Discover the Revolutionary Carbon Kevlar Weave Technology Transforming Industries

By:Admin

Introduction:

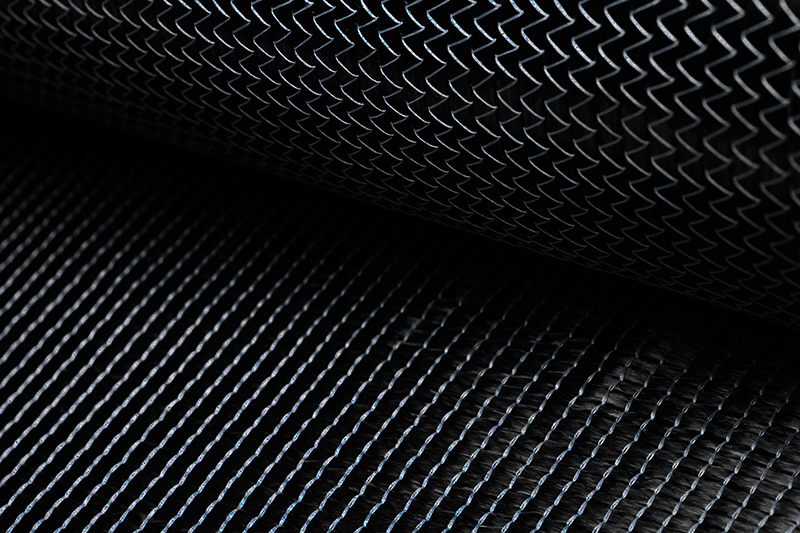

The automotive industry is constantly looking for groundbreaking materials to enhance performance, improve fuel efficiency, and ensure passenger safety. In the pursuit of innovation, {company name}, a renowned industry leader, has developed an exceptional composite material known as Carbon Kevlar Weave. This cutting-edge material combines the strength of carbon fiber with the durability of Kevlar, revolutionizing automotive manufacturing and paving the way for next-generation vehicles. In this article, we will explore the unparalleled properties of this composite material and its significant impact on the automotive industry.

Paragraph 1:

Carbon Kevlar Weave represents a breakthrough in composite-based manufacturing due to its exceptional strength-to-weight ratio. This unique material consists of a combination of carbon fiber and Kevlar, two highly regarded materials known for their individual qualities. By integrating these two materials, {company name} has harnessed the benefits of both, resulting in a composite that is incredibly lightweight yet remarkably robust. This groundbreaking amalgamation offers manufacturers a versatile solution with unparalleled strength, ease of use, and enhanced mechanical properties.

Paragraph 2:

One of the significant advantages of Carbon Kevlar Weave is its exceptional strength and rigidity. The carbon fiber component provides high tensile strength, making the material ideal for applications requiring rigidity and load-bearing capabilities. The Kevlar reinforcement ensures increased impact resistance and toughness, making it particularly suitable for safety-critical components in the automotive industry. These combined properties enable automakers to design lighter and more fuel-efficient vehicles without compromising safety standards.

Paragraph 3:

Another pivotal benefit of Carbon Kevlar Weave is its unique ability to dampen noise, vibrations, and harshness (NVH). By integrating this composite material into various vehicle body components, automakers can significantly reduce noise levels experienced by drivers and passengers. This improvement in NVH leads to a more comfortable and refined driving experience. Additionally, the use of Carbon Kevlar Weave can enhance structural integrity, resulting in improved overall ride quality and handling characteristics.

Paragraph 4:

The integration of Carbon Kevlar Weave in automotive manufacturing processes offers a multitude of aesthetic possibilities. The composite material lends itself to be molded into complex shapes and contours, allowing designers to explore innovative and eye-catching designs. Furthermore, the material's distinct weave pattern adds a touch of sophistication to the vehicle's interior and exterior surfaces. This versatility opens up new avenues for automakers to create visually appealing, lightweight, and aerodynamically optimized vehicles.

Paragraph 5:

With sustainability becoming an increasingly important focus for the automotive industry, Carbon Kevlar Weave offers a solution that contributes to environmental conservation. The material's lightweight nature translates into improved fuel efficiency, reducing greenhouse gas emissions and promoting eco-friendly driving. Furthermore, the carbon fiber component of the composite can be recycled or repurposed, further reinforcing the sustainable aspects of this innovative material.

Conclusion:

In conclusion, the introduction of Carbon Kevlar Weave by {company name} is set to revolutionize automotive manufacturing. This exceptional composite material combines the strength of carbon fiber with the durability of Kevlar, resulting in a high-strength, lightweight, and versatile solution. Automakers can design vehicles that are not only safer and more fuel-efficient but also aesthetically captivating. As the automotive industry continues to strive for advancements, the integration of Carbon Kevlar Weave will undoubtedly play a crucial role in shaping the future of vehicle design and manufacturing.

Company News & Blog

Discover the Revolutionary Carbon Kevlar Weave Technology Transforming Industries

Title: Innovative Composite Material Integration Revolutionizes Automotive ManufacturingIntroduction:The automotive industry is constantly looking for groundbreaking materials to enhance performance, improve fuel efficiency, and ensure passenger safety. In the pursuit of innovation, {company name}, a renowned industry leader, has developed an exceptional composite material known as Carbon Kevlar Weave. This cutting-edge material combines the strength of carbon fiber with the durability of Kevlar, revolutionizing automotive manufacturing and paving the way for next-generation vehicles. In this article, we will explore the unparalleled properties of this composite material and its significant impact on the automotive industry.Paragraph 1:Carbon Kevlar Weave represents a breakthrough in composite-based manufacturing due to its exceptional strength-to-weight ratio. This unique material consists of a combination of carbon fiber and Kevlar, two highly regarded materials known for their individual qualities. By integrating these two materials, {company name} has harnessed the benefits of both, resulting in a composite that is incredibly lightweight yet remarkably robust. This groundbreaking amalgamation offers manufacturers a versatile solution with unparalleled strength, ease of use, and enhanced mechanical properties.Paragraph 2:One of the significant advantages of Carbon Kevlar Weave is its exceptional strength and rigidity. The carbon fiber component provides high tensile strength, making the material ideal for applications requiring rigidity and load-bearing capabilities. The Kevlar reinforcement ensures increased impact resistance and toughness, making it particularly suitable for safety-critical components in the automotive industry. These combined properties enable automakers to design lighter and more fuel-efficient vehicles without compromising safety standards.Paragraph 3:Another pivotal benefit of Carbon Kevlar Weave is its unique ability to dampen noise, vibrations, and harshness (NVH). By integrating this composite material into various vehicle body components, automakers can significantly reduce noise levels experienced by drivers and passengers. This improvement in NVH leads to a more comfortable and refined driving experience. Additionally, the use of Carbon Kevlar Weave can enhance structural integrity, resulting in improved overall ride quality and handling characteristics.Paragraph 4:The integration of Carbon Kevlar Weave in automotive manufacturing processes offers a multitude of aesthetic possibilities. The composite material lends itself to be molded into complex shapes and contours, allowing designers to explore innovative and eye-catching designs. Furthermore, the material's distinct weave pattern adds a touch of sophistication to the vehicle's interior and exterior surfaces. This versatility opens up new avenues for automakers to create visually appealing, lightweight, and aerodynamically optimized vehicles.Paragraph 5:With sustainability becoming an increasingly important focus for the automotive industry, Carbon Kevlar Weave offers a solution that contributes to environmental conservation. The material's lightweight nature translates into improved fuel efficiency, reducing greenhouse gas emissions and promoting eco-friendly driving. Furthermore, the carbon fiber component of the composite can be recycled or repurposed, further reinforcing the sustainable aspects of this innovative material.Conclusion:In conclusion, the introduction of Carbon Kevlar Weave by {company name} is set to revolutionize automotive manufacturing. This exceptional composite material combines the strength of carbon fiber with the durability of Kevlar, resulting in a high-strength, lightweight, and versatile solution. Automakers can design vehicles that are not only safer and more fuel-efficient but also aesthetically captivating. As the automotive industry continues to strive for advancements, the integration of Carbon Kevlar Weave will undoubtedly play a crucial role in shaping the future of vehicle design and manufacturing.

Fiberglass Cloth: The Top Choice for Strengthening Materials

Title: Cloth for Fiberglass: A Revolutionary Innovation in the Composite IndustryIntroduction:In an era driven by innovation, the integration of advanced materials and revolutionary techniques is crucial in various sectors. In the field of composites, a recent breakthrough has been achieved with the development of Cloth for Fiberglass. This cutting-edge product has revolutionized the composite industry, enabling enhanced strength and durability across a wide range of applications. This news article aims to explore the features, benefits, and applications of Cloth for Fiberglass, while shedding light on the pioneering company behind this game-changing invention.Company Introduction:Owned and operated by a team of dedicated professionals, the company behind the development of Cloth for Fiberglass is committed to pushing the boundaries of composite materials. With decades of experience in the industry, their expertise has allowed them to engineer an innovative product that surpasses traditional fiberglass cloth. Leveraging their state-of-the-art facilities, the company has successfully manufactured Cloth for Fiberglass, catering to the growing demands and requirements of various sectors.Features of Cloth for Fiberglass:Cloth for Fiberglass boasts several key features that differentiate it from conventional materials. Firstly, its molecular structure has been meticulously designed to offer exceptional strength and sturdiness, making it resistant to impact and external forces. This remarkable strength not only improves the lifespan of the end products but also enhances their structural integrity. Additionally, Cloth for Fiberglass is lightweight and flexible, facilitating ease of use during manufacturing processes. Furthermore, it exhibits exceptional resistance to corrosion, chemicals, and extreme temperatures, making it an ideal choice for harsh environments.Benefits of Cloth for Fiberglass:The introduction of Cloth for Fiberglass provides numerous benefits across various industries. One of its primary advantages is its versatility, allowing its application in numerous sectors, including aerospace, automotive, marine, and construction. By using this innovative material, manufacturers can achieve the perfect balance between strength, weight reduction, and cost-effectiveness. Moreover, the inherent dimensional stability of Cloth for Fiberglass ensures that the end products retain their shape even under extreme conditions. This stability further contributes to the longevity of the final product, reducing maintenance and replacement costs.Applications of Cloth for Fiberglass:The revolutionary Cloth for Fiberglass has found applications across a wide range of sectors, with its unparalleled benefits making it an ideal choice for composite manufacturers. In the aerospace industry, it is utilized for the construction of aircraft components, providing lightweight and durable alternatives. In the automotive sector, it offers solutions for high-performance vehicles, allowing manufacturers to enhance fuel efficiency while maintaining safety standards. Furthermore, Cloth for Fiberglass finds extensive use in the marine industry, contributing to the design and production of sturdy and seaworthy vessels. Its resistance to corrosion and moisture make it particularly suitable for marine applications. Finally, in the construction industry, the cloth is extensively employed to produce durable and strong composite materials for infrastructure projects.Conclusion:The development of Cloth for Fiberglass marks a significant milestone in the composite industry, bringing forth a groundbreaking material that surpasses traditional alternatives. The company behind this innovative product continues to drive the industry forward by harnessing the endless potential of composites. With its remarkable strength, versatility, and resistance to various environmental factors, Cloth for Fiberglass is revolutionizing the way industries design and manufacture their products. As manufacturers increasingly adopt this game-changing cloth, we can expect a paradigm shift in the utilization of composites, opening avenues for enhanced performance, sustainability, and cost-effectiveness.

Discover the Latest Advancements in High-Quality Fiberglass Cloth for Enhanced Performance

Title: E Fiberglass Cloth revolutionizes the Fiberglass IndustryIntroduction:In today's ever-evolving world, innovative companies are constantly pushing boundaries and seeking ways to enhance existing industries. One such groundbreaking company, which we shall refer to as "Company X," has revolutionized the fiberglass industry with its path-breaking product, E Fiberglass Cloth. With commendable expertise and determination, Company X's diligent team has successfully disrupted the market, presenting a game-changing solution to fiberglass manufacturers worldwide.1. Understanding the Fiberglass Industry:The fiberglass industry has long been a critical component of numerous sectors, including construction, automotive, and aerospace. Fiberglass cloth, an essential material in this industry, has proven invaluable due to its high strength and versatility. Fiberglass cloth is commonly used to reinforce composites, enhance structural integrity, and offer exceptional thermal resistance properties. However, traditional fiberglass cloths have limitations, such as low impact resistance and overall fragility. Addressing these limitations is where Company X's E Fiberglass Cloth comes into play.2. Introducing E Fiberglass Cloth:Created after extensive research and development, Company X's E Fiberglass Cloth sets a new industry standard. It provides a unique and revolutionary approach to traditional fiberglass cloths, addressing their shortcomings and surpassing all expectations. This cutting-edge product exhibits outstanding impact resistance while delivering exceptional strength and durability. With a distinctive composition and fiber weaving technique, E Fiberglass Cloth offers manufacturers an opportunity to elevate their products to new heights.3. Unmatched Strength and Durability:E Fiberglass Cloth boasts remarkable tensile strength, making it ideally suited for demanding applications. The cloth's weaving pattern, combined with high-quality fiber, ensures enhanced damage tolerance and longevity. With this groundbreaking cloth, manufacturers can now create products that are stronger, lighter, and more robust, allowing for unprecedented design freedom without compromising structural integrity.4. Enhanced Thermal and Chemical Resistance:Another noteworthy characteristic of E Fiberglass Cloth is its extraordinary thermal and chemical resistance properties. This innovative cloth displays exceptional resistance to high temperatures, making it a reliable choice for applications where heat resistance is crucial. Moreover, its ability to withstand a wide range of chemicals and corrosive substances makes it an optimal solution across industries, including chemical processing and oil and gas.5. Versatility and Adaptability:E Fiberglass Cloth stands out due to its versatility and adaptability in various manufacturing processes. Due to its high-quality weave and compatibility with different resins, the cloth can be used for numerous applications, from reinforcing concrete structures to creating lightweight composite materials for automotive parts. This adaptability not only streamlines the manufacturing process but also opens doors to endless possibilities in product development.6. Environmental Consciousness:In addition to the product's phenomenal properties, Company X's E Fiberglass Cloth is manufactured with sustainability in mind. The company prioritizes environmentally friendly practices, ensuring that the production process minimizes waste and reduces its carbon footprint. By prioritizing sustainability, Company X underscores its commitment to responsible manufacturing and aligns with the global need for greener industrial solutions.Conclusion:Undeniably, Company X's E Fiberglass Cloth has shaken up the fiberglass industry, providing manufacturers with a revolutionary material that addresses traditional limitations while surpassing expectations in terms of strength, durability, and adaptability. With its unparalleled impact resistance, exceptional thermal and chemical resistance, and environmental consciousness, E Fiberglass Cloth offers endless possibilities across various sectors. This exceptional product has positioned Company X as an innovative frontrunner and a driving force behind the continuous evolution of the fiberglass industry on a global scale.

High-Quality Unidirectional Carbon Fiber Fabric for Industrial Applications

Unidirectional Carbon Fiber Fabric: A Strong and Lightweight Solution for Various IndustriesIn today's world, technology has revolutionized the way we live our lives. Innovations in the manufacturing industry have paved the way for the development of new materials that are stronger, lighter, and more durable than conventional materials. One such material is Unidirectional Carbon Fiber Fabric, which has become increasingly popular in industries such as automotive, aerospace, sporting goods, and many others. Unidirectional Carbon Fiber Fabric is a composite material made up of strong carbon fibers that are tightly bonded together using a polymer matrix. The fibers in this material are unidirectional, meaning that they are all aligned in the same direction, which gives it its exceptional strength and stiffness. This material is preferred over traditional materials like steel and aluminum due to its high strength-to-weight ratio, which helps to reduce the weight of the final product while maintaining its structural integrity.In the automotive industry, Unidirectional Carbon Fiber Fabric is used extensively in high-performance sports cars, racing vehicles, and electric cars. The reduction in weight of these vehicles leads to improved fuel efficiency and better handling, resulting in a more enjoyable driving experience. The use of Unidirectional Carbon Fiber Fabric in car manufacturing helps to reduce carbon emissions, contributing to a sustainable future.The aerospace industry also benefits from the use of Unidirectional Carbon Fiber Fabric in aircraft design. The lightweight properties of this material make it ideal for aircraft manufacturing, leading to a reduction in fuel consumption and improved performance. The use of this material in aircraft manufacturing has enabled the development of new, innovative designs that are more aerodynamic and offer better performance.Sporting goods companies are also increasingly using Unidirectional Carbon Fiber Fabric to develop high-performance equipment such as tennis rackets, hockey sticks, and bicycles. The strength and stiffness of this material improve the performance of these products, giving athletes a competitive edge.It is worth noting that different industries require different types of Unidirectional Carbon Fiber Fabric, depending on their specific applications. The fabric’s strength and stiffness can be controlled by varying the direction of the carbon fibers, the type of polymer matrix used, and the density of fiber layers. As such, it is crucial to have a reliable supplier who can manufacture custom-made Unidirectional Carbon Fiber Fabric to meet the different needs of each industry.One such supplier is (**remove brand name**), a leading manufacturer of high-quality Unidirectional Carbon Fiber Fabric. The company has been in business for more than ten years, and during this time, it has established a reputation for excellence in quality, reliable customer service, and competitive pricing. (**Remove brand name**) uses state-of-the-art manufacturing technology to ensure that each product meets the highest industry standards. The company's in-house team of experienced engineers uses their expertise to develop custom-made Unidirectional Carbon Fiber Fabric that meets the specific needs of each customer.(**Remove brand name**) understands the importance of quality control and follows strict guidelines to ensure that all products meet the required standards. The company's products have been certified by various industry-standard organizations, including ISO 9001, ISO 14001, and OHSAS 18001. This ensures that customers can rely on (**Remove brand name**) for consistently high-quality products and exceptional service.In conclusion, the use of Unidirectional Carbon Fiber Fabric has opened up new avenues of innovation in various industries. The combination of strength, durability, and lightweight properties of this material makes it an ideal choice for manufacturing high-performance products. (**Remove brand name**) is a trusted name in the industry and is well-equipped to provide custom-made Unidirectional Carbon Fiber Fabric that meets the specific requirements of its customers. Through continuous innovation and quality control, (**Remove brand name**) is set to become a leader in the Unidirectional Carbon Fiber Fabric industry.

Red Carbon Fiber Embossed Faux Leather Vinyl Upholstery Fabric for Various Projects

for Automotive, RV, Boat, Healthcare, Hospitality, Home decor, Fashion, and Commercial Projects.Are you looking for a versatile, stylish, and durable fabric for your next project? Look no further than our Red Carbon Fiber Embossed Faux Leather Vinyl, a top-quality upholstery fabric available at FabulessFabrics.com.Featuring an embossed cross weave pattern of carbon fibers, this fabric is perfect for adding a touch of sophistication and modern style to any project. Whether upholstering a car, RV, or boat, or creating custom home decor or fashion accessories, this fabric is sure to impress.But this fabric isn't just stylish – it's also incredibly functional. Thanks to its antibacterial properties and protective UV coating, it's perfect for healthcare, hospitality, and commercial projects. And with its water and stain-resistant properties, it's easy to clean and maintain, making it ideal for high-traffic areas.So why wait? Visit FabulessFabrics.com today to shop our wide selection of Red Carbon Fiber Embossed Faux Leather Vinyl and other top-quality upholstery fabrics. Whether you're a professional upholsterer or a DIY enthusiast, we have everything you need to bring your vision to life.

Strong and Lightweight Carbon Fiber Kevlar Hybrid Fabric Unveiled in Latest News

Title: Next-Generation Carbon Fiber Kevlar Hybrid Fabric Revolutionizes Lightweight and Resilient MaterialsIntroduction:In the ever-evolving world of advanced materials, a breakthrough innovation has taken center stage, offering unparalleled strength, durability, and lightweight properties. Carbon Fiber Kevlar Hybrid Fabric, a cutting-edge composite material, is destined to revolutionize various industries, ranging from automotive and aerospace to sports and defense. With its unique combination of carbon fiber and Kevlar, this composite fabric sets a new standard for resilience and efficiency, heralding a new era in material engineering.Carbon Fiber Kevlar Hybrid Fabric:The Carbon Fiber Kevlar Hybrid Fabric brings together the best aspects of carbon fiber and Kevlar, resulting in a material that surpasses the limitations of its individual components. Carbon fiber, recognized for its exceptional strength-to-weight ratio, provides rigidity, high tensile strength, and resistance to corrosion. On the other hand, Kevlar, a strong synthetic material known for its bulletproof properties, offers remarkable flexibility, impact resistance, and heat resistance.By combining the two, the hybrid fabric achieves a compounded effect, ensuring superior performance in demanding applications. The resultant material exhibits excellent structural integrity, resistance to fatigue, and impact absorption capabilities, making it an ideal candidate for various industries seeking lightweight yet resilient solutions.Application in Automotive Industry:In the automotive sector, manufacturers are continually striving to enhance fuel efficiency while maintaining safety and performance standards. Carbon Fiber Kevlar Hybrid Fabric presents a transformative solution, offering substantial weight reduction, improved crash safety, and increased structural integrity. With its remarkable properties, this fabric enables the production of lighter vehicles that require less fuel, contributing to more sustainable transportation solutions while minimizing the environment's impact.Application in Aerospace Industry:The aerospace industry holds stringent standards for materials used in constructing aircraft. Carbon Fiber Kevlar Hybrid Fabric provides a game-changing solution, delivering enhanced fuel efficiency, higher payload capacity, and increased resistance to impact forces. The lightweight nature of the fabric allows for considerable weight reduction, leading to reduced fuel consumption and emissions. Additionally, its exceptional resilience ensures improved safety while withstanding the rigors of flight and exposure to extreme temperatures.Application in Sports and Defense Industry:The sports industry demands materials that offer both high performance and exceptional durability. Carbon Fiber Kevlar Hybrid Fabric emerges as a formidable choice, with applications in sports equipment such as bicycles, golf clubs, helmets, and protective gear. Athletes benefit from the enhanced strength, reduced weight, and improved shock absorption, ultimately improving their performance and safety.In the defense sector, the hybrid fabric finds its application in manufacturing lightweight and robust body armor, bulletproof vests, and ballistic helmets. Its ability to absorb and disperse the impact of high-velocity projectiles significantly enhances the safety of military personnel in combat situations, making it an invaluable innovation for defense forces worldwide.Future Potential and Promising Developments:The introduction of Carbon Fiber Kevlar Hybrid Fabric opens up a world of possibilities for numerous industries. Ongoing research and development efforts aim to further optimize the properties of the composite materials and find innovative applications. The potential to increase strength, reduce weight further, and enhance insulation and conductivity characteristics unlocks exciting prospects across various sectors.Furthermore, the mass production of Carbon Fiber Kevlar Hybrid Fabric is gathering momentum, making it more accessible and affordable for a broader range of applications. The scalability and cost-effectiveness associated with manufacturing this remarkable material are expected to drive its adoption across multiple industries in the near future.Conclusion:Carbon Fiber Kevlar Hybrid Fabric represents a significant leap forward in advanced material engineering. Its unique combination of carbon fiber and Kevlar amplifies the strengths of both materials, resulting in a resilient, lightweight, and versatile fabric. From automotive and aerospace industries to sports and defense sectors, this groundbreaking innovation is set to revolutionize various fields, powering the creation of safer, more efficient, and environmentally friendly products. As further advancements and applications emerge, the potential of Carbon Fiber Kevlar Hybrid Fabric to shape the future of materials remains undeniably promising.

High-Quality Fiberglass Fabric Rolls: The Ultimate Solution for Various Applications

Title: The Impressive Innovations in Fiberglass Fabric Rolls Lead to Greater Safety and Reliability in Various IndustriesIntroduction:In recent years, Fiberglass Fabric Roll has emerged as a game-changer in numerous industries, offering unmatched versatility, strength, and durability. Its remarkable thermal and chemical resistance, as well as its lightness, make it ideal for a wide range of applications. With continuous research and development, Fiberglass Fabric Roll has proven to be a crucial material in numerous sectors, including manufacturing, automotive, aerospace, and construction.Background:The incorporation of fiberglass into fabric rolls has revolutionized the way industries approach challenging scenarios that demand high-performance materials. Primarily composed of fine fibers of glass, Fiberglass Fabric Roll possesses exceptional properties. These include high tensile strength, outstanding electrical insulation, flame retardancy, and low thermal conductivity. Moreover, it is highly resistant to chemicals, water, and UV radiation.Company Overview:{Company Name}, one of the leading manufacturers of Fiberglass Fabric Rolls, has spearheaded the development of innovative solutions based on this material. The company's relentless dedication to research and development, coupled with a commitment to quality, has positioned it at the forefront of the fiberglass industry. {Company Name} has revolutionized various sectors by creating customized solutions that cater to specific industry requirements while adhering to the highest manufacturing standards.The Advantages of Fiberglass Fabric Rolls:1. High Mechanical Strength: Fiberglass Fabric Rolls boast an exceptional strength-to-weight ratio, making them advantageous in load-bearing applications. These rolls can withstand heavy pressure, making them suitable for use in automotive parts, wind turbines, and infrastructure projects.2. Thermal Insulation: The inherent low thermal conductivity properties of Fiberglass Fabric Rolls make them invaluable in applications that require insulation against temperature variations. Industries such as HVAC (Heating, Ventilation, and Air Conditioning), refrigeration, and cryogenics have greatly benefited from the exceptional resistance offered by these rolls.3. Electrical Insulation: With excellent electrical insulation properties, Fiberglass Fabric Rolls are a preferred choice for manufacturing electrical components. They protect against electrical currents, reducing the risk of short circuits and other electrical hazards.4. Flame Retardancy: Safety is paramount in industries where fire hazards are a concern. Fiberglass Fabric Rolls are renowned for their exceptional flame resistance, making them an ideal choice for applications in aerospace, automotive, and building materials, ensuring reinforced safety measures.5. Chemical Resistance: Many industries face challenges related to chemical corrosion and exposure. Fiberglass Fabric Rolls offer outstanding resistance to chemicals, acids, and alkalis, making them an incredibly stable choice for applications such as chemical storage, pipe insulation, and chemical processing.6. UV Resistance: Outdoor applications often require materials that can withstand prolonged exposure to sunlight. The UV stability of Fiberglass Fabric Rolls makes them an excellent choice for outdoor structures, marine applications, and solar panels.7. Lightweight and Flexibility: Fiberglass Fabric Rolls have the advantage of being lightweight, combining strength with ease of handling. This makes them highly versatile and suitable for applications such as sports equipment, boat hulls, and aircraft components.Future Prospects:With continuous advancements in technology, the potential applications of Fiberglass Fabric Rolls are expected to expand further. Researchers and manufacturers, such as {Company Name}, are exploring opportunities to enhance the material's characteristics, develop new composites, and improve manufacturing processes. Some potential areas of growth include renewable energy systems, automotive engineering, and additive manufacturing.Conclusion:The increasing use of Fiberglass Fabric Rolls across a wide range of industries speaks volumes about its versatility, strength, and reliability. Its exceptional mechanical and thermal properties, combined with resistance to chemicals and flames, make it an indispensable material in various sectors. As companies like {Company Name} continue to advance fiberglass technology, we can expect even more groundbreaking innovations that push boundaries and create safer and more sustainable solutions for the future.

Understanding the Characteristics of Carbon-fiber Composites

Title: Exploring the Marvels of Fiber Carbon Cloth: Revolutionizing the World of CompositesIntroduction (70 words):Welcome to our extensive guide on the revolutionary material that is fiber carbon cloth. In this blog, we will delve deep into the world of this incredible composite, exploring its various applications and highlighting its remarkable traits. From its woven fibrous construction to its resiliency, versatility, and strength, fiber carbon cloth has emerged as a game-changer in multiple industries. So, without further ado, let's unravel the secrets behind this remarkable material!Understanding Fiber Carbon Cloth (100 words):Fiber carbon cloth is a fibrous carbon composite that has revolutionized countless industries in recent years. It begins with individual strands woven into a rough cloth, which is then carefully impregnated with epoxy resin after molding it into desired shapes. This combination produces a material boasting exceptional strength-to-weight ratio, rigidity, and high tensile strength. Fiber carbon cloth owes its incredible properties to the unique arrangement of carbon fibers that form its core structure. Now, let's explore the remarkable benefits and applications of this cutting-edge material.Applications and Advantages (250 words):1. Aerospace Industry:In the aerospace industry, fiber carbon cloth finds extensive use due to its lightweight, high strength, and excellent resistance to high temperatures and impacts. It enhances fuel efficiency in aircraft, reduces structural weight, and improves overall performance. From aircraft frames to wings, fiber carbon cloth has become an integral component in the manufacturing process.2. Automotive Industry:In the automotive sector, fiber carbon cloth is employed in the production of high-performance vehicles. By utilizing this material in car manufacturing, automotive companies can reduce weight, enhance fuel efficiency, and improve structural integrity. Carbon fiber components, such as hoods, fenders, and body panels, are gaining popularity due to their striking aesthetics and outstanding performance.3. Sports and Recreation:From professional sports equipment to recreational products, the sports industry has embraced fiber carbon cloth for its durability and lightness. Tennis rackets, bicycles, golf clubs, helmets, and ski poles are just a few examples of sporting goods that utilize carbon fiber composites for superior performance and reduced weight.4. Construction and Infrastructure:In the construction field, fiber carbon cloth helps strengthen existing structures by acting as reinforcement in concrete and other building materials. Its lightweight nature and high strength allow for efficient and long-lasting construction projects while reducing material usage. Additionally, fiber carbon cloth is increasingly used in earthquake-resistant building designs and bridge construction.5. Renewable Energy:The renewable energy sector has also recognized fiber carbon cloth as an ideal material for producing enhanced wind turbine blades. Its low weight and high strength characteristics enable turbines to convert wind energy more efficiently, contributing to the sustainable energy movement.Keywords: Fiber Carbon Cloth, carbon fiber composite, woven carbon fibers, strength-to-weight ratio, aerospace industry, automotive industry, sports and recreation, construction, infrastructure, renewable energyConclusion (80 words):Fiber carbon cloth has revolutionized various sectors, thanks to its exceptional strength, lightweight nature, and versatility. Industries such as aerospace, automotive, sports, construction, and renewable energy have witnessed significant advancements thanks to this game-changing material. As technology continues to advance, we can expect further innovations in the field of fiber carbon cloth, leading to new breakthroughs and applications across different industries. This remarkable composite will undoubtedly play a crucial role in shaping our future.

Unveiling the Futuristic Carbon Fiber Clothing Fabric: Discover its Potential

[Headline]Carbon Fiber Clothing Fabric: Revolutionizing the Future of Fashion[Sub-Headline]{Company Name}: Leading the Way in Carbon Fiber Clothing Innovation[Lead]In a groundbreaking development that is set to revolutionize the fashion industry, {Company Name}, a pioneer in textile manufacturing, is introducing carbon fiber clothing fabric. This innovative apparel material offers immense potential with its lightweight, durable, and breathable qualities. The introduction of carbon fiber clothing fabric opens up a world of possibilities for designers and consumers alike, ushering in an era of futuristic fashion.[Body]1. Carbon Fiber Fabric: The Game ChangerCarbon fiber fabric, derived from carbon fibers which are incredibly thin strands composed mostly of carbon atoms, brings a host of advantages when incorporated into clothing. Its exceptional strength-to-weight ratio makes it stronger than steel while being significantly lighter, providing comfort without compromising on durability. The fabric's breathability and moisture-wicking properties ensure enhanced comfort even in the most challenging of environments.2. The Rise of Carbon Fiber ClothingThe fashion industry is no stranger to innovation and experimentation. Carbon fiber clothing represents a natural progression in the industry's quest for cutting-edge and sustainable materials. From athletic wear and outdoor gear to high fashion, carbon fiber clothing offers unparalleled versatility. Designers can create garments that are not only fashionable but also eco-friendly, as carbon fiber is a highly recyclable material.3. {Company Name}: Pathfinders in Carbon Fiber ClothingLeading the charge in carbon fiber clothing innovation, {Company Name} has established itself as a trailblazer, pushing the boundaries of textile manufacturing. With a focus on sustainability and functionality, the company has harnessed the potential of carbon fiber to develop groundbreaking fabric that is poised to disrupt the fashion landscape.4. Embracing SustainabilityOne of the most significant advantages of carbon fiber clothing fabric is its sustainability. Carbon fiber is renowned for its durability, which means garments created from this fabric are built to last. By investing in carbon fiber clothing, consumers can enjoy clothing items with an extended lifespan, reducing the need for frequent replacements and contributing to a more sustainable fashion industry.5. Perfecting Style with ComfortWhile often associated with sports and outdoor gear, carbon fiber clothing is also making its mark in high fashion. Merging cutting-edge technology with sleek aesthetics, {Company Name}'s carbon fiber clothing fabric allows designers to create avant-garde and futuristic pieces that are as visually stunning as they are comfortable. The extreme lightness and breathability of carbon fiber fabric provide a seamless fusion of style and functionality.6. Rethinking Fashion PossibilitiesThe introduction of carbon fiber clothing fabric opens up a world of possibilities for designers. Its exceptional strength and flexibility enable the creation of unique and intricate designs that were previously unattainable. From architectural-inspired garments to sculptural pieces, carbon fiber clothing fabric offers a new creative dimension for designers to explore and experiment with.7. Catering to Various MarketsThe versatility of carbon fiber clothing fabric allows it to cater to a wide range of industries. Designers can incorporate this innovative fabric into activewear, creating sportswear that enhances performance and offers unbeatable comfort. Additionally, the automobile and aerospace industries are adopting carbon fiber clothing for applications such as seat covers and protective suits for astronauts and pilots.8. Overcoming ChallengesWhile carbon fiber clothing fabric represents a significant breakthrough in textile manufacturing, it does come with its share of challenges. Its high production costs and complex manufacturing processes may initially limit its accessibility to the mass market. However, with technological advancements and increasing demand, the cost of carbon fiber clothing is expected to lower, making it accessible to a broader consumer base in the future.9. Collaborations and Future ProspectsRecognizing the immense potential of carbon fiber clothing, {Company Name} is actively seeking collaborations with designers, fashion houses, and researchers. By fostering partnerships and sharing expertise, the company aims to further refine the fabric, expand its applications, and lower production costs. The future of carbon fiber clothing is undoubtedly bright, with endless possibilities waiting to be explored.[Conclusion]The introduction of carbon fiber clothing fabric by {Company Name} truly marks a new chapter in the fashion industry. With its lightweight, durable, and sustainable properties, this innovative fabric offers unprecedented possibilities for creating fashion-forward clothing. As designers and consumers embrace carbon fiber clothing, the world of fashion is poised to undergo a metamorphosis, one that promises a future where style, functionality, and sustainability seamlessly coexist.

24oz Vermiculite Coated Fiberglass Cloth: A Fire and Chemical Resistant Solution for High Temperature Insulation and Welding Applications

Acmetex Inc Launches Revolutionary 24oz Vermiculite Coated Fiberglass ClothAcmetex Inc, a leading manufacturer of high-performance fiberglass cloth and textile products, has announced the launch of its latest innovation, the 24oz Vermiculite Coated Fiberglass Cloth. This new product brings cutting-edge technology and design to the market, providing customers with an advanced and reliable solution for their high-temperature insulation and fire-resistant needs.Acmetex's 24oz Vermiculite Coated Fiberglass Cloth is made from continuous texturized E-fiberglass yarns, which offer exceptional strength and durability. These yarns are woven together to create a tight, dense fabric that can withstand high temperatures and harsh conditions. Vermiculite coating is added to the cloth to improve abrasion resistance and add an extra layer of protection against direct flame.Heat travels across the fabric, not through it, making this product an excellent choice for high-temperature insulation and heat shield applications. It provides superior thermal insulation, keeping heat from escaping and cold from seeping in, making it ideal for use in welding blankets, curtains, and expansion joints. The vermiculite coating also improves the cloth's strength and resistance to tearing, making it a great option for high-stress applications.Acmetex Inc has been a leading manufacturer of fiberglass cloth and textile products for over 20 years. The company has a proven track record of providing high-quality solutions to customers across a wide range of industries, including automotive, aerospace, marine, and construction. Acmetex's commitment to innovation and quality has made it a trusted partner for many leading companies in these industries."We are excited to launch our latest innovation, the 24oz Vermiculite Coated Fiberglass Cloth," said a spokesperson for Acmetex Inc. "This new product is a testament to our commitment to providing our customers with the highest quality solutions for their needs. We believe that this product will be a game-changer in the market, and we are confident that it will be very well received by our customers."Acmetex's 24oz Vermiculite Coated Fiberglass Cloth is available in a variety of widths and lengths, making it suitable for a wide range of applications. It is also customizable, allowing customers to tailor the fabric to meet their specific needs. The product is expected to be available for purchase on Acmetex's website and through its authorized distributors in the coming weeks.In conclusion, Acmetex Inc's 24oz Vermiculite Coated Fiberglass Cloth is a breakthrough product that offers exceptional strength, durability, and fire-resistant properties. It is a testament to the company's commitment to innovation and quality and a clear demonstration of its ability to bring cutting-edge solutions to the market. This product is sure to be a game-changer and a valuable asset for customers across a wide range of industries.