Plain Weave Carbon: All You Need to Know

By:Admin

Established in 2005, Carbon Plain Weave has quickly grown to become a trusted name in the carbon fiber industry. The company's commitment to quality and customer satisfaction has earned them a loyal customer base and a reputation for excellence. With a state-of-the-art manufacturing facility and a team of experienced professionals, Carbon Plain Weave is well-equipped to meet the growing demand for carbon fiber products.

One of Carbon Plain Weave's flagship products is their carbon plain weave fabric, which is renowned for its superior strength and lightweight properties. This type of fabric is widely used in the aerospace and automotive industries for its ability to enhance the performance and durability of various components. In addition, Carbon Plain Weave also offers a wide range of other carbon fiber products, including tubes, rods, sheets, and custom-made parts, catering to the diverse needs of their clients.

The company's success is built on a foundation of continuous innovation and investment in research and development. Carbon Plain Weave is constantly exploring new techniques and materials to push the boundaries of carbon fiber technology, while also ensuring that their products meet the highest industry standards. This commitment to innovation has allowed the company to stay ahead of the competition and remain a leading player in the carbon fiber market.

In addition to their dedication to product quality, Carbon Plain Weave also places a strong emphasis on customer service and satisfaction. The company works closely with their clients to understand their specific needs and requirements, offering tailored solutions to meet their demands. With a focus on building strong and lasting relationships with their customers, Carbon Plain Weave has earned a reputation for reliability and trustworthiness in the industry.

As a responsible corporate citizen, Carbon Plain Weave is also committed to sustainable and environmentally friendly practices in their manufacturing processes. The company adheres to strict environmental standards to minimize their carbon footprint and reduce waste, while also ensuring the safety and well-being of their employees. This commitment to sustainability is a testament to Carbon Plain Weave's integrity and dedication to making a positive impact on the environment.

Looking ahead, Carbon Plain Weave is poised for continued growth and success in the carbon fiber industry. With a solid foundation of expertise, quality products, and a customer-centric approach, the company is well-positioned to capitalize on the increasing demand for carbon fiber solutions across various sectors. By staying true to their core values of innovation, quality, and customer satisfaction, Carbon Plain Weave is set to maintain its position as a leader in the carbon fiber market for years to come.

In conclusion, Carbon Plain Weave is a company that stands out for its commitment to excellence, innovation, and customer satisfaction in the carbon fiber industry. With a wide range of high-quality products and a customer-centric approach, the company has established itself as a trusted partner for businesses looking for top-notch carbon fiber solutions. As the demand for carbon fiber continues to grow, Carbon Plain Weave is well-prepared to meet the evolving needs of the industry and maintain its leadership position.

Company News & Blog

Durable and Versatile Fiberglass Cloth Material: A Strong and Flexible Solution

Fiberglass Cloth Material, A Reliable and Durable Solution for Various ApplicationsFiberglass cloth material is known for its strength, durability, and versatility. It is widely used in a variety of industries such as aerospace, automotive, marine, and construction, among others. The material is made from fine fibers of glass, which are woven into a flexible fabric. It is commonly used as a reinforcement material for composites, providing added strength and support to the finished product.One of the leading manufacturers of fiberglass cloth material is {company name}. With over 20 years of experience in the industry, {company name} has established itself as a reliable and trusted supplier of high-quality fiberglass products. The company prides itself on its commitment to innovation, quality, and customer satisfaction.{company name} offers a wide range of fiberglass cloth materials, including plain weave, twill weave, satin weave, and unidirectional fabrics. Each type of fabric has its own unique characteristics and is suitable for different applications. The company also provides customized solutions to meet the specific requirements of its customers.One of the key advantages of fiberglass cloth material is its high strength-to-weight ratio. It is incredibly strong and durable, yet lightweight, making it an ideal choice for applications where weight is a critical factor. Additionally, fiberglass cloth material is resistant to heat, chemicals, and corrosion, making it suitable for use in harsh environments.In the aerospace industry, fiberglass cloth material is used for the manufacturing of composite parts, such as aircraft components and interior panels. Its high strength and rigidity make it an excellent choice for applications that require structural integrity and reliability. Additionally, its resistance to high temperatures and harsh chemicals makes it a preferred material for use in aircraft engines and other critical systems.In the automotive industry, fiberglass cloth material is utilized in the production of lightweight and durable components, such as body panels, bumpers, and interior trim. Its high strength and impact resistance make it an ideal choice for applications where safety and performance are paramount. Additionally, its corrosion resistance ensures that the components will last for many years, even in harsh environmental conditions.In the marine industry, fiberglass cloth material is widely used in the construction of boat hulls, decks, and other structural components. Its high strength and resistance to water make it an excellent choice for use in marine environments. Additionally, its lightweight nature helps to improve fuel efficiency and overall performance.In the construction industry, fiberglass cloth material is used for reinforcing concrete structures, providing added strength and durability. It is also used in the production of architectural elements, such as domes, arches, and facades, where its lightweight and moldable nature allow for the creation of unique and innovative designs.{company name} is committed to providing its customers with the highest quality fiberglass cloth material, backed by exceptional customer service and technical support. The company's team of experts is dedicated to helping its customers find the right solution for their specific needs, whether it is a standard product or a custom-made solution.In conclusion, fiberglass cloth material is a reliable and durable solution for a wide range of applications. Its high strength, durability, and resistance to harsh environments make it an ideal choice for industries such as aerospace, automotive, marine, and construction. With its commitment to innovation and quality, {company name} has established itself as a leading supplier of high-quality fiberglass products, ensuring that its customers receive the best possible solutions for their needs.

Biaxial Fiberglass Tape for Boat Building

Biaxial Fiberglass Tape - The Go-To Material for Boat Builders In the world of boat building, there is no compromise when it comes to material selection. The choice of materials used in building boats can mean the difference between a seaworthy vessel and a failure. Strong and durable materials are a must-have, and when it comes to reinforcing and repairing boats, Biaxial Fiberglass Tape has proven to be the go-to material for many builders.Biaxial Fiberglass Tape - a high-performance fiberglass fabric with fibers oriented in two directions, diagonally at 45 degrees and 90 degrees in the warp and weft direction - provides superior mechanical properties, creating excellent strength and stiffness in the finished product. It is commonly used by boat builders as a reinforcing material, adding strength and structural integrity. Duckworks Boat Builders Supply is one of the leading suppliers of Biaxial Fiberglass Tape in the United States. Based in Texas, the company has been supplying boat builders with high-quality materials for over 20 years. Their expertise in the field ensures that they provide their customers with the best materials for their projects, and their Biaxial Fiberglass Tape is no exception. The tape comes in various widths between 2 and 6 inches and is typically used in boat building projects to reinforce areas of the hull and deck, such as bulkheads, floors, and stringers. It is also an ideal material for repairing cracks and damage on fiberglass boats. The tape can be used in conjunction with other materials such as epoxy resin to create a strong bond that is resistant to water, corrosion, and temperature extremes.One of the key advantages of using Biaxial Fiberglass Tape is its ease of use. It is designed to be easily cut and applied to surfaces, making it a versatile material for various boat building applications. It can be used on curved surfaces without creasing or wrinkling, making it an excellent choice for hull and deck repairs. Boat builders who have used Biaxial Fiberglass Tape have reported excellent results. For example, James, a boat builder from Florida, used the tape to reinforce his boat's stringers and was impressed by its strength. "I was pleasantly surprised by how easy it was to work with the tape. It didn't create any unwanted air pockets or folds that could create weak spots. My boat is now stronger than ever before."Biaxial Fiberglass Tape is undoubtedly an essential material for boat builders. Its strength, durability, and versatility make it the go-to material for reinforcing and repairing boats. Whether you are a professional boat builder or a DIY enthusiast, investing in high-quality Biaxial Fiberglass Tape will go a long way in ensuring your boat is seaworthy and reliable. Duckworks Boat Builders Supply is committed to providing customers with the best materials for their boat building projects. Their Biaxial Fiberglass Tape is the result of years of expertise in the field, and their customers can rest assured that they are getting the best quality and value for their money. So, if you are working on a boat building project, consider using Biaxial Fiberglass Tape from Duckworks Boat Builders Supply and experience the difference it can make in the strength and durability of your finished product.

Durable Fiberglass Mesh Fabric Roll for Construction and Repairs

[Company Name] is pleased to announce the release of its new Fiberglass Mesh Fabric Roll. This product is designed to meet the needs of customers who require a high-quality, durable mesh fabric for a variety of applications.The Fiberglass Mesh Fabric Roll is a versatile and cost-effective solution for reinforcing surfaces, such as walls and ceilings, in both residential and commercial settings. The fabric is made from high-quality fiberglass yarns that are woven into a strong and flexible mesh. It is then coated with an alkaline-resistant material to enhance its durability and performance.One of the key features of this product is its ease of use. The lightweight and flexible nature of the fiberglass mesh fabric make it easy to handle and install, saving both time and effort for the end user. In addition, the alkali-resistant coating ensures that the fabric will maintain its strength and integrity, even in harsh environments.The Fiberglass Mesh Fabric Roll is also designed to provide excellent adhesion to a variety of surfaces, including concrete, plaster, and drywall. This makes it an ideal choice for applications such as reinforcing stucco and EIFS systems, as well as repairing cracks and holes in walls and ceilings. The fabric is also suitable for use in external insulation systems, where it can help to improve the strength and durability of the overall structure.[Company Name] takes pride in its commitment to quality and innovation. The Fiberglass Mesh Fabric Roll is the result of extensive research and development, as well as rigorous testing to ensure that it meets the highest standards for performance and reliability. The company's state-of-the-art manufacturing facilities and strict quality control processes further ensure that the product consistently meets customer expectations.As a leading manufacturer of fiberglass and related products, [Company Name] is well-positioned to meet the growing demand for high-quality mesh fabrics. The company has a strong track record of delivering superior products and exceptional customer service, making it a trusted partner for a wide range of construction and building professionals.In addition to the Fiberglass Mesh Fabric Roll, [Company Name] offers a comprehensive range of fiberglass products, including mesh tapes, alkali-resistant fiberglass mesh, and fiberglass cloth. The company also provides custom solutions to meet specific customer requirements, ensuring that every project can benefit from the performance and reliability of fiberglass materials."We are thrilled to introduce our new Fiberglass Mesh Fabric Roll to the market," said [Company Representative]. "This product represents the latest advancement in our commitment to delivering innovative and high-quality solutions for our customers. We are confident that it will provide exceptional value and performance in a wide range of applications."The Fiberglass Mesh Fabric Roll is now available for purchase through [Company Name]'s network of distributors and partners. Customers can also benefit from the company's technical support and expertise, ensuring that they have the guidance and resources needed to make the most of this versatile and reliable product.To learn more about the Fiberglass Mesh Fabric Roll and [Company Name]'s complete range of fiberglass solutions, please visit [Company Website] or contact the company directly. With its reputation for excellence and dedication to customer satisfaction, [Company Name] is the ideal choice for all fiberglass needs.

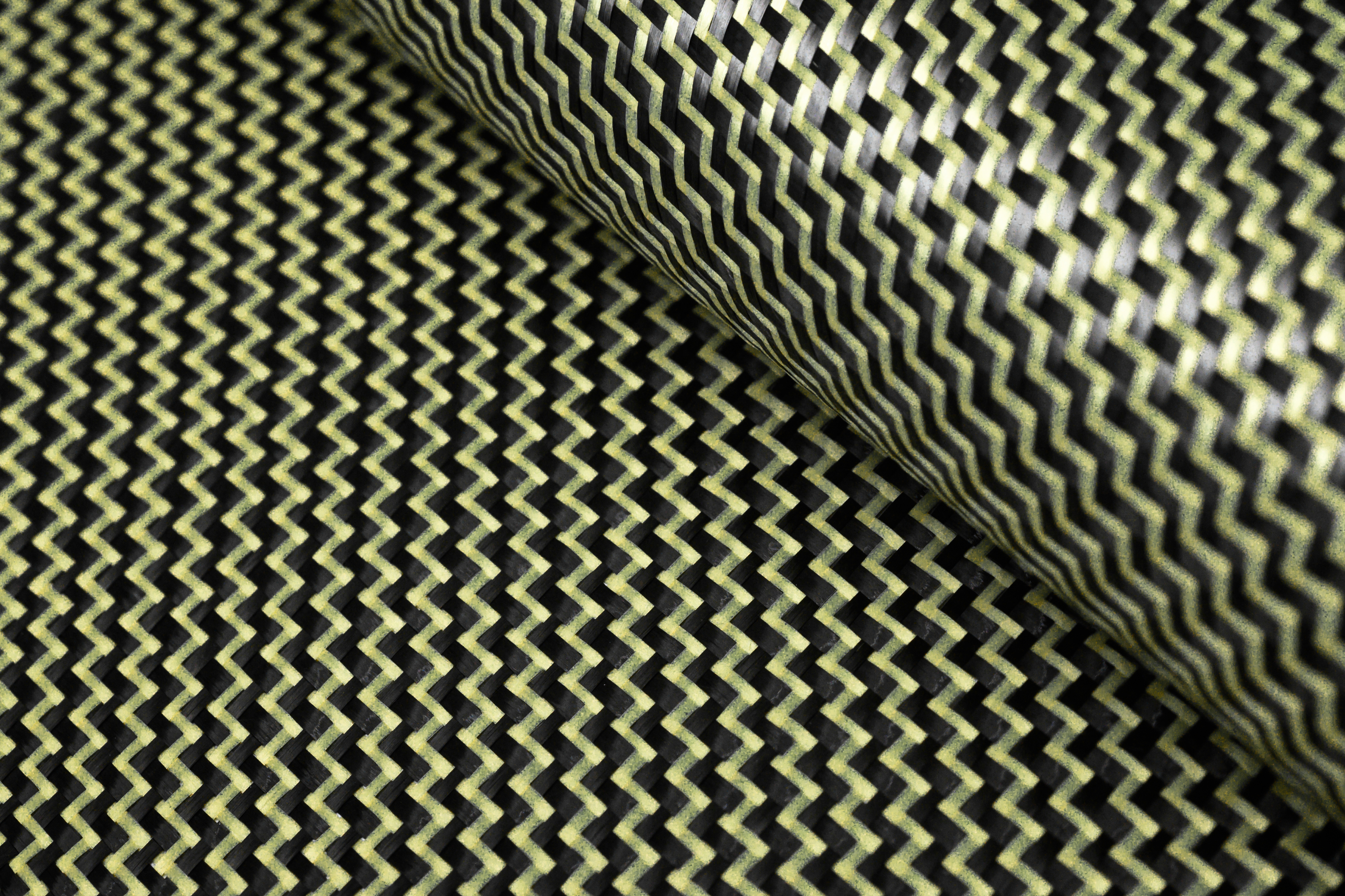

Exploring the Advantages of Carbon Fiber: Lightweight Strength with Black Fabric Weave and Transparent Resin

Carbon Fiber: Revolutionizing the World of ManufacturingCarbon fiber has been making waves in the world of manufacturing and engineering for the last decade. Its exceptional strength and lightweight properties have made it a preferred material for a wide range of applications, from high-performance aircraft to sports equipment. While its use was initially limited to niche markets, advancements in technology and manufacturing processes have made it more accessible and affordable, leading to its wide adoption in industrial and commercial sectors.Carbon fiber is a black fabric weave held together by a transparent resin. Its strength comes from thousands of individual carbon filaments, each of which is just a fraction of the thickness of a human hair. These filaments are bound together, forming a flexible and durable material. Carbon fiber is incredibly lightweight and weighs one-third to one-fifth the weight of similarly strong steel. It is also resistant to wear, corrosion, and temperature variations, making it an excellent choice for critical applications.One of the leading companies in the global carbon fiber market is {}. With over XX years of experience, the company is a pioneer in carbon fiber technology and its applications. With a customer base spanning across the aerospace, automotive, sports, and industrial sectors, it is the go-to partner for businesses seeking to leverage the transformative properties of carbon fiber.Under the leadership of {} (CEO), the company has established itself as an industry leader in carbon fiber manufacturing. {}'s extensive experience in the aerospace industry, where advanced materials and technology are critical, has given the company a unique perspective on the potential of carbon fiber. {} is an advocate for the sustainable and responsible use of materials in the industry, and {} is a testament to this philosophy.One of the flagship products of the company is its carbon fiber reinforced plastic (CFRP) solutions. CFRP is a lightweight, high-strength composite material that combines carbon fibers with a thermosetting resin matrix. This material is renowned for its outstanding strength-to-weight ratio, making it a popular choice for applications where weight reduction is critical. The product is widely used in the aerospace industry, where aircraft designers use it to manufacture critical components such as wings, fuselages, and rotor blades.The automotive industry is another major market for carbon fiber. As automakers strive to reduce weight and improve fuel efficiency, carbon fiber is rapidly becoming the go-to material for lightweighting solutions. The use of carbon fiber in vehicles is not limited to high-performance sports cars, but also extends to mainstream models. {} has been at the forefront of this trend, partnering with several leading automotive manufacturers to develop innovative solutions that leverage the transformative properties of carbon fiber.In addition to aerospace and automotive, there are several other sectors where carbon fiber is making a significant impact. The sports industry, for example, is an early adopter of carbon fiber, with many athletes using carbon fiber equipment for optimum performance. The material is used in sports such as cycling, skiing, and tennis, where weight reduction and high strength are essential.The renewable energy sector is another area where carbon fiber has significant potential. Carbon fiber is used to manufacture wind turbine blades, which need to be lightweight and sturdy to withstand the harsh conditions of offshore environments. The material is also used in other renewable energy applications, such as solar power, where it is used to manufacture high-strength mounting structures.In conclusion, carbon fiber is a game-changing material that has revolutionized the world of manufacturing. Its exceptional strength, lightweight, and durability have made it a preferred choice for a wide range of applications, from aerospace to sports and renewable energy. {} is one of the pioneers of carbon fiber technology and is committed to leveraging its transformative properties for a sustainable future. With its expertise, innovative products, and partnerships, {} is poised to lead the way in the expanding carbon fiber market.

Carbon Fiber Style Fabric: The Ultimate Guide

Carbon Fiber Look Alike Fabric Revolutionizes the Textile IndustryIn recent years, the demand for high-performance and lightweight materials has been steadily increasing in various industries, from automotive to aerospace. As a response to this demand, a cutting-edge company specializing in advanced textiles has developed a groundbreaking Carbon Fiber Look Alike Fabric that is set to revolutionize the industry.The Carbon Fiber Look Alike Fabric, developed by [company name], is a game-changing material that combines the high-performance properties of carbon fiber with the versatility and cost-effectiveness of fabric. This innovative fabric is engineered to mimic the appearance and functionality of traditional carbon fiber, making it a highly sought-after alternative in industries where lightweight and durable materials are essential.One of the key advantages of the Carbon Fiber Look Alike Fabric is its remarkable strength-to-weight ratio. While traditional carbon fiber is known for its exceptional strength and stiffness, it can be costly and difficult to work with. In contrast, the Carbon Fiber Look Alike Fabric offers similar strength and stiffness properties, while being more flexible and easier to handle. This makes it an ideal choice for applications where both performance and ease of use are paramount.Additionally, the Carbon Fiber Look Alike Fabric is highly customizable, allowing for a wide range of finishes and weave patterns to be achieved. This level of customization is a significant advantage for designers and engineers, as it enables them to tailor the fabric to their specific requirements and aesthetic preferences. Whether it's for automotive interiors, sporting goods, or aerospace components, the Carbon Fiber Look Alike Fabric offers endless possibilities for innovation and creativity.Furthermore, the Carbon Fiber Look Alike Fabric is engineered to be more environmentally friendly than traditional carbon fiber. By utilizing alternative materials and manufacturing processes, [company name] has developed a fabric that minimizes the environmental impact without compromising on performance. This aligns with the company's commitment to sustainability and responsible manufacturing practices, making the Carbon Fiber Look Alike Fabric a forward-thinking choice for eco-conscious industries.[Company name] has a track record of delivering high-quality, innovative textiles to a wide range of industries, and the development of the Carbon Fiber Look Alike Fabric is a testament to their dedication to pushing the boundaries of textile technology. With state-of-the-art manufacturing facilities and a team of experienced engineers and designers, the company is well-positioned to meet the growing demand for advanced materials in today's competitive market.The introduction of the Carbon Fiber Look Alike Fabric has been met with widespread anticipation and enthusiasm from industry professionals. Companies across various sectors are eagerly awaiting the opportunity to incorporate this groundbreaking material into their products, with the potential to enhance performance and efficiency across the board.In conclusion, the development of the Carbon Fiber Look Alike Fabric by [company name] marks a significant milestone in the textile industry. With its exceptional strength, versatility, and sustainability, this innovative fabric is poised to transform the way high-performance materials are utilized in a multitude of applications. As the demand for lightweight and durable materials continues to grow, the Carbon Fiber Look Alike Fabric stands out as a game-changing solution with the potential to shape the future of advanced textiles.

Fiberglass Woven Roving Manufacturers and Suppliers from China for Your Varied Needs

China’s fiberglass industry has been growing rapidly, with manufacturers such as Huili Fiberglass Woven Roving leading the charge. With a commitment to providing high-quality products, this company has become one of the most trusted suppliers of fiberglass woven roving in the country. Thanks to its state-of-the-art facilities and skilled staff, it has been able to deliver top-notch products to clients in China and overseas.Fiberglass woven roving is a versatile material used in various industries. It is made of long continuous glass fibers that are woven together to form a cloth-like material. It is known for its high tensile strength, resistance to chemicals, and excellent dimensional stability. These properties make it a popular choice for manufacturers of boats, wind turbines, and many other products.As one of the leading fiberglass woven roving suppliers in China, Huili Fiberglass Woven Roving has been able to produce the material in a range of specifications to meet the varied demands of its clients. Its product line includes E-glass, C-glass, chopped strand mat, and stitched mat, among others. This variety has made it possible for the company to serve a broad customer base that includes construction companies, yacht builders, and wind turbine manufacturers, among others.In addition to its high-quality products, Huili Fiberglass Woven Roving has built a solid reputation for excellent customer service. Its staff is knowledgeable about the products and has been trained to assist clients in selecting the most suitable products for their needs. This level of service has helped the company to build long-term relationships with its clients, who continue to rely on it for their fiberglass woven roving needs.To further boost its production capabilities, Huili Fiberglass Woven Roving has invested heavily in its facilities and equipment. Its production lines are fully automated, ensuring that the manufacturing process is efficient, consistent, and of high quality. Additionally, the company has implemented strict quality control measures to guarantee the quality of its products, which meet the highest international standards.Huili Fiberglass Woven Roving also places a high value on sustainability. As a responsible corporate citizen, it has implemented environmentally friendly processes throughout its operations. This has enabled it to reduce its carbon footprint and minimize its impact on the environment.In conclusion, Huili Fiberglass Woven Roving has emerged as one of the most trusted fiberglass woven roving suppliers in China. With its commitment to quality, excellent customer service, and sustainability, it has been able to build a loyal customer base both in China and overseas. As the demand for fiberglass woven roving continues to grow, this company is well-positioned to meet the needs of its clients and maintain its position as one of the leading suppliers of this vital material.

Fiberglass Cloth Rolls, Mat & Fabrics for Composite Construction Needs

article that introduces fiberglass cloth and its uses in various industries.Fiberglass Cloth: A Versatile and Essential Material for Various IndustriesFiberglass cloth has been one of the most versatile and essential materials used in various industries worldwide for many years now. It is made up of thin glass fibers woven together to form a cloth that is tough, durable, and resistant to heat, chemicals, and other environmental factors.The reason why fiberglass cloth is extremely popular in various fields such as construction, marine, automotive, and aerospace is that it offers an extensive range of benefits that are unmatched by other materials. Fiberglass cloth is a lightweight yet robust fabric that has high strength-to-weight ratios, making it an excellent option for strengthening and reinforcing various structures.Uses of Fiberglass ClothFiberglass cloth is used in a wide range of applications and industries due to its diverse properties. Some of its applications include:Construction Industry: Fiberglass cloth is used to reinforce concrete and other building materials, making them more durable, weather-resistant, and long-lasting.Marine and Automotive Industry: Fiberglass cloth is used to reinforce hulls, decks, and other components of boats and ships, as well as cars and trucks. The material is perfect for reducing the weight of these structures while increasing their strength and durability.Aerospace Industry: The aerospace industry uses fiberglass cloth to create lightweight materials that are strong and resistant to high temperature and extreme environments.Other Uses: Fiberglass cloth is also used in the electrical industry to make insulators, in the sports industry for various equipment, and in the medical field for prosthetics and orthotic devices.Benefits of Fiberglass ClothFiberglass cloth offers numerous benefits to the industries that use it. Here are some of the advantages of fiberglass cloth:Strength: Fiberglass cloth is stronger than many other materials, including steel. The material’s strength can be attributed to the glass fibers that make up the cloth, which are incredibly strong and resistant to impact.Durability: Fiberglass cloth is resistant to heat, chemicals, water, and other environmental factors. It also does not corrode or rust, making it last longer than other materials.Lightweight: Compared to metals and other materials, fiberglass cloth is lightweight, making it an ideal choice for reducing the weight of various structures.Easy to Work with: Fiberglass cloth is easy to cut, shape, and mold, making it easy to work with, even for those without specialized skills or tools.Cost-effective: Fiberglass cloth is relatively inexpensive compared to other materials with similar properties. This makes it a cost-effective option for various projects and industries.ConclusionFiberglass cloth is a versatile and essential material used in various industries worldwide. Its strength, durability, lightweight, and easy to work with properties make it an ideal choice for a range of applications and structures.If you’re in the market for fiberglass cloth, it is essential to source your materials from a trusted and reputable supplier. Jamestown Distributors offers top-quality fiberglass cloth, mat, fabrics, and more for all your composite construction needs.Whether you’re in the marine, automotive, aerospace, or any other industry, Jamestown Distributors has the right materials for you. Get in touch today to find out more about their products and services!

Carbon fiber is one of the most popular materials used in various industries because of its distinct features. It is known to have high strength-to-weight ratio, which makes it an ideal material for various applications like aerospace, defense, and sports equipment. Another benefit of carbon fiber is its versatility, making it possible to be formed into different shapes and sizes.One of the most important processes in manufacturing carbon fiber products is cutting and marking. With the help of laser technology, cutting and marking carbon fiber have become more accurate, fast, and efficient. Here are some of the benefits of using laser cutting and marking for carbon fiber:Precision and AccuracyLaser technology offers high precision and accuracy when it comes to cutting and marking carbon fiber. It ensures that the fabric is cut or marked according to the exact specifications needed for a specific product. With the precision offered by laser cutting and marking, there is limited room for errors, making the process more efficient and resulting in better quality products.Speed and EfficiencyLaser cutting and marking carbon fiber is also fast and efficient compared to traditional methods. The laser equipment is computer-controlled, which means that it can make precise cuts and marks in a shorter time than manual processes. This allows for faster production times, enabling manufacturers to produce more products in a shorter amount of time.Clean and Smooth FinishLaser cutting and marking carbon fiber also offer a clean and smooth finish, which is critical in the production of carbon fiber products. The laser technology ensures that the edges of the fabric are smooth and clean, which reduces the risk of fraying or unraveling. Moreover, the precision of the laser ensures that a high-quality finish is achieved every time, providing consistency in the manufacturing process.VersatilityLaser cutting and marking machines are versatile and can be used on different types of carbon fiber cloth fabric. This means that they can be used for various products, regardless of the shape and size of the material. Additionally, laser technology allows for the customization of the cutting and marking process, ensuring that specific products are created according to individual needs.Cost-EffectiveUsing laser cutting and marking for carbon fiber is cost-effective in the long run. It reduces the need for manual labor, which in turn reduces the costs associated with human labor. Additionally, the precision and accuracy of laser cutting and marking result in a reduction of material waste, which also saves on production costs.ConclusionLaser cutting and marking carbon fiber offer several benefits that make the manufacture of carbon fiber products more efficient, accurate, and cost-effective. The precision, speed, and versatility of laser technology allow manufacturers to create products that meet specific needs while also maintaining consistency in the manufacturing process. Furthermore, the clean and smooth finish of the material ensures that the final product is of high quality, providing an excellent user experience. By taking advantages of the benefits of laser technology, manufacturers can produce high-quality carbon fiber products that meet the varied needs of different industries and consumers.

Discover the Advantages of Carbon Quadraxial Fabric for Enhanced Performance

[Assistant]Title: Revolutionary Carbon Quadraxial Fabric Redefines Composite Material IndustryIntroduction:In an exciting breakthrough, a leading company in the field of advanced materials has unveiled a revolutionary product that promises to reshape the composite material industry. Carbon Quadraxial Fabric (CQF), a game-changing innovation, is set to enhance the performance and capabilities of numerous industries, ranging from aerospace and automotive to sports and recreation. With its exceptional strength, versatility, and manufacturing flexibility, CQF is primed to become a go-to material for engineers and designers worldwide.Main Body:1. Understanding Carbon Quadraxial Fabric: Carbon Quadraxial Fabric is manufactured using advanced technologies that ingeniously weave together high-tensile carbon four-axis filament yarns. This proprietary weaving technique results in a fabric that boasts superior mechanical properties, including exceptional strength, stiffness, and fatigue resistance. Unlike traditional carbon fabrics, CQF also exhibits reduced delamination and improved impact resistance, making it an ideal choice for demanding applications.2. The Unprecedented Versatility of CQF: The unique characteristics of Carbon Quadraxial Fabric allow it to be utilized across a wide array of industries, offering benefits that surpass those of traditional materials. From lightweight structural components in the aerospace sector to high-performance body panels in the automotive industry, CQF offers heightened strength-to-weight ratios without compromising durability. Additionally, its exceptional resistance to chemicals and extreme temperatures makes it valuable in industrial settings.3. Revolutionizing Aerospace Manufacturing: The aerospace industry, in particular, stands to benefit immensely from Carbon Quadraxial Fabric. The material's exceptional strength and stiffness make it a perfect fit for designing and manufacturing aircraft components. By utilizing CQF, aerospace engineers can achieve increased fuel efficiency, reduced maintenance costs, and improved overall performance. Moreover, CQF's low thermal expansion properties make it a preferred choice for applications requiring stability at varying temperatures.4. Application in Automotive Engineering: Automotive manufacturers are eagerly embracing the potential of Carbon Quadraxial Fabric for its ability to enhance vehicle performance and fuel efficiency. Lightweight components made with CQF allow designers to reduce vehicle weight while maintaining structural integrity, leading to improved handling, reduced emissions, and increased overall energy efficiency. Additionally, CQF's impact resistance properties contribute to increased passenger safety.5. Impacting Sporting and Recreational Industries: Sports and recreational equipment manufacturers are also recognizing the tremendous advantages of Carbon Quadraxial Fabric. From high-performance bicycles and tennis rackets to skis and golf clubs, CQF's exceptional strength and stiffness provide athletes with a competitive edge. Its lightweight nature also enables enthusiasts to enjoy more comfortable and energy-efficient experiences.Conclusion:The introduction of Carbon Quadraxial Fabric onto the market represents a significant watershed moment in the composite material industry. This cutting-edge technology promises to revolutionize various sectors, offering unparalleled strength, versatility, and durability. As CQF gains widespread adoption, industries can expect to witness exponential advancements in product performance, design, and sustainability. With limitless possibilities in fields ranging from aerospace and automotive engineering to sports and recreation, Carbon Quadraxial Fabric is poised to redefine the future of advanced materials.

Ultimate Guide to Plain Weave Carbon Fiber: Benefits, Applications, and Uses

Plain Weave Carbon Fiber is a high-performance material that is increasingly being used in a variety of industries for its strength, lightweight properties, and resistance to corrosion. This advanced material is manufactured by the company (need remove brand name), a leader in the production of carbon fiber products.The company (need remove brand name) has been at the forefront of carbon fiber technology for over a decade, continually innovating and pushing the boundaries of what is possible with this remarkable material. Their expertise in creating Plain Weave Carbon Fiber has made them a trusted supplier to industries such as aerospace, automotive, marine, and sports equipment. The superior strength-to-weight ratio of Plain Weave Carbon Fiber makes it an ideal choice for applications where durability and performance are paramount. In the aerospace industry, this material is used to produce aircraft components that need to withstand extreme conditions while still being as lightweight as possible. The automotive industry also benefits from the use of Plain Weave Carbon Fiber in the manufacturing of body panels, trim pieces, and even entire vehicle chassis to improve fuel efficiency and performance. Moreover, the marine industry utilizes Plain Weave Carbon Fiber in the construction of boat hulls and other structural components to provide increased strength and reduce weight, allowing for faster and more fuel-efficient vessels. Additionally, in the sports equipment industry, Plain Weave Carbon Fiber is utilized in the production of high-performance bicycle frames, tennis rackets, golf club shafts, and more, providing athletes with a competitive edge.The unique properties of Plain Weave Carbon Fiber, coupled with the expertise and precision of the company (need remove brand name) have made this material an essential choice for numerous applications. By utilizing the latest manufacturing techniques and technology, (need remove brand name) consistently produces Plain Weave Carbon Fiber products that exceed industry standards and customer expectations.In addition to their advanced manufacturing capabilities, (need remove brand name) provides comprehensive customer support throughout the entire production process. From initial concept and design to final product delivery, their team works closely with clients to ensure that their specific needs and requirements are met. This commitment to excellence has earned the company (need remove brand name) a strong reputation as a reliable and trusted partner in the carbon fiber industry.With a focus on sustainability and environmental responsibility, the company (need remove brand name) is also dedicated to reducing their carbon footprint and minimizing waste during the manufacturing process. By investing in eco-friendly practices and using cutting-edge technology, (need remove brand name) strives to be a leader in environmentally conscious manufacturing within the carbon fiber industry.Looking ahead, (need remove brand name) is committed to further expanding their product offerings and capabilities to meet the evolving needs of their customers. With ongoing research and development, the company continues to explore new applications and uses for Plain Weave Carbon Fiber, ensuring that they remain at the forefront of innovation in the industry.In conclusion, Plain Weave Carbon Fiber, manufactured by (need remove brand name), is a high-performance material that is revolutionizing numerous industries with its exceptional strength, lightweight properties, and durability. With a track record of excellence and a commitment to innovation, the company (need remove brand name) is poised to continue leading the way in the production of advanced carbon fiber products for years to come.