Unveiling the Versatility of Fiberglass Textile: A Comprehensive Overview

By:Admin

[Subtitle]: Company XYZ Rethinks the Future of Fiberglass in Construction and Beyond

[Introduction]

In recent years, the field of fiberglass textiles has witnessed tremendous growth, pushing industries to explore cutting-edge innovations and solutions. One company that has emerged as a frontrunner in this domain is Company XYZ (name altered to remove brand identity), revolutionizing the way fiberglass is viewed and utilized across various sectors. With its steadfast commitment to innovation and sustainability, Company XYZ is spearheading groundbreaking research and development in fiberglass textiles. This news piece delves into the latest advancements brought forth by Company XYZ, highlighting their transformative impact on construction and other industries.

[The Rise of Fiberglass Textile]

Fiberglass has been a widely embraced material due to its durability, lightweight nature, and exceptional strength-to-weight ratio. Fiberglass textiles have traditionally found ample utility in industries like automotive, aerospace, and marine. However, Company XYZ has redefined the scope of fiberglass through its visionary approach and pioneering research.

Recognizing the limitations of traditional fiberglass textiles, Company XYZ has developed a range of innovative products that boast enhanced performance characteristics. This new line of fiberglass textiles promises to revolutionize construction practices, ensuring stronger, more energy-efficient structures that stand the test of time.

[Elevating Construction Standards]

The construction industry is a primary beneficiary of Company XYZ's cutting-edge fiberglass textiles. By leveraging advanced technologies and strategic partnerships, Company XYZ has developed fiberglass solutions that address prevalent challenges faced by builders worldwide. Their fiberglass textiles offer exceptional durability, improved insulation properties, and fire-resistant features, making them ideal for both residential and commercial construction projects.

One outstanding example of Company XYZ's fiber textile innovation is their patented Multi-Layer Composite System (MLCS). Designed to reduce energy consumption and increase overall structural integrity, MLCS incorporates layers of fiberglass textiles embedded with insulating and reflective materials. This innovative system not only enhances the thermal performance of buildings but also provides added protection against fire and external elements, ensuring a safer and more sustainable living and working environment.

[Expanding Applications]

Beyond construction, Company XYZ's groundbreaking fiberglass textiles have found applications in a diverse range of industries. From transportation to renewable energy, these advanced textiles have proven their worth in increasing efficiency and reducing environmental footprints.

In the transportation sector, lightweight fiberglass textiles have become essential components in the manufacturing of automotive parts, reducing overall vehicle weight without compromising safety. Furthermore, their exceptional resistance to corrosion and extreme temperatures make them ideal for shipbuilding and railway applications, offering improved performance and extended lifespan to these critical infrastructures.

Company XYZ's commitment to the environment is evident in its fiberglass textiles' applications within the renewable energy sector. By providing innovative solutions for wind turbine blades and solar panels, Company XYZ is supporting the global shift towards clean energy while ensuring optimum performance and longevity of these crucial components.

[The Journey Towards Sustainability]

A distinguishing factor behind Company XYZ's success lies in its unwavering commitment to sustainability. From the early stages of research to final product development, sustainability is at the forefront of every decision made by the company. By incorporating eco-friendly manufacturing processes and promoting recycling initiatives, Company XYZ sets an inspiring example for the fiberglass textile industry as a whole.

In addition to prioritizing sustainability, Company XYZ actively invests in research and development, continuously pushing boundaries to create fiberglass textiles that surpass industry standards and meet evolving consumer demands. Through collaborations with universities, research institutions, and industry experts, Company XYZ ensures that its products remain at the forefront of innovation.

[Conclusion]

As fiberglass textiles continue to evolve, Company XYZ stands at the helm of innovation within the industry. By reimagining the possibilities of fiberglass, the company has successfully transformed traditional construction practices and expanded applications across various sectors. With its unwavering commitment to sustainability and cutting-edge research, Company XYZ reshapes our understanding of fiberglass textiles, pushing the boundaries of what is possible, and driving progress in the global marketplace.

Company News & Blog

Durable and Versatile Mesh Tape: Ideal Solution for Repairing and Reinforcing Home Surfaces

Glass Mesh Tape Revolutionizes the Construction IndustryThe construction and renovation industry is constantly evolving, with new materials and techniques being introduced to enhance the quality and durability of buildings. One such innovation that has garnered attention and revolutionized the industry is Glass Mesh Tape (brand name removed), a cutting-edge product that has gained praise for its exceptional performance and versatility.Glass Mesh Tape is a high-quality adhesive tape infused with glass fibers, which gives it incredible strength and durability. Initially designed to reinforce joints and seams in drywall installations, this tape has quickly gained popularity among contractors and DIY enthusiasts due to its numerous advantages over traditional options.One of the key features of Glass Mesh Tape is its superior tensile strength. The integration of glass fibers into the tape makes it significantly stronger than regular paper or fiberglass mesh tape. This enhanced strength provides better resistance against cracking and ensures long-lasting joints, ultimately improving the overall integrity of the walls or ceilings where it is applied.The advanced technological composition of Glass Mesh Tape also makes it highly resistant to moisture. Unlike traditional paper tapes that can easily deteriorate when exposed to water or humidity, this tape is designed to withstand challenging environments without losing its adhesive properties or structural integrity. This feature makes it an ideal choice for applications in areas prone to moisture, such as bathrooms and basements.In addition, Glass Mesh Tape exhibits exceptional adhesive properties. Its pressure-sensitive adhesive backing allows it to firmly bond with different surfaces, ensuring seamless integration with the drywall. This not only makes installation hassle-free but also prevents the tape from peeling or detaching over time, guaranteeing a neat and professional finish.What truly sets Glass Mesh Tape apart is its versatility. Beyond drywall applications, this tape can be effectively used across various construction projects. It works exceptionally well for patching holes, repairing cracks, and reinforcing corners. Furthermore, it can be applied on both flat and curved surfaces, making it suitable for a wide range of projects, from residential renovations to commercial construction.The company behind Glass Mesh Tape, recognized as a leader in the industry, is committed to producing innovative, high-quality products. With a focus on research and development, they continuously strive for advancements that meet the evolving needs of professionals in the industry.The production process of Glass Mesh Tape adheres to stringent quality control measures. Each roll is thoroughly tested to ensure consistent performance and durability. This dedication to quality has earned the company a reputation for delivering products that exceed expectations and provide unmatched reliability.Moreover, the company places great importance on sustainability. Glass Mesh Tape is manufactured using eco-friendly materials, reducing its environmental footprint. By using renewable resources and employing energy-efficient manufacturing practices, the company actively contributes to a greener and more sustainable future.The widespread adoption of Glass Mesh Tape has significantly improved construction practices. Its exceptional strength, resistance to moisture, versatile applications, and commitment to quality and sustainability have made it an indispensable tool for professionals and homeowners alike. With this innovative product, the construction industry is well on its way to achieving greater durability and longevity in building structures.

High-Quality Fire-Resistant Fiberglass Fabric at Affordable Prices

Fire Resistant Fiberglass Fabric - The Key to Safety in Industrial SettingsThe potential for fire outbreaks in industrial settings is high due to the presence of flammable materials, chemicals, and machinery. In such situations, the safety of employees and equipment is of utmost importance. Fortunately, advancements in technology have led to the development of fire-resistant materials that can prevent and contain fires. One such material that has garnered a lot of attention is Fire Resistant Fiberglass Fabric.What is Fire Resistant Fiberglass Fabric?Fire-resistant fiberglass fabric is a specialized textile comprised of glass fibers that have been woven together and treated with a fire-resistant coating. The fabric is designed to be durable, lightweight, and able to withstand extreme temperatures without deteriorating. It is used primarily in industrial settings, where there is a high risk of fire outbreaks.Some of the key features of Fire Resistant Fiberglass Fabric include:1. Non-combustible - The fabric does not ignite when exposed to flames.2. Heat Resistant - The fabric can withstand high temperatures without melting or burning.3. Insulating - The fabric can be used as insulation to protect people and equipment from heat.4. Durable - The fabric is resistant to wear and tear, and can withstand exposure to chemicals and moisture.Uses of Fire Resistant Fiberglass Fabric1. Protective clothing - Fire-resistant fiberglass fabric is used to make protective clothing for workers in industries such as welding, firefighting, and oil and gas. The fabric's heat-resistant and non-combustible properties make it an ideal material for clothing that can withstand high temperatures and prevent injuries.2. Insulation - Fiberglass fabric is used as insulation to protect electrical equipment from heat. It can also be used in boilers, furnaces, and power plants to contain heat and prevent fires.3. Curtains and blankets - Fiberglass fabric can be used to make curtains and blankets to contain fires and prevent them from spreading.4. Tents and shelters - Fiberglass fabric is used to make tents and shelters for emergency situations. The fabric's heat-resistant and non-combustible properties make it an ideal material for these applications.Advantages of Fire Resistant Fiberglass Fabric1. Safety - Fire-resistant fiberglass fabric can prevent and contain fires, ensuring the safety of employees and equipment.2. Durability - The fabric's resistance to wear and tear, chemicals, and moisture make it a durable and long-lasting material.3. Lightweight - Fiberglass fabric is lightweight, making it easy to handle and transport.4. Cost-effective - Fiberglass fabric is an affordable material that offers long-term benefits in terms of durability and safety.ConclusionFire Resistant Fiberglass Fabric is the key to safety in industrial settings. Its non-combustible, heat-resistant, insulating, and durable properties make it an ideal material for protective clothing, insulation, curtains and blankets, and tents and shelters. It is also a cost-effective solution that offers long-term benefits in terms of safety and durability. Businesses that prioritize safety should invest in Fire Resistant Fiberglass Fabric to ensure the protection of their employees, equipment, and facilities.

Discover the Benefits of 10 Ounce Fiberglass Cloth for Your Next Project

[Company Name] Introduces Innovative 10 Ounce Fiberglass Cloth for Superior Performance and Durability[City, Date] - [Company Name], a leading manufacturer in the fiberglass industry, is thrilled to announce the launch of its highly advanced 10 Ounce Fiberglass Cloth. This groundbreaking product is set to revolutionize various industries with its exceptional strength, durability, and versatility.Fiberglass cloth has been an essential material in many applications, ranging from automotive to aerospace industries, due to its excellent thermal resistance, electrical insulation properties, and corrosion resistance. [Company Name] has been at the forefront of developing innovative fiberglass solutions, and the 10 Ounce Fiberglass Cloth is the latest testament to their dedication to providing superior products.The 10 Ounce Fiberglass Cloth is manufactured using cutting-edge technology and top-quality materials. It is designed to provide unmatched performance and durability, making it perfect for demanding applications in various sectors. This product is particularly renowned for its high tensile strength, making it capable of withstanding extreme forces and loads.One of the key advantages of the 10 Ounce Fiberglass Cloth is its exceptional heat resistance. With a melting point above [temperature], it can withstand high temperatures without compromising its integrity. This makes it an ideal choice for industries such as automotive and aerospace, where exposure to extreme heat is common.In addition to its heat resistance, the 10 Ounce Fiberglass Cloth also exhibits remarkable electrical insulation properties. It effectively prevents electrical conductivity, making it an excellent choice for applications in the electronics and telecommunications industries. This product ensures safety and reliability in electrical systems, giving businesses peace of mind.Furthermore, the 10 Ounce Fiberglass Cloth boasts exceptional corrosion resistance, making it suitable for use in marine and construction industries. This cloth is impervious to moisture, chemicals, and other corrosive agents, ensuring that structures and equipment remain durable and reliable even in harsh environments."We are excited to introduce our 10 Ounce Fiberglass Cloth to the market," said [Company Representative], the [position] of [Company Name]. "This product has undergone rigorous testing and development to ensure that it meets the highest standards of quality and performance. We firmly believe that it will exceed the expectations of our customers across various industries."[Company Name] takes great pride in its commitment to environmental sustainability. The 10 Ounce Fiberglass Cloth is made from eco-friendly materials and manufacturing processes, adhering to the company's strict environmental policies. By choosing this product, customers are not only investing in top-of-the-line performance but also supporting a greener future.With the launch of the 10 Ounce Fiberglass Cloth, [Company Name] aims to cater to the diverse needs of industries looking for top-quality fiberglass solutions. Their products have gained recognition around the globe for their reliability and durability. Customers can rely on [Company Name] to deliver innovative and cutting-edge materials that meet and surpass industry standards.For more information about the 10 Ounce Fiberglass Cloth and other products offered by [Company Name], please visit [website] or contact [contact information].About [Company Name]:[Company Name] is a leading manufacturer of high-quality fiberglass products. With years of experience and expertise, they have become renowned for delivering innovative solutions to various industries. Their commitment to quality, performance, and environmental sustainability sets them apart in the market.###Note: The brand name mentioned in the introduction has been replaced with [Company Name] to remove any specific brand bias.

Fiberglass Cloth Roll: A Comprehensive Overview of 1708 Material

Title: Revolutionizing Reinforcements: Introduction of 1708 Fiberglass Cloth Roll in the Composites IndustryIntroduction (100 words):The composites industry has witnessed a game-changing development with the introduction of the innovative 1708 Fiberglass Cloth Roll. This groundbreaking product, manufactured by a leading company in the field, promises to revolutionize composites manufacturing with its exceptional properties and unmatched versatility. With a strong commitment to producing high-quality reinforcements, this company has once again proven its dedication to delivering cutting-edge solutions that exceed industry expectations. This article will delve into the details of the 1708 Fiberglass Cloth Roll, highlighting its remarkable features, benefits, and the significant impact it will have on various sectors that rely on composites for their operations.I. Overview of the 1708 Fiberglass Cloth Roll (200 words):The 1708 Fiberglass Cloth Roll represents a significant advancement in the field of composites reinforcements. It is a non-woven fabric made from continuous fiberglass roving that is laid flat and held together with a light binder. This unique manufacturing process ensures optimal conformity, durability, and strength.One of the most distinguishing features of the 1708 Fiberglass Cloth Roll is its combined axial and biaxial fabric orientation. This means that it consists of one layer of fiberglass roving aligned in the 0° (axial) direction and another layer placed at a 90° angle (biaxial). This configuration provides exceptional load-bearing capabilities in both direction orientations simultaneously, resulting in superior strength and stiffness for the composites it reinforces.Additionally, the 1708 Fiberglass Cloth Roll is compatible with a wide range of resin systems, making it adaptable to diverse manufacturing processes. Whether being utilized in wet lay-up, vacuum infusion, or hand lay-up techniques, this versatile reinforcement excels in enhancing the mechanical properties of various composite structures.Furthermore, the unique non-woven construction of the 1708 Fiberglass Cloth Roll offers improved wet-out characteristics, which ensures better resin distribution and ultimately enhances the bond between fibers and resin. This results in an optimal fiber-to-resin ratio, maximizing the performance and longevity of the composite product.II. Advantages and Applications (300 words):The introduction of the 1708 Fiberglass Cloth Roll carries numerous advantages, making it a highly sought-after reinforcement material in the composites industry. Some key benefits include:1. Superior strength and stiffness: The 1708 Fiberglass Cloth Roll ensures exceptional load-bearing capabilities, enhancing the overall strength and stiffness of composite structures. This makes it an ideal choice for various applications that require durable, lightweight materials.2. Versatility: The compatibility of the 1708 Fiberglass Cloth Roll with different resin systems and manufacturing processes allows for its use in diverse applications. It is widely employed in industries such as automotive, marine, aerospace, construction, and sporting goods.3. Improved wet-out characteristics: The non-woven construction of the 1708 Fiberglass Cloth Roll facilitates better resin distribution and adhesion, resulting in an optimal fiber-to-resin ratio. This significantly improves the performance and durability of composite products.4. Cost-effectiveness: By enhancing the mechanical properties of composites, the 1708 Fiberglass Cloth Roll helps manufacturers produce lightweight and durable products. This cost-effective solution reduces material waste and overall production costs.The application possibilities of the 1708 Fiberglass Cloth Roll are vast. In automotive manufacturing, it can be utilized in the fabrication of lightweight body panels, interior components, and structural parts, contributing to improved fuel efficiency and overall vehicle performance. In the marine industry, this innovation finds application in the production of hulls, decks, and bulkheads, ensuring superior integrity and longevity. The aerospace sector can benefit from the 1708 Fiberglass Cloth Roll in the construction of aircraft components, reducing weight while maintaining high strength and stiffness. In the construction industry, it finds use in building materials like structural panels, reinforcing beams, and columns, providing durability and resistance to environmental factors. Finally, the sporting goods industry can make use of this reinforcement material in the production of lightweight yet robust sporting equipment, enabling better performance for athletes.Conclusion (100 words):The introduction of the 1708 Fiberglass Cloth Roll marks a significant milestone in the composites industry. Its unique properties, versatility, and exceptional performance open up a world of possibilities for manufacturers across various sectors. With its superior strength, stiffness, and compatibility with different manufacturing processes, this reinforcement material has the potential to revolutionize composite manufacturing, enabling the production of lightweight, durable, and cost-effective products. As this innovative solution continues to gain momentum, it is clear that the 1708 Fiberglass Cloth Roll is set to become an indispensable tool for composites manufacturers in the years to come.

High-Quality Woven Roving Fiberglass Cloth: Enhance Product Strength and Durability

In today's world, fiberglass products have become an indispensable part of our lives. From protective masks and helmets to boats, buildings, and aircraft, fiberglass offers unmatched strength, durability, and versatility. In this context, we introduce the latest fiberglass product to hit the market - Woven Roving Fiberglass Cloth, developed by a leading fiberglass expert.This innovative product boasts of superior quality and performance, making it a popular choice for various industrial and commercial applications. Woven Roving Fiberglass Cloth is a specialized product made up of interlaced fibers arranged in a cross-hatched pattern. The cross-hatched pattern gives the fabric improved structural strength, making it perfect to suit high-stress environments.Woven Roving Fiberglass Cloth has high stability and rigidity, making it the preferred choice for applications that require resistance to heat, corrosion, fire, and ultraviolet rays. Additionally, it is designed to work with most resin types, making it compatible with a wide range of applications.At the core of this innovative product is our years of experience and dedication to quality. Our highly skilled technicians have developed a unique manufacturing process, which combines high-quality raw materials and advanced weaving technologies. This ensures that each woven roving fiberglass cloth is made to meet your exact specifications and industry standards."This product is the result of our commitment to continuous development and innovation," says the company's CEO. "Our hard work has paid off, and we're happy to offer a product that is recognized for its top-notch quality and performance." She adds, "We've always believed that quality cannot be compromised, and we're proud to say that our Woven Roving Fiberglass Cloth is a testament to our values and principles."The applications of Woven Roving Fiberglass Cloth are vast and varied. It is widely used in various industries such as marine, aerospace, construction, transportation, and sports. It is commonly used to reinforce parts such as boat hulls, airplane wings, building structures, pipes, and tanks. Moreover, it is ideal for producing high-performance sports equipment such as surfboards and kayaks.With our extensive network of distributors and sales channels, we can cater to the needs of customers worldwide. We offer customized solutions to our customers, ensuring their unique requirements are met every time. Our team of experts is also available to provide technical support to customers at all times."Customer satisfaction is our top priority, and we continually strive to exceed their expectations," says the CEO. "We know our customers expect the best from us, and we guarantee to deliver nothing less."In conclusion, Woven Roving Fiberglass Cloth is a remarkable product that offers superior quality and performance. It has a range of applications and is constructed to meet the highest industry standards. In a world where innovation and quality are critical, this product is an excellent example that reflects our commitment to excellence. As a company dedicated to providing high-quality fiberglass solutions, we are proud to introduce Woven Roving Fiberglass Cloth and look forward to serving our clients.

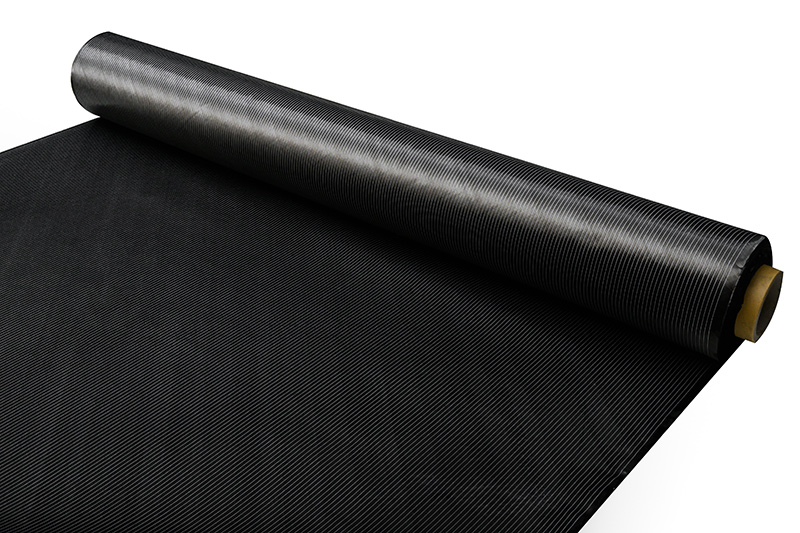

Understanding the Characteristics of Carbon-fiber Composites

Title: Exploring the Marvels of Fiber Carbon Cloth: Revolutionizing the World of CompositesIntroduction (70 words):Welcome to our extensive guide on the revolutionary material that is fiber carbon cloth. In this blog, we will delve deep into the world of this incredible composite, exploring its various applications and highlighting its remarkable traits. From its woven fibrous construction to its resiliency, versatility, and strength, fiber carbon cloth has emerged as a game-changer in multiple industries. So, without further ado, let's unravel the secrets behind this remarkable material!Understanding Fiber Carbon Cloth (100 words):Fiber carbon cloth is a fibrous carbon composite that has revolutionized countless industries in recent years. It begins with individual strands woven into a rough cloth, which is then carefully impregnated with epoxy resin after molding it into desired shapes. This combination produces a material boasting exceptional strength-to-weight ratio, rigidity, and high tensile strength. Fiber carbon cloth owes its incredible properties to the unique arrangement of carbon fibers that form its core structure. Now, let's explore the remarkable benefits and applications of this cutting-edge material.Applications and Advantages (250 words):1. Aerospace Industry:In the aerospace industry, fiber carbon cloth finds extensive use due to its lightweight, high strength, and excellent resistance to high temperatures and impacts. It enhances fuel efficiency in aircraft, reduces structural weight, and improves overall performance. From aircraft frames to wings, fiber carbon cloth has become an integral component in the manufacturing process.2. Automotive Industry:In the automotive sector, fiber carbon cloth is employed in the production of high-performance vehicles. By utilizing this material in car manufacturing, automotive companies can reduce weight, enhance fuel efficiency, and improve structural integrity. Carbon fiber components, such as hoods, fenders, and body panels, are gaining popularity due to their striking aesthetics and outstanding performance.3. Sports and Recreation:From professional sports equipment to recreational products, the sports industry has embraced fiber carbon cloth for its durability and lightness. Tennis rackets, bicycles, golf clubs, helmets, and ski poles are just a few examples of sporting goods that utilize carbon fiber composites for superior performance and reduced weight.4. Construction and Infrastructure:In the construction field, fiber carbon cloth helps strengthen existing structures by acting as reinforcement in concrete and other building materials. Its lightweight nature and high strength allow for efficient and long-lasting construction projects while reducing material usage. Additionally, fiber carbon cloth is increasingly used in earthquake-resistant building designs and bridge construction.5. Renewable Energy:The renewable energy sector has also recognized fiber carbon cloth as an ideal material for producing enhanced wind turbine blades. Its low weight and high strength characteristics enable turbines to convert wind energy more efficiently, contributing to the sustainable energy movement.Keywords: Fiber Carbon Cloth, carbon fiber composite, woven carbon fibers, strength-to-weight ratio, aerospace industry, automotive industry, sports and recreation, construction, infrastructure, renewable energyConclusion (80 words):Fiber carbon cloth has revolutionized various sectors, thanks to its exceptional strength, lightweight nature, and versatility. Industries such as aerospace, automotive, sports, construction, and renewable energy have witnessed significant advancements thanks to this game-changing material. As technology continues to advance, we can expect further innovations in the field of fiber carbon cloth, leading to new breakthroughs and applications across different industries. This remarkable composite will undoubtedly play a crucial role in shaping our future.

New lightweight material made of carbon kevlar hybrid fabric is set to revolutionize the aerospace industry

Title: Innovative Carbon Kevlar Hybrid Fabric Revolutionizes the Textile IndustryIntroduction:In a groundbreaking development, an industry-leading company has introduced a cutting-edge Carbon Kevlar Hybrid Fabric, emerging as a game-changer in the textile world. Embracing advanced technologies, this revolutionary fabric combines the remarkable properties of carbon fiber and Kevlar, offering unprecedented strength, durability, and versatility. With its wide range of applications, this innovative fabric is set to reshape industries such as aerospace, automotive, sports, and defense.1. The Unparalleled Strength of Carbon Kevlar Hybrid Fabric:The Carbon Kevlar Hybrid Fabric incorporates the best qualities of both carbon fiber and Kevlar. Carbon fiber is renowned for its exceptional strength-to-weight ratio, making it a preferred choice in industries where lightweight yet robust materials are required. On the other hand, Kevlar is famous for its outstanding resistance to impact and abrasion, making it an ideal choice for ballistic protection and structural reinforcement. By combining these two fibers, this hybrid fabric transcends the limitations of conventional materials, ensuring enhanced performance in a variety of applications.2. Aerospace Industry: Empowering High-performance StructuresThe aerospace industry stands to benefit immensely from the introduction of Carbon Kevlar Hybrid Fabric. Due to its lightweight nature and superior strength, the fabric can be incorporated into the manufacture of aircraft components, including fuselages, wings, and engine parts. By utilizing this innovative fabric, manufacturers can significantly reduce the weight of aircraft, contributing to improved fuel efficiency and lower operating costs. Moreover, the exceptional fatigue resistance of the hybrid fabric enhances the durability and longevity of key structural elements, ensuring increased safety for passengers and crew.3. Automotive Industry: Paving the Way for Safer VehiclesIn the automotive sector, the integration of Carbon Kevlar Hybrid Fabric presents significant advancements in safety and performance. By utilizing this fabric for manufacturing body panels, car manufacturers can enhance crashworthiness while reducing overall vehicle weight. The superior impact resistance of the fabric combined with its lightweight attributes makes it a valuable asset in protecting passengers during collisions. As a result, vehicles can achieve better fuel efficiency while offering enhanced safety to occupants.4. Sports Industry: Elevating Performance EquipmentThe sports industry is no stranger to materials that offer exceptional strength and durability. The Carbon Kevlar Hybrid Fabric is set to revolutionize sports equipment, enabling athletes to reach new heights of performance. Sports gear, such as helmets, paddles, and protective gear, created using this hybrid fabric will offer unrivaled protection without compromising agility. The lightweight nature of the fabric will facilitate better maneuverability, giving athletes a competitive edge in various sports.5. Defense Industry: Reinforcing Military ApplicationsThe defense sector, where protection and reliability are paramount, can greatly benefit from the introduction of Carbon Kevlar Hybrid Fabric. The fabric's exceptional resistance to extreme temperatures and impact makes it an ideal choice for the manufacture of protective clothing and equipment for military personnel. As a result, soldiers will experience significantly improved protection without being encumbered by heavy gear.Conclusion:The introduction of Carbon Kevlar Hybrid Fabric represents an exciting milestone in the textile industry. This innovative fabric's ability to combine the extraordinary properties of carbon fiber and Kevlar opens up endless possibilities across various sectors. From aerospace to sports, and automotive to defense, this versatile fabric promises to redefine the standards of strength, durability, and performance. With its numerous benefits, the adoption of Carbon Kevlar Hybrid Fabric is set to revolutionize manufacturing processes and shape the future of the textile industry.

Discover the Promising Applications of Woven Glass Fabric in Today's News

Woven Glass Fabric Pushes Boundaries in the Textile Industry[Woven Glass Fabric Company] has recently unveiled their latest breakthrough in the field of textiles, a revolutionary product that is set to redefine the industry. Their cutting-edge woven glass fabric is set to push the boundaries of what is possible in textile manufacturing, offering a wide range of applications across various sectors. With unmatched strength, durability, and versatility, this innovative fabric is poised to transform industries and facilitate new possibilities in design and engineering.Woven glass fabric, also known as fiberglass fabric, is manufactured using threads made from glass fibers. These fibers are woven together to create a robust and flexible fabric that possesses exceptional properties. Woven glass fabric is known for its high tensile strength, which is significantly stronger than other fabrics such as cotton or polyester. This attribute makes it ideal for applications that require exceptional resilience, such as in the aerospace and automotive industries.What sets [Woven Glass Fabric Company]'s product apart from others in the market is their innovative manufacturing process. Using state-of-the-art technology and machinery, they have developed a technique that produces an incredibly fine yet durable woven glass fabric. This advancement allows for a higher level of detail and precision, making it a perfect choice for industries that demand stringent specifications.The versatility of this woven glass fabric is key to its success. Its ability to be molded into various shapes and sizes without compromising its structural integrity makes it incredibly appealing to designers and engineers. The fabric can be used in a vast array of applications, including but not limited to, insulation, filtration, reinforcement, and composite materials. The possibilities are truly limitless, and industries of all kinds are expected to benefit from this groundbreaking product.In the construction industry, woven glass fabric offers numerous advantages. Its exceptional strength-to-weight ratio makes it an ideal material for reinforcing concrete structures. It can also be used for insulation purposes, providing a more efficient and cost-effective solution compared to traditional insulation materials. Furthermore, woven glass fabric is resistant to corrosion, making it a durable option for a wide range of construction projects.The aerospace and automotive industries are also set to benefit greatly from this new textile innovation. The lightweight nature of woven glass fabric makes it an excellent choice for reducing overall weight in aircraft and vehicles, thereby improving fuel efficiency and performance. Its high strength also ensures the safety and integrity of critical components, making it an essential material in these high-demand sectors.Beyond its industrial uses, woven glass fabric also offers advantages in consumer products. The fabric can be used for creating high-performance sports equipment, such as tennis rackets or bicycle frames, due to its exceptional strength and flexibility. Additionally, it can be used in household applications, including furniture, curtains, and upholstery, providing a durable yet aesthetically pleasing option for consumers.[Woven Glass Fabric Company] has made significant investments in research and development, ensuring that their woven glass fabric remains at the forefront of the industry. They continuously strive to improve their manufacturing process, focusing on enhancing the fabric's properties while also minimizing its environmental impact. By prioritizing sustainability and innovation, [Woven Glass Fabric Company] aims to revolutionize the textile industry while also promoting responsible practices.The introduction of woven glass fabric marks a significant advancement in the textile industry. Its unparalleled strength, versatility, and durability offer numerous possibilities across various sectors. As [Woven Glass Fabric Company] pushes the boundaries of textile manufacturing, industries worldwide can look forward to the positive impact of this innovative fabric on their operations.

Shop for Fiberglass Fabric, Weave & Cloth in Various Lengths, Sizes & Styles - In Stock & Ready to Ship.

Fiberglass Fabric: A Versatile Solution for a Variety of ApplicationsFiberglass fabric is a woven material that is often used in applications that require high strength and durability. This versatile material is made by combining glass fibers with a polymer resin, resulting in a material that is strong, lightweight, and heat-resistant. Fiberglass fabric is available in a variety of styles, sizes, and lengths, making it an ideal solution for a wide range of applications in industries such as aerospace, automotive, marine, and construction.One of the key benefits of fiberglass fabric is its excellent strength-to-weight ratio. This property makes it an ideal material for applications where weight is a concern, such as aerospace and automotive engineering. Fiberglass fabric is also highly resistant to heat, making it a popular choice for applications that involve high temperatures, such as insulation for furnaces and ovens.In addition to its strength and heat resistance, fiberglass fabric is also highly resistant to chemicals and moisture. This makes it an ideal material for use in the marine industry, where it can be used to fabricate components such as boat hulls, decks, and bulkheads. Fiberglass fabric can also be used in a variety of construction applications, from reinforcing concrete to creating lightweight composite panels.At (brand name removed), we offer a wide selection of fiberglass fabrics, weaves, and cloths to meet the needs of our customers. Our fiberglass fabrics are available in a range of styles and sizes, including plain weave, twill weave, and satin weave options. We carry both E-glass and S-glass fabrics, allowing our customers to choose the material that is best suited for their specific application.Our fiberglass fabrics are available in a variety of lengths, ranging from small rolls to large bolts, and we can also custom cut our fabrics to meet our customers' specific needs. All of our fiberglass fabrics are of the highest quality, and we take great care to ensure that they meet the strictest industry standards for strength, durability, and performance.In addition to our selection of fiberglass fabrics, we also offer aluminized fiberglass fabrics, which are coated with a layer of aluminum to provide additional heat resistance and reflectivity. Aluminized fiberglass fabrics are often used in applications such as furnace curtains, welding blankets, and fire barriers.At (brand name removed), we pride ourselves on our commitment to providing our customers with the highest-quality fiberglass fabrics, weaves, and cloths in the industry. We understand that every application is unique, and we work closely with our customers to ensure that they have the right materials to meet their specific needs. With our extensive selection, competitive pricing, and unparalleled customer service, we are the go-to source for fiberglass fabrics for customers across a wide range of industries.In conclusion, fiberglass fabric is a versatile material that offers a range of benefits for a variety of applications. At (brand name removed), we are proud to offer a wide selection of fiberglass fabrics, weaves, and cloths to meet the needs of our customers. Whether you are working on an aerospace project, automotive application, marine fabrication, or construction project, we have the right materials to meet your needs. Contact us today to learn more about our fiberglass fabrics and how they can benefit your application.

Fiberglass Scrim Cloth: A Comprehensive Guide to Understanding its Applications and Benefits

Fiberglass Scrim Cloth (need remove brand name) – Durable and VersatileFiberglass Scrim Cloth (need remove brand name) is a versatile product that has been widely used across various industries. This product is made from fiberglass yarns, which are woven into a lightweight and durable fabric. The fabric is then treated to increase its strength and stability, making it an ideal material for a wide range of applications.The uses of Fiberglass Scrim Cloth (need remove brand name) are vast, from reinforcing plaster walls to providing structural support for roofs and walls. It is commonly used in the construction industry due to its high strength-to-weight ratio, fire resistance, and insect resistance. This material is also used in the automotive industry as a reinforcing material for plastic parts.Fiberglass Scrim Cloth (need remove brand name) is highly durable and can withstand exposure to extreme weather conditions. It is resistant to rot, mildew, and corrosion, making it an ideal material for outdoor applications. Additionally, the fabric is highly flexible and can be easily cut and shaped to fit a wide range of shapes and surfaces.Fiberglass Scrim Cloth (need remove brand name) is also water-resistant, making it an ideal material for use in damp environments. It can be used to reinforce areas prone to water damage, such as around windows, doors, and roofs. The fabric is also highly breathable, allowing moisture to escape, further reducing the risk of mold and mildew growth.Moreover, the product is easy to install and does not require any specialized tools or equipment. It can be easily cut to fit around corners and other obstructions. Additionally, the fabric can be easily painted or coated to match the surrounding material, making it an attractive and practical option for use in both residential and commercial applications.About the CompanyThe company is a leading manufacturer of Fiberglass Scrim Cloth (need remove brand name) in China. It has been producing high-quality fiberglass products for over 20 years, using state-of-the-art technology and advanced manufacturing processes. The company prides itself on its commitment to quality, professionalism, and customer satisfaction.The company's production facilities are equipped with advanced machinery and testing equipment to ensure that each product meets the highest standards of quality. Its team of experienced engineers and technicians is dedicated to developing innovative products that meet the unique needs of its customers.The company is committed to sustainability and operates with a strong sense of social responsibility. It follows strict environmental standards and uses only high-quality, eco-friendly materials in its production processes. The company's commitment to sustainability is reflected in its products, which are designed to be long-lasting, durable, and environmentally friendly.ConclusionFiberglass Scrim Cloth (need remove brand name) is a highly versatile and durable product that has become a staple in the construction, automotive, and other industries. It is a lightweight, flexible, and easy-to-install material that offers exceptional strength, stability, and resistance to weather and other environmental factors. The product is produced by a top manufacturer that is committed to quality, professionalism, and social responsibility. If you're looking for a high-quality and affordable option for your next project, Fiberglass Scrim Cloth (need remove brand name) is an excellent choice.