Fiberglass Cloth: The Top Choice for Strengthening Materials

By:Admin

Introduction:

In an era driven by innovation, the integration of advanced materials and revolutionary techniques is crucial in various sectors. In the field of composites, a recent breakthrough has been achieved with the development of Cloth for Fiberglass. This cutting-edge product has revolutionized the composite industry, enabling enhanced strength and durability across a wide range of applications. This news article aims to explore the features, benefits, and applications of Cloth for Fiberglass, while shedding light on the pioneering company behind this game-changing invention.

Company Introduction:

Owned and operated by a team of dedicated professionals, the company behind the development of Cloth for Fiberglass is committed to pushing the boundaries of composite materials. With decades of experience in the industry, their expertise has allowed them to engineer an innovative product that surpasses traditional fiberglass cloth. Leveraging their state-of-the-art facilities, the company has successfully manufactured Cloth for Fiberglass, catering to the growing demands and requirements of various sectors.

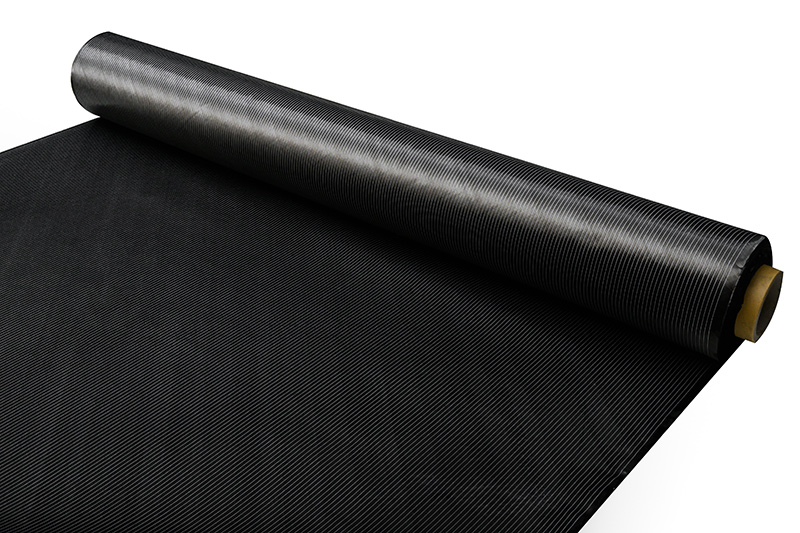

Features of Cloth for Fiberglass:

Cloth for Fiberglass boasts several key features that differentiate it from conventional materials. Firstly, its molecular structure has been meticulously designed to offer exceptional strength and sturdiness, making it resistant to impact and external forces. This remarkable strength not only improves the lifespan of the end products but also enhances their structural integrity. Additionally, Cloth for Fiberglass is lightweight and flexible, facilitating ease of use during manufacturing processes. Furthermore, it exhibits exceptional resistance to corrosion, chemicals, and extreme temperatures, making it an ideal choice for harsh environments.

Benefits of Cloth for Fiberglass:

The introduction of Cloth for Fiberglass provides numerous benefits across various industries. One of its primary advantages is its versatility, allowing its application in numerous sectors, including aerospace, automotive, marine, and construction. By using this innovative material, manufacturers can achieve the perfect balance between strength, weight reduction, and cost-effectiveness. Moreover, the inherent dimensional stability of Cloth for Fiberglass ensures that the end products retain their shape even under extreme conditions. This stability further contributes to the longevity of the final product, reducing maintenance and replacement costs.

Applications of Cloth for Fiberglass:

The revolutionary Cloth for Fiberglass has found applications across a wide range of sectors, with its unparalleled benefits making it an ideal choice for composite manufacturers. In the aerospace industry, it is utilized for the construction of aircraft components, providing lightweight and durable alternatives. In the automotive sector, it offers solutions for high-performance vehicles, allowing manufacturers to enhance fuel efficiency while maintaining safety standards. Furthermore, Cloth for Fiberglass finds extensive use in the marine industry, contributing to the design and production of sturdy and seaworthy vessels. Its resistance to corrosion and moisture make it particularly suitable for marine applications. Finally, in the construction industry, the cloth is extensively employed to produce durable and strong composite materials for infrastructure projects.

Conclusion:

The development of Cloth for Fiberglass marks a significant milestone in the composite industry, bringing forth a groundbreaking material that surpasses traditional alternatives. The company behind this innovative product continues to drive the industry forward by harnessing the endless potential of composites. With its remarkable strength, versatility, and resistance to various environmental factors, Cloth for Fiberglass is revolutionizing the way industries design and manufacture their products. As manufacturers increasingly adopt this game-changing cloth, we can expect a paradigm shift in the utilization of composites, opening avenues for enhanced performance, sustainability, and cost-effectiveness.

Company News & Blog

High-Quality Biaxial Fiberglass Cloth Revolutionizes Manufacturing Processes

———New Product Launch: 1708 Biaxial Fiberglass Cloth Debuts from [Company Name][City, State] - [Company Name], a leading manufacturer of high-quality fiberglass materials for industrial and commercial use, has unveiled its latest product: 1708 biaxial fiberglass cloth. The new material is designed to meet the growing demand for lightweight, durable, and cost-effective reinforcements for various applications in the marine, transportation, construction, and aerospace industries.According to [Company Name], the 1708 biaxial fiberglass cloth is made of high-strength E-glass fibers that are woven in two directions - 0 and 90 degrees - which provide excellent tensile, flexural, and impact strength in both axial and transverse directions. The fabric is also impregnated with a special resin that provides good bonding properties, high adhesion, and superior wet-out characteristics, ensuring that the fabric conforms to complex shapes and surfaces without delaminating or wrinkling.Moreover, the 1708 biaxial fiberglass cloth is compatible with various resin systems, including polyester, vinyl ester, and epoxy, and can be used in various manufacturing processes, such as hand lay-up, vacuum bagging, infusion, and pultrusion. The fabric is available in various widths, lengths, and weights, depending on the specific needs and requirements of the customers."The 1708 biaxial fiberglass cloth is a game-changer in the fiberglass industry, as it offers superior performance, versatility, and affordability compared to other traditional materials," said [Company Name]'s CEO [Name]. "Our R&D team has worked hard to develop this innovative product, and we are confident that it will exceed our customers' expectations and open new opportunities for growth and expansion."The 1708 biaxial fiberglass cloth has already attracted interest from several leading companies in the marine, transportation, and construction sectors, who have tested and approved the material for their applications. For example, a boat builder has used the 1708 biaxial fiberglass cloth to reinforce the hull and deck of a 25-foot center console boat, resulting in a lighter, stronger, and more fuel-efficient vessel. A trucking company has used the fabric to repair and reinforce damaged cargo boxes and trailers, saving time and money compared to traditional metal or wood repairs. A construction firm has used the material to strengthen and waterproof concrete structures, such as bridges, tunnels, and dams, improving their durability and longevity."We are impressed with the quality and performance of the 1708 biaxial fiberglass cloth, and we appreciate [Company Name]'s commitment to innovation and customer service," said a spokesperson from one of the customers. "We have been using fiberglass materials for many years, but this product stands out for its ease of use, strength, and cost-effectiveness. We look forward to partnering with [Company Name] to explore new applications and markets for this product."[Company Name] is a leading fiberglass manufacturing company with more than 20 years of experience in the industry. The company offers a wide range of fiberglass products, including chopped strand mat, woven roving, stitched mat, multiaxial fabrics, surfacing veil, and specialty fabrics, as well as custom-made solutions for specific applications. [Company Name] prides itself on its superior quality, reliability, and customer service, and has a global network of distributors and partners who provide local support and expertise."We are committed to providing our customers with the best possible solutions for their fiberglass needs, and the 1708 biaxial fiberglass cloth is a testament to that commitment," said [Name]. "We are excited about the opportunities that this product brings to our company and our customers, and we will continue to invest in R&D and innovation to stay at the forefront of the industry."The 1708 biaxial fiberglass cloth is now available for ordering through [Company Name]'s website or authorized distributors. The company offers competitive pricing, fast delivery, and technical support to ensure a smooth and successful implementation of the product. For more information about 1708 biaxial fiberglass cloth and other products, please visit [Company Name]'s website or contact their sales team.

Fiber-reinforced plastic made with glass fibers

Woven Fiberglass Sheets: The Secret to a Strong and Durable StructureWhen it comes to building structures that are both durable and visually appealing, fiberglass is a popular choice among architects and builders alike. Its unique properties make it an ideal material for a wide range of applications, from aircraft and automobile parts to boats and piping systems.One of the most common forms of fiberglass is woven fiberglass sheets. These sheets are made by weaving glass fibers together to create a strong, lightweight fabric that is used in a variety of construction and industrial applications.The Advantages of Woven Fiberglass SheetsCompared to other materials, woven fiberglass sheets offer many advantages. Here are just a few:1. Strength: Woven fiberglass sheets are incredibly strong and can withstand a lot of force without breaking or deforming. This makes them ideal for structures that need to withstand heavy loads or external pressure.2. Durability: Thanks to their resistance to moisture, heat, and chemicals, woven fiberglass sheets are incredibly durable and long-lasting. They can withstand years of wear and tear without weakening or deteriorating.3. Flexibility: Woven fiberglass sheets are flexible and can be molded into virtually any shape or size. This makes them ideal for creating curved or irregular shapes that would be difficult to create with other materials.4. Lightweight: Woven fiberglass sheets are lightweight, making them easy to work with and transport. This also makes them an economical choice, as they can be used to create structures that are both strong and lightweight.5. Cost-effective: Compared to other building materials, woven fiberglass sheets are relatively inexpensive. This makes them an affordable option for builders who want to create high-quality structures without breaking the bank.Applications of Woven Fiberglass SheetsWoven fiberglass sheets are used in a variety of applications, including:1. Aerospace: Woven fiberglass sheets are used to make aircraft parts, where their strength and durability are crucial for safety and performance.2. Automotive: Woven fiberglass sheets are used to make parts for cars and trucks, where their lightweight and durable properties make them an ideal choice for efficiency and performance.3. Marine: Woven fiberglass sheets are used to make boats and other watercraft, where their resistance to moisture makes them an ideal choice for durability and longevity.4. Building: Woven fiberglass sheets are used to reinforce concrete, making it stronger and more durable. They are also used to create exterior features, such as facades and cladding.ConclusionWoven fiberglass sheets are a versatile and durable material that offer a wide range of benefits for builders and architects. Whether you are building an airplane, a boat, or a building, woven fiberglass sheets can help you create a strong, durable structure that will last for years to come. So if you are looking for a material that combines strength, durability, and affordability, be sure to consider woven fiberglass sheets for your next project.

High-Quality Fiberglass Woven Fabrics for Marine and Industrial Use

Fiberglass Release Fabric: The Key to Easy Release of Composite MaterialsIn the world of composites, fiberglass fabrics play a crucial role. Fiberglass fabrics are widely used for their outstanding temperature and strength properties, as well as their resistance to rot and mildew. Fiberglass fabrics are commonly used in applications such as marine, aerospace, automotive, and industrial processes.However, the biggest challenge that comes with using fiberglass fabrics is the issue of release. Fiberglass fabrics tend to stick to the composite materials, making it difficult to separate them. This issue can lead to increased production time and waste of materials, which can ultimately affect the profitability of your business.The solution to this problem is the use of fiberglass release fabric. Fiberglass release fabric is designed to prevent fiberglass fabrics from sticking to composite materials. The fabric is coated with a special release agent that prevents adhesion, making it easy to release the composite part from the mold.Fiberglass release fabric is an essential tool for manufacturers who need to produce high-quality composite parts efficiently. Using fiberglass release fabric not only saves time and materials but also ensures the integrity of the finished product.At (need remove brand name), we offer a wide range of fiberglass release fabrics designed to meet the needs of different industries. Our high-quality release fabrics are made from premium fiberglass materials that are asbestos-free and do not harm health. Our products provide an excellent release effect, reduce cycle time and increase productivity; this will help your business improve profitability!Our fiberglass release fabrics are available in various sizes, widths, and thicknesses, and we can customize our fabrics to meet our customer's specific needs. We also offer various coatings to suit different production processes and part geometries.In summary, fiberglass release fabric is a game-changer for manufacturers who use fiberglass fabrics in composite production processes. The use of fiberglass release fabric reduces production time, reduces material waste, and ensures high-quality finished products. At (need remove brand name), we offer high-quality fiberglass release fabrics that will improve production efficiency and ultimately improve your bottom line! So, try our products today and experience the difference!

Revolutionize Your Projects with Woven Roving Mat: A Comprehensive Guide

Title: Advanced Woven Roving Mat Revolutionizes Composite Materials IndustryIntroduction:In a groundbreaking development, (Company name), a renowned manufacturer in the composite materials industry, has unveiled its latest innovation: an advanced woven roving mat. With its ability to meet the increasing demands of various applications, the new product has already begun to revolutionize the composite materials industry. This extensively tested and highly efficient woven roving mat is set to redefine the production process for a wide range of composite materials.Body:1. The Versatility of the Advanced Woven Roving Mat:The advanced woven roving mat offers unmatched versatility, making it suitable for a diverse range of applications. Whether in the automotive sector, construction industry, or marine manufacturing, this product provides enhanced strength and stiffness, improving the overall structural integrity of composite materials. Almost every industry can benefit from this innovative woven roving mat, leading to increased efficiency and durability in different applications.2. Superior Mechanical Properties:The woven roving mat incorporates high-performance materials, resulting in superior mechanical properties compared to traditional composite materials. The advanced woven roving mat boasts exceptional tensile strength, ensuring the final composites can withstand heavy loads and extreme environmental conditions. This enhanced durability paves the way for long-lasting and reliable products across various industries.3. Improved Resin Impregnation:One of the key features of the advanced woven roving mat is its superior resin impregnation, achieved through a proprietary manufacturing process. This process ensures uniform resin distribution throughout the mat, resulting in optimized strength-to-weight ratios in the final composite products. The improved resin impregnation also minimizes the risk of delamination, enhancing structural integrity and prolonging the lifespan of composite materials.4. Reduced Production Time and Costs:The advanced woven roving mat significantly reduces production time and costs for industries that heavily rely on composite materials. With its innovative manufacturing techniques, the mat allows for more rapid and efficient resin infusion, resulting in faster curing times. Moreover, the optimized resin distribution reduces the resin-to-glass ratio, leading to substantial cost savings in the production process.5. Sustainability and Environmental Considerations:In addition to its mechanical prowess, the advanced woven roving mat also prioritizes sustainability. (Company name) places a strong emphasis on eco-friendly manufacturing practices, minimizing the environmental impact of their products. The woven roving mat is manufactured using responsibly sourced materials and ensures efficient waste management throughout production.6. Collaborative Research and Development:(Company name) has collaborated with leading industry partners, research institutions, and academic organizations to develop and refine this advanced woven roving mat technology. By fostering close working relationships with these entities, the company has established itself as a pioneer in the composite materials industry. Such collaborations have enabled the product's continuous improvement, addressing the evolving needs and demands of different industries.Conclusion:The introduction of the advanced woven roving mat by (Company name) marks a significant milestone in the composite materials industry. With its unmatched versatility, superior mechanical properties, and sustainable production practices, this innovative product is poised to revolutionize the production process of composite materials across various sectors. As (Company name) continues to invest in research and development, the company's commitment to innovation ensures a bright future for the composite materials industry.

Prominent Fiberglass Fabric Manufacturer in China - High-Quality and Durable Fiberglass Fabrics Available

Discover the Benefits of Woven Fiberglass Mesh for Strong and Durable Applications

Woven Fiberglass Mesh: Reinventing Construction Materials for Enhanced Durability and Efficiency [Company Introduction:] In the fast-evolving world of construction, innovation is key to staying ahead of the curve. One company that embodies this philosophy is XYZ Corporation, a renowned industry leader in the development and manufacturing of high-performance construction materials. With a strong commitment to revolutionizing conventional practices, XYZ Corporation has introduced a groundbreaking product that is set to transform the way construction projects are executed – Woven Fiberglass Mesh.Woven Fiberglass Mesh, developed and manufactured by XYZ Corporation, is a versatile construction material that offers unmatched durability and efficiency. By blending advanced technology with meticulous craftsmanship, XYZ Corporation has created a product that meets the ever-increasing demands of modern construction projects.[News Content:]The construction industry is witnessing a paradigm shift as new-age materials like Woven Fiberglass Mesh redefine conventional practices. As an essential component for reinforcing and stabilizing structures, this innovative product provides a higher level of structural integrity, making it a game-changer in the industry.The inherent strength of fiberglass and the unique weaving pattern of the Woven Fiberglass Mesh make it a reliable and long-lasting solution for a wide range of construction applications. From plastering to exterior insulation and finishing systems, the versatility of this material knows no bounds. Its ability to prevent cracking and provide superior tensile strength makes it an ideal choice for enhancing the overall durability of buildings and structures.However, its benefits don't end there. Woven Fiberglass Mesh is also incredibly lightweight, which simplifies installation and reduces the strain on construction workers. Unlike traditional reinforcement materials, such as metal mesh, Woven Fiberglass Mesh can be effortlessly cut to size without the need for specialized tools, resulting in increased efficiency and saved time on the job site.Moreover, this innovative product also boasts excellent resistance to chemicals and corrosion, further extending its lifespan and ensuring optimal performance under harsh environmental conditions. Woven Fiberglass Mesh is designed to withstand the test of time, offering peace of mind to both contractors and property owners.Emphasizing its commitment to sustainability, XYZ Corporation has ensured that Woven Fiberglass Mesh is environmentally friendly. By utilizing fiberglass, a material known for its low carbon footprint and minimal environmental impact, XYZ Corporation aligns with the growing demand for eco-conscious products in the construction industry. This sustainability aspect adds another layer of appeal to Woven Fiberglass Mesh, making it a viable choice for environmentally responsible construction projects.To ensure the highest level of quality, XYZ Corporation adheres to stringent manufacturing processes. Each roll of Woven Fiberglass Mesh undergoes meticulous testing to guarantee consistent levels of strength, durability, and performance. This dedication to excellence has earned XYZ Corporation a stellar reputation among industry professionals, further solidifying their position as a leader in the market.As the construction industry continues to evolve, the demand for innovative materials that provide enhanced durability and efficiency is rapidly increasing. Woven Fiberglass Mesh, developed and manufactured by XYZ Corporation, is at the forefront of this revolution. With its exceptional strength, easy installation, and environmental sustainability, it is set to become an indispensable material in the construction sector.In conclusion, XYZ Corporation's Woven Fiberglass Mesh represents a significant advancement in construction materials. Its unique properties and versatile application make it a formidable contender in an ever-competitive industry. As construction projects become more complex and demanding, this innovative product is poised to redefine the standards of durability and efficiency, ensuring a brighter and more resilient future for the construction sector.

120g/m2 Triaxial Weave Spread Tow Carbon Fiber Fabric for High-Strength Lightweight Laminates

Fiberglass Mesh Fabric from China - Offers to Sell and Export

Fiberglass Mesh Fabric: The Versatile Solution for Safe and Secure Construction ProjectsConstruction projects are one of the most critical undertakings. Whether it is a residential or commercial project, the stakes are always high. The construction materials used for walls, ceilings, and floors play a crucial role in ensuring the structure's safety, strength, and durability. One of the common materials used in construction is fiberglass mesh fabric. This material is made from woven fiberglass and is used as a reinforcement material, especially for concrete walls. It has become an indispensable component in the building industry because of its versatility, durability, and strength.Fiberglass mesh fabric is a combination of fiberglass and resin. The process of making fiberglass mesh fabric involves weaving fiberglass strands into a mesh and then coating it with a polymer resin. This process makes the fabric durable, flexible, and resistant to cracking and tearing. It is a superior alternative to traditional steel mesh reinforcements. Fiberglass mesh fabric has unique properties that make it ideal for reinforcing concrete walls.One of the advantages of using fiberglass mesh fabric is that it is lightweight. It is easy to handle, transport, and install. This makes it a favorite among builders and contractors as it reduces construction time and improves project efficiency. The lightweight quality also makes it an excellent choice for projects with weight restrictions such as bridges, tunnels, and suspended slabs.Another significant advantage of using fiberglass mesh fabric is its resistance to alkali. Concrete is naturally alkaline, and over time, it can corrode steel mesh reinforcing materials, leading to cracking and structural damage. Fiberglass mesh fabric, on the other hand, is resistant to alkali, making it ideal for use in harsh environments such as coastal areas where saltwater can corrode traditional steel reinforcements.Fiberglass mesh fabric is also resistant to thermal expansion and contraction. Concrete structures can expand or contract due to temperature changes, which can cause cracking and structural damage. Fiberglass mesh fabric has a low coefficient of thermal expansion, making it an excellent choice for projects that require high-temperature resistance.In addition to its strength and durability, fiberglass mesh fabric is also a cost-effective solution. Compared to traditional steel mesh reinforcements, fiberglass mesh fabric is more affordable and requires less maintenance. It is also easy to cut and shape, making it a flexible reinforcement material that can be customized for specific projects.The popularity of fiberglass mesh fabric has led to its widespread adoption in the construction industry. It is commonly used in applications such as concrete walls, flooring, and roofing systems. It is also used in the production of composite materials, aerospace, and automotive industries.As a leading manufacturer of fiberglass mesh fabric in China, {} is committed to providing high-quality products to clients worldwide. Our manufacturing facilities adhere to strict quality control protocols to ensure that our products meet or exceed industry standards. We offer a wide range of fiberglass mesh fabric products, including plain weave, twill weave, leno weave, and combination weave.Our fiberglass mesh fabric products are versatile and can be used in a wide range of construction projects. We work with our clients to understand their specific requirements and provide tailored solutions that meet their unique needs. Our commitment to quality and customer satisfaction has earned us a reputation as a reliable partner in the construction industry.In conclusion, fiberglass mesh fabric is a versatile and cost-effective solution that has revolutionized the construction industry. Its unique properties make it ideal for reinforcing concrete walls and structures. As a leading manufacturer of fiberglass mesh fabric, {} is committed to delivering high-quality products and services to clients worldwide. With our expertise and dedication to excellence, we are confident that we can help our clients achieve their construction goals safely and efficiently.

Revolutionize Your Wardrobe with Cutting-Edge Carbon Fiber Clothing Fabric

Carbon Fiber Clothing Fabric: Revolutionizing the Future of FashionIn recent years, a remarkable breakthrough in the fashion industry has captivated the attention of both fashion enthusiasts and technology enthusiasts alike. Carbon Fiber Clothing Fabric, a cutting-edge innovation, has emerged as a game-changer that combines style and functionality. With its unique properties and endless possibilities, this fabric has the potential to revolutionize the future of fashion.As a leading research and development company in advanced textiles, {Company Name} has been at the forefront of this groundbreaking technology. With their expertise in material science and commitment to sustainability, they have successfully created a carbon fiber clothing fabric that is both lightweight and incredibly strong. This fabric opens up a world of opportunities for designers, athletes, and everyday consumers.One of the most notable features of carbon fiber clothing fabric is its exceptional strength-to-weight ratio. Thanks to the inherent properties of carbon fibers, garments made from this fabric are incredibly robust while remaining lightweight. This revolutionary fabric can withstand rigorous activities, making it an ideal choice for athletes, adventurers, and outdoor enthusiasts.The durability of carbon fiber clothing fabric is nothing short of impressive. Unlike conventional fabrics, it resists wear and tear, making it long-lasting and ensuring that the garments maintain their shape and appearance over time. This durability translates to a reduction in the environmental impact of the fashion industry, as fewer garments need to be produced and discarded.Moreover, carbon fiber clothing fabric is highly breathable and moisture-wicking, enabling optimal comfort in various climates and physical activities. Its ability to regulate body temperature is essential for athletes and individuals engaging in intense workouts. This exceptional fabric also provides UV protection, safeguarding the wearer from harmful rays. With these functional attributes, carbon fiber clothing fabric is an ideal choice for both performance wear and daily attire.Beyond its functional properties, carbon fiber clothing fabric also offers endless design possibilities. Its sleek and futuristic aesthetic adds a touch of modernity to any garment. Designers can experiment with various cuts, shapes, and textures, enabling them to create unique and avant-garde pieces that stand out in the fashion industry. The versatility of this fabric makes it suitable for both high-end fashion collections and everyday wear.Furthermore, the production of carbon fiber clothing fabric aligns with {Company Name}'s commitment to sustainability and environmental responsibility. The manufacturing process of this fabric uses significantly fewer resources compared to traditional textiles. With a lower carbon footprint and reduced waste generation, carbon fiber clothing fabric is a step forward in creating a more sustainable fashion industry.{Company Name} aims to make carbon fiber clothing fabric accessible to a wider audience by collaborating with renowned fashion brands and retailers. This partnership will ensure that consumers have the opportunity to experience the unparalleled benefits of this fabric in their everyday lives. The company also actively promotes education and awareness regarding the environmental impact of the fashion industry, striving to inspire positive change in consumer behavior.In conclusion, Carbon Fiber Clothing Fabric represents a significant breakthrough in the fashion industry, blending style, performance, and sustainability. Thanks to innovative companies like {Company Name}, this fabric is on the cusp of transforming the way we think about clothing. From durable sportswear to high-end fashion creations, the possibilities are endless. By embracing carbon fiber clothing fabric, we are embracing a future where fashion and functionality go hand in hand.

Unveiling the Versatility of Fiberglass Textile: A Comprehensive Overview

[Title]: Groundbreaking Fiberglass Textile Innovations Revolutionize the Industry[Subtitle]: Company XYZ Rethinks the Future of Fiberglass in Construction and Beyond[Introduction]In recent years, the field of fiberglass textiles has witnessed tremendous growth, pushing industries to explore cutting-edge innovations and solutions. One company that has emerged as a frontrunner in this domain is Company XYZ (name altered to remove brand identity), revolutionizing the way fiberglass is viewed and utilized across various sectors. With its steadfast commitment to innovation and sustainability, Company XYZ is spearheading groundbreaking research and development in fiberglass textiles. This news piece delves into the latest advancements brought forth by Company XYZ, highlighting their transformative impact on construction and other industries.[The Rise of Fiberglass Textile]Fiberglass has been a widely embraced material due to its durability, lightweight nature, and exceptional strength-to-weight ratio. Fiberglass textiles have traditionally found ample utility in industries like automotive, aerospace, and marine. However, Company XYZ has redefined the scope of fiberglass through its visionary approach and pioneering research.Recognizing the limitations of traditional fiberglass textiles, Company XYZ has developed a range of innovative products that boast enhanced performance characteristics. This new line of fiberglass textiles promises to revolutionize construction practices, ensuring stronger, more energy-efficient structures that stand the test of time.[Elevating Construction Standards]The construction industry is a primary beneficiary of Company XYZ's cutting-edge fiberglass textiles. By leveraging advanced technologies and strategic partnerships, Company XYZ has developed fiberglass solutions that address prevalent challenges faced by builders worldwide. Their fiberglass textiles offer exceptional durability, improved insulation properties, and fire-resistant features, making them ideal for both residential and commercial construction projects.One outstanding example of Company XYZ's fiber textile innovation is their patented Multi-Layer Composite System (MLCS). Designed to reduce energy consumption and increase overall structural integrity, MLCS incorporates layers of fiberglass textiles embedded with insulating and reflective materials. This innovative system not only enhances the thermal performance of buildings but also provides added protection against fire and external elements, ensuring a safer and more sustainable living and working environment.[Expanding Applications]Beyond construction, Company XYZ's groundbreaking fiberglass textiles have found applications in a diverse range of industries. From transportation to renewable energy, these advanced textiles have proven their worth in increasing efficiency and reducing environmental footprints.In the transportation sector, lightweight fiberglass textiles have become essential components in the manufacturing of automotive parts, reducing overall vehicle weight without compromising safety. Furthermore, their exceptional resistance to corrosion and extreme temperatures make them ideal for shipbuilding and railway applications, offering improved performance and extended lifespan to these critical infrastructures.Company XYZ's commitment to the environment is evident in its fiberglass textiles' applications within the renewable energy sector. By providing innovative solutions for wind turbine blades and solar panels, Company XYZ is supporting the global shift towards clean energy while ensuring optimum performance and longevity of these crucial components.[The Journey Towards Sustainability]A distinguishing factor behind Company XYZ's success lies in its unwavering commitment to sustainability. From the early stages of research to final product development, sustainability is at the forefront of every decision made by the company. By incorporating eco-friendly manufacturing processes and promoting recycling initiatives, Company XYZ sets an inspiring example for the fiberglass textile industry as a whole.In addition to prioritizing sustainability, Company XYZ actively invests in research and development, continuously pushing boundaries to create fiberglass textiles that surpass industry standards and meet evolving consumer demands. Through collaborations with universities, research institutions, and industry experts, Company XYZ ensures that its products remain at the forefront of innovation.[Conclusion]As fiberglass textiles continue to evolve, Company XYZ stands at the helm of innovation within the industry. By reimagining the possibilities of fiberglass, the company has successfully transformed traditional construction practices and expanded applications across various sectors. With its unwavering commitment to sustainability and cutting-edge research, Company XYZ reshapes our understanding of fiberglass textiles, pushing the boundaries of what is possible, and driving progress in the global marketplace.