Top Lightweight Fiberglass Cloth for Versatile Use

By:Admin

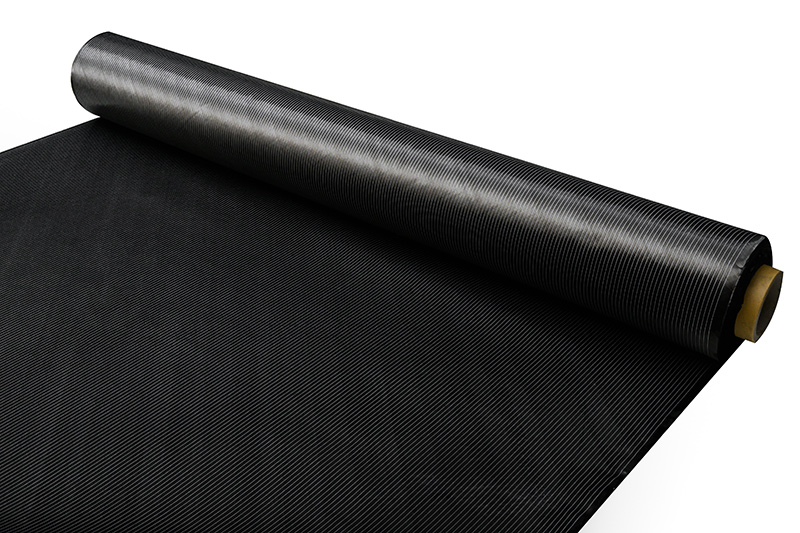

[CITY], [DATE] - [Company Name], a dynamic and innovative leader in the production of advanced materials, has recently launched its latest product – a game-changing Lightweight Fiberglass Cloth. This revolutionary solution is set to transform multiple industries, including aerospace, automotive, and construction.

[Company Name] has always been at the forefront of research and development to provide the market with high-performance materials. Their new Lightweight Fiberglass Cloth is a testament to their commitment to innovation and pushing boundaries. This cutting-edge product offers a wide range of advantages that make it a superior choice over traditional cloth options.

One of the standout features of [Company Name]'s Lightweight Fiberglass Cloth is its exceptional strength-to-weight ratio. The cloth is engineered using an advanced manufacturing process that ensures it remains lightweight while offering unparalleled strength and durability. This characteristic makes it a preferred choice in industries where weight reduction is essential, such as aerospace and automotive manufacturing.

Moreover, [Company Name]'s Lightweight Fiberglass Cloth boasts excellent thermal and electrical insulation properties. This feature makes it highly desirable for applications in the construction industry, where insulation is crucial for energy efficiency and comfort. The cloth's ability to resist heat penetration ensures optimum thermal regulation, leading to reduced energy consumption and lower carbon footprints.

The manufacturing process of the Lightweight Fiberglass Cloth also ensures its exceptional corrosion resistance. Traditional cloth materials often succumb to the harmful effects of corrosion over time, compromising their structural integrity. However, the specialized manufacturing techniques employed by [Company Name] provide the cloth with a powerful shield against corrosion, prolonging its lifespan and reducing maintenance costs significantly.

[Company Name]'s commitment to sustainability is also evident in the production of their Lightweight Fiberglass Cloth. The cloth is crafted using eco-friendly materials and adheres to strict environmental standards throughout the manufacturing process. By reducing the carbon footprint associated with traditional cloth manufacturing, [Company Name] is positioning itself as a responsible and forward-thinking company.

Furthermore, [Company Name] aims to ensure that their customers experience a seamless integration of the Lightweight Fiberglass Cloth into their manufacturing processes. To achieve this, the company offers comprehensive support services, including technical guidance, training seminars, and even customized solutions to suit specific applications. Regardless of the size or complexity of the project, [Company Name] ensures that their customers receive the necessary assistance to maximize the benefits of the Lightweight Fiberglass Cloth.

With the introduction of their Lightweight Fiberglass Cloth, [Company Name] has set the benchmark for excellence in the industry. Its exceptional attributes and numerous applications have garnered attention from major players across various sectors. Customers are already witnessing significant improvements in product performance and cost savings by replacing their traditional cloths with [Company Name]'s groundbreaking solution.

By continuously investing in research and development, [Company Name] demonstrates its commitment to pioneering the next generation of high-performance materials. The company's Lightweight Fiberglass Cloth exemplifies its relentless pursuit of innovation and the desire to provide customers with superior products that drive efficiency and sustainability.

As the industry continues to applaud [Company Name]'s groundbreaking solutions, it is clear that the Lightweight Fiberglass Cloth is transforming the landscape of materials used in multiple sectors. The future of lightweight materials is in the hands of [Company Name], and they are gearing up to revolutionize industries, one fiber at a time.

About [Company Name]:

[Company Name], founded in [YEAR], is a leading provider of advanced materials, specializing in the production of high-performance fibers and fabrics. With a strong focus on innovation and customer satisfaction, [Company Name] has established itself as a renowned name in the industry. Their products are known for their exceptional quality, durability, and cutting-edge technology. Through extensive research and development, [Company Name] continues to redefine industry standards and provide market-leading solutions. For more information, please visit [www.companywebsite.com].

Company News & Blog

Top Lightweight Fiberglass Cloth for Versatile Use

[Company Name], Leading Provider of Lightweight Fiberglass Cloth, Revolutionizes the Industry with its Cutting-Edge Solution[CITY], [DATE] - [Company Name], a dynamic and innovative leader in the production of advanced materials, has recently launched its latest product – a game-changing Lightweight Fiberglass Cloth. This revolutionary solution is set to transform multiple industries, including aerospace, automotive, and construction.[Company Name] has always been at the forefront of research and development to provide the market with high-performance materials. Their new Lightweight Fiberglass Cloth is a testament to their commitment to innovation and pushing boundaries. This cutting-edge product offers a wide range of advantages that make it a superior choice over traditional cloth options.One of the standout features of [Company Name]'s Lightweight Fiberglass Cloth is its exceptional strength-to-weight ratio. The cloth is engineered using an advanced manufacturing process that ensures it remains lightweight while offering unparalleled strength and durability. This characteristic makes it a preferred choice in industries where weight reduction is essential, such as aerospace and automotive manufacturing.Moreover, [Company Name]'s Lightweight Fiberglass Cloth boasts excellent thermal and electrical insulation properties. This feature makes it highly desirable for applications in the construction industry, where insulation is crucial for energy efficiency and comfort. The cloth's ability to resist heat penetration ensures optimum thermal regulation, leading to reduced energy consumption and lower carbon footprints.The manufacturing process of the Lightweight Fiberglass Cloth also ensures its exceptional corrosion resistance. Traditional cloth materials often succumb to the harmful effects of corrosion over time, compromising their structural integrity. However, the specialized manufacturing techniques employed by [Company Name] provide the cloth with a powerful shield against corrosion, prolonging its lifespan and reducing maintenance costs significantly.[Company Name]'s commitment to sustainability is also evident in the production of their Lightweight Fiberglass Cloth. The cloth is crafted using eco-friendly materials and adheres to strict environmental standards throughout the manufacturing process. By reducing the carbon footprint associated with traditional cloth manufacturing, [Company Name] is positioning itself as a responsible and forward-thinking company.Furthermore, [Company Name] aims to ensure that their customers experience a seamless integration of the Lightweight Fiberglass Cloth into their manufacturing processes. To achieve this, the company offers comprehensive support services, including technical guidance, training seminars, and even customized solutions to suit specific applications. Regardless of the size or complexity of the project, [Company Name] ensures that their customers receive the necessary assistance to maximize the benefits of the Lightweight Fiberglass Cloth.With the introduction of their Lightweight Fiberglass Cloth, [Company Name] has set the benchmark for excellence in the industry. Its exceptional attributes and numerous applications have garnered attention from major players across various sectors. Customers are already witnessing significant improvements in product performance and cost savings by replacing their traditional cloths with [Company Name]'s groundbreaking solution.By continuously investing in research and development, [Company Name] demonstrates its commitment to pioneering the next generation of high-performance materials. The company's Lightweight Fiberglass Cloth exemplifies its relentless pursuit of innovation and the desire to provide customers with superior products that drive efficiency and sustainability.As the industry continues to applaud [Company Name]'s groundbreaking solutions, it is clear that the Lightweight Fiberglass Cloth is transforming the landscape of materials used in multiple sectors. The future of lightweight materials is in the hands of [Company Name], and they are gearing up to revolutionize industries, one fiber at a time.About [Company Name]:[Company Name], founded in [YEAR], is a leading provider of advanced materials, specializing in the production of high-performance fibers and fabrics. With a strong focus on innovation and customer satisfaction, [Company Name] has established itself as a renowned name in the industry. Their products are known for their exceptional quality, durability, and cutting-edge technology. Through extensive research and development, [Company Name] continues to redefine industry standards and provide market-leading solutions. For more information, please visit [www.companywebsite.com].

New lightweight material made of carbon kevlar hybrid fabric is set to revolutionize the aerospace industry

Title: Innovative Carbon Kevlar Hybrid Fabric Revolutionizes the Textile IndustryIntroduction:In a groundbreaking development, an industry-leading company has introduced a cutting-edge Carbon Kevlar Hybrid Fabric, emerging as a game-changer in the textile world. Embracing advanced technologies, this revolutionary fabric combines the remarkable properties of carbon fiber and Kevlar, offering unprecedented strength, durability, and versatility. With its wide range of applications, this innovative fabric is set to reshape industries such as aerospace, automotive, sports, and defense.1. The Unparalleled Strength of Carbon Kevlar Hybrid Fabric:The Carbon Kevlar Hybrid Fabric incorporates the best qualities of both carbon fiber and Kevlar. Carbon fiber is renowned for its exceptional strength-to-weight ratio, making it a preferred choice in industries where lightweight yet robust materials are required. On the other hand, Kevlar is famous for its outstanding resistance to impact and abrasion, making it an ideal choice for ballistic protection and structural reinforcement. By combining these two fibers, this hybrid fabric transcends the limitations of conventional materials, ensuring enhanced performance in a variety of applications.2. Aerospace Industry: Empowering High-performance StructuresThe aerospace industry stands to benefit immensely from the introduction of Carbon Kevlar Hybrid Fabric. Due to its lightweight nature and superior strength, the fabric can be incorporated into the manufacture of aircraft components, including fuselages, wings, and engine parts. By utilizing this innovative fabric, manufacturers can significantly reduce the weight of aircraft, contributing to improved fuel efficiency and lower operating costs. Moreover, the exceptional fatigue resistance of the hybrid fabric enhances the durability and longevity of key structural elements, ensuring increased safety for passengers and crew.3. Automotive Industry: Paving the Way for Safer VehiclesIn the automotive sector, the integration of Carbon Kevlar Hybrid Fabric presents significant advancements in safety and performance. By utilizing this fabric for manufacturing body panels, car manufacturers can enhance crashworthiness while reducing overall vehicle weight. The superior impact resistance of the fabric combined with its lightweight attributes makes it a valuable asset in protecting passengers during collisions. As a result, vehicles can achieve better fuel efficiency while offering enhanced safety to occupants.4. Sports Industry: Elevating Performance EquipmentThe sports industry is no stranger to materials that offer exceptional strength and durability. The Carbon Kevlar Hybrid Fabric is set to revolutionize sports equipment, enabling athletes to reach new heights of performance. Sports gear, such as helmets, paddles, and protective gear, created using this hybrid fabric will offer unrivaled protection without compromising agility. The lightweight nature of the fabric will facilitate better maneuverability, giving athletes a competitive edge in various sports.5. Defense Industry: Reinforcing Military ApplicationsThe defense sector, where protection and reliability are paramount, can greatly benefit from the introduction of Carbon Kevlar Hybrid Fabric. The fabric's exceptional resistance to extreme temperatures and impact makes it an ideal choice for the manufacture of protective clothing and equipment for military personnel. As a result, soldiers will experience significantly improved protection without being encumbered by heavy gear.Conclusion:The introduction of Carbon Kevlar Hybrid Fabric represents an exciting milestone in the textile industry. This innovative fabric's ability to combine the extraordinary properties of carbon fiber and Kevlar opens up endless possibilities across various sectors. From aerospace to sports, and automotive to defense, this versatile fabric promises to redefine the standards of strength, durability, and performance. With its numerous benefits, the adoption of Carbon Kevlar Hybrid Fabric is set to revolutionize manufacturing processes and shape the future of the textile industry.

Fiberglass Cloth: The Top Choice for Strengthening Materials

Title: Cloth for Fiberglass: A Revolutionary Innovation in the Composite IndustryIntroduction:In an era driven by innovation, the integration of advanced materials and revolutionary techniques is crucial in various sectors. In the field of composites, a recent breakthrough has been achieved with the development of Cloth for Fiberglass. This cutting-edge product has revolutionized the composite industry, enabling enhanced strength and durability across a wide range of applications. This news article aims to explore the features, benefits, and applications of Cloth for Fiberglass, while shedding light on the pioneering company behind this game-changing invention.Company Introduction:Owned and operated by a team of dedicated professionals, the company behind the development of Cloth for Fiberglass is committed to pushing the boundaries of composite materials. With decades of experience in the industry, their expertise has allowed them to engineer an innovative product that surpasses traditional fiberglass cloth. Leveraging their state-of-the-art facilities, the company has successfully manufactured Cloth for Fiberglass, catering to the growing demands and requirements of various sectors.Features of Cloth for Fiberglass:Cloth for Fiberglass boasts several key features that differentiate it from conventional materials. Firstly, its molecular structure has been meticulously designed to offer exceptional strength and sturdiness, making it resistant to impact and external forces. This remarkable strength not only improves the lifespan of the end products but also enhances their structural integrity. Additionally, Cloth for Fiberglass is lightweight and flexible, facilitating ease of use during manufacturing processes. Furthermore, it exhibits exceptional resistance to corrosion, chemicals, and extreme temperatures, making it an ideal choice for harsh environments.Benefits of Cloth for Fiberglass:The introduction of Cloth for Fiberglass provides numerous benefits across various industries. One of its primary advantages is its versatility, allowing its application in numerous sectors, including aerospace, automotive, marine, and construction. By using this innovative material, manufacturers can achieve the perfect balance between strength, weight reduction, and cost-effectiveness. Moreover, the inherent dimensional stability of Cloth for Fiberglass ensures that the end products retain their shape even under extreme conditions. This stability further contributes to the longevity of the final product, reducing maintenance and replacement costs.Applications of Cloth for Fiberglass:The revolutionary Cloth for Fiberglass has found applications across a wide range of sectors, with its unparalleled benefits making it an ideal choice for composite manufacturers. In the aerospace industry, it is utilized for the construction of aircraft components, providing lightweight and durable alternatives. In the automotive sector, it offers solutions for high-performance vehicles, allowing manufacturers to enhance fuel efficiency while maintaining safety standards. Furthermore, Cloth for Fiberglass finds extensive use in the marine industry, contributing to the design and production of sturdy and seaworthy vessels. Its resistance to corrosion and moisture make it particularly suitable for marine applications. Finally, in the construction industry, the cloth is extensively employed to produce durable and strong composite materials for infrastructure projects.Conclusion:The development of Cloth for Fiberglass marks a significant milestone in the composite industry, bringing forth a groundbreaking material that surpasses traditional alternatives. The company behind this innovative product continues to drive the industry forward by harnessing the endless potential of composites. With its remarkable strength, versatility, and resistance to various environmental factors, Cloth for Fiberglass is revolutionizing the way industries design and manufacture their products. As manufacturers increasingly adopt this game-changing cloth, we can expect a paradigm shift in the utilization of composites, opening avenues for enhanced performance, sustainability, and cost-effectiveness.

Discover the Promising Applications of Woven Glass Fabric in Today's News

Woven Glass Fabric Pushes Boundaries in the Textile Industry[Woven Glass Fabric Company] has recently unveiled their latest breakthrough in the field of textiles, a revolutionary product that is set to redefine the industry. Their cutting-edge woven glass fabric is set to push the boundaries of what is possible in textile manufacturing, offering a wide range of applications across various sectors. With unmatched strength, durability, and versatility, this innovative fabric is poised to transform industries and facilitate new possibilities in design and engineering.Woven glass fabric, also known as fiberglass fabric, is manufactured using threads made from glass fibers. These fibers are woven together to create a robust and flexible fabric that possesses exceptional properties. Woven glass fabric is known for its high tensile strength, which is significantly stronger than other fabrics such as cotton or polyester. This attribute makes it ideal for applications that require exceptional resilience, such as in the aerospace and automotive industries.What sets [Woven Glass Fabric Company]'s product apart from others in the market is their innovative manufacturing process. Using state-of-the-art technology and machinery, they have developed a technique that produces an incredibly fine yet durable woven glass fabric. This advancement allows for a higher level of detail and precision, making it a perfect choice for industries that demand stringent specifications.The versatility of this woven glass fabric is key to its success. Its ability to be molded into various shapes and sizes without compromising its structural integrity makes it incredibly appealing to designers and engineers. The fabric can be used in a vast array of applications, including but not limited to, insulation, filtration, reinforcement, and composite materials. The possibilities are truly limitless, and industries of all kinds are expected to benefit from this groundbreaking product.In the construction industry, woven glass fabric offers numerous advantages. Its exceptional strength-to-weight ratio makes it an ideal material for reinforcing concrete structures. It can also be used for insulation purposes, providing a more efficient and cost-effective solution compared to traditional insulation materials. Furthermore, woven glass fabric is resistant to corrosion, making it a durable option for a wide range of construction projects.The aerospace and automotive industries are also set to benefit greatly from this new textile innovation. The lightweight nature of woven glass fabric makes it an excellent choice for reducing overall weight in aircraft and vehicles, thereby improving fuel efficiency and performance. Its high strength also ensures the safety and integrity of critical components, making it an essential material in these high-demand sectors.Beyond its industrial uses, woven glass fabric also offers advantages in consumer products. The fabric can be used for creating high-performance sports equipment, such as tennis rackets or bicycle frames, due to its exceptional strength and flexibility. Additionally, it can be used in household applications, including furniture, curtains, and upholstery, providing a durable yet aesthetically pleasing option for consumers.[Woven Glass Fabric Company] has made significant investments in research and development, ensuring that their woven glass fabric remains at the forefront of the industry. They continuously strive to improve their manufacturing process, focusing on enhancing the fabric's properties while also minimizing its environmental impact. By prioritizing sustainability and innovation, [Woven Glass Fabric Company] aims to revolutionize the textile industry while also promoting responsible practices.The introduction of woven glass fabric marks a significant advancement in the textile industry. Its unparalleled strength, versatility, and durability offer numerous possibilities across various sectors. As [Woven Glass Fabric Company] pushes the boundaries of textile manufacturing, industries worldwide can look forward to the positive impact of this innovative fabric on their operations.

Fiber-reinforced plastic made with glass fibers

Woven Fiberglass Sheets: The Secret to a Strong and Durable StructureWhen it comes to building structures that are both durable and visually appealing, fiberglass is a popular choice among architects and builders alike. Its unique properties make it an ideal material for a wide range of applications, from aircraft and automobile parts to boats and piping systems.One of the most common forms of fiberglass is woven fiberglass sheets. These sheets are made by weaving glass fibers together to create a strong, lightweight fabric that is used in a variety of construction and industrial applications.The Advantages of Woven Fiberglass SheetsCompared to other materials, woven fiberglass sheets offer many advantages. Here are just a few:1. Strength: Woven fiberglass sheets are incredibly strong and can withstand a lot of force without breaking or deforming. This makes them ideal for structures that need to withstand heavy loads or external pressure.2. Durability: Thanks to their resistance to moisture, heat, and chemicals, woven fiberglass sheets are incredibly durable and long-lasting. They can withstand years of wear and tear without weakening or deteriorating.3. Flexibility: Woven fiberglass sheets are flexible and can be molded into virtually any shape or size. This makes them ideal for creating curved or irregular shapes that would be difficult to create with other materials.4. Lightweight: Woven fiberglass sheets are lightweight, making them easy to work with and transport. This also makes them an economical choice, as they can be used to create structures that are both strong and lightweight.5. Cost-effective: Compared to other building materials, woven fiberglass sheets are relatively inexpensive. This makes them an affordable option for builders who want to create high-quality structures without breaking the bank.Applications of Woven Fiberglass SheetsWoven fiberglass sheets are used in a variety of applications, including:1. Aerospace: Woven fiberglass sheets are used to make aircraft parts, where their strength and durability are crucial for safety and performance.2. Automotive: Woven fiberglass sheets are used to make parts for cars and trucks, where their lightweight and durable properties make them an ideal choice for efficiency and performance.3. Marine: Woven fiberglass sheets are used to make boats and other watercraft, where their resistance to moisture makes them an ideal choice for durability and longevity.4. Building: Woven fiberglass sheets are used to reinforce concrete, making it stronger and more durable. They are also used to create exterior features, such as facades and cladding.ConclusionWoven fiberglass sheets are a versatile and durable material that offer a wide range of benefits for builders and architects. Whether you are building an airplane, a boat, or a building, woven fiberglass sheets can help you create a strong, durable structure that will last for years to come. So if you are looking for a material that combines strength, durability, and affordability, be sure to consider woven fiberglass sheets for your next project.

Fiberglass Cloth Roll: A Comprehensive Overview of 1708 Material

Title: Revolutionizing Reinforcements: Introduction of 1708 Fiberglass Cloth Roll in the Composites IndustryIntroduction (100 words):The composites industry has witnessed a game-changing development with the introduction of the innovative 1708 Fiberglass Cloth Roll. This groundbreaking product, manufactured by a leading company in the field, promises to revolutionize composites manufacturing with its exceptional properties and unmatched versatility. With a strong commitment to producing high-quality reinforcements, this company has once again proven its dedication to delivering cutting-edge solutions that exceed industry expectations. This article will delve into the details of the 1708 Fiberglass Cloth Roll, highlighting its remarkable features, benefits, and the significant impact it will have on various sectors that rely on composites for their operations.I. Overview of the 1708 Fiberglass Cloth Roll (200 words):The 1708 Fiberglass Cloth Roll represents a significant advancement in the field of composites reinforcements. It is a non-woven fabric made from continuous fiberglass roving that is laid flat and held together with a light binder. This unique manufacturing process ensures optimal conformity, durability, and strength.One of the most distinguishing features of the 1708 Fiberglass Cloth Roll is its combined axial and biaxial fabric orientation. This means that it consists of one layer of fiberglass roving aligned in the 0° (axial) direction and another layer placed at a 90° angle (biaxial). This configuration provides exceptional load-bearing capabilities in both direction orientations simultaneously, resulting in superior strength and stiffness for the composites it reinforces.Additionally, the 1708 Fiberglass Cloth Roll is compatible with a wide range of resin systems, making it adaptable to diverse manufacturing processes. Whether being utilized in wet lay-up, vacuum infusion, or hand lay-up techniques, this versatile reinforcement excels in enhancing the mechanical properties of various composite structures.Furthermore, the unique non-woven construction of the 1708 Fiberglass Cloth Roll offers improved wet-out characteristics, which ensures better resin distribution and ultimately enhances the bond between fibers and resin. This results in an optimal fiber-to-resin ratio, maximizing the performance and longevity of the composite product.II. Advantages and Applications (300 words):The introduction of the 1708 Fiberglass Cloth Roll carries numerous advantages, making it a highly sought-after reinforcement material in the composites industry. Some key benefits include:1. Superior strength and stiffness: The 1708 Fiberglass Cloth Roll ensures exceptional load-bearing capabilities, enhancing the overall strength and stiffness of composite structures. This makes it an ideal choice for various applications that require durable, lightweight materials.2. Versatility: The compatibility of the 1708 Fiberglass Cloth Roll with different resin systems and manufacturing processes allows for its use in diverse applications. It is widely employed in industries such as automotive, marine, aerospace, construction, and sporting goods.3. Improved wet-out characteristics: The non-woven construction of the 1708 Fiberglass Cloth Roll facilitates better resin distribution and adhesion, resulting in an optimal fiber-to-resin ratio. This significantly improves the performance and durability of composite products.4. Cost-effectiveness: By enhancing the mechanical properties of composites, the 1708 Fiberglass Cloth Roll helps manufacturers produce lightweight and durable products. This cost-effective solution reduces material waste and overall production costs.The application possibilities of the 1708 Fiberglass Cloth Roll are vast. In automotive manufacturing, it can be utilized in the fabrication of lightweight body panels, interior components, and structural parts, contributing to improved fuel efficiency and overall vehicle performance. In the marine industry, this innovation finds application in the production of hulls, decks, and bulkheads, ensuring superior integrity and longevity. The aerospace sector can benefit from the 1708 Fiberglass Cloth Roll in the construction of aircraft components, reducing weight while maintaining high strength and stiffness. In the construction industry, it finds use in building materials like structural panels, reinforcing beams, and columns, providing durability and resistance to environmental factors. Finally, the sporting goods industry can make use of this reinforcement material in the production of lightweight yet robust sporting equipment, enabling better performance for athletes.Conclusion (100 words):The introduction of the 1708 Fiberglass Cloth Roll marks a significant milestone in the composites industry. Its unique properties, versatility, and exceptional performance open up a world of possibilities for manufacturers across various sectors. With its superior strength, stiffness, and compatibility with different manufacturing processes, this reinforcement material has the potential to revolutionize composite manufacturing, enabling the production of lightweight, durable, and cost-effective products. As this innovative solution continues to gain momentum, it is clear that the 1708 Fiberglass Cloth Roll is set to become an indispensable tool for composites manufacturers in the years to come.

Fiber, USA-made Carbon Fiber, Benefits of Plain Weave Carbon FiberCarbon fiber is a popular material that has become a staple in various industries. It possesses excellent properties, such as high strength-to-weight ratio, corrosion resistance, and fatigue resistance, among others. Manufacturers often use carbon fiber to produce lightweight and durable products, including automotive parts, aerospace components, sports equipment, and more. One type of carbon fiber that manufacturers commonly use is plain weave carbon fiber.Plain weave carbon fiber is a type of carbon fiber that uses a basic over-and-under weaving pattern to produce a tight, symmetric weave. This weaving pattern results in a checkerboard-like appearance on the surface of the carbon fiber. Compared to other weaving patterns, such as twill and satin, plain weave carbon fiber is less expensive, has a lower profile, and has a more uniform surface texture.One of the benefits of using plain weave carbon fiber is its improved mechanical properties. Its tightly woven pattern gives it increased tensile strength, stiffness, and resistance to deformation. Plain weave carbon fiber also has better fatigue resistance than other weaving patterns, making it ideal for applications that undergo repeated stress and strain.Another benefit of using plain weave carbon fiber is its ability to create a smooth and uniform surface finish. Its tight weave pattern produces a more consistent surface texture, which is especially useful for aesthetic applications. Manufacturers often use plain weave carbon fiber for parts that require painting, as it provides a smooth and even surface for paint to adhere to.Plain weave carbon fiber is also compatible with various resin systems, such as epoxy, polyester, and vinyl ester. This compatibility allows manufacturers to tailor the mechanical properties of plain weave carbon fiber to specific applications. They can adjust the resin-to-fiber ratio, curing temperature, and curing time to achieve the desired properties.At Elevated Materials, we take pride in producing USA-made carbon fiber products, including our plain weave carbon fiber sheets. We use high-quality materials and state-of-the-art equipment to manufacture our carbon fiber products. Our plain weave carbon fiber sheets are available in various thicknesses and sizes to accommodate different applications. Whether you need carbon fiber sheets for automotive, aerospace, or industrial use, we have the right product for you.In conclusion, plain weave carbon fiber is an excellent choice for lightweight and durable applications that require improved mechanical properties and uniform surface finish. Its basic over-and-under weaving pattern results in a more affordable and uniform surface texture, making it ideal for aesthetic applications. If your project requires high-quality, USA-made plain weave carbon fiber sheets, look no further than Elevated Materials.

Understanding the Properties and Applications of Carbon Fiber Composites

Carbon Fiber Cloth: A Lightweight and Strong MaterialCarbon fiber cloth is a material composed of small, thin carbon fibers, woven together to form a flexible and strong cloth. This cloth is widely used in industries such as aerospace, automotive, and sports equipment due to its high strength-to-weight ratio. In this blog post, we will discuss the properties and applications of carbon fiber cloth and its significance in various industries.Properties of Carbon Fiber ClothCarbon fiber cloth is known for its exceptional strength, stiffness, and low weight. The individual strands of carbon fibers, usually one-tenth the diameter of a human hair, are woven together to form sheets or rolls of varying thicknesses. These sheets are then layered or sandwiched with epoxy resin to form composite materials, which are rigid, flexible, or semi-soft depending on the resin type and the number of carbon fiber layers.One of the key properties of carbon fiber cloth is its strength. It has a tensile strength five times that of steel and is exceptionally resistant to breaking, bending, or stretching. This makes it ideal for products that require high-strength and lightweight materials, such as airplane wings, racing bicycles, and tennis rackets.In addition to strength, carbon fiber cloth provides high stiffness and rigidity. It has a stiffness that is nearly twice that of aluminum and is highly resistant to deformation. This makes it useful in applications where stiffness is required, such as in the production of wind turbine blades and construction of structural beams and columns.Applications of Carbon Fiber ClothCarbon fiber cloths are used extensively in various industries due to their exceptional properties. Here are some of the most significant applications:Aerospace Industry - The aerospace industry uses carbon fiber cloths extensively in airplanes, helicopters, and missiles. These materials are used to make airplane wings, body panels, and other components due to their high strength-to-weight ratio, which reduces the overall weight of the aircraft and improves fuel efficiency.Automotive Industry - Carbon fiber cloths are used in high-performance vehicles such as race cars and supercars. The lightweight and strong material is also used for manufacturing components such as brakes, wheels, and chassis elements.Sports Equipment - Carbon fiber cloth is widely used in the sports industry to make lightweight, high-performance products such as tennis rackets, golf clubs, and fishing rods. The stiffness of the material provides enhanced control and performance in these products.Medical Industry - Carbon fiber cloths are used in the medical industry for orthopedic implants, prosthetics, and medical equipment. These lightweight materials are ideal for medical applications where weight and strength are critical for long-term patient use.ConclusionCarbon fiber cloth is a remarkable material that has revolutionized various industries. Its high strength-to-weight ratio, stiffness, and low weight make it ideal for high-performance products and applications. The aerospace, automotive, sports equipment, and medical industries all benefit from the exceptional properties of carbon fiber cloth, and its significance in these markets is expected to grow in the years to come.Keywords: Fiber Carbon Cloth, Carbon Fiber Cloth, Properties of Carbon Fiber Cloth, Aerospace Industry, Automotive Industry, Sports Equipment, Medical Industry.

Key Benefits of Carbon Fiber Fiberglass Cloth

Carbon Fiber Fiberglass Cloth Revolutionizes the Automotive Industry: A Product of Innovation and Dedication to ExcellenceInnovation, quality, and customer satisfaction are the core values of {Company Name}. With years of experience and expertise in the manufacturing and supply of advanced materials and composites, {Company Name} has been at the forefront of industry-transforming technologies.Carbon fiber fiberglass cloth is the latest addition to the range of premium quality products from {Company Name}. This advanced material has been making waves in the automotive industry due to its exceptional strength, durability, and versatility.The ever-growing demand for lightweight and high-performance materials in the automotive sector has led to the rise of carbon fiber composites. Carbon fiber fiberglass cloth is a hybrid composite made up of carbon fibers and fiberglass threads woven together. This combination of materials produces a high-strength cloth that is lightweight, flexible, and resistant to corrosion.One of the primary advantages of carbon fiber fiberglass cloth is its ability to withstand high-temperature environments. This feature makes it ideal for use in the manufacture of engine parts and other components that are exposed to high heat and pressure. Furthermore, carbon fiber fiberglass cloth has excellent stiffness and tensile strength, which makes it ideal for applications that require high mechanical performance.Another benefit of carbon fiber fiberglass cloth is its aesthetic appeal. The unique texture and patterns of the woven carbon fibers offer a distinctive and luxurious look that enhances the overall aesthetics of the automobile. Many luxury car makers have adopted carbon fiber composites for their cars, as it provides a sleek and modern feel to the design.{Company Name} understands the importance of quality and performance for our customers. That is why our carbon fiber fiberglass cloth undergoes a rigorous testing process to ensure it meets high industry standards. Our manufacturing processes use only the highest quality raw materials with strict quality control measures. This ensures that every order we send out is of the highest quality possible.In addition to the automotive industry, carbon fiber composites are also used in the aerospace, marine, and sporting goods industries. These industries demand materials that can withstand extreme conditions, yet still provide optimal performance. It is worth noting that carbon fiber composites are also being used in newer industries, such as medical and construction.The benefits of carbon fiber composites are enormous, and there is no doubt that they will continue to revolutionize all areas they have been applied. At {Company Name}, we are committed to providing our customers with innovative products that offer the best in class performance. Our dedication to quality, innovation, and customer satisfaction sets us apart from our competitors, and our carbon fiber fiberglass cloth product is a testimony to this.We have a team of experienced and dedicated professionals who strive to ensure that our customers receive the best products and services we can offer. We have established ourselves as a trusted and reputable supplier of advanced materials and composites. We are always looking for ways to innovate and improve our product offerings to keep up with ever-evolving industry demands.In conclusion, carbon fiber fiberglass cloth is a game-changing material that is transforming the automotive industry. It provides unmatched strength, durability, and lightweight properties that make it ideal for a wide range of applications. At {Company Name}, we are proud to offer high-quality carbon fiber fiberglass cloth that is backed by our commitment to excellence. Our customers can be assured that every purchase they make from us is a sound investment in quality and performance.

Explore the Versatility of Fiberglass Mat and Woven Roving for Various Applications

[Company Name], a leading manufacturer specializing in fiberglass composite materials, has recently introduced a new product called Fiberglass Mat Woven Roving. This innovative material is set to revolutionize various industries with its exceptional strength, durability, and versatility.Fiberglass Mat Woven Roving is a high-performance composite fabric made by interweaving fine fiberglass rovings and a layer of chopped strand mat. This unique combination creates a fabric that offers exceptional properties for a wide range of applications. The material is widely used in the automotive, marine, construction, and aerospace industries due to its outstanding strength-to-weight ratio and resistance to corrosion and fire.With continuously advancing technology and increasing demand for lightweight and high-performance materials, Fiberglass Mat Woven Roving stands out as a remarkable solution. It offers excellent dimensional stability, ensuring optimal shape retention under various environmental conditions. This is particularly crucial in the marine industry, where the material is extensively used in boat building and repair.The automotive industry can also benefit greatly from Fiberglass Mat Woven Roving. Its exceptional strength makes it ideal for reinforcing body panels, frames, and internal structures, providing added safety without compromising weight. Additionally, the material's resistance to chemicals and high temperatures makes it suitable for numerous components and under-the-hood applications.In the construction industry, Fiberglass Mat Woven Roving is highly preferred for its durability and resistance to moisture and weathering. It is commonly utilized in the construction of pipelines, storage tanks, and infrastructure projects, ensuring long-lasting and reliable structures. The material's fire resistance further adds to its appeal, making it an essential choice for fireproofing applications.Aerospace and defense industries also find Fiberglass Mat Woven Roving invaluable. It is widely incorporated into aircraft structures, satellites, and other aerospace components due to its high strength and excellent thermal and electrical insulation properties. Moreover, its lightweight nature contributes to significant fuel savings and overall cost reduction.With its unparalleled versatility, Fiberglass Mat Woven Roving offers endless possibilities for various other applications, including wind turbine blades, sporting goods, and even art and design. Its ease of handling and compatibility with different resin systems make it a preferred choice for manufacturers seeking to enhance their products' mechanical properties.[Company Name], as a trusted leader in the fiberglass composite materials industry, ensures that all its products, including Fiberglass Mat Woven Roving, are manufactured with the highest quality standards. Their state-of-the-art production facilities and rigorous quality control processes guarantee consistent performance and reliability.In addition to providing exceptional products, [Company Name] also prioritizes customer satisfaction by offering excellent customer service and technical support. Their team of experts is readily available to provide guidance and assistance, ensuring that customers can fully maximize the benefits of Fiberglass Mat Woven Roving in their respective applications.As a result of their commitment to innovation and customer-centric approach, [Company Name] has garnered a strong reputation in the market. Their products are trusted by industry professionals worldwide, and their continual investment in research and development ensures that they stay at the forefront of the fiberglass composite materials industry.In conclusion, [Company Name]'s introduction of Fiberglass Mat Woven Roving is set to revolutionize a multitude of industries. This high-performance material offers exceptional strength, durability, and versatility, serving as a game-changer for manufacturers in the automotive, marine, construction, and aerospace sectors. With a commitment to quality and customer satisfaction, [Company Name] continues to shape the future of fiberglass composite materials.