Understanding the Properties and Applications of Carbon Fiber Composites

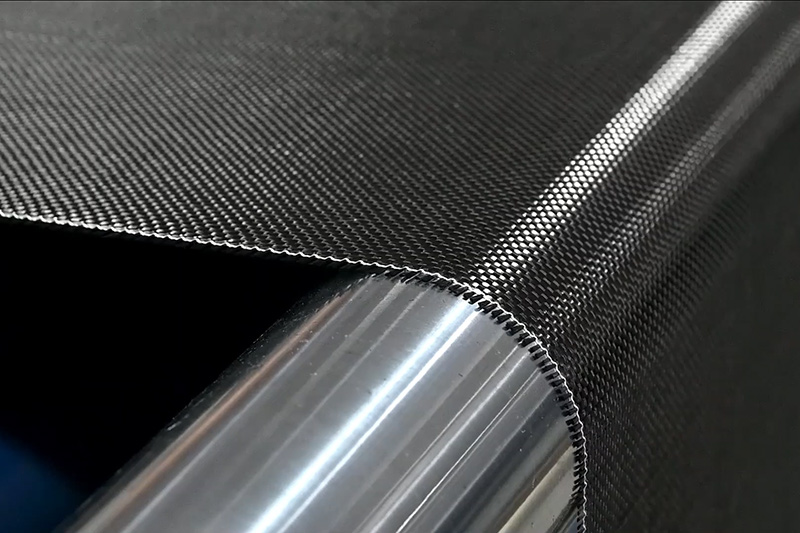

Carbon Fiber Cloth: A Lightweight and Strong MaterialCarbon fiber cloth is a material composed of small, thin carbon fibers, woven together to form a flexible and strong cloth. This cloth is widely used in industries such as aerospace, automotive, and sports equipment due to its high strength-to-weight ratio. In this blog post, we will discuss the properties and applications of carbon fiber cloth and its significance in various industries.Properties of Carbon Fiber ClothCarbon fiber cloth is known for its exceptional strength, stiffness, and low weight. The individual strands of carbon fibers, usually one-tenth the diameter of a human hair, are woven together to form sheets or rolls of varying thicknesses. These sheets are then layered or sandwiched with epoxy resin to form composite materials, which are rigid, flexible, or semi-soft depending on the resin type and the number of carbon fiber layers.One of the key properties of carbon fiber cloth is its strength. It has a tensile strength five times that of steel and is exceptionally resistant to breaking, bending, or stretching. This makes it ideal for products that require high-strength and lightweight materials, such as airplane wings, racing bicycles, and tennis rackets.In addition to strength, carbon fiber cloth provides high stiffness and rigidity. It has a stiffness that is nearly twice that of aluminum and is highly resistant to deformation. This makes it useful in applications where stiffness is required, such as in the production of wind turbine blades and construction of structural beams and columns.Applications of Carbon Fiber ClothCarbon fiber cloths are used extensively in various industries due to their exceptional properties. Here are some of the most significant applications:Aerospace Industry - The aerospace industry uses carbon fiber cloths extensively in airplanes, helicopters, and missiles. These materials are used to make airplane wings, body panels, and other components due to their high strength-to-weight ratio, which reduces the overall weight of the aircraft and improves fuel efficiency.Automotive Industry - Carbon fiber cloths are used in high-performance vehicles such as race cars and supercars. The lightweight and strong material is also used for manufacturing components such as brakes, wheels, and chassis elements.Sports Equipment - Carbon fiber cloth is widely used in the sports industry to make lightweight, high-performance products such as tennis rackets, golf clubs, and fishing rods. The stiffness of the material provides enhanced control and performance in these products.Medical Industry - Carbon fiber cloths are used in the medical industry for orthopedic implants, prosthetics, and medical equipment. These lightweight materials are ideal for medical applications where weight and strength are critical for long-term patient use.ConclusionCarbon fiber cloth is a remarkable material that has revolutionized various industries. Its high strength-to-weight ratio, stiffness, and low weight make it ideal for high-performance products and applications. The aerospace, automotive, sports equipment, and medical industries all benefit from the exceptional properties of carbon fiber cloth, and its significance in these markets is expected to grow in the years to come.Keywords: Fiber Carbon Cloth, Carbon Fiber Cloth, Properties of Carbon Fiber Cloth, Aerospace Industry, Automotive Industry, Sports Equipment, Medical Industry.

Read More

Carbon Fiber Style Fabric: The Ultimate Guide

Carbon Fiber Look Alike Fabric Revolutionizes the Textile IndustryIn recent years, the demand for high-performance and lightweight materials has been steadily increasing in various industries, from automotive to aerospace. As a response to this demand, a cutting-edge company specializing in advanced textiles has developed a groundbreaking Carbon Fiber Look Alike Fabric that is set to revolutionize the industry.The Carbon Fiber Look Alike Fabric, developed by [company name], is a game-changing material that combines the high-performance properties of carbon fiber with the versatility and cost-effectiveness of fabric. This innovative fabric is engineered to mimic the appearance and functionality of traditional carbon fiber, making it a highly sought-after alternative in industries where lightweight and durable materials are essential.One of the key advantages of the Carbon Fiber Look Alike Fabric is its remarkable strength-to-weight ratio. While traditional carbon fiber is known for its exceptional strength and stiffness, it can be costly and difficult to work with. In contrast, the Carbon Fiber Look Alike Fabric offers similar strength and stiffness properties, while being more flexible and easier to handle. This makes it an ideal choice for applications where both performance and ease of use are paramount.Additionally, the Carbon Fiber Look Alike Fabric is highly customizable, allowing for a wide range of finishes and weave patterns to be achieved. This level of customization is a significant advantage for designers and engineers, as it enables them to tailor the fabric to their specific requirements and aesthetic preferences. Whether it's for automotive interiors, sporting goods, or aerospace components, the Carbon Fiber Look Alike Fabric offers endless possibilities for innovation and creativity.Furthermore, the Carbon Fiber Look Alike Fabric is engineered to be more environmentally friendly than traditional carbon fiber. By utilizing alternative materials and manufacturing processes, [company name] has developed a fabric that minimizes the environmental impact without compromising on performance. This aligns with the company's commitment to sustainability and responsible manufacturing practices, making the Carbon Fiber Look Alike Fabric a forward-thinking choice for eco-conscious industries.[Company name] has a track record of delivering high-quality, innovative textiles to a wide range of industries, and the development of the Carbon Fiber Look Alike Fabric is a testament to their dedication to pushing the boundaries of textile technology. With state-of-the-art manufacturing facilities and a team of experienced engineers and designers, the company is well-positioned to meet the growing demand for advanced materials in today's competitive market.The introduction of the Carbon Fiber Look Alike Fabric has been met with widespread anticipation and enthusiasm from industry professionals. Companies across various sectors are eagerly awaiting the opportunity to incorporate this groundbreaking material into their products, with the potential to enhance performance and efficiency across the board.In conclusion, the development of the Carbon Fiber Look Alike Fabric by [company name] marks a significant milestone in the textile industry. With its exceptional strength, versatility, and sustainability, this innovative fabric is poised to transform the way high-performance materials are utilized in a multitude of applications. As the demand for lightweight and durable materials continues to grow, the Carbon Fiber Look Alike Fabric stands out as a game-changing solution with the potential to shape the future of advanced textiles.

Read More

High-Quality Fiberglass Cloth for Improved Strength and Durability

article, addressing the following:1. Briefly explain what fiberglass cloth 1708 is and its main uses.2. Discuss the unique features of fiberglass cloth 1708 that set it apart from other materials.3. Highlight the benefits that users can expect to enjoy when using fiberglass cloth 1708.4. Provide examples of companies that have used fiberglass cloth 1708 to achieve their objectives.5. Articulate the company's commitment to quality and customer satisfaction.6. Discuss the future of fiberglass cloth 1708 and the company's plans to improve its product offeringFiberglass Cloth 1708: An All-Round Reinforcement Solution Fiberglass cloth is known for its ability to resist moisture, fire, and corrosion while providing excellent adhesive properties and high tensile strength. It's extensively used in construction, automotive, marine, and aerospace industries. Fiberglass cloth 1708, in particular, is known for its incredible strength and versatility. It's considered one of the best all-round reinforcement fabrics thanks to its unique features.What is Fiberglass Cloth 1708?Fiberglass cloth 1708 comprises two layers of fiberglass fabric: one layer of biaxial reinforcement and another of chopped strand. The biaxial reinforcement layer reinforces the fabric in two directions, providing superior strength, while the chopped strand layer provides extra durability, making the fabric easy to handle. Unique Features of Fiberglass Cloth 1708Fiberglass cloth 1708 boasts unique features that set it apart from other materials in the market. Among these features is its high-resistance to water, chemicals, and UV radiation. The unique combining of the chopped strand and biaxial fabrics offers exceptional coverage, with the chopped strand layer preventing fraying, making it extremely easy to work with. The high strength and flexibility of fiberglass cloth 1708 make it a preferred material for use in applications with curves and edges. What's more, it's lightweight, which makes it ideal for transportation, facilitating handling of large structures. Benefits of Fiberglass Cloth 1708 Thanks to its unique features, users can enjoy various benefits when using fiberglass cloth 1708. The material offers excellent bonding properties, saving on adhesives, hence reducing overall production costs. Fiberglass cloth 1708 is also incredibly stiff and flexible, allowing the material to conform to various shapes and objects. Additionally, the cloth is non-porous, which ensures that it remains water-resistant, enhancing its lifespan and durability. Companies' Applications of Fiberglass Cloth 1708Fiberglass cloth 1708 has been used in a variety of applications across different industries. For example, the aviation industry uses the material to repair damage to the aircraft's fiberglass body parts. Fiberglass cloth 1708 has also been used in the marine industry for boat repairs, construction of boats, and various other marine applications such as wind turbine blades. In the automotive industry, fiberglass cloth 1708 is used for mold making, repairing old cars, and fixing fiberglass car parts. Company's Approach to Quality and Customer Satisfaction At our company, quality and customer satisfaction are among our primary objectives. We strive to ensure that we consistently produce high-quality products. We achieve this by maintaining a highly-skilled workforce that uses the latest technologies and processes to produce and test our fiberglass cloth 1708 products. The Future of Fiberglass Cloth 1708 and Its Product Offering Our company is committed to consistently improving our products to meet your ever-changing needs. To this end, we are continually adopting new technologies and processes to produce the best fiberglass cloth 1708. We're confident that our ongoing efforts will ensure that we remain leaders in the production of high-quality fiberglass cloth 1708 for years to come. Conclusion Fiberglass cloth 1708 is an incredible material known for its versatility and exceptional strength. It is no wonder that it's a reliable reinforcement solution for many companies across various industrial sectors such as marine, aerospace, and automotive, among others. Our company remains committed to producing high-quality products that meet your every need. Contact us today for all your fiberglass cloth 1708 needs!

Read More

High-Quality Fiberglass Fabric for Various Applications

Fiberglass is an incredibly versatile and durable material that is used in a wide range of applications. From construction to automotive manufacturing, fiberglass plays a crucial role in many industries. One of the key components of fiberglass is the fabric that is used to create the material. Without high-quality fabric, fiberglass would not have the strength and resilience that it is known for.One company that has been at the forefront of producing top-quality fabric for fiberglass is {}. With over 20 years of experience in the industry, {} has established itself as a leader in the production of fiberglass fabric. The company has a strong focus on research and development, constantly striving to improve their products and stay ahead of the competition.The fabric produced by {} is made from high-quality materials that are carefully selected to ensure the strength and durability of the final product. By using top-of-the-line equipment and cutting-edge manufacturing processes, {} is able to produce fabric that meets the demanding requirements of the fiberglass industry.One of the key factors that sets {} apart from its competitors is its commitment to quality control. The company has strict quality control procedures in place to ensure that every roll of fabric that leaves their facility meets the highest standards. This attention to detail has earned {} a reputation for consistency and reliability in the industry.In addition to producing standard fiberglass fabric, {} also specializes in creating custom fabric solutions to meet the specific needs of their clients. This ability to tailor their products to the individual requirements of each customer has made {} a trusted partner for many businesses in the fiberglass industry.{}'s dedication to innovation and quality has not gone unnoticed. The company has received several certifications and awards for its achievements in the field of fiberglass fabric production. These accolades further demonstrate {}'s commitment to excellence and their position as a leader in the industry.Looking to the future, {} is continuously exploring new ways to improve their products and expand their capabilities. The company's research and development team is constantly working on developing new materials and technologies that will further enhance the performance of fiberglass fabric.In addition to their focus on innovation, {} is also dedicated to sustainability. The company has implemented environmentally friendly practices throughout its operations and is committed to reducing its impact on the environment. By using sustainable materials and minimizing waste, {} is working towards a greener future for the fiberglass industry.As the demand for fiberglass continues to grow across various industries, the need for high-quality fabric will only increase. {} is well-positioned to meet this demand with its dedication to excellence, innovation, and sustainability. With a strong track record and a commitment to continuous improvement, {} is set to remain a leader in the production of fiberglass fabric for years to come.

Read More

High-Quality Quick Change Fiberglass Laminating Rollers for Efficient and Smooth Fiberglass Applications

ers, Quick Change Fiberglass Rollers, Pure Bristle Fiberglass Rollers, and Bodi Company, Inc.Bodi Company, Inc. is a well-known and trusted manufacturer of fiberglass laminating rollers. Their products have been favored by many professionals in the industry for their efficiency and durability. The latest addition to their line of fiberglass laminating rollers is the Bristle Roller Quick Change Fiberglass Laminating Roller. This innovative product has quickly gained popularity among professionals due to its unique features and benefits.The Bristle Roller Quick Change Fiberglass Laminating Roller is made of pure bristle fiberglass rollers that are spirally wound. This construction method results in a strong fiberglass lamination while also allowing for smooth application of the fiberglass matting. The roller is designed to produce consistent results and can even be used in tight places where traditional rollers may be unable to reach.One of the most significant advantages of this roller is that you can hear the bubbles popping as you apply it to the fiberglass matting. This sound indicates that the air pockets are being removed from the lamination, ensuring that a uniform and strong bond is formed. This feature is especially useful for those who are new to working with fiberglass and may be unsure of the proper lamination techniques.The Bristle Roller Quick Change Fiberglass Laminating Roller is also very easy to use. Its quick change mechanism allows you to replace the rollers quickly and easily, which saves you time and effort. Additionally, the roller is designed to work efficiently with different types of fiberglass matting, making it a versatile tool for any fiberglass laminating project.In conclusion, the Bristle Roller Quick Change Fiberglass Laminating Roller by Bodi Company, Inc. is an excellent choice for professionals and beginners alike. Its innovative features and benefits make it stand out among other fiberglass laminating rollers on the market. Whether you are working on small or large projects, this roller is sure to provide you with consistent and reliable results. So, if you're looking for a high-quality fiberglass laminating roller, the Bristle Roller Quick Change Fiberglass Laminating Roller is definitely worth considering.

Read More

High-Quality Fibreglass Cloth Roll for Industrial Use

The Fibreglass Cloth Roll, a high-quality product from a renowned company, is gaining attention in the construction and manufacturing industries due to its durability and versatility. This product has been widely used in various applications such as reinforcement for composite materials, insulation for electrical appliances, and repairing and strengthening structures.The company, with a rich history in producing fibreglass products, has been at the forefront of innovation and excellence in the industry. They have established a solid reputation for delivering top-notch fibreglass products that meet the highest standards. The Fibreglass Cloth Roll is one of the company’s flagship products, known for its superior quality and performance.The Fibreglass Cloth Roll is made from fine fibreglass strands woven together to form a strong and flexible cloth. It is designed to provide excellent tensile strength and resistance to heat, chemicals, and corrosion. These properties make it an ideal material for a wide range of applications that require a durable and long-lasting solution.One of the key benefits of the Fibreglass Cloth Roll is its versatility. It can be used in various industries, including construction, automotive, marine, and aerospace. In the construction industry, it is commonly used as reinforcement for concrete, plaster, and other building materials. Its high tensile strength and resistance to wear and tear make it an ideal material for strengthening and repairing structures. Additionally, it is used as insulation for electrical appliances and machinery due to its heat-resistant properties.The Fibreglass Cloth Roll is also widely used in the manufacturing of composite materials. It is often combined with resins to create strong and lightweight composites that are used in the production of automotive parts, sports equipment, aerospace components, and more. The flexibility of the fibreglass cloth allows it to conform to complex shapes and contours, making it a preferred material for creating custom-made parts and components.The company’s commitment to quality and innovation is evident in the production of the Fibreglass Cloth Roll. They have invested in state-of-the-art manufacturing facilities and rigorous quality control processes to ensure that each roll meets the highest standards. This dedication to excellence has earned them the trust and confidence of their customers, who rely on the Fibreglass Cloth Roll for their most demanding applications.In addition to its outstanding performance, the Fibreglass Cloth Roll is also environmentally friendly. It is made from natural and sustainable raw materials, and its production processes are designed to minimize waste and energy consumption. This aligns with the company’s commitment to sustainability and responsible manufacturing practices.As the demand for durable and high-performance materials continues to grow, the Fibreglass Cloth Roll is poised to play a crucial role in meeting the needs of various industries. Its versatility, strength, and resistance to environmental factors make it a preferred choice for a wide range of applications. With the backing of a trusted and reputable company, customers can have full confidence in the quality and reliability of the Fibreglass Cloth Roll for their projects.In conclusion, the Fibreglass Cloth Roll from the esteemed company represents a pinnacle of excellence in fibreglass products. Its outstanding performance, versatility, and environmentally friendly nature make it a standout choice for a diverse range of applications. As industries continue to seek durable and high-quality materials, the Fibreglass Cloth Roll stands ready to meet and exceed their expectations.

Read More

China-based Fiberglass Woven Roving Suppliers: Providing Assurance for Varied Consumer Needs

Roving, Fiberglass Manufacturers, China Fiberglass, Fiberglass Suppliers, Fiberglass Factory.Woven Fiberglass Roving - A Versatile Material for Various IndustriesWoven fiberglass roving, also known as fiberglass fabric, is a versatile material used widely in various industrial applications. It is made by weaving fiberglass strands together in a crosshatch pattern to form a fabric with high strength and durability. Fiberglass fabric is widely used in construction, automotive, aerospace, marine, and other industries due to its excellent thermal and mechanical properties.Fiberglass Manufacturers in ChinaChina is one of the largest manufacturers and suppliers of fiberglass products in the world. Huili Fiberglass is a leading fiberglass woven roving manufacturer, factory, and supplier from China. The company offers a wide range of woven fiberglass roving products, including E-glass and C-glass woven roving, chopped strand mat, fiberglass mesh, and other related items.Huili Fiberglass is committed to providing high-quality products and excellent services to its customers worldwide. The company has a team of experienced professionals who work tirelessly to ensure that its products meet the highest standards of quality and performance. The company has also invested in advanced equipment and technology to ensure that it is at the forefront of innovation in the fiberglass industry.Fiberglass Suppliers in ChinaHuili Fiberglass is one of the leading fiberglass suppliers in China. The company supplies fiberglass products to customers in various industries in China and abroad. The company's products are highly sought after due to their high quality and competitive prices. Huili Fiberglass prides itself on its excellent customer service and timely delivery of products.Fiberglass Factory in ChinaHuili Fiberglass has a state-of-the-art fiberglass factory in China. The factory is equipped with advanced machinery and technology to ensure that the company's products are of the highest quality. The company's factory adheres to strict quality control measures to ensure that its products meet the highest standards of quality and performance.ConclusionIn conclusion, woven fiberglass roving is a versatile material used widely in various industrial applications. Huili Fiberglass is a leading fiberglass woven roving manufacturer, factory, and supplier from China. The company offers a wide range of high-quality fiberglass products at competitive prices. With its excellent customer service, advanced technology, and strict quality control measures, Huili Fiberglass is a reliable partner for customers in various industries.

Read More

High Quality 3k 5.8oz Carbon Fiber Fabric - Ideal for Composites

and Toray T300.Carbon fiber is a revolutionary material that is changing the way modern industries design and manufacture products. Carbon fiber twill cloth, or Toray T300 carbon fiber fabric, is a high-quality material that is sought after for its strength and lightweight properties.The Toray T300 carbon fiber is a popular choice in the composite industry due to its exceptional balance of strength, stiffness, and toughness. The fabric boasts remarkable mechanical properties that are ideal for a wide range of applications, including aerospace, automotive, marine, and sports equipment.The carbon fiber twill cloth features a 2x2 twill weave that provides excellent drapability and conformability. The fabric is lightweight, weighing only 5.8oz/196gsm, making it ideal for weight-sensitive applications. The fabric has a thickness of .010", making it easy to handle and manipulate.To use the raw fabric, it must be hardened into a usable form using an appropriate resin or epoxy. The fabric can be hand-laid or vacuum infused with the resin to create composite parts that are lightweight, high-strength, and durable.The carbon fiber twill cloth is a versatile material that can be used for various applications. It is commonly used to manufacture aircraft components, automobile parts, bicycle frames, and sports equipment. The fabric is also used in the fashion industry to create high-tech, lightweight clothing.In conclusion, Toray T300 carbon fiber fabric is an exceptional material that offers unmatched strength, stiffness, and toughness. The 2x2 twill weave provides excellent drapability, allowing it to conform to complex shapes. The fabric is lightweight, easy to handle, and perfect for weight-sensitive applications. When combined with the proper resin or epoxy, the fabric can be used to create high-strength composite parts that are ideal for a wide range of applications.

Read More

Buy 1/2 oz Fiberglass Cloth - 38" Wide, 3m Long - Accessories Included

Read More