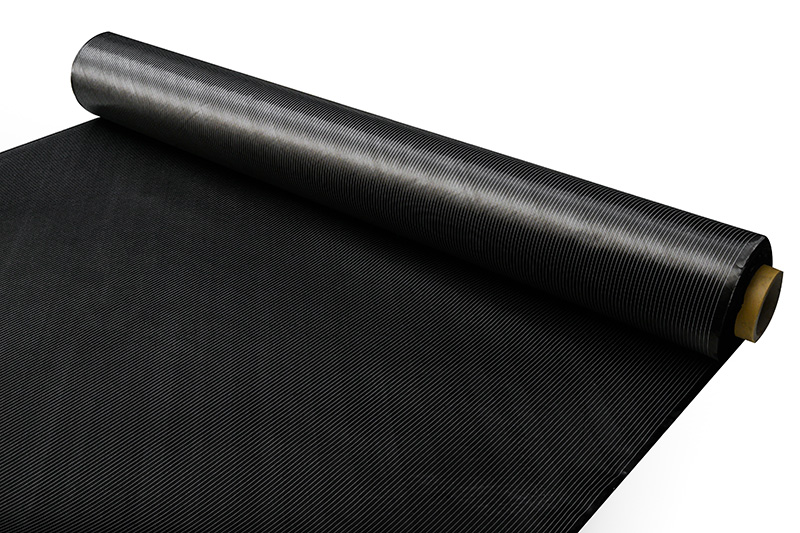

High-quality Woven Roving for Industrial Applications

By:Admin

{The Company} was founded in {year} and has since grown into a global leader in the production of Glass Woven Roving. Their state-of-the-art manufacturing facilities and extensive research and development capabilities have allowed them to consistently deliver top-quality products to their clients. They pride themselves on their ability to tailor their products to meet the specific needs of their customers, providing customized solutions that exceed expectations.

Their Glass Woven Roving is manufactured using high-quality glass fibers that are woven into a uniform and high-strength fabric. This fabric is then coated with a proprietary sizing to enhance its compatibility with resin systems. The result is a product that offers excellent mechanical properties, including high tensile strength, impact resistance, and dimensional stability. This makes it an ideal reinforcement material for a wide range of applications, from boat building to wind turbine blade production.

One of the key advantages of {The Company}'s Glass Woven Roving is its versatility. It can be used in conjunction with various resin systems, including polyester, epoxy, and vinyl ester, giving their customers the flexibility to work with the materials that best suit their needs. This versatility, combined with the product's high performance, has made it a popular choice among manufacturers looking to create lightweight yet durable composite products.

In addition to their standard Glass Woven Roving products, {The Company} also offers a range of specialty options to meet specific industry requirements. These include products with enhanced surface finish, improved drapeability, and increased resin flow, among others. By continuously expanding their product offerings, they have been able to cater to a diverse customer base, including those in the aerospace, marine, and automotive industries.

Furthermore, {The Company} is committed to sustainability and environmental responsibility in their manufacturing processes. They adhere to strict environmental standards and invest in eco-friendly technologies to minimize their carbon footprint. This dedication to sustainability has not only earned them the trust of their customers but has also helped them become a leader in the green materials movement.

Looking to the future, {The Company} continues to focus on innovation and product development to stay ahead of the curve in the rapidly evolving composite materials industry. Their research and development team works tirelessly to create new and improved Glass Woven Roving products, utilizing the latest technologies and materials to push the boundaries of what is possible in composite material production. They are also dedicated to expanding their global reach, building strong partnerships with clients and distributors around the world.

In conclusion, Glass Woven Roving is an essential component in the production of high-performance composite materials, and {The Company} has proven to be a reliable and innovative supplier in this space. With a commitment to excellence, sustainability, and customer satisfaction, they have solidified their position as a leader in the industry. As they continue to push the boundaries of what is possible in composite material production, they are well positioned to shape the future of the industry for years to come.

Company News & Blog

High-Quality Fiberglass Matting Roll for Your Needs

The company, a leading manufacturer of industrial materials, is pleased to introduce a new product to its line-up - the Fiberglass Matting Roll. This innovative product is a versatile material that offers a wide range of applications and benefits for various industries.The Fiberglass Matting Roll is a high-quality material that is made from woven fiberglass yarns. It is designed to provide excellent strength, durability, and resistance to heat and chemicals. The roll comes in varying widths and lengths, making it suitable for a wide variety of applications in industries such as automotive, construction, marine, and aerospace.One of the key features of the Fiberglass Matting Roll is its versatility. It can be used for a wide range of applications, including reinforcement for composites, insulation, and soundproofing. Its high strength and durability make it a great choice for reinforcing materials such as plastics, resins, and concrete. Additionally, its resistance to heat and chemicals makes it an ideal material for use in harsh environments.The Fiberglass Matting Roll is also easy to work with, making it suitable for a wide range of fabrication processes. It can be easily cut, shaped, and molded to fit the specific requirements of different applications. This makes it a cost-effective and efficient solution for manufacturers looking to improve the performance and durability of their products.In addition to its technical benefits, the Fiberglass Matting Roll is also environmentally friendly. It is made from recyclable materials and is free from harmful substances, making it a sustainable choice for companies looking to reduce their environmental impact."We are thrilled to introduce the Fiberglass Matting Roll to our product line-up," said a spokesperson for the company. "This innovative material offers a wide range of benefits for our customers, including strength, durability, and versatility. We believe that it will be a valuable addition to our product range and will help our customers to improve the performance and quality of their products."The Fiberglass Matting Roll is now available for purchase from the company, and customers are encouraged to contact their sales team for more information. Additionally, the company is offering custom manufacturing services for customers looking for specific sizes or specifications.The introduction of the Fiberglass Matting Roll demonstrates the company's commitment to innovation and its focus on providing high-quality, sustainable materials to its customers. With its excellent technical properties, versatility, and environmental benefits, the Fiberglass Matting Roll is set to become a valuable addition to the company's product range and a valuable resource for its customers in a wide range of industries. Overall, the introduction of the Fiberglass Matting Roll is a testament to the company's dedication to providing innovative solutions to its customers and its commitment to sustainability and environmental responsibility.

Durable and Versatile Fiberglass Cloth for Various Applications

Light Fiberglass Cloth is becoming a popular material for various industries due to its lightweight and strong properties. It is widely used in aerospace, automotive, marine, and construction industries for its ability to provide strength and durability while being lightweight. One company that specializes in the production of Light Fiberglass Cloth is [Company Name].[Company Name] is a leading manufacturer of Light Fiberglass Cloth, offering a wide range of products for different applications. With years of experience in the industry, [Company Name] has become a trusted name in providing high-quality fiberglass cloth that meets the specific requirements of its customers.The company understands the importance of using top-quality materials in the manufacturing process, and that's why they have invested in state-of-the-art technology and equipment to ensure the production of the highest quality Light Fiberglass Cloth. Their products are designed to meet industry standards and are known for their exceptional performance and durability.One of the key advantages of Light Fiberglass Cloth is its versatility. It can be used in various applications such as aircraft components, automotive parts, boat hulls, and building materials. The lightweight nature of the material makes it an ideal choice for industries that require strong and durable materials without adding unnecessary weight.In addition to its strength and lightweight properties, Light Fiberglass Cloth is also known for its resistance to heat, chemicals, and corrosion. This makes it a popular choice for applications that involve exposure to harsh environmental conditions. Its ability to withstand high temperatures and corrosive chemicals makes it an ideal material for a wide range of industrial applications.Moreover, Light Fiberglass Cloth is also easy to work with, making it a preferred choice for manufacturers. It can be easily cut, shaped, and molded to fit specific requirements, making it a versatile material for various production processes. Its flexibility and ease of use make it an attractive option for companies looking for reliable and efficient materials for their manufacturing needs.[Company Name] takes pride in delivering top-quality Light Fiberglass Cloth to its customers. They are committed to providing excellent customer service and technical support to ensure that their clients receive the best products for their specific applications. Their team of experts is dedicated to helping customers find the right fiberglass cloth solutions for their needs, providing guidance and support throughout the process.As a company, [Company Name] is also committed to sustainability and environmental responsibility. They strive to minimize their environmental impact by implementing eco-friendly manufacturing processes and utilizing recyclable materials. This commitment to sustainability aligns with the growing demand for environmentally friendly products in various industries, making [Company Name] a preferred partner for companies looking to reduce their carbon footprint.In conclusion, Light Fiberglass Cloth is a versatile and reliable material that is gaining popularity in various industries for its strength, lightweight properties, and resistance to heat and corrosion. Companies like [Company Name] play a crucial role in providing high-quality fiberglass cloth solutions to meet the specific needs of their customers. With their commitment to excellence, customer service, and sustainability, [Company Name] is a trusted name in the industry, delivering top-quality Light Fiberglass Cloth for a wide range of applications.

Discover the Revolutionary World of Glass Fibre Textiles: Unleash the Potential of High-Performance Materials

In today's fast-paced world, people are constantly seeking out innovative materials that can address their needs. One such material that is gaining popularity is Glass Fibre Textiles. This is a high-performance material that is made from a combination of glass and textile fibers. Glass Fibre Textiles are being used in a wide range of applications across various industries. From construction to textiles, and from aerospace to consumer goods, Glass Fibre Textiles have become a trend setter due to their unique qualities and features.Glass Fibre Textiles are manufactured using different methods, but the most common one is the continuous filament process. In this process, glass fibers are drawn out from molten glass through small orifices. These fibers are then combined with textile materials such as nylon, polyester, or aramid fibers to create the final product. The result is a material that is strong, flexible, and lightweight.One of the key advantages of Glass Fibre Textiles is their high strength-to-weight ratio. This means that they are much stronger than other conventional materials such as steel, while they are also much lighter in weight. This makes Glass Fibre Textiles especially useful in applications where weight is a critical factor, such as in aerospace and automotive industries. Another advantage of Glass Fibre Textiles is their ability to resist high temperatures. They are highly heat-resistant and can withstand temperatures of up to 400°C. This makes them ideal for use in applications where high temperatures are present, such as in the manufacturing and processing of chemicals and in engine components.In addition, Glass Fibre Textiles are also highly abrasion-resistant, making them ideal for use in the construction industry. They can withstand heavy wear and tear, and they are often used as a reinforcement material in concrete structures. Furthermore, Glass Fibre Textiles have excellent electrical insulation properties, which make them ideal for use in electrical and electronic applications.Glass Fibre Textiles have found a wide range of applications in the textile industry. They are incorporated into high-performance fabrics such as fire-resistant fabrics and bullet-proof vests. This is because of their ability to provide excellent protection against heat, abrasion, and impacts.Glass Fibre Textiles are also widely used in the automotive industry. They are used to manufacture body panels, engine components, and suspension components. The high strength-to-weight ratio of Glass Fibre Textiles makes them an ideal material for use in the automobile industry, where weight reduction is a critical factor.Another sector that has seen significant growth in its use of Glass Fibre Textiles is the wind turbine industry. Glass Fibre Textiles are used to manufacture the blades of the wind turbines. The lightweight and durable nature of Glass Fibre Textiles makes it an ideal material for use in this application.In conclusion, Glass Fibre Textiles have become a popular material for use in various industries due to their unique properties. They are strong, lightweight, and durable, making them ideal for use in applications where weight is a critical factor. Glass Fibre Textiles are also highly heat-resistant and abrasion-resistant, making them suitable for use in harsh environments. With the increased demand for high-performance materials that offer excellent protection, Glass Fibre Textiles are expected to continue growing in popularity across various industries.

Nonwoven Activated Carbon Filter Cotton for Functional Fabric Applications

New Fabric Technology: Nonwoven Activated Carbon Filter CottonFabric technology has come a long way from being just a means to cover the body. Today, it has evolved to include functional fabrics that provide additional benefits to the wearer. One such fabric technology is nonwoven activated carbon filter cotton, which is quickly gaining popularity in the market for its ability to filter harmful substances and protect the wearer from pollution.Ruibang, a leading brand in the industry, has introduced a new product called the AC05-01 nonwoven activated carbon filter cotton. This product is made of a combination of activated carbon cloth, melt-blown nonwoven fabric, and carbon fiber cloth. The activated carbon cloth has a strong adsorption capacity, which effectively filters out harmful substances such as odors and gases. The melt-blown nonwoven fabric is highly efficient at filtering out particles, including PM2.5, dust, and bacteria. The carbon fiber cloth is durable and adds structural support to the fabric.The AC05-01 nonwoven activated carbon filter cotton has a weight of 250g per square meter and is available in various colors. The fabric has excellent air permeability, making it comfortable to wear for extended periods. It is also washable and reusable, making it an eco-friendly option compared to disposable alternatives.One of the main applications of this fabric technology is in the production of respiratory masks. The AC05-01 nonwoven activated carbon filter cotton can be used as the filter layer of masks to help protect the wearer from harmful substances in the air. With the rise of air pollution in many cities around the world, this technology offers a solution to help people breathe cleaner air.Besides masks, this fabric technology has other applications in various industries. It can be used in the production of air purifiers, car air filters, and even insoles for shoes. The ability to filter out harmful substances makes it a valuable addition to products that aim to improve indoor air quality.In conclusion, the introduction of nonwoven activated carbon filter cotton has opened up new possibilities in the fabric industry. Ruibang's AC05-01 product offers a high-quality solution to help protect people from the harmful effects of pollution. With its excellent filtering abilities and comfortable wear, it is sure to become a popular choice for those looking for functional fabrics.

New lightweight material made of carbon kevlar hybrid fabric is set to revolutionize the aerospace industry

Title: Innovative Carbon Kevlar Hybrid Fabric Revolutionizes the Textile IndustryIntroduction:In a groundbreaking development, an industry-leading company has introduced a cutting-edge Carbon Kevlar Hybrid Fabric, emerging as a game-changer in the textile world. Embracing advanced technologies, this revolutionary fabric combines the remarkable properties of carbon fiber and Kevlar, offering unprecedented strength, durability, and versatility. With its wide range of applications, this innovative fabric is set to reshape industries such as aerospace, automotive, sports, and defense.1. The Unparalleled Strength of Carbon Kevlar Hybrid Fabric:The Carbon Kevlar Hybrid Fabric incorporates the best qualities of both carbon fiber and Kevlar. Carbon fiber is renowned for its exceptional strength-to-weight ratio, making it a preferred choice in industries where lightweight yet robust materials are required. On the other hand, Kevlar is famous for its outstanding resistance to impact and abrasion, making it an ideal choice for ballistic protection and structural reinforcement. By combining these two fibers, this hybrid fabric transcends the limitations of conventional materials, ensuring enhanced performance in a variety of applications.2. Aerospace Industry: Empowering High-performance StructuresThe aerospace industry stands to benefit immensely from the introduction of Carbon Kevlar Hybrid Fabric. Due to its lightweight nature and superior strength, the fabric can be incorporated into the manufacture of aircraft components, including fuselages, wings, and engine parts. By utilizing this innovative fabric, manufacturers can significantly reduce the weight of aircraft, contributing to improved fuel efficiency and lower operating costs. Moreover, the exceptional fatigue resistance of the hybrid fabric enhances the durability and longevity of key structural elements, ensuring increased safety for passengers and crew.3. Automotive Industry: Paving the Way for Safer VehiclesIn the automotive sector, the integration of Carbon Kevlar Hybrid Fabric presents significant advancements in safety and performance. By utilizing this fabric for manufacturing body panels, car manufacturers can enhance crashworthiness while reducing overall vehicle weight. The superior impact resistance of the fabric combined with its lightweight attributes makes it a valuable asset in protecting passengers during collisions. As a result, vehicles can achieve better fuel efficiency while offering enhanced safety to occupants.4. Sports Industry: Elevating Performance EquipmentThe sports industry is no stranger to materials that offer exceptional strength and durability. The Carbon Kevlar Hybrid Fabric is set to revolutionize sports equipment, enabling athletes to reach new heights of performance. Sports gear, such as helmets, paddles, and protective gear, created using this hybrid fabric will offer unrivaled protection without compromising agility. The lightweight nature of the fabric will facilitate better maneuverability, giving athletes a competitive edge in various sports.5. Defense Industry: Reinforcing Military ApplicationsThe defense sector, where protection and reliability are paramount, can greatly benefit from the introduction of Carbon Kevlar Hybrid Fabric. The fabric's exceptional resistance to extreme temperatures and impact makes it an ideal choice for the manufacture of protective clothing and equipment for military personnel. As a result, soldiers will experience significantly improved protection without being encumbered by heavy gear.Conclusion:The introduction of Carbon Kevlar Hybrid Fabric represents an exciting milestone in the textile industry. This innovative fabric's ability to combine the extraordinary properties of carbon fiber and Kevlar opens up endless possibilities across various sectors. From aerospace to sports, and automotive to defense, this versatile fabric promises to redefine the standards of strength, durability, and performance. With its numerous benefits, the adoption of Carbon Kevlar Hybrid Fabric is set to revolutionize manufacturing processes and shape the future of the textile industry.

Durable and Versatile Mesh Tape: Ideal Solution for Repairing and Reinforcing Home Surfaces

Glass Mesh Tape Revolutionizes the Construction IndustryThe construction and renovation industry is constantly evolving, with new materials and techniques being introduced to enhance the quality and durability of buildings. One such innovation that has garnered attention and revolutionized the industry is Glass Mesh Tape (brand name removed), a cutting-edge product that has gained praise for its exceptional performance and versatility.Glass Mesh Tape is a high-quality adhesive tape infused with glass fibers, which gives it incredible strength and durability. Initially designed to reinforce joints and seams in drywall installations, this tape has quickly gained popularity among contractors and DIY enthusiasts due to its numerous advantages over traditional options.One of the key features of Glass Mesh Tape is its superior tensile strength. The integration of glass fibers into the tape makes it significantly stronger than regular paper or fiberglass mesh tape. This enhanced strength provides better resistance against cracking and ensures long-lasting joints, ultimately improving the overall integrity of the walls or ceilings where it is applied.The advanced technological composition of Glass Mesh Tape also makes it highly resistant to moisture. Unlike traditional paper tapes that can easily deteriorate when exposed to water or humidity, this tape is designed to withstand challenging environments without losing its adhesive properties or structural integrity. This feature makes it an ideal choice for applications in areas prone to moisture, such as bathrooms and basements.In addition, Glass Mesh Tape exhibits exceptional adhesive properties. Its pressure-sensitive adhesive backing allows it to firmly bond with different surfaces, ensuring seamless integration with the drywall. This not only makes installation hassle-free but also prevents the tape from peeling or detaching over time, guaranteeing a neat and professional finish.What truly sets Glass Mesh Tape apart is its versatility. Beyond drywall applications, this tape can be effectively used across various construction projects. It works exceptionally well for patching holes, repairing cracks, and reinforcing corners. Furthermore, it can be applied on both flat and curved surfaces, making it suitable for a wide range of projects, from residential renovations to commercial construction.The company behind Glass Mesh Tape, recognized as a leader in the industry, is committed to producing innovative, high-quality products. With a focus on research and development, they continuously strive for advancements that meet the evolving needs of professionals in the industry.The production process of Glass Mesh Tape adheres to stringent quality control measures. Each roll is thoroughly tested to ensure consistent performance and durability. This dedication to quality has earned the company a reputation for delivering products that exceed expectations and provide unmatched reliability.Moreover, the company places great importance on sustainability. Glass Mesh Tape is manufactured using eco-friendly materials, reducing its environmental footprint. By using renewable resources and employing energy-efficient manufacturing practices, the company actively contributes to a greener and more sustainable future.The widespread adoption of Glass Mesh Tape has significantly improved construction practices. Its exceptional strength, resistance to moisture, versatile applications, and commitment to quality and sustainability have made it an indispensable tool for professionals and homeowners alike. With this innovative product, the construction industry is well on its way to achieving greater durability and longevity in building structures.

High-Quality Fiberglass Cloth for Various Applications

E Glass Fiberglass Cloth, a high-quality material manufactured by a leading company in the industry, has been gaining widespread attention for its exceptional strength, durability, and versatility. This innovative product has a wide range of applications in various industries, making it an ideal choice for both commercial and industrial purposes.The company, a prominent player in the field of fiberglass production, has been at the forefront of developing cutting-edge solutions for its diverse clientele. With a strong commitment to quality and innovation, they have consistently delivered products that meet the highest standards and exceed customer expectations.E Glass Fiberglass Cloth, in particular, has garnered significant interest due to its outstanding properties. This specialized cloth is made from high-quality E glass fibers, which are known for their superior strength and thermal resistance. The fiberglass cloth is woven meticulously to ensure uniformity and consistency, making it suitable for a wide range of applications.One of the key characteristics of E Glass Fiberglass Cloth is its exceptional strength-to-weight ratio. This makes it an ideal material for reinforcing structures and components, particularly in industries such as aerospace, automotive, construction, and marine. The cloth provides a high level of tensile strength, allowing it to support heavy loads and withstand extreme conditions.Moreover, E Glass Fiberglass Cloth offers excellent resistance to heat, chemicals, and abrasion. This makes it a reliable choice for applications that involve exposure to harsh environments, such as insulation, filtration, and protective barriers. The cloth’s ability to maintain its structural integrity under challenging conditions has made it a preferred material for demanding industrial applications.In addition to its strength and durability, E Glass Fiberglass Cloth is highly versatile and can be easily customized to meet specific requirements. It can be coated, laminated, or impregnated with various resins and compounds to enhance its performance and adapt to different applications. This flexibility makes it a valuable resource for engineers and designers seeking innovative solutions for their projects.The company’s commitment to sustainability and environmental stewardship is also reflected in the production of E Glass Fiberglass Cloth. The manufacturing process is designed to minimize waste and energy consumption, while ensuring that the product meets rigorous quality standards. As a result, customers can be confident that they are using a reliable and eco-friendly material for their projects.Furthermore, the company’s dedication to customer satisfaction extends to its comprehensive support services for E Glass Fiberglass Cloth. They offer technical assistance, product customization, and timely delivery to meet the specific needs of their clients. This personalized approach has earned them a reputation for reliability and excellence in the industry.The versatility, durability, and reliability of E Glass Fiberglass Cloth, combined with the company’s commitment to quality and customer satisfaction, have positioned this product as a top choice for a wide range of applications. As industries continue to evolve and demand high-performance materials, E Glass Fiberglass Cloth is expected to play a crucial role in driving innovation and progress across various sectors.In conclusion, E Glass Fiberglass Cloth, backed by the expertise and dedication of the leading company in the industry, represents a significant advancement in material technology. Its exceptional properties and adaptability make it a valuable resource for diverse applications, while its commitment to sustainability and customer satisfaction underscores its position as a trusted and reliable solution for the future.

Revolutionize Your Car's Appearance with Carbon Fiber Cloth Wrap

Carbon Fiber Cloth Wrap Offers a Revolutionary Solution to Improve Performance of Automotive IndustryCarbon fiber cloth wrap is a revolutionary technology that has transformed the automotive industry by offering improved performance, efficiency, and strength in high-demanding applications. This innovative solution has gained popularity due to its unique properties that give it a competitive edge compared to traditional materials such as steel, aluminum, and plastic.One of the main benefits of carbon fiber cloth wrap is has a high strength-to-weight ratio, which makes it ideal for applications that require strength and durability. Automotive manufacturers have found that this advantage provides a significant reduction in vehicle weight, contributing to improved fuel efficiency, and reduced carbon emissions.The use of carbon fiber cloth wrap has also allowed automakers to introduce new designs with complex shapes that were previously impossible to achieve with traditional materials. This technology enables them to create lightweight, high-performance components that contribute to better handling, reduced noise, and vibration, making the driving experience more enjoyable and comfortable.Another advantage of carbon fiber cloth wrap is its resistance to corrosion, heat, and chemicals. This quality makes it an ideal material for components that are exposed to harsh environments such as engines, exhaust systems, and suspension components.Companies such as XXXX have been at the forefront of the development and production of carbon fiber cloth wrap. The company has built a reputation as a leading manufacturer, offering a diverse range of products that cater to different industries, including aerospace, marine, and automotive.XXXX Company was founded in XXXX and has grown to be a global leader in advanced composite solutions, producing carbon fiber cloth wrap that is renowned for its quality, consistency, and performance. The company has invested heavily in research and development to keep up with the rapidly evolving needs of the market and to offer innovative solutions that meet and exceed customer expectations.The carbon fiber cloth wrap produced by XXXX is manufactured using state-of-the-art equipment and high-quality raw materials, ensuring consistent quality and maximum performance. The company's products have been used by major automotive manufacturers such as XXXX, XXXX and XXXX, contributing to the production of fast and high-performance cars.The company's Director of Sales and Marketing, Mr. XXXX, stated that "the use of carbon fiber cloth wrap has significantly revolutionized the automotive industry, and we are proud to be at the forefront of this transformation. Our products have been designed to meet the needs of our customers and provide an outstanding performance that exceeds their expectations. We are committed to innovation, quality, and customer satisfaction, and we will continue to invest in new technologies to stay ahead of the competition."Carbon fiber cloth wrap has become a game-changer in the automotive industry, offering a revolutionary solution that contributes to improved performance, efficiency, and durability. As the demand for lighter, stronger, and more efficient vehicles continues to grow, the use of this innovative technology is expected to become even more popular in the years to come.In conclusion, the use of carbon fiber cloth wrap has transformed the automotive industry and offers an array of advantages, including lightweight, high strength-to-weight ratio, resistance to corrosion and heat, and improved design flexibility. Companies such as XXXX have played a significant role in the development and production of this innovative technology, providing high-quality products that exceed customer expectations. As the market for lightweight and high-performance vehicles continues to grow, the use of carbon fiber cloth wrap is expected to become even more significant in shaping the future of the automotive industry.

High-Quality Fiberglass Fabric Rolls: The Ultimate Solution for Various Applications

Title: The Impressive Innovations in Fiberglass Fabric Rolls Lead to Greater Safety and Reliability in Various IndustriesIntroduction:In recent years, Fiberglass Fabric Roll has emerged as a game-changer in numerous industries, offering unmatched versatility, strength, and durability. Its remarkable thermal and chemical resistance, as well as its lightness, make it ideal for a wide range of applications. With continuous research and development, Fiberglass Fabric Roll has proven to be a crucial material in numerous sectors, including manufacturing, automotive, aerospace, and construction.Background:The incorporation of fiberglass into fabric rolls has revolutionized the way industries approach challenging scenarios that demand high-performance materials. Primarily composed of fine fibers of glass, Fiberglass Fabric Roll possesses exceptional properties. These include high tensile strength, outstanding electrical insulation, flame retardancy, and low thermal conductivity. Moreover, it is highly resistant to chemicals, water, and UV radiation.Company Overview:{Company Name}, one of the leading manufacturers of Fiberglass Fabric Rolls, has spearheaded the development of innovative solutions based on this material. The company's relentless dedication to research and development, coupled with a commitment to quality, has positioned it at the forefront of the fiberglass industry. {Company Name} has revolutionized various sectors by creating customized solutions that cater to specific industry requirements while adhering to the highest manufacturing standards.The Advantages of Fiberglass Fabric Rolls:1. High Mechanical Strength: Fiberglass Fabric Rolls boast an exceptional strength-to-weight ratio, making them advantageous in load-bearing applications. These rolls can withstand heavy pressure, making them suitable for use in automotive parts, wind turbines, and infrastructure projects.2. Thermal Insulation: The inherent low thermal conductivity properties of Fiberglass Fabric Rolls make them invaluable in applications that require insulation against temperature variations. Industries such as HVAC (Heating, Ventilation, and Air Conditioning), refrigeration, and cryogenics have greatly benefited from the exceptional resistance offered by these rolls.3. Electrical Insulation: With excellent electrical insulation properties, Fiberglass Fabric Rolls are a preferred choice for manufacturing electrical components. They protect against electrical currents, reducing the risk of short circuits and other electrical hazards.4. Flame Retardancy: Safety is paramount in industries where fire hazards are a concern. Fiberglass Fabric Rolls are renowned for their exceptional flame resistance, making them an ideal choice for applications in aerospace, automotive, and building materials, ensuring reinforced safety measures.5. Chemical Resistance: Many industries face challenges related to chemical corrosion and exposure. Fiberglass Fabric Rolls offer outstanding resistance to chemicals, acids, and alkalis, making them an incredibly stable choice for applications such as chemical storage, pipe insulation, and chemical processing.6. UV Resistance: Outdoor applications often require materials that can withstand prolonged exposure to sunlight. The UV stability of Fiberglass Fabric Rolls makes them an excellent choice for outdoor structures, marine applications, and solar panels.7. Lightweight and Flexibility: Fiberglass Fabric Rolls have the advantage of being lightweight, combining strength with ease of handling. This makes them highly versatile and suitable for applications such as sports equipment, boat hulls, and aircraft components.Future Prospects:With continuous advancements in technology, the potential applications of Fiberglass Fabric Rolls are expected to expand further. Researchers and manufacturers, such as {Company Name}, are exploring opportunities to enhance the material's characteristics, develop new composites, and improve manufacturing processes. Some potential areas of growth include renewable energy systems, automotive engineering, and additive manufacturing.Conclusion:The increasing use of Fiberglass Fabric Rolls across a wide range of industries speaks volumes about its versatility, strength, and reliability. Its exceptional mechanical and thermal properties, combined with resistance to chemicals and flames, make it an indispensable material in various sectors. As companies like {Company Name} continue to advance fiberglass technology, we can expect even more groundbreaking innovations that push boundaries and create safer and more sustainable solutions for the future.

Biaxial Fiberglass Fabric: What You Need to Know

Fiberglass Biaxial Fabric Gaining Popularity in Construction IndustryIn recent years, the construction industry has seen a significant shift towards the use of innovative and advanced materials to improve the quality and durability of structures. One such material that has gained popularity in the industry is Fiberglass Biaxial Fabric, a versatile and high-performance material that is used for reinforcing and strengthening concrete and other construction materials. With its exceptional strength and flexibility, Fiberglass Biaxial Fabric has quickly become a preferred choice for construction professionals looking for reliable and durable reinforcement solutions.Fiberglass Biaxial Fabric is a composite material made from high-quality fiberglass strands that are woven together in a biaxial pattern, providing equal strength in both the horizontal and vertical directions. This unique construction results in a material that offers superior mechanical properties and exceptional load-carrying capacity. The fabric is available in various weights and widths, making it suitable for a wide range of construction applications, including roads, bridges, buildings, and other infrastructure projects.One of the leading providers of Fiberglass Biaxial Fabric is [company name removed], a renowned company with a strong reputation for delivering high-quality reinforcement solutions to the construction industry. With extensive experience and expertise in fiberglass technology, [company name removed] has become a trusted partner for construction professionals looking for reliable and innovative reinforcement materials.[Company name removed] offers a wide range of Fiberglass Biaxial Fabric products designed to meet the specific needs of different construction projects. The company's Fiberglass Biaxial Fabric is known for its exceptional tensile strength, corrosion resistance, and ease of handling and installation. In addition, [company name removed] provides customized solutions to accommodate unique project requirements, ensuring that construction professionals have access to high-performance reinforcement materials that are tailored to their needs.The use of Fiberglass Biaxial Fabric in construction offers several significant benefits. Firstly, the material significantly improves the tensile and flexural strength of concrete, contributing to the overall structural integrity and longevity of the construction. Furthermore, Fiberglass Biaxial Fabric is lightweight and easy to handle, reducing labor costs and speeding up the construction process. The material's corrosion resistance properties also make it ideal for use in harsh environmental conditions, ensuring long-term durability and performance.One of the key advantages of Fiberglass Biaxial Fabric is its versatility. The material can be used in a wide range of construction applications, including concrete slabs, walls, and foundations, as well as in road and pavement construction. Its high tensile strength and low elongation make it an ideal choice for reinforcing structural elements, providing added support and stability to the construction.The growing demand for Fiberglass Biaxial Fabric in the construction industry can be attributed to its proven performance and reliability in reinforcing concrete and other construction materials. With an increasing emphasis on building resilient and long-lasting structures, construction professionals are turning to innovative materials like Fiberglass Biaxial Fabric to enhance the quality and durability of their projects.[Company name removed] remains at the forefront of providing high-quality Fiberglass Biaxial Fabric to meet the evolving needs of the construction industry. With a commitment to innovation and excellence, the company continues to drive advancements in fiberglass technology, delivering reinforcement solutions that set new standards for performance and durability in construction.As the construction industry continues to embrace advanced materials for improving construction practices, Fiberglass Biaxial Fabric is poised to play a pivotal role in shaping the future of construction. With its unmatched strength, versatility, and performance, Fiberglass Biaxial Fabric is set to remain a preferred choice for construction professionals looking to build resilient and sustainable structures for years to come.