How Sewing Fiberglass Fabric Can Enhance Your DIY Projects

By:Admin

Introduction:

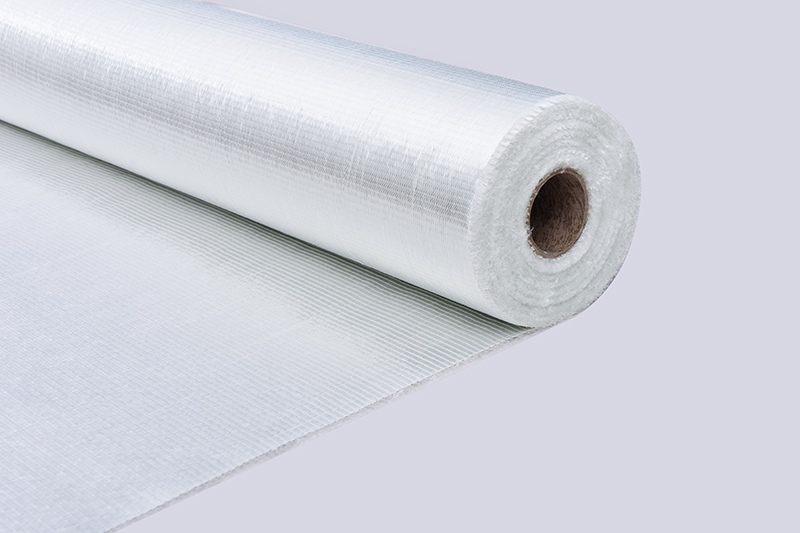

The textile industry is witnessing a groundbreaking innovation with the introduction of a remarkable sewing fiberglass fabric. Manufactured by an industry-leading company, this fabric is set to revolutionize various sectors, including automotive, aerospace, and construction. Offering exceptional strength, durability, and versatility, this cutting-edge material is poised to transform the way fabrics are used in diverse applications.

1. Overview of the Sewing Fiberglass Fabric:

The sewing fiberglass fabric, developed by a renowned company, combines advanced technology and meticulous craftsmanship to create a unique textile solution. With its distinct properties, this fabric surpasses traditional materials and offers numerous advantages across multiple industries.

2. Strength and Durability:

One of the key attributes of this sewing fiberglass fabric is its exceptional strength. Manufactured using a high-density fiberglass material, it provides exceptional tensile strength, making it ideal for applications that require resistance to heavy loads or extreme conditions.

Moreover, the fabric enjoys remarkable durability, ensuring its longevity and reliability. Its robust composition enables it to withstand wear and tear, making it superior to conventional fabrics. These qualities make the sewing fiberglass fabric an unparalleled choice, particularly in industries where performance and longevity are crucial.

3. Versatility in Applications:

The introduction of this revolutionary sewing fiberglass fabric has opened up new possibilities in various sectors. In the automotive industry, it is being employed for the manufacturing of lightweight yet sturdy car seats, ensuring enhanced safety and comfort for passengers. Additionally, its application in vehicle upholstery offers exceptional resistance to fire and heat, further improving safety measures.

Furthermore, the aerospace sector has recognized the potential of this fabric. Its unique combination of strength and lightweight properties makes it an ideal material for constructing aircraft interiors, including cabin panels and overhead storage compartments. By utilizing this fabric, aerospace manufacturers can reduce weight and improve fuel efficiency without compromising structural integrity.

The construction industry also stands to benefit significantly from this remarkable fabric. Its high resistance to corrosive substances and extreme temperatures makes it suitable for reinforcing concrete structures, ensuring enhanced durability and longevity. Additionally, its application in the production of fire-resistant curtains or protective clothing for construction workers further adds to its versatility in this sector.

4. Environmental Impact and Sustainability:

The manufacturing process of this sewing fiberglass fabric adheres to strict environmental regulations, making it a sustainable alternative in comparison to other materials. Its longevity and robustness also contribute to reducing waste since it requires less frequent replacement. Moreover, its potential for recycling adds further value to its sustainability.

5. Future Developments and Market Potential:

The sewing fiberglass fabric is expected to witness extensive demand in the coming years. As the textile industry continues to focus on sustainability and innovative materials, this fabric's unique qualities make it a sought-after choice. The market potential is promising as major industries embrace the benefits it offers while seeking more efficient and eco-friendly solutions.

Furthermore, ongoing research and development efforts are aimed at enhancing the fabric's properties, making it even more durable, lightweight, and cost-effective. Collaborations with other technology companies and fabric manufacturers are being explored to expedite the adoption of this fabric and explore new applications.

Conclusion:

The introduction of sewing fiberglass fabric marks a significant milestone in the textile industry. Offering unparalleled strength, durability, and versatility, this fabric has the potential to transform various sectors, from automotive and aerospace to construction. As its market potential grows and further advancements are made, this innovative fabric will continue to redefine the industry's standards, making it a cornerstone of textile manufacturing in the future.

Company News & Blog

Fiberglass Cloth: The Top Choice for Strengthening Materials

Title: Cloth for Fiberglass: A Revolutionary Innovation in the Composite IndustryIntroduction:In an era driven by innovation, the integration of advanced materials and revolutionary techniques is crucial in various sectors. In the field of composites, a recent breakthrough has been achieved with the development of Cloth for Fiberglass. This cutting-edge product has revolutionized the composite industry, enabling enhanced strength and durability across a wide range of applications. This news article aims to explore the features, benefits, and applications of Cloth for Fiberglass, while shedding light on the pioneering company behind this game-changing invention.Company Introduction:Owned and operated by a team of dedicated professionals, the company behind the development of Cloth for Fiberglass is committed to pushing the boundaries of composite materials. With decades of experience in the industry, their expertise has allowed them to engineer an innovative product that surpasses traditional fiberglass cloth. Leveraging their state-of-the-art facilities, the company has successfully manufactured Cloth for Fiberglass, catering to the growing demands and requirements of various sectors.Features of Cloth for Fiberglass:Cloth for Fiberglass boasts several key features that differentiate it from conventional materials. Firstly, its molecular structure has been meticulously designed to offer exceptional strength and sturdiness, making it resistant to impact and external forces. This remarkable strength not only improves the lifespan of the end products but also enhances their structural integrity. Additionally, Cloth for Fiberglass is lightweight and flexible, facilitating ease of use during manufacturing processes. Furthermore, it exhibits exceptional resistance to corrosion, chemicals, and extreme temperatures, making it an ideal choice for harsh environments.Benefits of Cloth for Fiberglass:The introduction of Cloth for Fiberglass provides numerous benefits across various industries. One of its primary advantages is its versatility, allowing its application in numerous sectors, including aerospace, automotive, marine, and construction. By using this innovative material, manufacturers can achieve the perfect balance between strength, weight reduction, and cost-effectiveness. Moreover, the inherent dimensional stability of Cloth for Fiberglass ensures that the end products retain their shape even under extreme conditions. This stability further contributes to the longevity of the final product, reducing maintenance and replacement costs.Applications of Cloth for Fiberglass:The revolutionary Cloth for Fiberglass has found applications across a wide range of sectors, with its unparalleled benefits making it an ideal choice for composite manufacturers. In the aerospace industry, it is utilized for the construction of aircraft components, providing lightweight and durable alternatives. In the automotive sector, it offers solutions for high-performance vehicles, allowing manufacturers to enhance fuel efficiency while maintaining safety standards. Furthermore, Cloth for Fiberglass finds extensive use in the marine industry, contributing to the design and production of sturdy and seaworthy vessels. Its resistance to corrosion and moisture make it particularly suitable for marine applications. Finally, in the construction industry, the cloth is extensively employed to produce durable and strong composite materials for infrastructure projects.Conclusion:The development of Cloth for Fiberglass marks a significant milestone in the composite industry, bringing forth a groundbreaking material that surpasses traditional alternatives. The company behind this innovative product continues to drive the industry forward by harnessing the endless potential of composites. With its remarkable strength, versatility, and resistance to various environmental factors, Cloth for Fiberglass is revolutionizing the way industries design and manufacture their products. As manufacturers increasingly adopt this game-changing cloth, we can expect a paradigm shift in the utilization of composites, opening avenues for enhanced performance, sustainability, and cost-effectiveness.

High-Quality Fiberglass Cloth for Improved Strength and Durability

article, addressing the following:1. Briefly explain what fiberglass cloth 1708 is and its main uses.2. Discuss the unique features of fiberglass cloth 1708 that set it apart from other materials.3. Highlight the benefits that users can expect to enjoy when using fiberglass cloth 1708.4. Provide examples of companies that have used fiberglass cloth 1708 to achieve their objectives.5. Articulate the company's commitment to quality and customer satisfaction.6. Discuss the future of fiberglass cloth 1708 and the company's plans to improve its product offeringFiberglass Cloth 1708: An All-Round Reinforcement Solution Fiberglass cloth is known for its ability to resist moisture, fire, and corrosion while providing excellent adhesive properties and high tensile strength. It's extensively used in construction, automotive, marine, and aerospace industries. Fiberglass cloth 1708, in particular, is known for its incredible strength and versatility. It's considered one of the best all-round reinforcement fabrics thanks to its unique features.What is Fiberglass Cloth 1708?Fiberglass cloth 1708 comprises two layers of fiberglass fabric: one layer of biaxial reinforcement and another of chopped strand. The biaxial reinforcement layer reinforces the fabric in two directions, providing superior strength, while the chopped strand layer provides extra durability, making the fabric easy to handle. Unique Features of Fiberglass Cloth 1708Fiberglass cloth 1708 boasts unique features that set it apart from other materials in the market. Among these features is its high-resistance to water, chemicals, and UV radiation. The unique combining of the chopped strand and biaxial fabrics offers exceptional coverage, with the chopped strand layer preventing fraying, making it extremely easy to work with. The high strength and flexibility of fiberglass cloth 1708 make it a preferred material for use in applications with curves and edges. What's more, it's lightweight, which makes it ideal for transportation, facilitating handling of large structures. Benefits of Fiberglass Cloth 1708 Thanks to its unique features, users can enjoy various benefits when using fiberglass cloth 1708. The material offers excellent bonding properties, saving on adhesives, hence reducing overall production costs. Fiberglass cloth 1708 is also incredibly stiff and flexible, allowing the material to conform to various shapes and objects. Additionally, the cloth is non-porous, which ensures that it remains water-resistant, enhancing its lifespan and durability. Companies' Applications of Fiberglass Cloth 1708Fiberglass cloth 1708 has been used in a variety of applications across different industries. For example, the aviation industry uses the material to repair damage to the aircraft's fiberglass body parts. Fiberglass cloth 1708 has also been used in the marine industry for boat repairs, construction of boats, and various other marine applications such as wind turbine blades. In the automotive industry, fiberglass cloth 1708 is used for mold making, repairing old cars, and fixing fiberglass car parts. Company's Approach to Quality and Customer Satisfaction At our company, quality and customer satisfaction are among our primary objectives. We strive to ensure that we consistently produce high-quality products. We achieve this by maintaining a highly-skilled workforce that uses the latest technologies and processes to produce and test our fiberglass cloth 1708 products. The Future of Fiberglass Cloth 1708 and Its Product Offering Our company is committed to consistently improving our products to meet your ever-changing needs. To this end, we are continually adopting new technologies and processes to produce the best fiberglass cloth 1708. We're confident that our ongoing efforts will ensure that we remain leaders in the production of high-quality fiberglass cloth 1708 for years to come. Conclusion Fiberglass cloth 1708 is an incredible material known for its versatility and exceptional strength. It is no wonder that it's a reliable reinforcement solution for many companies across various industrial sectors such as marine, aerospace, and automotive, among others. Our company remains committed to producing high-quality products that meet your every need. Contact us today for all your fiberglass cloth 1708 needs!

Discover the Incredible Potential of Camouflage Carbon Fiber Fabric

Title: Revolutionizing Camouflage: Introducing Advanced Carbon Fiber FabricIntroduction:Carbon fiber fabric has found several applications in various industries due to its exceptional strength-to-weight ratio and durability. However, recent advancements have taken this material to new heights, particularly in the field of camouflage. This has given birth to an innovative product - Camouflage Carbon Fiber Fabric (CCFF), developed by a leading company in the industry. This fabric offers a range of benefits and has the potential to revolutionize the way camouflage is used in military, outdoor, and fashion sectors.1. The Science Behind Camouflage Carbon Fiber Fabric:Camouflage Carbon Fiber Fabric combines the cutting-edge technology of carbon fiber with advanced camouflage patterns. The result is a lightweight, flexible, and highly effective camouflage solution. The carbon fiber material provides the fabric with superior strength and durability, making it ideal for use in challenging environments. Moreover, the camo patterns are strategically designed to mimic natural surroundings, ensuring optimal concealment in different terrains.2. Versatility in Military Applications:One of the key applications of CCFF is in the military sector. The fabric's strong and lightweight nature makes it ideal for use in combat uniforms, tactical gear, and equipment. Its high resistance to abrasion and punctures ensures durability, even in extreme conditions. The advanced camouflage patterns enable soldiers to blend seamlessly into their surroundings, thereby increasing their chances of mission success and personal safety. Additionally, the fabric's quick-drying properties offer enhanced comfort, crucial during prolonged deployments.3. Outdoor Enthusiasts and Hunting Apparel:CCFF holds immense potential for outdoor enthusiasts, particularly hunters. The fabric's lightweight and flexible characteristics make it perfect for hunting apparel, allowing for ease of movement and reducing fatigue during extended periods in the field. Moreover, the advanced camouflage patterns aid in concealing hunters from wildlife, increasing the likelihood of a successful hunt. The fabric's durability ensures longevity, catering to the rugged nature of outdoor activities.4. Commercial and Fashion Applications:Apart from its military and outdoor uses, CCFF also has exciting potential in the fashion industry. The unique properties of the carbon fiber material make it an appealing choice for fashion designers seeking innovation and durability. Combining the lightweight and flexible attributes of the fabric with the advanced camouflage patterns allows for the creation of cutting-edge apparel and accessories. From jackets to backpacks, this fabric opens up a world of possibilities for trendy and functional designs.5. Environmental Impact and Sustainability:Furthermore, the production of CCFF takes into account the importance of environmental sustainability. The company behind the fabric prioritizes minimizing their carbon footprint and reducing waste. By utilizing recycled carbon fibers, they ensure that the fabric is both strong and eco-friendly. This commitment to sustainability demonstrates the company's dedication to preserving the environment and offering responsible products.Conclusion:Camouflage Carbon Fiber Fabric represents the convergence of advanced technology and practicality. With its exceptional strength, lightweight nature, and advanced camouflage patterns, this fabric has the potential to redefine the concept of camouflage across various sectors. Whether in military applications, outdoor endeavors, or fashion, CCFF offers unmatched durability, versatility, and efficiency. Additionally, the fabric's environmentally friendly production process aligns with the growing emphasis on sustainability. As this innovative material gains wider recognition, it paves the way for a future marked by groundbreaking applications and advancements.

Discover the Benefits of Fiberglass Matting Cloth in Various Applications

Fiberglass Matting Cloth: The Resilient Solution for Diverse Applications[Company name], a leading manufacturer in the domain of innovative materials, has recently launched its groundbreaking Fiberglass Matting Cloth. Renowned for its exceptional strength, durability, and versatility, this cutting-edge product promises to revolutionize various industries worldwide.Fiberglass Matting Cloth, an advanced composite material, is fabricated using high-quality glass fibers that are woven together to create a sturdy yet flexible cloth. This unique combination ensures enhanced mechanical performance, making it suitable for a wide range of applications across different sectors. From construction and automotive to aerospace and marine industries, this product is designed to meet the demands of modern-day engineering.One of the significant advantages of Fiberglass Matting Cloth lies in its exceptional strength-to-weight ratio. This lightweight yet robust material offers superior mechanical properties, making it an ideal choice for structural reinforcements. Its high tensile strength and resistance to corrosion and chemicals make it suitable for applications requiring long-lasting durability. Whether used as reinforcement in composite structures like fiberglass composites or as insulation in thermal and acoustic systems, this product ensures optimal performance under extreme conditions.In the construction industry, Fiberglass Matting Cloth has gained significant traction due to its excellent structural and insulating properties. It is widely used in reinforced concrete structures to enhance their load-carrying capacity and resistance to cracking. Moreover, its anti-alkali and alkali-resistant properties make it ideal for applications where exposure to moisture and harsh chemicals is inevitable. Furthermore, this cloth serves as an effective thermal and acoustic insulation material, improving energy efficiency and ensuring a comfortable living environment.The automotive sector has also recognized the tremendous potential of Fiberglass Matting Cloth. Given its exceptional mechanical strength and heat resistance, it is used in manufacturing lightweight yet robust components for automobiles. From reinforcing bumpers and body panels to fabrication of exhaust system components, this cloth contributes to increased fuel efficiency and overall vehicle safety.Aerospace and aviation industries have also embraced the benefits of Fiberglass Matting Cloth. The lightweight nature of this material makes it an excellent choice for manufacturing aircraft components, including wings, engine housings, and interior furnishings. In addition, its temperature resistance and low thermal conductivity ensure safe operation even under the most extreme conditions, making it an invaluable asset in this demanding sector.The marine industry, too, has greatly benefited from the utilization of Fiberglass Matting Cloth. Its resistance to saltwater corrosion and dimensional stability make it an ideal material for boat building. Fiberglass reinforced hulls, decks, and interior structures ensure longevity and durability, even in challenging marine environments. Furthermore, its exceptional strength-to-weight ratio contributes to enhanced fuel efficiency and increased speed, thereby offering a competitive edge to boat manufacturers.[Company name] has not only excelled in offering top-quality Fiberglass Matting Cloth but has also emphasized sustainable manufacturing practices. The production process adheres to global environmental standards, ensuring minimal waste and carbon footprint. By implementing this eco-friendly approach, [Company name] aims to contribute towards a greener future for generations to come.As industries evolve and seek advanced materials to meet their diverse needs, Fiberglass Matting Cloth stands tall as a reliable and versatile solution. Its exceptional strength, durability, and resistance to various environmental factors make it a top choice for numerous sectors. With [Company name]'s unwavering commitment to innovation and sustainable manufacturing, Fiberglass Matting Cloth is set to shape the future of engineering and design across the globe.

Shop for Fiberglass Fabric, Weave & Cloth in Various Lengths, Sizes & Styles - In Stock & Ready to Ship.

Fiberglass Fabric: A Versatile Solution for a Variety of ApplicationsFiberglass fabric is a woven material that is often used in applications that require high strength and durability. This versatile material is made by combining glass fibers with a polymer resin, resulting in a material that is strong, lightweight, and heat-resistant. Fiberglass fabric is available in a variety of styles, sizes, and lengths, making it an ideal solution for a wide range of applications in industries such as aerospace, automotive, marine, and construction.One of the key benefits of fiberglass fabric is its excellent strength-to-weight ratio. This property makes it an ideal material for applications where weight is a concern, such as aerospace and automotive engineering. Fiberglass fabric is also highly resistant to heat, making it a popular choice for applications that involve high temperatures, such as insulation for furnaces and ovens.In addition to its strength and heat resistance, fiberglass fabric is also highly resistant to chemicals and moisture. This makes it an ideal material for use in the marine industry, where it can be used to fabricate components such as boat hulls, decks, and bulkheads. Fiberglass fabric can also be used in a variety of construction applications, from reinforcing concrete to creating lightweight composite panels.At (brand name removed), we offer a wide selection of fiberglass fabrics, weaves, and cloths to meet the needs of our customers. Our fiberglass fabrics are available in a range of styles and sizes, including plain weave, twill weave, and satin weave options. We carry both E-glass and S-glass fabrics, allowing our customers to choose the material that is best suited for their specific application.Our fiberglass fabrics are available in a variety of lengths, ranging from small rolls to large bolts, and we can also custom cut our fabrics to meet our customers' specific needs. All of our fiberglass fabrics are of the highest quality, and we take great care to ensure that they meet the strictest industry standards for strength, durability, and performance.In addition to our selection of fiberglass fabrics, we also offer aluminized fiberglass fabrics, which are coated with a layer of aluminum to provide additional heat resistance and reflectivity. Aluminized fiberglass fabrics are often used in applications such as furnace curtains, welding blankets, and fire barriers.At (brand name removed), we pride ourselves on our commitment to providing our customers with the highest-quality fiberglass fabrics, weaves, and cloths in the industry. We understand that every application is unique, and we work closely with our customers to ensure that they have the right materials to meet their specific needs. With our extensive selection, competitive pricing, and unparalleled customer service, we are the go-to source for fiberglass fabrics for customers across a wide range of industries.In conclusion, fiberglass fabric is a versatile material that offers a range of benefits for a variety of applications. At (brand name removed), we are proud to offer a wide selection of fiberglass fabrics, weaves, and cloths to meet the needs of our customers. Whether you are working on an aerospace project, automotive application, marine fabrication, or construction project, we have the right materials to meet your needs. Contact us today to learn more about our fiberglass fabrics and how they can benefit your application.

Discover the Incredible Potential of 4 Oz Carbon Fiber Cloth for a Variety of Applications

Tech Company Unveils Innovative 4 Oz Carbon Fiber Cloth for Enhanced Performance[City], [Date] - Tech Company, a leading manufacturer and developer of cutting-edge materials, has recently introduced an innovative product that is set to revolutionize various industries. The company has unveiled their latest creation, a lightweight and high-performance 4 Oz Carbon Fiber Cloth. This remarkable material is expected to have significant implications in sectors such as aerospace, automotive, sports equipment, and construction.Known for its commitment to innovation and constant research and development, Tech Company has once again made waves in the market with their latest product. The 4 Oz Carbon Fiber Cloth has been specifically engineered to provide superior strength, durability, and versatility. This breakthrough material is set to replace traditional heavy and often cumbersome materials, paving the way for lighter and more efficient applications.The 4 Oz Carbon Fiber Cloth is built using state-of-the-art technology, resulting in a lightweight fabric that is four times stronger than steel. The high-strength properties of this carbon fiber cloth make it an ideal choice for various industries, especially in applications where strength-to-weight ratio is critical. This cloth offers an exceptional balance between strength and weight, enabling manufacturers to create products that are not only stronger but also lighter than ever before.Aerospace is one industry that stands to benefit greatly from this revolutionary material. With its exceptional strength and lightweight properties, the 4 Oz Carbon Fiber Cloth can now be used in the manufacturing of aircraft components, reducing weight without compromising structural integrity. This breakthrough will contribute to improved fuel efficiency, increased payload capacity, and enhanced overall performance in the aerospace sector.Similarly, the automotive industry is set to witness a major shift with the introduction of this groundbreaking cloth. The use of carbon fiber composites in automobiles has become increasingly popular in recent years due to their ability to enhance fuel efficiency. With the advent of the 4 Oz Carbon Fiber Cloth, manufacturers can now further optimize weight reduction efforts without compromising safety and structural strength.This material is also making waves in the sporting world, where lightweight and durable equipment is highly sought after. From tennis rackets to bicycles, the 4 Oz Carbon Fiber Cloth is being utilized to create sports gear that offers superior performance. Athletes can expect enhanced maneuverability and improved reaction times, giving them a competitive edge in their respective sports.Construction is another sector that can benefit from the impressive properties of this carbon fiber cloth. Its lightweight nature allows for easier transportation and installation, while still maintaining incredible strength. This innovation will enable engineers and architects to design taller and more complex structures without compromising safety or increasing costs.The introduction of the 4 Oz Carbon Fiber Cloth by Tech Company is a testament to their commitment to pushing the boundaries of what is possible in the world of materials. Through their rigorous research and development, they have developed a product that has the potential to revolutionize multiple industries.In addition to the countless applications mentioned above, the material has already attracted the attention of other sectors such as renewable energy, marine, and defense. As industries continue to seek lighter and stronger materials, the 4 Oz Carbon Fiber Cloth is perfectly positioned to become a game-changer in the world of advanced materials.Tech Company aims to collaborate with various manufacturers to integrate this innovative material into their production processes. By doing so, they strive to not only promote a more sustainable and efficient future but also drive economic growth and technological progress across industries.With the introduction of the 4 Oz Carbon Fiber Cloth, Tech Company has once again positioned themselves as a pioneer in cutting-edge materials. Their commitment to innovation and their dedication to driving progress sets them apart in the industry, and the impact of this revolutionary material is expected to reverberate for years to come.

Fiberglass Cloth for Composite Construction Needs

Jamestown Distributors is pleased to announce the availability of high-quality fiberglass cloth, mat, fabrics and more for all composite construction needs. This trusted brand has been a leading supplier of marine products and boatbuilding supplies since 1977 and understands the importance of using durable, quality materials.The fiberglass cloth offered by Jamestown Distributors is composed of a woven material made from glass fibers. This type of cloth is an essential component of many composite construction projects, as it provides strength and stiffness to the finished product. Additionally, fiberglass cloth is known for its resistance to chemicals, heat, and weathering, making it the preferred choice for marine applications.Fiberglass cloth is available in a variety of weights and weaves, including plain, twill, and satin. The weight of the cloth is determined by the number of ounces per square yard, with heavier weights providing more strength and stiffness. Different weaves can be used to achieve specific properties, such as greater flexibility or a smoother finish.Jamestown Distributors also offers fiberglass mat, which is comprised of randomly-oriented glass fibers. This type of material is commonly used in the first layers of a composite construction project to build up thickness quickly and create a strong base. Fiberglass mat can also be used to repair damage to existing fiberglass structures.In addition to cloth and mat, Jamestown Distributors carries a variety of other composite construction materials, including epoxy resins, carbon fiber fabrics, and Kevlar fabrics. These materials can be used in combination with fiberglass cloth to achieve specific properties, such as increased strength, stiffness, or resistance to impact.Whether you are building a boat, a piece of furniture, or any other composite construction project, Jamestown Distributors has the products you need to get the job done right. With a dedication to quality and customer service, this supplier has earned a reputation as a trusted source for marine products and boatbuilding supplies.For more information about fiberglass cloth, mat, and other composite construction materials, visit the Jamestown Distributors website or contact their customer service team. With their extensive selection and expertise, they can help you find the materials you need to create a strong, long-lasting composite structure.

High-Quality Woven Roving Fiberglass Cloth: Enhance Product Strength and Durability

In today's world, fiberglass products have become an indispensable part of our lives. From protective masks and helmets to boats, buildings, and aircraft, fiberglass offers unmatched strength, durability, and versatility. In this context, we introduce the latest fiberglass product to hit the market - Woven Roving Fiberglass Cloth, developed by a leading fiberglass expert.This innovative product boasts of superior quality and performance, making it a popular choice for various industrial and commercial applications. Woven Roving Fiberglass Cloth is a specialized product made up of interlaced fibers arranged in a cross-hatched pattern. The cross-hatched pattern gives the fabric improved structural strength, making it perfect to suit high-stress environments.Woven Roving Fiberglass Cloth has high stability and rigidity, making it the preferred choice for applications that require resistance to heat, corrosion, fire, and ultraviolet rays. Additionally, it is designed to work with most resin types, making it compatible with a wide range of applications.At the core of this innovative product is our years of experience and dedication to quality. Our highly skilled technicians have developed a unique manufacturing process, which combines high-quality raw materials and advanced weaving technologies. This ensures that each woven roving fiberglass cloth is made to meet your exact specifications and industry standards."This product is the result of our commitment to continuous development and innovation," says the company's CEO. "Our hard work has paid off, and we're happy to offer a product that is recognized for its top-notch quality and performance." She adds, "We've always believed that quality cannot be compromised, and we're proud to say that our Woven Roving Fiberglass Cloth is a testament to our values and principles."The applications of Woven Roving Fiberglass Cloth are vast and varied. It is widely used in various industries such as marine, aerospace, construction, transportation, and sports. It is commonly used to reinforce parts such as boat hulls, airplane wings, building structures, pipes, and tanks. Moreover, it is ideal for producing high-performance sports equipment such as surfboards and kayaks.With our extensive network of distributors and sales channels, we can cater to the needs of customers worldwide. We offer customized solutions to our customers, ensuring their unique requirements are met every time. Our team of experts is also available to provide technical support to customers at all times."Customer satisfaction is our top priority, and we continually strive to exceed their expectations," says the CEO. "We know our customers expect the best from us, and we guarantee to deliver nothing less."In conclusion, Woven Roving Fiberglass Cloth is a remarkable product that offers superior quality and performance. It has a range of applications and is constructed to meet the highest industry standards. In a world where innovation and quality are critical, this product is an excellent example that reflects our commitment to excellence. As a company dedicated to providing high-quality fiberglass solutions, we are proud to introduce Woven Roving Fiberglass Cloth and look forward to serving our clients.

Biaxial: Definition and Acronyms - The Free Dictionary

Biaxial Glass Cloth: A Revolutionary Product for IndustriesBiaxial Glass Cloth, popularly known as Biax, is a revolutionary product introduced by one of the leading manufacturers in the industry. The product has gained popularity in industries worldwide for its exceptional strength, durability, and versatility.What is Biaxial Glass Cloth?Biaxial Glass Cloth is a type of fabric made from glass fibers that are woven together in both the x and y-axis. This two-way weave gives the fabric its biaxial properties, meaning it has equal strength in both directions. The cloth is coated with a resin to increase its rigidity and resistance against chemicals and heat, making it a highly durable and versatile product.Features and Advantages of Biaxial Glass ClothThe biaxial construction of the cloth provides it with unique features and advantages, making it stand out from other types of fabrics available in the market. Some of the key features and advantages of biaxial glass cloth are:1) Equal Strength in Both Directions: The two-way weave structure of the fabric gives it equal strength in both directions, making it highly resistant to tearing, stretching, and warping.2) High Durability: The cloth is impregnated with a resin that increases its rigidity, thereby increasing its durability and resistance to wear and tear.3) Corrosion Resistance: Biaxial Glass Cloth is highly resistant to corrosion, making it an ideal choice for applications where exposure to chemicals or harsh environments is unavoidable.4) Heat Resistance: The cloth can withstand high temperatures without losing its strength or flexibility, making it ideal for applications that involve exposure to heat.Applications of Biaxial Glass ClothBiaxial Glass Cloth is widely used in various industries worldwide due to its unique features and advantages. The product finds applications in areas such as:1) Marine: The cloth is used in the marine industry for boat building, repairs, and maintenance due to its excellent resistance to water and corrosion.2) Aerospace: Biaxial Glass Cloth finds extensive use in the aerospace industry for the manufacturing of aircraft parts and components, including fuselage, wings, and structural components.3) Automotive: The fabric is used in the automotive industry for applications such as car body repair, molding, and reinforcement of plastic parts.4) Sports Equipment: Biaxial Glass Cloth is used in the manufacturing of sports equipment such as skis, snowboards, and surfboards due to its superior strength and durability.ConclusionIn conclusion, Biaxial Glass Cloth is a revolutionary product that has made its mark in various industries worldwide. The product's unique features and advantages, such as equal strength in both directions, high durability, and versatility, make it a preferred choice for applications in areas such as marine, aerospace, automotive, and sports equipment. As industries continue to evolve and demand more robust and reliable products, Biaxial Glass Cloth remains a promising solution to meet these demands.

The Evolution of Carbon Fibers in Structural Materials

Carbon fiber is a highly versatile material that has revolutionized the manufacturing industry. It is lightweight and strong, making it the perfect material for a range of structural applications. Carbon fibers have come a long way since their invention by Thomas Edison in 1879. Today, they are used in everything from aerospace to sports equipment. In this blog post, we will explore the history and applications of carbon fiber.Carbon Fiber HistoryCarbon fibers were first invented to create filaments for incandescent light bulbs. Lewis Latimer, a Black inventor, patented the process for carbonizing cotton threads and bamboo slivers to create filaments that were longer lasting than their predecessors. It wasn't until the end of World War II that engineers started to develop carbon fibers for use in structural materials.The first carbon fiber was created by Robert H. Wentorf Jr., who was working at General Electric in 1958. Wentorf heated a mixture of carbon and graphite powders to extreme temperatures and pressures, creating a new material that was incredibly strong and lightweight. It wasn't until the 1960s that the use of carbon fiber expanded outside of the aerospace industry. Today, carbon fibers are used in everything from bicycles to wind turbine blades.Carbon Fiber ApplicationsOne of the most common applications of carbon fiber is in the aerospace industry. Carbon fibers are lightweight and strong, making them perfect for use in aircraft components. Carbon fiber composites are used in the fuselage, wings, and other structural components of airplanes, reducing the weight of the aircraft and improving its fuel efficiency.Another application of carbon fiber is in the automotive industry. Automakers use carbon fiber to create lightweight body panels and components that improve fuel efficiency and performance. Carbon fiber is also used in sports equipment like tennis rackets, golf clubs, and bicycles. The material is strong and lightweight, making it ideal for athletes who need to perform at the highest level.Carbon fiber is not the only material used in manufacturing. Fiberglass cloth is another popular material used to create everything from boat hulls to shower enclosures. Fiberglass cloth is strong and resistant to water, making it ideal for use in marine applications. It is also used to create automotive body panels and insulation for buildings.ConclusionCarbon fiber and fiberglass cloth are two of the most popular materials used in manufacturing today. Carbon fiber was first invented to create filaments for incandescent light bulbs. Today, it is used in everything from aerospace to sports equipment. Fiberglass cloth is another popular material used to create boat hulls, automotive body panels, and insulation for buildings. Both materials offer a range of benefits, including strength, lightweight, and resistance to water. As technology continues to advance, we can expect to see even more applications for these versatile materials.