High-Quality Carbon Fiber Cloth for Various Applications - Product Information

Read More

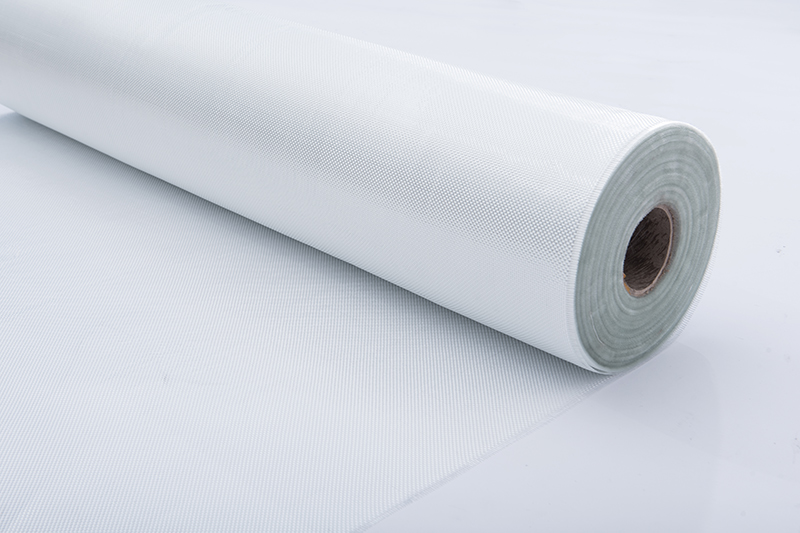

High-Quality Colored Fiberglass Cloth for Various Applications

Colored Fiberglass Cloth is a versatile and innovative product that has revolutionized the industrial and manufacturing sectors. This cutting-edge material is being utilized for a wide range of applications, from automotive and aerospace components to construction materials and consumer goods.The use of fiberglass in cloth form is advantageous for a number of reasons. It is lightweight, strong, and resistant to heat, chemicals, and abrasion. This makes it an ideal choice for a variety of industries where durability and performance are essential.One company that has been at the forefront of producing high-quality Colored Fiberglass Cloth is {}. With a strong focus on research and development, they have been able to create a range of colored fiberglass cloths that not only offer the traditional benefits of fiberglass, but also add an aesthetic appeal to the finished products. This has opened up new possibilities for designers and manufacturers looking to combine the strength and durability of fiberglass with vibrant and eye-catching colors.The colored fiberglass cloth produced by {} is available in a wide spectrum of colors, allowing for greater design flexibility and creativity. This means that manufacturers can now incorporate colored fiberglass cloth into their products in a way that was previously not possible, creating visually stunning and unique items that stand out in the market.One of the key advantages of {}'s colored fiberglass cloth is its superior quality. Thanks to their advanced manufacturing processes, the company is able to produce colored fiberglass cloth that is consistently high in quality, ensuring that it meets the strict standards required by industries such as automotive, aerospace, and construction.In addition to its aesthetic appeal, the colored fiberglass cloth from {} also offers all the traditional benefits of fiberglass. It is incredibly strong and durable, making it an ideal material for applications where performance is crucial. It is also resistant to heat, chemicals, and abrasion, ensuring that products made with this material are long-lasting and reliable.Furthermore, the colored fiberglass cloth from {} is lightweight and easy to work with, allowing for greater efficiency in the manufacturing process. This makes it a cost-effective choice for companies looking to improve their production methods and create high-quality products at a competitive price point.The applications of colored fiberglass cloth are extensive and varied. In the automotive industry, it is being used to create lightweight and durable body panels that are both visually striking and capable of withstanding the rigors of everyday use. In the aerospace sector, it is being utilized to produce strong and resilient components that can handle the demanding conditions of space travel. In the construction industry, it is being incorporated into building materials that are not only sturdy and long-lasting, but also add a splash of color to architectural designs.With its wide range of benefits and applications, it is no wonder that the demand for colored fiberglass cloth is on the rise. {} is well-positioned to meet this demand, thanks to their focus on innovation and their commitment to producing high-quality products that exceed the expectations of their customers.In conclusion, colored fiberglass cloth is a game-changing material that is transforming the way products are designed and manufactured. With its combination of strength, durability, and aesthetic appeal, it is opening up new possibilities for a wide range of industries. As a leading producer of colored fiberglass cloth, {} is poised to play a key role in shaping the future of manufacturing and design.

Read More

Durable Carbon Fiber Vinyl Upholstery Fabric for Long-Lasting Furniture

[Company Name] Introduces Innovative Carbon Fiber Vinyl Upholstery Fabric[City, State], [Date] - [Company Name], a leading manufacturer of high-quality automotive upholstery fabrics, has recently introduced an innovative Carbon Fiber Vinyl Upholstery Fabric. This new product offers a perfect combination of style, durability, and performance, making it an ideal choice for those seeking a premium upholstery solution for their vehicles.Made from the finest quality carbon fiber vinyl, this new upholstery fabric is designed to withstand the harshest of conditions, including extreme temperatures, UV rays, and moisture. Its carbon fiber construction makes it lightweight yet incredibly strong, providing excellent support and comfort for the occupants of the vehicle."We are thrilled to introduce our latest Carbon Fiber Vinyl Upholstery Fabric to the market," said [Spokesperson Name], the spokesperson for [Company Name]. "This product represents a significant advancement in automotive upholstery technology, offering superior performance and durability compared to traditional upholstery fabrics. We are confident that it will quickly become a top choice for car enthusiasts, customizers, and automotive professionals alike."In addition to its exceptional durability, the Carbon Fiber Vinyl Upholstery Fabric also boasts a sleek and modern aesthetic. Its textured surface and unique carbon fiber pattern add a touch of sophistication and style to any vehicle's interior, making it a popular choice for those looking to enhance the overall look and feel of their cars.Furthermore, this innovative upholstery fabric is easy to clean and maintain, allowing vehicle owners to keep their interiors looking pristine with minimal effort. Its resistance to stains, odors, and fading ensures that it will continue to look great for years to come, even in the most demanding of usage scenarios.As with all of [Company Name]'s products, the Carbon Fiber Vinyl Upholstery Fabric is developed using state-of-the-art manufacturing processes and the highest quality materials. The company's commitment to excellence and innovation has made it a trusted name in the automotive upholstery industry, with a reputation for delivering products that meet the highest standards of quality and performance."We take great pride in our ability to provide our customers with cutting-edge upholstery solutions that exceed their expectations," [Spokesperson Name] added. "The introduction of our Carbon Fiber Vinyl Upholstery Fabric is a testament to our ongoing dedication to pushing the boundaries of what is possible in automotive upholstery, and we are excited to see the impact it will have on the market."Whether for a classic car restoration project, a custom aftermarket upgrade, or a new vehicle build, the Carbon Fiber Vinyl Upholstery Fabric from [Company Name] is poised to become a top choice for those seeking a superior upholstery solution. Its combination of style, durability, and performance makes it a standout option in an increasingly competitive market.For more information about [Company Name] and its innovative Carbon Fiber Vinyl Upholstery Fabric, please visit [company website] or contact [company email] for inquiries.

Read More

Discover the Promising Applications of Woven Glass Fabric in Today's News

Woven Glass Fabric Pushes Boundaries in the Textile Industry[Woven Glass Fabric Company] has recently unveiled their latest breakthrough in the field of textiles, a revolutionary product that is set to redefine the industry. Their cutting-edge woven glass fabric is set to push the boundaries of what is possible in textile manufacturing, offering a wide range of applications across various sectors. With unmatched strength, durability, and versatility, this innovative fabric is poised to transform industries and facilitate new possibilities in design and engineering.Woven glass fabric, also known as fiberglass fabric, is manufactured using threads made from glass fibers. These fibers are woven together to create a robust and flexible fabric that possesses exceptional properties. Woven glass fabric is known for its high tensile strength, which is significantly stronger than other fabrics such as cotton or polyester. This attribute makes it ideal for applications that require exceptional resilience, such as in the aerospace and automotive industries.What sets [Woven Glass Fabric Company]'s product apart from others in the market is their innovative manufacturing process. Using state-of-the-art technology and machinery, they have developed a technique that produces an incredibly fine yet durable woven glass fabric. This advancement allows for a higher level of detail and precision, making it a perfect choice for industries that demand stringent specifications.The versatility of this woven glass fabric is key to its success. Its ability to be molded into various shapes and sizes without compromising its structural integrity makes it incredibly appealing to designers and engineers. The fabric can be used in a vast array of applications, including but not limited to, insulation, filtration, reinforcement, and composite materials. The possibilities are truly limitless, and industries of all kinds are expected to benefit from this groundbreaking product.In the construction industry, woven glass fabric offers numerous advantages. Its exceptional strength-to-weight ratio makes it an ideal material for reinforcing concrete structures. It can also be used for insulation purposes, providing a more efficient and cost-effective solution compared to traditional insulation materials. Furthermore, woven glass fabric is resistant to corrosion, making it a durable option for a wide range of construction projects.The aerospace and automotive industries are also set to benefit greatly from this new textile innovation. The lightweight nature of woven glass fabric makes it an excellent choice for reducing overall weight in aircraft and vehicles, thereby improving fuel efficiency and performance. Its high strength also ensures the safety and integrity of critical components, making it an essential material in these high-demand sectors.Beyond its industrial uses, woven glass fabric also offers advantages in consumer products. The fabric can be used for creating high-performance sports equipment, such as tennis rackets or bicycle frames, due to its exceptional strength and flexibility. Additionally, it can be used in household applications, including furniture, curtains, and upholstery, providing a durable yet aesthetically pleasing option for consumers.[Woven Glass Fabric Company] has made significant investments in research and development, ensuring that their woven glass fabric remains at the forefront of the industry. They continuously strive to improve their manufacturing process, focusing on enhancing the fabric's properties while also minimizing its environmental impact. By prioritizing sustainability and innovation, [Woven Glass Fabric Company] aims to revolutionize the textile industry while also promoting responsible practices.The introduction of woven glass fabric marks a significant advancement in the textile industry. Its unparalleled strength, versatility, and durability offer numerous possibilities across various sectors. As [Woven Glass Fabric Company] pushes the boundaries of textile manufacturing, industries worldwide can look forward to the positive impact of this innovative fabric on their operations.

Read More

Red Carbon Fiber Embossed Faux Leather Vinyl Upholstery Fabric for Various Projects

for Automotive, RV, Boat, Healthcare, Hospitality, Home decor, Fashion, and Commercial Projects.Are you looking for a versatile, stylish, and durable fabric for your next project? Look no further than our Red Carbon Fiber Embossed Faux Leather Vinyl, a top-quality upholstery fabric available at FabulessFabrics.com.Featuring an embossed cross weave pattern of carbon fibers, this fabric is perfect for adding a touch of sophistication and modern style to any project. Whether upholstering a car, RV, or boat, or creating custom home decor or fashion accessories, this fabric is sure to impress.But this fabric isn't just stylish – it's also incredibly functional. Thanks to its antibacterial properties and protective UV coating, it's perfect for healthcare, hospitality, and commercial projects. And with its water and stain-resistant properties, it's easy to clean and maintain, making it ideal for high-traffic areas.So why wait? Visit FabulessFabrics.com today to shop our wide selection of Red Carbon Fiber Embossed Faux Leather Vinyl and other top-quality upholstery fabrics. Whether you're a professional upholsterer or a DIY enthusiast, we have everything you need to bring your vision to life.

Read More

High-quality Carbon Fiber Clothing Fabric for Superior Performance

Carbon fiber clothing fabric is revolutionizing the fashion industry with its lightweight, durable, and high-performance properties. This innovative fabric is changing the way we think about clothing and is quickly gaining popularity among consumers and designers alike.Carbon fiber is a material that is known for its strength and lightness, making it an ideal choice for use in performance-oriented clothing. The fabric is also incredibly durable, with the ability to withstand the rigors of daily wear and tear. This makes it a popular choice for athletes and outdoor enthusiasts who require clothing that can keep up with their active lifestyles.One company that is at the forefront of this trend is {}. The company has been a leader in the development and production of carbon fiber clothing fabric, and their innovative approach to design and technology has set them apart in the industry.The company’s carbon fiber clothing fabric is made from high-quality carbon fiber materials that are carefully woven together to create a strong and flexible fabric. This fabric can be used to create a wide range of clothing, including outerwear, activewear, and even accessories such as hats and bags. The company’s focus on quality and performance has made them a preferred choice among athletes and outdoor enthusiasts who demand the best from their clothing.In addition to its durability and performance, carbon fiber clothing fabric also has a sleek and modern aesthetic that has captured the attention of fashion designers and consumers. The fabric has a unique sheen and texture that sets it apart from traditional materials, and its versatility allows for a wide range of designs and styles. This has led to a surge in popularity for carbon fiber clothing among fashion-forward consumers who are looking for something new and exciting in their wardrobes.One of the key advantages of carbon fiber clothing fabric is its lightweight nature. Despite its strength and durability, carbon fiber fabric is incredibly lightweight, making it a comfortable and practical choice for everyday wear. This has made it a popular choice among athletes and outdoor enthusiasts who require clothing that won’t weigh them down during their activities.The company’s commitment to innovation and sustainability has also played a key role in its success with carbon fiber clothing fabric. They have developed a range of environmentally-friendly production techniques that minimize waste and reduce the carbon footprint of their products. This has resonated with consumers who are increasingly mindful of the environmental impact of the products they buy, and has helped to position the company as a leader in sustainable fashion.As the popularity of carbon fiber clothing fabric continues to grow, {} is at the forefront of driving the trend forward. Their dedication to quality, performance, and sustainability has positioned them as a key player in the industry, and their innovative approach to design and technology has set them apart from their competitors. With a commitment to pushing the boundaries of what is possible with carbon fiber clothing fabric, the company is well-positioned to continue leading the way in this exciting and rapidly evolving field.

Read More

Discover the Versatility and Durable Nature of Woven Roving Cloth

Title: Revolutionary Woven Roving Cloth Enhances Reinforcement in Composite ManufacturingIntroduction:In the ever-evolving field of composite manufacturing, one company stands out for its relentless pursuit of innovation and its commitment to delivering cutting-edge solutions. With a strong focus on research and development, the company has recently introduced a revolutionary product - Woven Roving Cloth. This groundbreaking cloth is set to revolutionize the way composites are reinforced, propelling the industry forward into a new era of strength and durability.[Company Name], a renowned leader in composite manufacturing, has invested significant time and resources to develop a technologically advanced woven roving cloth. This newly launched product is poised to elevate the performance and capabilities of composites used in numerous sectors, including automotive, building and construction, marine, aerospace, and renewable energy.Woven Roving Cloth brings a host of advantages to the composite manufacturing process, including increased strength, enhanced mechanical properties, and improved resistance to cracks and fractures. By effectively distributing tensile and shear forces within composites, this cloth creates a reinforced structure that can support greater loads and withstand harsh environmental conditions.The company's Woven Roving Cloth is fabricated using a meticulous process, ensuring uniform fiber distribution and optimal resin impregnation. This results in improved fiber-to-resin ratio and superior consolidation, leading to enhanced composite performance. The cloth's high-quality materials and advanced weaving techniques contribute to its excellent dimensional stability and compatibility with a variety of resins.Key Features and Benefits of Woven Roving Cloth:1. Exceptional Strength: The precisely woven fibers of the cloth provide exceptional tensile strength, enabling composites to bear higher loads and resist deformation.2. Improved Mechanical Properties: By reinforcing the matrix of composites, the cloth enhances its stiffness, impact resistance, and fatigue life, ensuring the longevity of the final products.3. Crack and Fracture Resistance: Woven Roving Cloth disperses stresses evenly, minimizing the tendency for cracks and fractures, enhancing the overall durability of composites.4. Versatility: The cloth is compatible with various resin systems, such as polyester, vinyl ester, and epoxy, making it suitable for a wide range of manufacturing processes and applications.5. Dimensional Stability: The advanced production techniques guarantee the cloth's excellent dimensional stability, allowing for precise fabrication and reduced waste.By incorporating Woven Roving Cloth into composite manufacturing processes, manufacturers can develop products that meet the stringent requirements of modern industries. The cloth's exceptional strength and mechanical properties make it ideal for the production of lighter, more fuel-efficient automotive parts, stronger infrastructure components, and more durable marine vessels and wind turbine blades.Moreover, the cloth's widespread applicability in various sectors ensures its potential to address the demanding requirements of the aerospace industry, where weight reduction and enhanced structural integrity are paramount. Additionally, its resistance to corrosion and extreme temperatures further expands its potential utilization in renewable energy applications.The launch of Woven Roving Cloth by [Company Name] signifies a significant milestone in the advancement of composite manufacturing. With its exceptional strength, improved mechanical properties, and superior resistance to cracks and fractures, this innovative product holds immense potential to revolutionize various industries reliant on lightweight, high-strength materials.As [Company Name] continues to push the boundaries of composite technology, this latest development further cements their position as a global leader in the field of advanced materials. By embracing Woven Roving Cloth, manufacturers have a game-changing tool at their disposal, unlocking endless possibilities for improving the performance and durability of their products, and ultimately propelling their industries into the future.

Read More

New lightweight material made of carbon kevlar hybrid fabric is set to revolutionize the aerospace industry

Title: Innovative Carbon Kevlar Hybrid Fabric Revolutionizes the Textile IndustryIntroduction:In a groundbreaking development, an industry-leading company has introduced a cutting-edge Carbon Kevlar Hybrid Fabric, emerging as a game-changer in the textile world. Embracing advanced technologies, this revolutionary fabric combines the remarkable properties of carbon fiber and Kevlar, offering unprecedented strength, durability, and versatility. With its wide range of applications, this innovative fabric is set to reshape industries such as aerospace, automotive, sports, and defense.1. The Unparalleled Strength of Carbon Kevlar Hybrid Fabric:The Carbon Kevlar Hybrid Fabric incorporates the best qualities of both carbon fiber and Kevlar. Carbon fiber is renowned for its exceptional strength-to-weight ratio, making it a preferred choice in industries where lightweight yet robust materials are required. On the other hand, Kevlar is famous for its outstanding resistance to impact and abrasion, making it an ideal choice for ballistic protection and structural reinforcement. By combining these two fibers, this hybrid fabric transcends the limitations of conventional materials, ensuring enhanced performance in a variety of applications.2. Aerospace Industry: Empowering High-performance StructuresThe aerospace industry stands to benefit immensely from the introduction of Carbon Kevlar Hybrid Fabric. Due to its lightweight nature and superior strength, the fabric can be incorporated into the manufacture of aircraft components, including fuselages, wings, and engine parts. By utilizing this innovative fabric, manufacturers can significantly reduce the weight of aircraft, contributing to improved fuel efficiency and lower operating costs. Moreover, the exceptional fatigue resistance of the hybrid fabric enhances the durability and longevity of key structural elements, ensuring increased safety for passengers and crew.3. Automotive Industry: Paving the Way for Safer VehiclesIn the automotive sector, the integration of Carbon Kevlar Hybrid Fabric presents significant advancements in safety and performance. By utilizing this fabric for manufacturing body panels, car manufacturers can enhance crashworthiness while reducing overall vehicle weight. The superior impact resistance of the fabric combined with its lightweight attributes makes it a valuable asset in protecting passengers during collisions. As a result, vehicles can achieve better fuel efficiency while offering enhanced safety to occupants.4. Sports Industry: Elevating Performance EquipmentThe sports industry is no stranger to materials that offer exceptional strength and durability. The Carbon Kevlar Hybrid Fabric is set to revolutionize sports equipment, enabling athletes to reach new heights of performance. Sports gear, such as helmets, paddles, and protective gear, created using this hybrid fabric will offer unrivaled protection without compromising agility. The lightweight nature of the fabric will facilitate better maneuverability, giving athletes a competitive edge in various sports.5. Defense Industry: Reinforcing Military ApplicationsThe defense sector, where protection and reliability are paramount, can greatly benefit from the introduction of Carbon Kevlar Hybrid Fabric. The fabric's exceptional resistance to extreme temperatures and impact makes it an ideal choice for the manufacture of protective clothing and equipment for military personnel. As a result, soldiers will experience significantly improved protection without being encumbered by heavy gear.Conclusion:The introduction of Carbon Kevlar Hybrid Fabric represents an exciting milestone in the textile industry. This innovative fabric's ability to combine the extraordinary properties of carbon fiber and Kevlar opens up endless possibilities across various sectors. From aerospace to sports, and automotive to defense, this versatile fabric promises to redefine the standards of strength, durability, and performance. With its numerous benefits, the adoption of Carbon Kevlar Hybrid Fabric is set to revolutionize manufacturing processes and shape the future of the textile industry.

Read More

Get to Know Fiberglass: The Common Fiber-Reinforced Plastic

Fiberglass – A Breakthrough in Reinforced PlasticsFiberglass, also known as fibreglass in the UK, is a type of fiber-reinforced plastic that uses glass fiber as its primary reinforcement material. It is one of the most popular and widely used engineering materials in various industries, including aerospace, construction, automotive, marine, and many more. In this blog, we will dive deep into the world of fiberglass, its properties, applications, and various forms, including woven fiberglass sheets.What is Fiberglass?Fiberglass is composed of fine glass fibers that are woven or randomly arranged and held together by a plastic resin matrix. The glass fibers are made up of silicon dioxide and other additives and can be manufactured in a range of diameters and lengths. The plastic resin matrix can be a thermosetting polymer matrix, such as epoxy, polyester resin, or vinylester, or a thermoplastic.Fiberglass is available in several different forms, including chopped strand mat, woven fiberglass sheets, rovings, and continuous strand mat. Unlike metal, fiberglass is a lightweight and strong material that is resistant to corrosion, rot, and mildew. The glass fibers provide superior tensile strength, while the plastic matrix offers excellent compressive strength and durability.What are the Properties of Fiberglass?Fiberglass has numerous properties that make it an ideal material for various applications.1. Light Weight: Fiberglass is a lightweight material that offers excellent strength-to-weight ratio.2. High Strength: Fiberglass is a high-strength material that can withstand high loads and stresses.3. Chemical Resistance: Fiberglass is resistant to many chemicals, including acids, alkalis, and salts.4. Heat Resistance: Fiberglass can withstand high temperatures without deformation, making it ideal for high-temperature applications.5. Electrical Insulation: Fiberglass is an excellent electrical insulator, making it suitable for electrical applications.6. Weather Resistance: Fiberglass is resistant to UV radiation, wind, and rain, making it durable in outdoor applications.What are the Applications of Fiberglass?Fiberglass has a wide range of applications across various industries.1. Aerospace: Fiberglass is widely used in the aerospace industry to manufacture aircraft components, such as wings, fuselage, and nose cones.2. Construction: Fiberglass is commonly used in construction applications, such as insulation, roofing, and cladding.3. Automotive: Fiberglass is used to manufacture auto body panels, bumpers, and fenders for vehicles.4. Marine: Fiberglass is commonly used in the marine industry to manufacture boats, yachts, and other watercraft.5. Sports and Recreation: Fiberglass is used to manufacture sports equipment, such as fishing rods, surfboards, and golf club shafts.What are Woven Fiberglass Sheets?One of the most common forms of fiberglass is woven fiberglass sheets. Woven fiberglass is composed of glass fibers that are woven into a fabric-like material. The weaving process arranges the fibers into a criss-cross pattern, providing multidirectional strength. The woven fiberglass sheets are then coated with a plastic resin matrix to provide additional strength and durability.Woven fiberglass sheets are used in various applications, including:1. Mold Making: Woven fiberglass sheets are used to make molds for various applications, including automotive parts, bathtubs, and countertops.2. Reinforcement: Woven fiberglass is used to reinforce concrete, making it stronger and more durable.3. Electrical Insulation: Woven fiberglass is an excellent electrical insulator, making it suitable for electrical applications.4. Soundproofing: Woven fiberglass sheets are used as a soundproofing material in walls and ceilings.ConclusionFiberglass is a versatile and widely used material that offers numerous benefits, including high strength, light weight, and chemical resistance. The various forms of fiberglass, including woven fiberglass sheets, make it suitable for various applications across various industries. As technology continues to improve, the use of fiberglass is only set to increase, offering new and exciting solutions for engineering and manufacturing needs.

Read More

High-Quality Quick Change Fiberglass Laminating Rollers for Efficient and Smooth Fiberglass Applications

ers, Quick Change Fiberglass Rollers, Pure Bristle Fiberglass Rollers, and Bodi Company, Inc.Bodi Company, Inc. is a well-known and trusted manufacturer of fiberglass laminating rollers. Their products have been favored by many professionals in the industry for their efficiency and durability. The latest addition to their line of fiberglass laminating rollers is the Bristle Roller Quick Change Fiberglass Laminating Roller. This innovative product has quickly gained popularity among professionals due to its unique features and benefits.The Bristle Roller Quick Change Fiberglass Laminating Roller is made of pure bristle fiberglass rollers that are spirally wound. This construction method results in a strong fiberglass lamination while also allowing for smooth application of the fiberglass matting. The roller is designed to produce consistent results and can even be used in tight places where traditional rollers may be unable to reach.One of the most significant advantages of this roller is that you can hear the bubbles popping as you apply it to the fiberglass matting. This sound indicates that the air pockets are being removed from the lamination, ensuring that a uniform and strong bond is formed. This feature is especially useful for those who are new to working with fiberglass and may be unsure of the proper lamination techniques.The Bristle Roller Quick Change Fiberglass Laminating Roller is also very easy to use. Its quick change mechanism allows you to replace the rollers quickly and easily, which saves you time and effort. Additionally, the roller is designed to work efficiently with different types of fiberglass matting, making it a versatile tool for any fiberglass laminating project.In conclusion, the Bristle Roller Quick Change Fiberglass Laminating Roller by Bodi Company, Inc. is an excellent choice for professionals and beginners alike. Its innovative features and benefits make it stand out among other fiberglass laminating rollers on the market. Whether you are working on small or large projects, this roller is sure to provide you with consistent and reliable results. So, if you're looking for a high-quality fiberglass laminating roller, the Bristle Roller Quick Change Fiberglass Laminating Roller is definitely worth considering.

Read More