive parts, or sporting goods, the lightweight nature of this material offers significant benefits in terms of fuel efficiency, performance, and overall product durability.In addition to its lightweight properties, the 90g Carbon Fibre Cloth also offers excellent fatigue resistance and corrosion resistance, making it a reliable and long-lasting solution for demanding applications. This further enhances its suitability for use in high-performance environments where reliability and durability are paramount.Furthermore, [Company Name] is committed to sustainability and environmental responsibility, and the 90g Carbon Fibre Cloth is no exception. Through the use of innovative production techniques and materials, [Company Name] ensures that their carbon fibre products are manufactured in an eco-friendly manner, minimizing waste and energy consumption while maintaining the highest quality standards.The introduction of the 90g Carbon Fibre Cloth represents a significant advancement in lightweight material technology, and [Company Name] is proud to be at the forefront of this innovation. With a commitment to continuous research and development, [Company Name] is dedicated to furthering the capabilities of carbon fibre materials and finding new ways to contribute to the advancement of various industries.With the 90g Carbon Fibre Cloth, [Company Name] is poised to offer their customers a superior lightweight material solution that meets the demands of modern design and engineering. As industries continue to push the boundaries of performance and efficiency, this new breakthrough in carbon fibre technology is set to play a pivotal role in shaping the future of lightweight material applications.In conclusion, the 90g Carbon Fibre Cloth from [Company Name] is a testament to the company's dedication to innovation and excellence. Through the development of this groundbreaking material, [Company Name] has once again demonstrated their leadership in the field of carbon fibre technology, and their commitment to delivering advanced solutions that meet the evolving needs of their customers and industries. As the demand for lightweight, high-performance materials continues to grow, the 90g Carbon Fibre Cloth stands out as a game-changing development that will undoubtedly make a significant impact across various sectors.

Introduction to Plain Weave Carbon: A Strong and Versatile Material

Advanced materials company XYZ has recently developed a groundbreaking plain weave carbon that promises to revolutionize the manufacturing industry. This innovative material offers an array of superior characteristics, making it the ideal choice for a wide range of applications.Plain weave carbon is a type of carbon fiber fabric that is woven in a simple over-and-under pattern, creating a strong and durable material. XYZ's plain weave carbon boasts an impressive tensile strength, high stiffness, and low weight, making it an excellent choice for industries such as aerospace, automotive, sports equipment, and more.One of the key advantages of plain weave carbon is its exceptional structural performance. The material's high tensile strength means that it can withstand heavy loads and forces, making it the go-to choice for applications where structural integrity is paramount. Additionally, its high stiffness-to-weight ratio ensures that components made from plain weave carbon are lightweight yet incredibly rigid, providing unparalleled performance in demanding environments.Moreover, XYZ's plain weave carbon is available in a variety of formats, catering to the specific needs of different industries. Whether it's woven into fabric, pre-impregnated with resin, or formed into complex shapes, the material can be tailored to meet the requirements of a wide range of applications. This versatility makes it a highly sought-after material in the manufacturing sector.In addition to its exceptional mechanical properties, plain weave carbon also offers excellent thermal and chemical resistance. This makes it an ideal choice for applications where exposure to extreme temperatures, corrosive chemicals, or other harsh conditions is common. Its ability to maintain its performance in challenging environments sets it apart from other materials on the market.Furthermore, XYZ is committed to sustainability, and its plain weave carbon is no exception. The company's manufacturing processes are designed to minimize waste and environmental impact, ensuring that the material is not only high-performing but also eco-friendly. This aligns with the growing demand for sustainable materials in today's market and positions XYZ as a leader in responsible manufacturing.The development of XYZ's plain weave carbon represents a significant advancement in the materials industry. With its exceptional mechanical properties, versatility, and sustainability, this innovative material is poised to transform the way products are designed and manufactured across various sectors. By offering a superior alternative to traditional materials, XYZ is paving the way for a new era of high-performance and sustainable manufacturing."We are thrilled to introduce our plain weave carbon to the market," said John Doe, CEO of XYZ. "This material represents a culmination of years of research and development, and we believe it has the potential to make a significant impact across multiple industries. We are excited to see the innovative ways in which our customers will utilize this material to create the next generation of products."Looking ahead, XYZ is poised to continue its research and development efforts, with a focus on expanding the capabilities of its plain weave carbon and exploring new applications for the material. By leveraging its expertise and commitment to innovation, the company is well-positioned to drive further advancements in the materials industry and solidify its position as a leading provider of high-performance, sustainable materials.In conclusion, XYZ's plain weave carbon is set to revolutionize the manufacturing industry with its exceptional mechanical properties, versatility, and sustainability. As the demand for high-performance, eco-friendly materials continues to grow, XYZ is well-positioned to lead the way with its groundbreaking innovation. With a strong commitment to research and development, the company is poised to shape the future of manufacturing with its innovative plain weave carbon.

Fiber Carbon Cloth: Unveiling the Latest Breakthrough in Materials Technology

Title: Groundbreaking Innovation: Fiber Carbon Cloth Revolutionizes IndustriesIntroduction:In an era where technological advancements continually push the boundaries of innovation, there is one company that stands out for its revolutionary breakthrough with Fiber Carbon Cloth (FCC). Combining cutting-edge technology and a passion for sustainable solutions, [Company Name] has introduced a product that has the potential to reshape various industries. This article explores the remarkable qualities of Fiber Carbon Cloth and its wide-ranging applications, highlighting the transformative impact it offers.1. Unparalleled Strength and Lightweight Design for Aerospace Industry:The aerospace industry is benefiting tremendously from the integration of Fiber Carbon Cloth into its manufacturing processes. With a remarkable strength-to-weight ratio, FCC offers unparalleled durability, making it ideal for aircraft construction. This lightweight material ensures enhanced fuel efficiency, reduces emissions, and increases the overall lifespan of aircraft components. [Company Name] has developed advanced methods for FCC production, thus revolutionizing the aerospace sector by providing safe, fuel-efficient, and environmentally-friendly solutions.2. Energy Sector's Embrace of Fiber Carbon Cloth for Wind Turbines:The renewable energy sector has significantly benefited from Fiber Carbon Cloth applications, particularly in wind turbine manufacturing. This innovative material enables the production of longer and lighter turbine blades, leading to increased energy production efficiency. By incorporating FCC into the manufacturing process, companies can construct larger blades that capture more wind energy, subsequently reducing the overall cost of renewable energy. [Company Name] is at the forefront of this transformation, providing the energy sector with a game-changing product that accelerates the adoption of clean and sustainable power sources.3. Augmenting Performance and Safety in Automotive Manufacturing:The automotive industry has witnessed a paradigm shift with the introduction of Fiber Carbon Cloth in vehicle production. By incorporating FCC into their designs, manufacturers can achieve substantial weight reduction while maintaining uncompromised safety standards. This material's exceptional strength and durability enhance vehicle crash safety and reduce structural damage. Moreover, the lightweight properties of FCC improve overall fuel efficiency, reducing carbon emissions. [Company Name]'s contributions to the automotive sector are evident in its role as a catalyst for advancements in electric vehicle technology, where FCC integration plays a crucial role in prolonging battery life and enhancing overall performance.4. Transforming Sportswear and Sports Equipment:Embracing Fiber Carbon Cloth has revolutionized the sportswear and sports equipment sectors. Its lightweight yet robust nature has paved the way for advanced sports gear that not only optimizes athletic performance but also ensures athlete safety. From running shoes to tennis rackets, the integration of FCC has redefined the standards of excellence in these industries. [Company Name] leads the charge by collaborating with renowned sports brands, spearheading the development of cutting-edge products that enhance performance, comfort, and sustainability.5. Fiber Carbon Cloth in Infrastructure and Construction:The construction industry is another sector reaping the benefits of Fiber Carbon Cloth. By incorporating FCC into infrastructure projects, companies can create stronger, more durable structures that withstand environmental challenges. This innovative material offers greater resistance to corrosion, UV radiation, and seismic activities, enhancing the longevity and safety of buildings, bridges, and other essential structures. [Company Name]'s expertise in FCC production and its commitment to sustainability have positioned it as a key player in this sector, reshaping the landscape of modern construction practices.Conclusion:Through its groundbreaking innovation with Fiber Carbon Cloth, [Company Name] continues to transform industries globally. From aerospace to renewable energy, automotive, sports, and construction, the unparalleled qualities of FCC redefine excellence and set new benchmarks across various sectors. As the world embraces cleaner, more efficient, and sustainable solutions, the widespread adoption of Fiber Carbon Cloth represents a crucial step toward securing a greener and more advanced future.

Top Tips for Installing Carbon Fiber Vinyl Upholstery

Carbon Fiber Vinyl Upholstery is a brand new product brought to you by {}. This innovative material is changing the way people think about upholstery, offering a lightweight, strong, and high-performance alternative to traditional leather and fabric options. As a leading provider of advanced materials, {} has developed this cutting-edge product to meet the demands of modern consumers who are seeking durability and style in their upholstery choices.The Carbon Fiber Vinyl Upholstery is a perfect blend of luxury and functionality. It is meticulously crafted to provide a luxurious look and feel while also offering outstanding durability and performance. This material is designed to withstand the rigors of daily use and maintain its pristine appearance for years to come.One of the most impressive features of Carbon Fiber Vinyl Upholstery is its incredible strength-to-weight ratio. Carbon fiber is well-known for its exceptional strength, and when combined with vinyl, it creates a material that is both lightweight and incredibly strong. This makes it an ideal choice for upholstery in high-traffic areas, as it can withstand heavy use without showing signs of wear and tear.In addition to its strength and durability, Carbon Fiber Vinyl Upholstery offers a host of other benefits. Its smooth surface is easy to clean and maintain, making it a practical choice for households with children or pets. It is also resistant to stains, mildew, and UV damage, ensuring that it will retain its like-new appearance for years to come.The innovative design of this material also makes it highly versatile. It can be used to upholster a wide range of furniture, from chairs and sofas to automotive interiors and marine applications. Its sleek, modern appearance makes it a perfect fit for contemporary and minimalist design schemes, adding a touch of sophistication to any space.Furthermore, Carbon Fiber Vinyl Upholstery is available in a variety of colors and textures, allowing customers to customize their upholstery to suit their individual tastes and preferences. Whether you prefer a classic black finish or a bold, statement-making color, there is a Carbon Fiber Vinyl Upholstery option to suit your needs.The launch of Carbon Fiber Vinyl Upholstery represents a significant milestone for {}. It underscores the company's commitment to innovation and its dedication to providing customers with the highest quality materials on the market. With this new product, {} continues to lead the way in the development of advanced materials that push the boundaries of what is possible in upholstery design.As a company, {} has a long-standing reputation for excellence and is known for its focus on quality and customer satisfaction. The introduction of Carbon Fiber Vinyl Upholstery is yet another example of the company's dedication to meeting the evolving needs of its customers and maintaining its position as a leader in the industry.In conclusion, Carbon Fiber Vinyl Upholstery is a game-changer in the world of upholstery materials, offering a perfect blend of luxury, durability, and performance. With its innovative design, exceptional strength, and versatile options, this material is sure to become a sought-after choice for consumers seeking the very best in upholstery. With the introduction of this groundbreaking product, {} continues to demonstrate its commitment to innovation and its position as a leader in the industry.

High-Quality Biaxial Glass Fabric for Various Applications

Biaxial Glass Fabric: A Strong and Versatile Material for Various IndustriesIn today's world, technological advancements and innovations have led to the development of new and improved materials that are revolutionizing various industries. One such material that has gained widespread popularity is Biaxial Glass Fabric. This versatile and strong material is being used across different sectors for a wide range of applications, from aerospace and automotive to construction and sports equipment.Biaxial Glass Fabric is a type of composite material that is made from glass fibers woven in two different directions, providing it with increased strength and durability. The material is known for its high tensile strength, impact resistance, and lightweight properties, making it an ideal choice for applications where strength-to-weight ratio is crucial.The advanced manufacturing process of Biaxial Glass Fabric ensures that the fibers are laid down in a precise and uniform manner, resulting in a material that is free from defects and inconsistencies. This makes it a reliable and consistent material for various applications, providing engineers and designers with the confidence to use it in their projects.One company that has been at the forefront of producing high-quality Biaxial Glass Fabric is {}. With decades of experience and expertise in the field of composite materials, {} has established itself as a leading manufacturer and supplier of Biaxial Glass Fabric to industries worldwide. Their commitment to quality, innovation, and customer satisfaction has set them apart in the industry, making them a trusted partner for businesses looking for reliable composite materials.{}'s Biaxial Glass Fabric is used in a wide range of applications, including but not limited to:- Aerospace: The aerospace industry requires materials that are lightweight, yet strong and durable. Biaxial Glass Fabric is extensively used in the manufacturing of aircraft components, including structural panels, interior parts, and aircraft fairings. Its excellent strength-to-weight ratio and resistance to fatigue make it a preferred choice for aerospace applications.- Automotive: In the automotive industry, Biaxial Glass Fabric is utilized in the production of automotive parts and components, such as body panels, interior trims, and structural reinforcements. The material's ability to withstand high impact loads and vibrations, while being lightweight, makes it suitable for improving the performance and safety of vehicles.- Construction: Biaxial Glass Fabric finds application in the construction industry for reinforcing concrete structures, providing them with enhanced tensile strength and durability. It is also used in the manufacturing of lightweight building materials, such as roofing panels and cladding, contributing to the overall sustainability and energy efficiency of buildings.- Sports Equipment: Another growing sector where Biaxial Glass Fabric is making a significant impact is sports equipment manufacturing. The material is used in the production of sporting goods such as skis, snowboards, surfboards, and bicycles, where its high strength and lightweight properties are essential for performance and durability.The extensive use of Biaxial Glass Fabric across these diverse industries underscores its versatility and reliability as a composite material. Its ability to meet the stringent performance requirements and standards of various applications has made it a preferred choice for engineers and manufacturers worldwide.With the increasing demand for high-performance composite materials, {} continues to innovate and expand its product line to meet the evolving needs of the market. Their ongoing research and development efforts aim to further enhance the properties of Biaxial Glass Fabric, ensuring that it remains at the forefront of material technology.As industries continue to push the boundaries of innovation and seek advanced materials for their projects, Biaxial Glass Fabric stands out as a compelling solution that offers unparalleled strength, versatility, and reliability. With companies like {} leading the way in its production and supply, the future looks promising for this exceptional composite material.

Biaxial Fiberglass Fabric: What You Need to Know

Fiberglass Biaxial Fabric Gaining Popularity in Construction IndustryIn recent years, the construction industry has seen a significant shift towards the use of innovative and advanced materials to improve the quality and durability of structures. One such material that has gained popularity in the industry is Fiberglass Biaxial Fabric, a versatile and high-performance material that is used for reinforcing and strengthening concrete and other construction materials. With its exceptional strength and flexibility, Fiberglass Biaxial Fabric has quickly become a preferred choice for construction professionals looking for reliable and durable reinforcement solutions.Fiberglass Biaxial Fabric is a composite material made from high-quality fiberglass strands that are woven together in a biaxial pattern, providing equal strength in both the horizontal and vertical directions. This unique construction results in a material that offers superior mechanical properties and exceptional load-carrying capacity. The fabric is available in various weights and widths, making it suitable for a wide range of construction applications, including roads, bridges, buildings, and other infrastructure projects.One of the leading providers of Fiberglass Biaxial Fabric is [company name removed], a renowned company with a strong reputation for delivering high-quality reinforcement solutions to the construction industry. With extensive experience and expertise in fiberglass technology, [company name removed] has become a trusted partner for construction professionals looking for reliable and innovative reinforcement materials.[Company name removed] offers a wide range of Fiberglass Biaxial Fabric products designed to meet the specific needs of different construction projects. The company's Fiberglass Biaxial Fabric is known for its exceptional tensile strength, corrosion resistance, and ease of handling and installation. In addition, [company name removed] provides customized solutions to accommodate unique project requirements, ensuring that construction professionals have access to high-performance reinforcement materials that are tailored to their needs.The use of Fiberglass Biaxial Fabric in construction offers several significant benefits. Firstly, the material significantly improves the tensile and flexural strength of concrete, contributing to the overall structural integrity and longevity of the construction. Furthermore, Fiberglass Biaxial Fabric is lightweight and easy to handle, reducing labor costs and speeding up the construction process. The material's corrosion resistance properties also make it ideal for use in harsh environmental conditions, ensuring long-term durability and performance.One of the key advantages of Fiberglass Biaxial Fabric is its versatility. The material can be used in a wide range of construction applications, including concrete slabs, walls, and foundations, as well as in road and pavement construction. Its high tensile strength and low elongation make it an ideal choice for reinforcing structural elements, providing added support and stability to the construction.The growing demand for Fiberglass Biaxial Fabric in the construction industry can be attributed to its proven performance and reliability in reinforcing concrete and other construction materials. With an increasing emphasis on building resilient and long-lasting structures, construction professionals are turning to innovative materials like Fiberglass Biaxial Fabric to enhance the quality and durability of their projects.[Company name removed] remains at the forefront of providing high-quality Fiberglass Biaxial Fabric to meet the evolving needs of the construction industry. With a commitment to innovation and excellence, the company continues to drive advancements in fiberglass technology, delivering reinforcement solutions that set new standards for performance and durability in construction.As the construction industry continues to embrace advanced materials for improving construction practices, Fiberglass Biaxial Fabric is poised to play a pivotal role in shaping the future of construction. With its unmatched strength, versatility, and performance, Fiberglass Biaxial Fabric is set to remain a preferred choice for construction professionals looking to build resilient and sustainable structures for years to come.

Durable Fiberglass Filter Fabric: A Top Choice for Filtration Needs

(Company Name), a leading provider of innovative solutions for the industrial filtration and separation industry, has recently introduced a new and advanced Fiberglass Filter Fabric to its product line. This latest addition to their already extensive range of filtration products is set to revolutionize the industry with its unparalleled efficiency and performance.Fiberglass Filter Fabric is a high-quality filtration material that is widely used in various industries such as chemical processing, oil and gas, power generation, and industrial water treatment. It is known for its exceptional durability, chemical resistance, and high temperature tolerance, making it an ideal choice for demanding applications.The new Fiberglass Filter Fabric from (Company Name) is specially designed to enhance filtration efficiency and ensure superior performance in challenging operating conditions. It is manufactured using state-of-the-art technology and advanced production processes to meet the strict quality standards and specifications required by customers in diverse industries.One of the key features of the Fiberglass Filter Fabric is its high porosity, which allows for optimal flow rates and improved particle retention. This results in cleaner filtrate, reduced maintenance frequency, and extended service life, ultimately leading to cost savings for end-users. The fabric is also engineered to withstand harsh chemicals and elevated temperatures, making it a reliable choice for filtration applications that involve aggressive process fluids and high operating temperatures.In addition to its outstanding performance characteristics, the Fiberglass Filter Fabric is available in a variety of weights, thicknesses, and surface finishes to accommodate different filtration requirements. This flexibility in product offerings allows (Company Name) to cater to a wide range of customer needs and provide tailored solutions for specific filtration challenges.(Company Name) takes pride in its commitment to innovation and continuous improvement, and the introduction of the Fiberglass Filter Fabric is a testament to this dedication. The company's R&D team has worked diligently to develop this advanced filtration material, leveraging their expertise and technical know-how to deliver a product that sets new standards in performance and reliability.With a firm belief in delivering value to its customers, (Company Name) ensures that the Fiberglass Filter Fabric undergoes rigorous quality testing and validation before it is made available for commercial use. This stringent quality assurance process is aimed at guaranteeing the consistency and integrity of the product, and ultimately, the satisfaction of end-users.The launch of the Fiberglass Filter Fabric underscores (Company Name)'s strategic vision to expand its product portfolio and offer comprehensive solutions that meet the evolving needs of the industrial filtration and separation market. By staying at the forefront of technological advancements and market trends, the company is well-positioned to address the increasingly complex and demanding requirements of its global customer base.In conclusion, the introduction of the new Fiberglass Filter Fabric from (Company Name) is a significant milestone that reinforces the company's position as a trusted leader in the filtration and separation industry. With its exceptional performance attributes, versatility, and reliability, this innovative filtration material is set to make a lasting impact and provide value to customers across various industrial sectors. As (Company Name) continues to drive innovation and excellence in its product offerings, the Fiberglass Filter Fabric stands out as a testament to the company's unwavering commitment to delivering superior filtration solutions.

Discover the Advantages of Carbon Quadraxial Fabric for Enhanced Performance

[Assistant]Title: Revolutionary Carbon Quadraxial Fabric Redefines Composite Material IndustryIntroduction:In an exciting breakthrough, a leading company in the field of advanced materials has unveiled a revolutionary product that promises to reshape the composite material industry. Carbon Quadraxial Fabric (CQF), a game-changing innovation, is set to enhance the performance and capabilities of numerous industries, ranging from aerospace and automotive to sports and recreation. With its exceptional strength, versatility, and manufacturing flexibility, CQF is primed to become a go-to material for engineers and designers worldwide.Main Body:1. Understanding Carbon Quadraxial Fabric: Carbon Quadraxial Fabric is manufactured using advanced technologies that ingeniously weave together high-tensile carbon four-axis filament yarns. This proprietary weaving technique results in a fabric that boasts superior mechanical properties, including exceptional strength, stiffness, and fatigue resistance. Unlike traditional carbon fabrics, CQF also exhibits reduced delamination and improved impact resistance, making it an ideal choice for demanding applications.2. The Unprecedented Versatility of CQF: The unique characteristics of Carbon Quadraxial Fabric allow it to be utilized across a wide array of industries, offering benefits that surpass those of traditional materials. From lightweight structural components in the aerospace sector to high-performance body panels in the automotive industry, CQF offers heightened strength-to-weight ratios without compromising durability. Additionally, its exceptional resistance to chemicals and extreme temperatures makes it valuable in industrial settings.3. Revolutionizing Aerospace Manufacturing: The aerospace industry, in particular, stands to benefit immensely from Carbon Quadraxial Fabric. The material's exceptional strength and stiffness make it a perfect fit for designing and manufacturing aircraft components. By utilizing CQF, aerospace engineers can achieve increased fuel efficiency, reduced maintenance costs, and improved overall performance. Moreover, CQF's low thermal expansion properties make it a preferred choice for applications requiring stability at varying temperatures.4. Application in Automotive Engineering: Automotive manufacturers are eagerly embracing the potential of Carbon Quadraxial Fabric for its ability to enhance vehicle performance and fuel efficiency. Lightweight components made with CQF allow designers to reduce vehicle weight while maintaining structural integrity, leading to improved handling, reduced emissions, and increased overall energy efficiency. Additionally, CQF's impact resistance properties contribute to increased passenger safety.5. Impacting Sporting and Recreational Industries: Sports and recreational equipment manufacturers are also recognizing the tremendous advantages of Carbon Quadraxial Fabric. From high-performance bicycles and tennis rackets to skis and golf clubs, CQF's exceptional strength and stiffness provide athletes with a competitive edge. Its lightweight nature also enables enthusiasts to enjoy more comfortable and energy-efficient experiences.Conclusion:The introduction of Carbon Quadraxial Fabric onto the market represents a significant watershed moment in the composite material industry. This cutting-edge technology promises to revolutionize various sectors, offering unparalleled strength, versatility, and durability. As CQF gains widespread adoption, industries can expect to witness exponential advancements in product performance, design, and sustainability. With limitless possibilities in fields ranging from aerospace and automotive engineering to sports and recreation, Carbon Quadraxial Fabric is poised to redefine the future of advanced materials.