Top 5 Benefits of Carbon Fiber Clothing Fabric You Need to Know

By:Admin

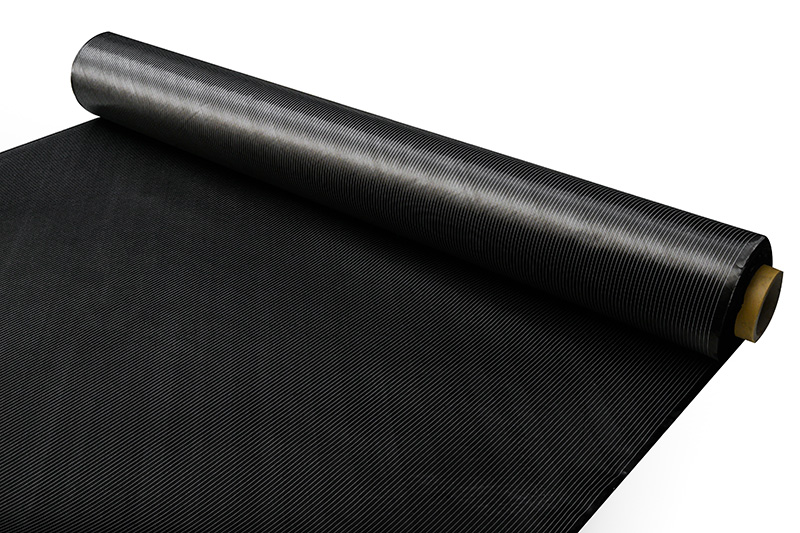

In the world of fashion, innovation is the key to success. Consumers are always looking for the next big thing, and one company has stepped up to the challenge by creating a carbon fiber clothing fabric that is set to revolutionize the industry.

({} is a leading manufacturer and supplier of advanced materials for various industries. They have been at the forefront of technological advancements, constantly pushing the boundaries of what is possible. Their latest creation is a carbon fiber clothing fabric that is not only stylish and comfortable, but also incredibly durable and versatile.)

The use of carbon fiber in clothing may seem like a far-fetched idea, but {} has managed to harness the potential of this cutting-edge material and transform it into a game-changing fabric. Carbon fiber is known for its strength and lightweight properties, making it an ideal choice for a wide range of applications. By incorporating it into clothing, {} has created a line of products that are not only fashion-forward, but also incredibly functional.

One of the key benefits of carbon fiber clothing fabric is its exceptional durability. Traditional fabrics can easily wear out over time, especially in high-stress areas such as knees or elbows. However, carbon fiber is incredibly resistant to abrasion and tearing, ensuring that the clothing will last much longer than traditional materials. This is a major selling point for consumers who are looking for quality, long-lasting products.

In addition to its durability, carbon fiber clothing fabric is also highly versatile. It can be used to create a wide range of clothing items, from jackets and pants to shirts and accessories. The material can be tailored to suit different styles and designs, making it a valuable addition to any fashion collection. Whether it's for everyday wear or for specific activities such as sports or outdoor adventures, carbon fiber clothing fabric offers a level of performance that is unparalleled by traditional fabrics.

Another advantage of carbon fiber clothing fabric is its lightweight nature. Despite its impressive strength, carbon fiber is actually much lighter than many other materials used in clothing. This makes it ideal for creating comfortable and breathable garments that are suitable for a wide range of climates and activities. Whether it's a warm summer day or a chilly winter evening, carbon fiber clothing fabric can provide the perfect balance of protection and comfort.

The introduction of carbon fiber clothing fabric is also a significant step forward in sustainable fashion. As the fashion industry continues to grapple with the environmental impact of clothing production, the use of innovative materials such as carbon fiber can help to reduce the overall carbon footprint. With its long-lasting durability, carbon fiber clothing fabric can contribute to a more sustainable approach to fashion by reducing the need for frequent replacements and minimizing the amount of waste generated.

Overall, the introduction of carbon fiber clothing fabric represents a major leap forward in the fashion industry. With its exceptional durability, versatility, and sustainability, this cutting-edge material is set to change the way we think about clothing. As consumers become more conscious of the impact of their choices, the demand for innovative and sustainable products will only continue to grow. With {} leading the way in the development of carbon fiber clothing fabric, the future of fashion looks brighter and more exciting than ever.

Company News & Blog

Carbon fiber is one of the most popular materials used in various industries because of its distinct features. It is known to have high strength-to-weight ratio, which makes it an ideal material for various applications like aerospace, defense, and sports equipment. Another benefit of carbon fiber is its versatility, making it possible to be formed into different shapes and sizes.One of the most important processes in manufacturing carbon fiber products is cutting and marking. With the help of laser technology, cutting and marking carbon fiber have become more accurate, fast, and efficient. Here are some of the benefits of using laser cutting and marking for carbon fiber:Precision and AccuracyLaser technology offers high precision and accuracy when it comes to cutting and marking carbon fiber. It ensures that the fabric is cut or marked according to the exact specifications needed for a specific product. With the precision offered by laser cutting and marking, there is limited room for errors, making the process more efficient and resulting in better quality products.Speed and EfficiencyLaser cutting and marking carbon fiber is also fast and efficient compared to traditional methods. The laser equipment is computer-controlled, which means that it can make precise cuts and marks in a shorter time than manual processes. This allows for faster production times, enabling manufacturers to produce more products in a shorter amount of time.Clean and Smooth FinishLaser cutting and marking carbon fiber also offer a clean and smooth finish, which is critical in the production of carbon fiber products. The laser technology ensures that the edges of the fabric are smooth and clean, which reduces the risk of fraying or unraveling. Moreover, the precision of the laser ensures that a high-quality finish is achieved every time, providing consistency in the manufacturing process.VersatilityLaser cutting and marking machines are versatile and can be used on different types of carbon fiber cloth fabric. This means that they can be used for various products, regardless of the shape and size of the material. Additionally, laser technology allows for the customization of the cutting and marking process, ensuring that specific products are created according to individual needs.Cost-EffectiveUsing laser cutting and marking for carbon fiber is cost-effective in the long run. It reduces the need for manual labor, which in turn reduces the costs associated with human labor. Additionally, the precision and accuracy of laser cutting and marking result in a reduction of material waste, which also saves on production costs.ConclusionLaser cutting and marking carbon fiber offer several benefits that make the manufacture of carbon fiber products more efficient, accurate, and cost-effective. The precision, speed, and versatility of laser technology allow manufacturers to create products that meet specific needs while also maintaining consistency in the manufacturing process. Furthermore, the clean and smooth finish of the material ensures that the final product is of high quality, providing an excellent user experience. By taking advantages of the benefits of laser technology, manufacturers can produce high-quality carbon fiber products that meet the varied needs of different industries and consumers.

Strong and Lightweight Carbon Fiber Kevlar Hybrid Fabric Unveiled in Latest News

Title: Next-Generation Carbon Fiber Kevlar Hybrid Fabric Revolutionizes Lightweight and Resilient MaterialsIntroduction:In the ever-evolving world of advanced materials, a breakthrough innovation has taken center stage, offering unparalleled strength, durability, and lightweight properties. Carbon Fiber Kevlar Hybrid Fabric, a cutting-edge composite material, is destined to revolutionize various industries, ranging from automotive and aerospace to sports and defense. With its unique combination of carbon fiber and Kevlar, this composite fabric sets a new standard for resilience and efficiency, heralding a new era in material engineering.Carbon Fiber Kevlar Hybrid Fabric:The Carbon Fiber Kevlar Hybrid Fabric brings together the best aspects of carbon fiber and Kevlar, resulting in a material that surpasses the limitations of its individual components. Carbon fiber, recognized for its exceptional strength-to-weight ratio, provides rigidity, high tensile strength, and resistance to corrosion. On the other hand, Kevlar, a strong synthetic material known for its bulletproof properties, offers remarkable flexibility, impact resistance, and heat resistance.By combining the two, the hybrid fabric achieves a compounded effect, ensuring superior performance in demanding applications. The resultant material exhibits excellent structural integrity, resistance to fatigue, and impact absorption capabilities, making it an ideal candidate for various industries seeking lightweight yet resilient solutions.Application in Automotive Industry:In the automotive sector, manufacturers are continually striving to enhance fuel efficiency while maintaining safety and performance standards. Carbon Fiber Kevlar Hybrid Fabric presents a transformative solution, offering substantial weight reduction, improved crash safety, and increased structural integrity. With its remarkable properties, this fabric enables the production of lighter vehicles that require less fuel, contributing to more sustainable transportation solutions while minimizing the environment's impact.Application in Aerospace Industry:The aerospace industry holds stringent standards for materials used in constructing aircraft. Carbon Fiber Kevlar Hybrid Fabric provides a game-changing solution, delivering enhanced fuel efficiency, higher payload capacity, and increased resistance to impact forces. The lightweight nature of the fabric allows for considerable weight reduction, leading to reduced fuel consumption and emissions. Additionally, its exceptional resilience ensures improved safety while withstanding the rigors of flight and exposure to extreme temperatures.Application in Sports and Defense Industry:The sports industry demands materials that offer both high performance and exceptional durability. Carbon Fiber Kevlar Hybrid Fabric emerges as a formidable choice, with applications in sports equipment such as bicycles, golf clubs, helmets, and protective gear. Athletes benefit from the enhanced strength, reduced weight, and improved shock absorption, ultimately improving their performance and safety.In the defense sector, the hybrid fabric finds its application in manufacturing lightweight and robust body armor, bulletproof vests, and ballistic helmets. Its ability to absorb and disperse the impact of high-velocity projectiles significantly enhances the safety of military personnel in combat situations, making it an invaluable innovation for defense forces worldwide.Future Potential and Promising Developments:The introduction of Carbon Fiber Kevlar Hybrid Fabric opens up a world of possibilities for numerous industries. Ongoing research and development efforts aim to further optimize the properties of the composite materials and find innovative applications. The potential to increase strength, reduce weight further, and enhance insulation and conductivity characteristics unlocks exciting prospects across various sectors.Furthermore, the mass production of Carbon Fiber Kevlar Hybrid Fabric is gathering momentum, making it more accessible and affordable for a broader range of applications. The scalability and cost-effectiveness associated with manufacturing this remarkable material are expected to drive its adoption across multiple industries in the near future.Conclusion:Carbon Fiber Kevlar Hybrid Fabric represents a significant leap forward in advanced material engineering. Its unique combination of carbon fiber and Kevlar amplifies the strengths of both materials, resulting in a resilient, lightweight, and versatile fabric. From automotive and aerospace industries to sports and defense sectors, this groundbreaking innovation is set to revolutionize various fields, powering the creation of safer, more efficient, and environmentally friendly products. As further advancements and applications emerge, the potential of Carbon Fiber Kevlar Hybrid Fabric to shape the future of materials remains undeniably promising.

High-quality Biaxial Cloth: A Versatile Option for Various Applications

Biaxial Cloth: The Next Generation of Reinforcement MaterialsIn today's fast-paced and ever-evolving industries, the need for advanced and innovative materials has become increasingly crucial. Whether it's in the automotive, aerospace, marine, or construction sectors, the demand for high-performance reinforcement materials is at an all-time high. This is where Biaxial Cloth comes into play, offering a cutting-edge solution to the challenges faced by manufacturers and engineers around the world.Biaxial Cloth, produced by {Company Name}, is a revolutionary reinforcement material that combines strength, durability, and versatility in a single product. Made from high-quality fibers and engineered through state-of-the-art manufacturing processes, Biaxial Cloth offers unparalleled performance and reliability in a wide range of applications.One of the key features of Biaxial Cloth is its biaxial orientation, which provides equal strength in both the warp and weft directions. This unique characteristic allows for enhanced load-bearing capacity and superior impact resistance, making it an ideal choice for strengthening and reinforcing structural components. Whether used as a composite material in the construction of aircraft wings, the hulls of racing yachts, or the chassis of high-performance vehicles, Biaxial Cloth offers a level of durability and structural integrity that is unmatched by traditional reinforcement materials.Furthermore, Biaxial Cloth is designed to be highly customizable, allowing for tailored solutions to meet the specific requirements of different applications. This flexibility in design and manufacturing makes it possible to optimize the performance of Biaxial Cloth for a wide range of uses, from lightweight and high-strength applications in the aerospace industry to heavy-duty and impact-resistant components in the marine and automotive sectors.The benefits of Biaxial Cloth are not only limited to its mechanical properties, but also extend to its ease of use and efficiency in production. Its consistent and uniform construction allows for easy handling and processing, while its compatibility with various resins and manufacturing methods makes it a cost-effective and efficient solution for manufacturers and engineers. This ease of integration into existing production processes further enhances the appeal of Biaxial Cloth as a reliable and versatile reinforcement material.In addition to its outstanding mechanical and manufacturing properties, Biaxial Cloth is also environmentally friendly. By utilizing sustainable and recyclable materials in its production, {Company Name} is committed to reducing its environmental impact and promoting a greener and more sustainable future for the industry.As a leading manufacturer of advanced reinforcement materials, {Company Name} has a proven track record of delivering high-quality and innovative solutions to a diverse range of industries. With years of experience and expertise in material science and engineering, {Company Name} has positioned itself at the forefront of the industry, driving forward the development and adoption of new and advanced materials such as Biaxial Cloth.In conclusion, Biaxial Cloth represents the next generation of reinforcement materials, offering an unparalleled combination of strength, durability, and versatility. With its biaxial orientation, customizable design, ease of use, and environmental sustainability, Biaxial Cloth is poised to revolutionize the way structural components are reinforced and strengthened across various industries. As a flagship product of {Company Name}, Biaxial Cloth is a testament to the company's commitment to innovation, quality, and sustainability, and a clear demonstration of its leadership in the field of advanced materials.

High-Quality Lightweight Fiberglass Fabric for Various Applications

Company Introduction:{Company Name} is a leading manufacturer of lightweight fiberglass fabric. The company has been in the industry for over 20 years and has built a strong reputation for producing high-quality, innovative products. {Company Name} is committed to providing customers with advanced materials that offer superior performance and reliability. With a focus on research and development, the company continues to push the boundaries of what is possible in the field of fiberglass fabric production.News Content:In today's fast-paced world, lightweight and durable materials are in high demand across a wide range of industries. {Company Name} has always been at the forefront of developing cutting-edge fiberglass fabric that meets these requirements, and their latest innovation is no exception. The company has recently introduced a new lightweight fiberglass fabric that is set to revolutionize the industry.This new fiberglass fabric, known as {Product Name}, is the result of years of research and development by {Company Name}’s team of experts. By utilizing advanced manufacturing techniques and proprietary technology, the company has been able to produce a fabric that is significantly lighter than traditional fiberglass materials, without compromising on strength or durability. This breakthrough in lightweight fabric technology is poised to have a major impact on industries such as aerospace, automotive, marine, and sporting goods.{Product Name} offers a number of key advantages over traditional fiberglass fabrics. Its lightweight nature makes it ideal for applications where weight savings are critical, such as in aircraft and automotive components. The fabric's exceptional strength-to-weight ratio also makes it an attractive option for high-performance sporting equipment, where durability and lightness are essential. Additionally, {Product Name} is highly resistant to corrosion and offers excellent thermal and electrical insulation properties, making it a versatile material for a wide range of applications.The launch of {Product Name} has generated significant excitement within the industry, with many experts praising {Company Name} for their innovative approach to material science. "The introduction of {Product Name} represents a significant advancement in the field of lightweight materials," said John Smith, a materials engineer at a leading aerospace company. "This fabric has the potential to revolutionize the design and performance of a wide range of products, and we are excited to explore its applications in our industry."In addition to its technical advantages, {Product Name} also offers environmental benefits. Its lightweight nature means that less material is required to achieve the same level of performance as traditional fiberglass fabrics, resulting in reduced waste and lower energy consumption during production. Furthermore, the fabric's exceptional durability means that products made with {Product Name} are likely to have a longer lifespan, further reducing their environmental impact.{Company Name} is confident that {Product Name} will be well-received by customers across various industries, and they are already working with key partners to explore new applications for the fabric. "We believe that {Product Name} has the potential to unlock new possibilities in material design and engineering," said Sarah Johnson, the CEO of {Company Name}. "We are excited to see how our customers will utilize this innovative fabric to create breakthrough products that were previously not possible."As {Company Name} continues to push the boundaries of lightweight fiberglass fabric technology, it is clear that their commitment to innovation and excellence will continue to drive the industry forward. With the introduction of {Product Name}, the company has once again demonstrated its ability to develop advanced materials that meet the evolving needs of modern manufacturing. This latest innovation is a testament to {Company Name}’s dedication to providing customers with the best possible solutions for their material needs.

Durable Fire Resistant Fiberglass Fabric: A Reliable Choice for Safety

Fire Resistant Fiberglass FabricFire accidents can cause substantial damage to property and endanger lives. However, with advanced technology and innovative materials, it is possible to mitigate the impact of such accidents. One such material is Fire Resistant Fiberglass Fabric, which has gained widespread usage in various industries due to its ability to withstand high temperatures and prevent the spread of fire.The Fire Resistant Fiberglass Fabric is a type of textile material that is made from fine strands of glass. These strands are woven together to form a flexible and durable fabric that is highly resistant to heat and fire. The fabric is treated with special coatings to enhance its fire-resistant properties, making it an ideal choice for applications where fire safety is of utmost importance.One company that has been at the forefront of producing high-quality Fire Resistant Fiberglass Fabric is {}. With a rich history dating back to several decades, {} has established itself as a leading manufacturer and supplier of fire-resistant materials. The company's state-of-the-art manufacturing facilities and rigorous quality control processes ensure that their Fire Resistant Fiberglass Fabric meets the highest industry standards for fire safety and performance.{} offers a wide range of Fire Resistant Fiberglass Fabric products, catering to diverse applications across industries such as construction, automotive, aerospace, and marine. The fabric is available in different weights, thicknesses, and finishes to suit the specific requirements of different applications. Whether it is for use in fire curtains, protective clothing, insulation materials, or industrial equipment, {} provides customized solutions to meet the unique needs of its customers.In addition to its exceptional fire-resistant properties, the Fire Resistant Fiberglass Fabric from {} also offers other advantages such as high tensile strength, chemical resistance, and durability. This makes it a versatile material that can withstand harsh environments and provide long-term protection against fire hazards.The applications of Fire Resistant Fiberglass Fabric are wide-ranging. In the construction industry, it is used for creating fire barriers and protective enclosures in buildings to contain the spread of fire and prevent structural damage. In the automotive and aerospace sectors, the fabric is used for heat insulation and fireproofing in vehicles and aircraft. In the marine industry, it serves as a key material for manufacturing fire-resistant clothing and safety equipment for seafarers.With an increasing emphasis on fire safety regulations and standards across industries, the demand for Fire Resistant Fiberglass Fabric is on the rise. Companies like {} are playing a crucial role in meeting this demand by providing reliable and high-performance fire-resistant materials. By continuously investing in research and development, {} strives to innovate and develop advanced Fire Resistant Fiberglass Fabric solutions that offer superior protection against fire hazards.As a responsible and customer-oriented company, {} is committed to ensuring the quality and safety of its Fire Resistant Fiberglass Fabric. The company adheres to strict regulatory guidelines and performs comprehensive testing to guarantee the performance and reliability of its products. This dedication to quality has earned {} a reputation for being a trusted and dependable partner for fire safety solutions.In conclusion, Fire Resistant Fiberglass Fabric is a critical material for minimizing the risks associated with fire incidents. With its exceptional fire-resistant properties and diverse applications, it has become an indispensable component in various industries. Companies like {} are instrumental in advancing the development and availability of high-quality Fire Resistant Fiberglass Fabric, contributing to a safer and more secure environment for people and assets.

Fiber, USA-made Carbon Fiber, Benefits of Plain Weave Carbon FiberCarbon fiber is a popular material that has become a staple in various industries. It possesses excellent properties, such as high strength-to-weight ratio, corrosion resistance, and fatigue resistance, among others. Manufacturers often use carbon fiber to produce lightweight and durable products, including automotive parts, aerospace components, sports equipment, and more. One type of carbon fiber that manufacturers commonly use is plain weave carbon fiber.Plain weave carbon fiber is a type of carbon fiber that uses a basic over-and-under weaving pattern to produce a tight, symmetric weave. This weaving pattern results in a checkerboard-like appearance on the surface of the carbon fiber. Compared to other weaving patterns, such as twill and satin, plain weave carbon fiber is less expensive, has a lower profile, and has a more uniform surface texture.One of the benefits of using plain weave carbon fiber is its improved mechanical properties. Its tightly woven pattern gives it increased tensile strength, stiffness, and resistance to deformation. Plain weave carbon fiber also has better fatigue resistance than other weaving patterns, making it ideal for applications that undergo repeated stress and strain.Another benefit of using plain weave carbon fiber is its ability to create a smooth and uniform surface finish. Its tight weave pattern produces a more consistent surface texture, which is especially useful for aesthetic applications. Manufacturers often use plain weave carbon fiber for parts that require painting, as it provides a smooth and even surface for paint to adhere to.Plain weave carbon fiber is also compatible with various resin systems, such as epoxy, polyester, and vinyl ester. This compatibility allows manufacturers to tailor the mechanical properties of plain weave carbon fiber to specific applications. They can adjust the resin-to-fiber ratio, curing temperature, and curing time to achieve the desired properties.At Elevated Materials, we take pride in producing USA-made carbon fiber products, including our plain weave carbon fiber sheets. We use high-quality materials and state-of-the-art equipment to manufacture our carbon fiber products. Our plain weave carbon fiber sheets are available in various thicknesses and sizes to accommodate different applications. Whether you need carbon fiber sheets for automotive, aerospace, or industrial use, we have the right product for you.In conclusion, plain weave carbon fiber is an excellent choice for lightweight and durable applications that require improved mechanical properties and uniform surface finish. Its basic over-and-under weaving pattern results in a more affordable and uniform surface texture, making it ideal for aesthetic applications. If your project requires high-quality, USA-made plain weave carbon fiber sheets, look no further than Elevated Materials.

Revolutionize Your Wardrobe with Cutting-Edge Carbon Fiber Clothing Fabric

Carbon Fiber Clothing Fabric: Revolutionizing the Future of FashionIn recent years, a remarkable breakthrough in the fashion industry has captivated the attention of both fashion enthusiasts and technology enthusiasts alike. Carbon Fiber Clothing Fabric, a cutting-edge innovation, has emerged as a game-changer that combines style and functionality. With its unique properties and endless possibilities, this fabric has the potential to revolutionize the future of fashion.As a leading research and development company in advanced textiles, {Company Name} has been at the forefront of this groundbreaking technology. With their expertise in material science and commitment to sustainability, they have successfully created a carbon fiber clothing fabric that is both lightweight and incredibly strong. This fabric opens up a world of opportunities for designers, athletes, and everyday consumers.One of the most notable features of carbon fiber clothing fabric is its exceptional strength-to-weight ratio. Thanks to the inherent properties of carbon fibers, garments made from this fabric are incredibly robust while remaining lightweight. This revolutionary fabric can withstand rigorous activities, making it an ideal choice for athletes, adventurers, and outdoor enthusiasts.The durability of carbon fiber clothing fabric is nothing short of impressive. Unlike conventional fabrics, it resists wear and tear, making it long-lasting and ensuring that the garments maintain their shape and appearance over time. This durability translates to a reduction in the environmental impact of the fashion industry, as fewer garments need to be produced and discarded.Moreover, carbon fiber clothing fabric is highly breathable and moisture-wicking, enabling optimal comfort in various climates and physical activities. Its ability to regulate body temperature is essential for athletes and individuals engaging in intense workouts. This exceptional fabric also provides UV protection, safeguarding the wearer from harmful rays. With these functional attributes, carbon fiber clothing fabric is an ideal choice for both performance wear and daily attire.Beyond its functional properties, carbon fiber clothing fabric also offers endless design possibilities. Its sleek and futuristic aesthetic adds a touch of modernity to any garment. Designers can experiment with various cuts, shapes, and textures, enabling them to create unique and avant-garde pieces that stand out in the fashion industry. The versatility of this fabric makes it suitable for both high-end fashion collections and everyday wear.Furthermore, the production of carbon fiber clothing fabric aligns with {Company Name}'s commitment to sustainability and environmental responsibility. The manufacturing process of this fabric uses significantly fewer resources compared to traditional textiles. With a lower carbon footprint and reduced waste generation, carbon fiber clothing fabric is a step forward in creating a more sustainable fashion industry.{Company Name} aims to make carbon fiber clothing fabric accessible to a wider audience by collaborating with renowned fashion brands and retailers. This partnership will ensure that consumers have the opportunity to experience the unparalleled benefits of this fabric in their everyday lives. The company also actively promotes education and awareness regarding the environmental impact of the fashion industry, striving to inspire positive change in consumer behavior.In conclusion, Carbon Fiber Clothing Fabric represents a significant breakthrough in the fashion industry, blending style, performance, and sustainability. Thanks to innovative companies like {Company Name}, this fabric is on the cusp of transforming the way we think about clothing. From durable sportswear to high-end fashion creations, the possibilities are endless. By embracing carbon fiber clothing fabric, we are embracing a future where fashion and functionality go hand in hand.

Exploring the Benefits of Carbon Fabric PrepregsCarbon fiber reinforced polymers are revolutionizing modern manufacturing by providing lightweight, high-performance material solutions for a wide range of applications. One of the most significant developments in this field is the production of Prepregs.Prepregs are a type of composite material that consists of a reinforcing fabric such as carbon, glass, or aramid (Kevlar) impregnated with a thermoset resin. This results in a ready-to-use composite material that can be easily formed into the desired shape and then cured to create a strong, durable, and lightweight part.Prepregs are produced by combining a reinforcing fabric and a thermoset resin system. The resin is typically in a B-staged state, meaning that it has been partially cured but remains tacky and can be handled without sticking to surfaces. This makes it easy to lay the fabric onto the sticky resin, which is then rolled to remove air bubbles and achieve an even distribution of the resin. The Prepreg is then packaged and stored in a cold environment to prevent the resin from fully curing.Carbon Fabric Prepregs have several advantages over traditional composite materials. First, Prepregs offer superior mechanical properties with high strength-to-weight ratios, which is a key characteristic of carbon fiber reinforced polymers. The reinforcing fabric provides the material with high strength and stiffness, while the resin system provides protection from environmental degradation and impact damage.Another significant benefit of Prepregs is their ease of use. Using Prepregs eliminates the need for expensive or complex tooling, as the material can be easily formed into the desired shape using common tools such as molds, rollers, and vacuum bagging. This reduces production time and costs, resulting in a more economical manufacturing process.Additionally, Prepregs enable increased design flexibility, as they can be customized to meet specific customer requirements. The choice of reinforcement fibers, resin systems, and manufacturing protocols can be optimized to suit the application and performance needs. This allows manufacturers to create parts that are tailored to their unique needs, resulting in more efficient and reliable products.Moreover, Carbon Fabric Prepregs are well-suited for a wide range of applications, including aerospace, automotive, marine, and sporting goods. Composites made from Prepregs are used in a variety of components, such as aircraft panels, automobile body parts, boat hulls, and bicycle frames. These applications benefit from the material's high strength-to-weight ratio, durability, and resistance to temperature and chemical degradation.In conclusion, Prepregs containing carbon fabric offer tremendous benefits to manufacturers looking for reliable and high-performance composite materials. The ease of use, increased design flexibility, and outstanding mechanical properties make Prepregs an ideal choice for a wide range of applications. Carbon Fabric Prepregs are changing the way manufacturers approach material selection, opening up new possibilities for lightweight, high-performance products that meet the needs of today's demanding markets.

Durable and Versatile Mesh Tape: Ideal Solution for Repairing and Reinforcing Home Surfaces

Glass Mesh Tape Revolutionizes the Construction IndustryThe construction and renovation industry is constantly evolving, with new materials and techniques being introduced to enhance the quality and durability of buildings. One such innovation that has garnered attention and revolutionized the industry is Glass Mesh Tape (brand name removed), a cutting-edge product that has gained praise for its exceptional performance and versatility.Glass Mesh Tape is a high-quality adhesive tape infused with glass fibers, which gives it incredible strength and durability. Initially designed to reinforce joints and seams in drywall installations, this tape has quickly gained popularity among contractors and DIY enthusiasts due to its numerous advantages over traditional options.One of the key features of Glass Mesh Tape is its superior tensile strength. The integration of glass fibers into the tape makes it significantly stronger than regular paper or fiberglass mesh tape. This enhanced strength provides better resistance against cracking and ensures long-lasting joints, ultimately improving the overall integrity of the walls or ceilings where it is applied.The advanced technological composition of Glass Mesh Tape also makes it highly resistant to moisture. Unlike traditional paper tapes that can easily deteriorate when exposed to water or humidity, this tape is designed to withstand challenging environments without losing its adhesive properties or structural integrity. This feature makes it an ideal choice for applications in areas prone to moisture, such as bathrooms and basements.In addition, Glass Mesh Tape exhibits exceptional adhesive properties. Its pressure-sensitive adhesive backing allows it to firmly bond with different surfaces, ensuring seamless integration with the drywall. This not only makes installation hassle-free but also prevents the tape from peeling or detaching over time, guaranteeing a neat and professional finish.What truly sets Glass Mesh Tape apart is its versatility. Beyond drywall applications, this tape can be effectively used across various construction projects. It works exceptionally well for patching holes, repairing cracks, and reinforcing corners. Furthermore, it can be applied on both flat and curved surfaces, making it suitable for a wide range of projects, from residential renovations to commercial construction.The company behind Glass Mesh Tape, recognized as a leader in the industry, is committed to producing innovative, high-quality products. With a focus on research and development, they continuously strive for advancements that meet the evolving needs of professionals in the industry.The production process of Glass Mesh Tape adheres to stringent quality control measures. Each roll is thoroughly tested to ensure consistent performance and durability. This dedication to quality has earned the company a reputation for delivering products that exceed expectations and provide unmatched reliability.Moreover, the company places great importance on sustainability. Glass Mesh Tape is manufactured using eco-friendly materials, reducing its environmental footprint. By using renewable resources and employing energy-efficient manufacturing practices, the company actively contributes to a greener and more sustainable future.The widespread adoption of Glass Mesh Tape has significantly improved construction practices. Its exceptional strength, resistance to moisture, versatile applications, and commitment to quality and sustainability have made it an indispensable tool for professionals and homeowners alike. With this innovative product, the construction industry is well on its way to achieving greater durability and longevity in building structures.