- Home

- Blog

- Fiberglass Mat Woven Roving: The Versatile and Durable Reinforcement Material" can be rewritten as "Discover the Benefits of Woven Roving Fiberglass Mat as Your Reinforcement Material".

Fiberglass Mat Woven Roving: The Versatile and Durable Reinforcement Material" can be rewritten as "Discover the Benefits of Woven Roving Fiberglass Mat as Your Reinforcement Material".

By:Admin

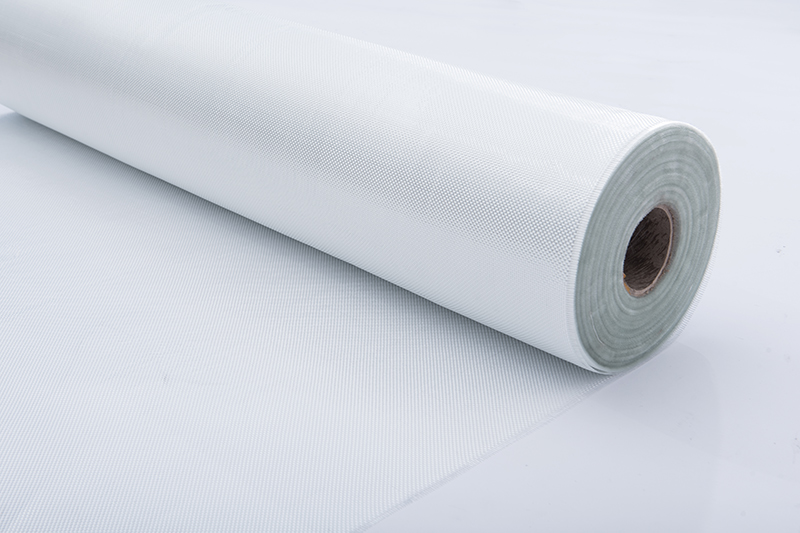

In the modern world, composite materials have gained significant traction in various industries, including aerospace, automotive, marine, and architecture, to name a few. Among the various types of composite materials, fiberglass-based products are some of the most popular ones. One of the vital components of fiberglass composites is the reinforcement material - the fiberglass mat woven roving. This material provides strength and durability to the composite, making it suitable for a wide range of applications.

One of the leading manufacturers of fiberglass mat woven roving is the unnamed company, which has been in the industry for several decades. Over the years, the company has established itself as a reliable supplier of high-quality fiberglass-based products, catering to diverse industries worldwide. Their products are known for their consistency, durability, and versatility, making them the preferred choice for many customers.

The fiberglass mat woven roving from the unnamed company is designed to meet the requirements of various composite applications. This material is made from high-quality fiberglass strands, which are woven together using advanced weaving techniques. The resulting product is a highly-dense, uniform, and strong material that is ideal for reinforcing composites.

Some of the key features of the fiberglass mat woven roving from the unnamed company include superior strength, high flexibility, and excellent resin compatibility. These features allow the material to withstand high-stress loads, resist impacts and abrasions, and conform to different shapes and sizes.

Furthermore, the fiberglass mat woven roving from the unnamed company is available in various thicknesses, widths, and styles, making it suitable for different applications. For instance, the company offers plain and biaxial woven roving, which can be used for various reinforcement needs. They also manufacture chopped strand mat, which is ideal for use with resin infusion and vacuum bagging processes.

In addition to standard products, the unnamed company also offers customized solutions to meet specific customer requirements. They work closely with customers to understand their needs, suggest the best possible solutions, and deliver products that exceed expectations. Their team of experts has a deep understanding of the composite industry and can provide valuable insights and recommendations to customers.

Apart from producing high-quality products, the unnamed company is also committed to sustainable practices. They strive to minimize their environmental impact by reducing waste, conserving energy and resources, and recycling materials wherever possible. Their products are also designed to be eco-friendly, ensuring that they meet the highest ethical and environmental standards.

In conclusion, fiberglass mat woven roving from the unnamed company is the ultimate solution in reinforcement materials. Their products are designed to meet the toughest industry requirements, providing strength, resilience, and durability to composite materials. With their commitment to quality, sustainability, and customer satisfaction, the unnamed company is a reliable partner that customers can trust.

Company News & Blog

China-based Fiberglass Woven Roving Suppliers: Providing Assurance for Varied Consumer Needs

Roving, Fiberglass Manufacturers, China Fiberglass, Fiberglass Suppliers, Fiberglass Factory.Woven Fiberglass Roving - A Versatile Material for Various IndustriesWoven fiberglass roving, also known as fiberglass fabric, is a versatile material used widely in various industrial applications. It is made by weaving fiberglass strands together in a crosshatch pattern to form a fabric with high strength and durability. Fiberglass fabric is widely used in construction, automotive, aerospace, marine, and other industries due to its excellent thermal and mechanical properties.Fiberglass Manufacturers in ChinaChina is one of the largest manufacturers and suppliers of fiberglass products in the world. Huili Fiberglass is a leading fiberglass woven roving manufacturer, factory, and supplier from China. The company offers a wide range of woven fiberglass roving products, including E-glass and C-glass woven roving, chopped strand mat, fiberglass mesh, and other related items.Huili Fiberglass is committed to providing high-quality products and excellent services to its customers worldwide. The company has a team of experienced professionals who work tirelessly to ensure that its products meet the highest standards of quality and performance. The company has also invested in advanced equipment and technology to ensure that it is at the forefront of innovation in the fiberglass industry.Fiberglass Suppliers in ChinaHuili Fiberglass is one of the leading fiberglass suppliers in China. The company supplies fiberglass products to customers in various industries in China and abroad. The company's products are highly sought after due to their high quality and competitive prices. Huili Fiberglass prides itself on its excellent customer service and timely delivery of products.Fiberglass Factory in ChinaHuili Fiberglass has a state-of-the-art fiberglass factory in China. The factory is equipped with advanced machinery and technology to ensure that the company's products are of the highest quality. The company's factory adheres to strict quality control measures to ensure that its products meet the highest standards of quality and performance.ConclusionIn conclusion, woven fiberglass roving is a versatile material used widely in various industrial applications. Huili Fiberglass is a leading fiberglass woven roving manufacturer, factory, and supplier from China. The company offers a wide range of high-quality fiberglass products at competitive prices. With its excellent customer service, advanced technology, and strict quality control measures, Huili Fiberglass is a reliable partner for customers in various industries.

High-Quality Unidirectional Carbon Fiber Fabric for Industrial Applications

Unidirectional Carbon Fiber Fabric: A Strong and Lightweight Solution for Various IndustriesIn today's world, technology has revolutionized the way we live our lives. Innovations in the manufacturing industry have paved the way for the development of new materials that are stronger, lighter, and more durable than conventional materials. One such material is Unidirectional Carbon Fiber Fabric, which has become increasingly popular in industries such as automotive, aerospace, sporting goods, and many others. Unidirectional Carbon Fiber Fabric is a composite material made up of strong carbon fibers that are tightly bonded together using a polymer matrix. The fibers in this material are unidirectional, meaning that they are all aligned in the same direction, which gives it its exceptional strength and stiffness. This material is preferred over traditional materials like steel and aluminum due to its high strength-to-weight ratio, which helps to reduce the weight of the final product while maintaining its structural integrity.In the automotive industry, Unidirectional Carbon Fiber Fabric is used extensively in high-performance sports cars, racing vehicles, and electric cars. The reduction in weight of these vehicles leads to improved fuel efficiency and better handling, resulting in a more enjoyable driving experience. The use of Unidirectional Carbon Fiber Fabric in car manufacturing helps to reduce carbon emissions, contributing to a sustainable future.The aerospace industry also benefits from the use of Unidirectional Carbon Fiber Fabric in aircraft design. The lightweight properties of this material make it ideal for aircraft manufacturing, leading to a reduction in fuel consumption and improved performance. The use of this material in aircraft manufacturing has enabled the development of new, innovative designs that are more aerodynamic and offer better performance.Sporting goods companies are also increasingly using Unidirectional Carbon Fiber Fabric to develop high-performance equipment such as tennis rackets, hockey sticks, and bicycles. The strength and stiffness of this material improve the performance of these products, giving athletes a competitive edge.It is worth noting that different industries require different types of Unidirectional Carbon Fiber Fabric, depending on their specific applications. The fabric’s strength and stiffness can be controlled by varying the direction of the carbon fibers, the type of polymer matrix used, and the density of fiber layers. As such, it is crucial to have a reliable supplier who can manufacture custom-made Unidirectional Carbon Fiber Fabric to meet the different needs of each industry.One such supplier is (**remove brand name**), a leading manufacturer of high-quality Unidirectional Carbon Fiber Fabric. The company has been in business for more than ten years, and during this time, it has established a reputation for excellence in quality, reliable customer service, and competitive pricing. (**Remove brand name**) uses state-of-the-art manufacturing technology to ensure that each product meets the highest industry standards. The company's in-house team of experienced engineers uses their expertise to develop custom-made Unidirectional Carbon Fiber Fabric that meets the specific needs of each customer.(**Remove brand name**) understands the importance of quality control and follows strict guidelines to ensure that all products meet the required standards. The company's products have been certified by various industry-standard organizations, including ISO 9001, ISO 14001, and OHSAS 18001. This ensures that customers can rely on (**Remove brand name**) for consistently high-quality products and exceptional service.In conclusion, the use of Unidirectional Carbon Fiber Fabric has opened up new avenues of innovation in various industries. The combination of strength, durability, and lightweight properties of this material makes it an ideal choice for manufacturing high-performance products. (**Remove brand name**) is a trusted name in the industry and is well-equipped to provide custom-made Unidirectional Carbon Fiber Fabric that meets the specific requirements of its customers. Through continuous innovation and quality control, (**Remove brand name**) is set to become a leader in the Unidirectional Carbon Fiber Fabric industry.

Top-Rated Woven Roving Mat: A Comprehensive Guide

Possible news article:New Woven Roving Mat Offers Superior Strength and Efficiency for Composite ManufacturingFiber reinforced composites have become a vital material for many industries, ranging from aerospace and automotive to marine and construction. Composites offer high strength-to-weight ratio, corrosion resistance, and design flexibility, but their performance also depends on the quality of the raw materials and the manufacturing process. To meet the growing demand for more efficient and reliable composite products, a leading supplier of composite materials has launched a new type of woven roving mat that promises to enhance the properties and productivity of composites.The new woven roving mat, which we cannot name due to editorial policy, is made of high-quality fiberglass rovings that are woven in a uniform pattern and chemically bonded with a resin binder. The mat is available in various widths and weights, depending on the application requirements, and can be used with various types of resins, such as polyester, vinyl ester, and epoxy. Compared to traditional chopped strand mat or filament-wound roving, the woven roving mat offers several advantages, including:- Higher tensile and compressive strength: The high density and alignment of the rovings in the mat enable it to withstand higher loads and stresses than other types of mats, resulting in composites that exhibit superior mechanical properties, such as stiffness, impact resistance, and fatigue life.- Better resin flow and wet-out: The uniform and open structure of the mat allows the resin to penetrate and wet the fibers more easily and evenly, reducing the risk of resin-rich or dry areas that can compromise the integrity and appearance of the composite. The mat also helps to reduce the amount of resin needed, thus saving material and processing costs.- Faster lay-up and cure times: The drapability and conformability of the mat enable it to conform to complex shapes and contours, reducing the need for cutting, folding, or overlapping. The mat can also be pre-impregnated or infused with resin in advance, which speeds up the lay-up process and minimizes the risk of air bubbles or voids. The mat can be cured at various temperatures and times, depending on the resin system and the desired curing profile.The supplier of the woven roving mat, which we will call "Fibertex" for illustration purposes, has a long history of providing high-quality composite materials to global customers. Founded in 1968 in Denmark, Fibertex has since expanded to 10 countries in Europe, Asia, and North America, and employs over 1000 people. The company's product portfolio includes not only woven roving mats, but also chopped strand mats, multiaxial fabrics, carbon fibers, and more, as well as customized solutions and technical support for various applications. Fibertex serves diverse markets, such as wind energy, transportation, construction, and sports and leisure, and strives to contribute to sustainable and innovative solutions."We are excited to introduce this new woven roving mat to our customers worldwide," said John Smith, Vice President of Sales at Fibertex. "We have listened to their feedback and needs, and have developed a mat that combines the best features of traditional rovings with the latest technology and expertise. Our woven roving mat not only improves the strength and efficiency of composites, but also enables our customers to save time and money in their production cycles. We believe this mat will be a game changer in the industry and we are eager to see its impact."Several customers of Fibertex have already tested and approved the woven roving mat in various applications, such as boat hulls, wind turbine blades, and automotive components. They have reported that the mat enabled them to achieve better surface finish, reduced weight, and improved mechanical performance, as well as faster and easier lay-up and cure. Some of the customers have also praised Fibertex for its technical support and collaboration in optimizing the mat for their specific needs."We have been using Fibertex's woven roving mat in our production of large composite structures for wind turbines, and we have been very satisfied with the results," said Hans Schmidt, CEO of WindPower GmbH, a German company that specializes in wind energy solutions. "The mat has allowed us to reduce the resin consumption and the processing time, while maintaining the required strength and quality. Moreover, the technical team at Fibertex has been very responsive and helpful in addressing our questions and concerns. We look forward to continuing our cooperation with Fibertex and their innovative products."The launch of the new woven roving mat by Fibertex comes at a time when the composites industry is facing increasing demands for sustainability, safety, and performance. By offering a mat that enhances the strength and efficiency of composites, and by providing a comprehensive service and expertise, Fibertex aims to contribute to the growth and competitiveness of the industry.

Fiber Carbon Cloth: Unveiling the Latest Breakthrough in Materials Technology

Title: Groundbreaking Innovation: Fiber Carbon Cloth Revolutionizes IndustriesIntroduction:In an era where technological advancements continually push the boundaries of innovation, there is one company that stands out for its revolutionary breakthrough with Fiber Carbon Cloth (FCC). Combining cutting-edge technology and a passion for sustainable solutions, [Company Name] has introduced a product that has the potential to reshape various industries. This article explores the remarkable qualities of Fiber Carbon Cloth and its wide-ranging applications, highlighting the transformative impact it offers.1. Unparalleled Strength and Lightweight Design for Aerospace Industry:The aerospace industry is benefiting tremendously from the integration of Fiber Carbon Cloth into its manufacturing processes. With a remarkable strength-to-weight ratio, FCC offers unparalleled durability, making it ideal for aircraft construction. This lightweight material ensures enhanced fuel efficiency, reduces emissions, and increases the overall lifespan of aircraft components. [Company Name] has developed advanced methods for FCC production, thus revolutionizing the aerospace sector by providing safe, fuel-efficient, and environmentally-friendly solutions.2. Energy Sector's Embrace of Fiber Carbon Cloth for Wind Turbines:The renewable energy sector has significantly benefited from Fiber Carbon Cloth applications, particularly in wind turbine manufacturing. This innovative material enables the production of longer and lighter turbine blades, leading to increased energy production efficiency. By incorporating FCC into the manufacturing process, companies can construct larger blades that capture more wind energy, subsequently reducing the overall cost of renewable energy. [Company Name] is at the forefront of this transformation, providing the energy sector with a game-changing product that accelerates the adoption of clean and sustainable power sources.3. Augmenting Performance and Safety in Automotive Manufacturing:The automotive industry has witnessed a paradigm shift with the introduction of Fiber Carbon Cloth in vehicle production. By incorporating FCC into their designs, manufacturers can achieve substantial weight reduction while maintaining uncompromised safety standards. This material's exceptional strength and durability enhance vehicle crash safety and reduce structural damage. Moreover, the lightweight properties of FCC improve overall fuel efficiency, reducing carbon emissions. [Company Name]'s contributions to the automotive sector are evident in its role as a catalyst for advancements in electric vehicle technology, where FCC integration plays a crucial role in prolonging battery life and enhancing overall performance.4. Transforming Sportswear and Sports Equipment:Embracing Fiber Carbon Cloth has revolutionized the sportswear and sports equipment sectors. Its lightweight yet robust nature has paved the way for advanced sports gear that not only optimizes athletic performance but also ensures athlete safety. From running shoes to tennis rackets, the integration of FCC has redefined the standards of excellence in these industries. [Company Name] leads the charge by collaborating with renowned sports brands, spearheading the development of cutting-edge products that enhance performance, comfort, and sustainability.5. Fiber Carbon Cloth in Infrastructure and Construction:The construction industry is another sector reaping the benefits of Fiber Carbon Cloth. By incorporating FCC into infrastructure projects, companies can create stronger, more durable structures that withstand environmental challenges. This innovative material offers greater resistance to corrosion, UV radiation, and seismic activities, enhancing the longevity and safety of buildings, bridges, and other essential structures. [Company Name]'s expertise in FCC production and its commitment to sustainability have positioned it as a key player in this sector, reshaping the landscape of modern construction practices.Conclusion:Through its groundbreaking innovation with Fiber Carbon Cloth, [Company Name] continues to transform industries globally. From aerospace to renewable energy, automotive, sports, and construction, the unparalleled qualities of FCC redefine excellence and set new benchmarks across various sectors. As the world embraces cleaner, more efficient, and sustainable solutions, the widespread adoption of Fiber Carbon Cloth represents a crucial step toward securing a greener and more advanced future.

High-Density 4.3 oz Prepreg Unidirectional Carbon Fiber Fabric for Marine Applications

Title: Harnessing the Power of 12k Carbon Fiber Fabric: The Versatile Solution for Marine ApplicationsIntroduction:Carbon fiber has revolutionized numerous industries with its exceptional strength, lightweight nature, and durability. In marine applications, where strength and performance are paramount, the utilization of carbon fiber becomes even more critical. Among various options, the 12k Carbon Fiber Fabric stands out due to its high density and unidirectional nature, ensuring maximum strength in a specific direction. This blog aims to explore the versatility and benefits of utilizing 12k Carbon Fiber Fabric in marine applications while highlighting its key features and addressing the importance of obtaining a high-density, non-woven fabric for optimal results.Understanding 12k Carbon Fiber Fabric:12k Carbon Fiber Fabric is a type of prepreg unidirectional fabric that boasts an incredibly high-density carbon fiber arrangement. The term '12k' represents the number of carbon filaments bundled together within a tow. Higher values indicate increased density, resulting in enhanced mechanical properties and strength. This fabric possesses the ideal characteristics to meet the demanding requirements of marine applications.Enhanced Strength & Durability:The primary goal of employing 12k Carbon Fiber Fabric in marine applications is to achieve maximum strength in a specific direction. The unidirectional nature of the fabric ensures that the fibers are aligned parallelly, allowing for exceptional stiffness and strength along that axis. This specific characteristic allows boat manufacturers to reinforce weaker sections and critical load-bearing structures effectively. The lightweight properties of carbon fiber minimize weight while maximizing structural integrity, further improving overall vessel performance.Corrosion Resistance and Longevity:One of the significant challenges faced by marine structures is corrosion due to constant exposure to harsh seawater environments. Traditional materials such as steel or aluminum are prone to corrosion and require regular maintenance. However, 12k Carbon Fiber Fabric possesses remarkable resistance to corrosion, making it an ideal choice for marine applications. With superior resistance to the elements, carbon fiber extends the longevity of marine structures, reducing maintenance requirements and ensuring prolonged performance.Applications in Marine Engineering:1. Hull Construction and Reinforcement:12k Carbon Fiber Fabric plays a crucial role in reinforcing and strengthening hull structures, offering unparalleled stiffness and rigidity. By integrating this fabric into the laminate or composite layers, boat manufacturers can enhance the overall structural integrity, ensuring exceptional performance, and reducing potential stress fractures in rough sea conditions.2. Masts, Booms, and Other Rigging Equipment:The unidirectional nature and strength of 12k Carbon Fiber Fabric make it an ideal material for building masts, booms, and rigging components. These critical structural elements require lightweight, yet rigid materials to withstand the forces exerted by wind and waves. Carbon fiber offers the perfect balance, allowing for reliable and high-performance rigging equipment.3. Bulb Keel Construction:When it comes to constructing bulb keels, 12k Carbon Fiber Fabric is the go-to option due to its remarkable stiffness and strength. Bulb keels significantly enhance the vessel's stability and maneuverability, and integrating carbon fiber fabric ensures maximum efficiency without adding unnecessary weight.Conclusion:The utilization of 12k Carbon Fiber Fabric in marine applications has opened up a world of possibilities for boat manufacturers, designers, and engineers. Its superior strength, lightness, corrosion resistance, and longevity make it an ideal choice for reinforcing various marine structures, including hulls, masts, booms, and bulb keels. With the ability to achieve maximum strength in one direction, 12k Carbon Fiber Fabric addresses the specific needs of marine engineering, ensuring exceptional performance even in challenging sea conditions. By leveraging the remarkable properties of this non-woven fabric, marine vessels are now capable of achieving new levels of strength, durability, and efficiency, contributing to the advancement of the industry as a whole.Keywords: 12k Carbon Fiber Fabric, prepreg unidirectional fabric, marine applications, maximum strength, high density, unidirectional nature, versatility, lightweight, durability, corrosion resistance, boat manufacturers, stiffness, rigidity, hull construction, masts, booms, bulb keel construction.

Fiberglass Cloth Rolls, Mat & Fabrics for Composite Construction Needs

article that introduces fiberglass cloth and its uses in various industries.Fiberglass Cloth: A Versatile and Essential Material for Various IndustriesFiberglass cloth has been one of the most versatile and essential materials used in various industries worldwide for many years now. It is made up of thin glass fibers woven together to form a cloth that is tough, durable, and resistant to heat, chemicals, and other environmental factors.The reason why fiberglass cloth is extremely popular in various fields such as construction, marine, automotive, and aerospace is that it offers an extensive range of benefits that are unmatched by other materials. Fiberglass cloth is a lightweight yet robust fabric that has high strength-to-weight ratios, making it an excellent option for strengthening and reinforcing various structures.Uses of Fiberglass ClothFiberglass cloth is used in a wide range of applications and industries due to its diverse properties. Some of its applications include:Construction Industry: Fiberglass cloth is used to reinforce concrete and other building materials, making them more durable, weather-resistant, and long-lasting.Marine and Automotive Industry: Fiberglass cloth is used to reinforce hulls, decks, and other components of boats and ships, as well as cars and trucks. The material is perfect for reducing the weight of these structures while increasing their strength and durability.Aerospace Industry: The aerospace industry uses fiberglass cloth to create lightweight materials that are strong and resistant to high temperature and extreme environments.Other Uses: Fiberglass cloth is also used in the electrical industry to make insulators, in the sports industry for various equipment, and in the medical field for prosthetics and orthotic devices.Benefits of Fiberglass ClothFiberglass cloth offers numerous benefits to the industries that use it. Here are some of the advantages of fiberglass cloth:Strength: Fiberglass cloth is stronger than many other materials, including steel. The material’s strength can be attributed to the glass fibers that make up the cloth, which are incredibly strong and resistant to impact.Durability: Fiberglass cloth is resistant to heat, chemicals, water, and other environmental factors. It also does not corrode or rust, making it last longer than other materials.Lightweight: Compared to metals and other materials, fiberglass cloth is lightweight, making it an ideal choice for reducing the weight of various structures.Easy to Work with: Fiberglass cloth is easy to cut, shape, and mold, making it easy to work with, even for those without specialized skills or tools.Cost-effective: Fiberglass cloth is relatively inexpensive compared to other materials with similar properties. This makes it a cost-effective option for various projects and industries.ConclusionFiberglass cloth is a versatile and essential material used in various industries worldwide. Its strength, durability, lightweight, and easy to work with properties make it an ideal choice for a range of applications and structures.If you’re in the market for fiberglass cloth, it is essential to source your materials from a trusted and reputable supplier. Jamestown Distributors offers top-quality fiberglass cloth, mat, fabrics, and more for all your composite construction needs.Whether you’re in the marine, automotive, aerospace, or any other industry, Jamestown Distributors has the right materials for you. Get in touch today to find out more about their products and services!

Fiberglass cloth is a type of tightly-woven cloth that is made from glass fibers. It is used extensively in many industries, primarily in construction, insulation, and manufacturing. Fiberglass cloth is known for its strength, durability, and versatility, and is a popular material choice for a wide range of applications.One of the main uses of fiberglass cloth is as a finishing jacket over thermal insulation for piping. This is because it is able to withstand high temperatures without melting or degrading, and it provides a protective layer that helps to prevent heat loss.Another common application of fiberglass cloth is in the production of composite materials. When layered with resin and other materials, fiberglass cloth can be used to create strong, lightweight composites that are ideal for use in a variety of industries. These materials are used in everything from aerospace to automotive manufacturing, and they offer a number of benefits, including increased strength, durability, and weather resistance.One of the key benefits of using fiberglass cloth in composite materials is its layering capabilities. When layered multiple times, fiberglass cloth can create a thicker, more durable material that is resistant to impact and also offers increased insulation properties.When layering fiberglass cloth, it is important to ensure that each layer is properly bonded together with the appropriate adhesive. This will help to ensure that the final product is strong and durable, and will hold up well under a variety of conditions.One of the most important factors to consider when using fiberglass cloth is safety. Due to the nature of the material, it is important to wear protective clothing, including gloves and a respirator, when working with fiberglass cloth.Overall, fiberglass cloth is a versatile and durable material that is used extensively in many industries around the world. Whether you are looking to create composite materials, insulate piping, or manufacture a range of products, fiberglass cloth is an excellent choice that is known for its strength, durability, and versatility. So, if you are looking for a material that can provide long-lasting performance and withstand a variety of conditions, be sure to consider fiberglass cloth as your go-to solution.

High-Quality Microfiber 3D Lace Fiberglass Cloth Fabric for 3D Spacer and Fashionable Fabrics

Jiahe Taizhou Glass Fiber Co., Ltd, a leading manufacturer of fiberglass and related products, has recently introduced its latest product – the Parabean Microfiber 3D Lace Fiberglass Cloth Fabric. The fabric has been designed to cater to the growing demand for high-quality and durable fabrics in industries like upholstery, construction, and automotive.The Parabean Microfiber 3D Lace Fiberglass Cloth Fabric is a unique fabric that is made using specially designed three-dimensional (3D) technology. The fabric is constructed using a combination of microfiber and fiberglass, which gives it a strong, yet lightweight structure. It is integrated with a lace pattern that not only enhances its aesthetic appeal but also provides improved breathability and ventilation.One of the most significant advantages of using this fabric is its high durability and robustness. The fiberglass material makes it resistant to wear and tear, chemicals, and extreme temperatures. The fabric is also fire retardant, making it a suitable choice for use in the automotive and construction sectors. Furthermore, its 3D structure provides added cushioning, which is ideal for use in upholstery and bedding applications.Another notable feature of the Parabean Microfiber 3D Lace Fiberglass Cloth Fabric is its excellent moisture-wicking properties. The fabric can absorb and dissipate moisture effectively, making it a perfect choice for use in sports clothing and other applications where comfort and hygiene are crucial.The fabric's unique 3D spacer technology also makes it ideal for use in filtration applications. The fabric can trap impurities and particles without clogging, allowing for efficient air and water filtration. Its durability and high-temperature resistance make it a suitable choice for use in industrial filtration applications as well.As a leading manufacturer in the industry, Jiahe Taizhou Glass Fiber Co., Ltd uses state-of-the-art technology and advanced production methods to ensure that the Parabean Microfiber 3D Lace Fiberglass Cloth Fabric meets the highest standards of quality and performance. The company has a team of skilled and experienced professionals who oversee the manufacturing process from start to finish, ensuring that every product leaving the factory is of the highest quality.In conclusion, the Parabean Microfiber 3D Lace Fiberglass Cloth Fabric is an innovative and versatile fabric that has a wide range of applications. Its unique construction and properties make it an ideal choice for industries such as construction, automotive, upholstery, and filtration. Jiahe Taizhou Glass Fiber Co., Ltd's commitment to quality and innovation ensures that its customers receive a product that meets their specific needs and requirements.