High-Quality Fiberglass Mat Cloth: A Breakthrough Innovation in Construction Materials

By:Admin

The Fiberglass Mat Cloth is a non-woven material made from glass fibers that are bonded together using a unique resin. This results in a strong and lightweight fabric that is ideal for a wide range of applications. The material is available in various thicknesses and can be customized to meet specific project requirements, making it a popular choice for many industries.

One of the key features of Fiberglass Mat Cloth is its exceptional strength and durability. The material is highly resistant to heat, chemicals, and corrosion, making it suitable for use in harsh environments. It also has excellent tensile strength, meaning it can withstand heavy loads without losing its shape or integrity. This makes it an ideal material for reinforcing structures and components in construction and manufacturing.

In addition to its strength, Fiberglass Mat Cloth is also known for its versatility. It can be easily molded and shaped to fit the contours of different surfaces, making it suitable for a wide range of applications. Whether it's used as a reinforcing material in concrete or as a protective layer in composite materials, the possibilities are endless.

Furthermore, Fiberglass Mat Cloth is also highly resistant to moisture, making it an ideal choice for outdoor and marine applications. Its non-corrosive properties make it ideal for use in boats, bridges, and other structures exposed to water and harsh weather conditions.

The company behind Fiberglass Mat Cloth has been a leader in the industry for over 20 years, consistently delivering high-quality products to their customers. Their state-of-the-art manufacturing facilities and dedicated research and development team have enabled them to stay ahead of the curve and continue to innovate in the field of fiber-reinforced materials.

With a strong focus on quality and customer satisfaction, the company has built a reputation for reliability and excellence. Their commitment to innovation and product development has led to the creation of Fiberglass Mat Cloth, a product that is set to revolutionize the industry.

The company's extensive experience and expertise in the field of fiber-reinforced materials have allowed them to develop Fiberglass Mat Cloth to meet the growing demands of the construction and manufacturing industries. Their dedication to quality and innovation has made Fiberglass Mat Cloth a popular choice among leading companies in various sectors.

As the demand for durable and versatile materials continues to grow, Fiberglass Mat Cloth is well-positioned to become a go-to choice for companies looking to strengthen their structures and components. With its exceptional properties and the backing of a reputable company, this innovative material is set to make a significant impact on the industry.

In conclusion, Fiberglass Mat Cloth is a game-changing material that is set to revolutionize the construction and manufacturing industry. With its exceptional strength, durability, and versatility, it is an ideal choice for a wide range of applications. Backed by a leading company with a strong track record of delivering high-quality products, Fiberglass Mat Cloth is poised to become a staple in the industry for years to come.

Company News & Blog

Fiberglass Woven Roving Manufacturers and Suppliers from China for Your Varied Needs

China’s fiberglass industry has been growing rapidly, with manufacturers such as Huili Fiberglass Woven Roving leading the charge. With a commitment to providing high-quality products, this company has become one of the most trusted suppliers of fiberglass woven roving in the country. Thanks to its state-of-the-art facilities and skilled staff, it has been able to deliver top-notch products to clients in China and overseas.Fiberglass woven roving is a versatile material used in various industries. It is made of long continuous glass fibers that are woven together to form a cloth-like material. It is known for its high tensile strength, resistance to chemicals, and excellent dimensional stability. These properties make it a popular choice for manufacturers of boats, wind turbines, and many other products.As one of the leading fiberglass woven roving suppliers in China, Huili Fiberglass Woven Roving has been able to produce the material in a range of specifications to meet the varied demands of its clients. Its product line includes E-glass, C-glass, chopped strand mat, and stitched mat, among others. This variety has made it possible for the company to serve a broad customer base that includes construction companies, yacht builders, and wind turbine manufacturers, among others.In addition to its high-quality products, Huili Fiberglass Woven Roving has built a solid reputation for excellent customer service. Its staff is knowledgeable about the products and has been trained to assist clients in selecting the most suitable products for their needs. This level of service has helped the company to build long-term relationships with its clients, who continue to rely on it for their fiberglass woven roving needs.To further boost its production capabilities, Huili Fiberglass Woven Roving has invested heavily in its facilities and equipment. Its production lines are fully automated, ensuring that the manufacturing process is efficient, consistent, and of high quality. Additionally, the company has implemented strict quality control measures to guarantee the quality of its products, which meet the highest international standards.Huili Fiberglass Woven Roving also places a high value on sustainability. As a responsible corporate citizen, it has implemented environmentally friendly processes throughout its operations. This has enabled it to reduce its carbon footprint and minimize its impact on the environment.In conclusion, Huili Fiberglass Woven Roving has emerged as one of the most trusted fiberglass woven roving suppliers in China. With its commitment to quality, excellent customer service, and sustainability, it has been able to build a loyal customer base both in China and overseas. As the demand for fiberglass woven roving continues to grow, this company is well-positioned to meet the needs of its clients and maintain its position as one of the leading suppliers of this vital material.

Discover the Advantages of Carbon Quadraxial Fabric for Enhanced Performance

[Assistant]Title: Revolutionary Carbon Quadraxial Fabric Redefines Composite Material IndustryIntroduction:In an exciting breakthrough, a leading company in the field of advanced materials has unveiled a revolutionary product that promises to reshape the composite material industry. Carbon Quadraxial Fabric (CQF), a game-changing innovation, is set to enhance the performance and capabilities of numerous industries, ranging from aerospace and automotive to sports and recreation. With its exceptional strength, versatility, and manufacturing flexibility, CQF is primed to become a go-to material for engineers and designers worldwide.Main Body:1. Understanding Carbon Quadraxial Fabric: Carbon Quadraxial Fabric is manufactured using advanced technologies that ingeniously weave together high-tensile carbon four-axis filament yarns. This proprietary weaving technique results in a fabric that boasts superior mechanical properties, including exceptional strength, stiffness, and fatigue resistance. Unlike traditional carbon fabrics, CQF also exhibits reduced delamination and improved impact resistance, making it an ideal choice for demanding applications.2. The Unprecedented Versatility of CQF: The unique characteristics of Carbon Quadraxial Fabric allow it to be utilized across a wide array of industries, offering benefits that surpass those of traditional materials. From lightweight structural components in the aerospace sector to high-performance body panels in the automotive industry, CQF offers heightened strength-to-weight ratios without compromising durability. Additionally, its exceptional resistance to chemicals and extreme temperatures makes it valuable in industrial settings.3. Revolutionizing Aerospace Manufacturing: The aerospace industry, in particular, stands to benefit immensely from Carbon Quadraxial Fabric. The material's exceptional strength and stiffness make it a perfect fit for designing and manufacturing aircraft components. By utilizing CQF, aerospace engineers can achieve increased fuel efficiency, reduced maintenance costs, and improved overall performance. Moreover, CQF's low thermal expansion properties make it a preferred choice for applications requiring stability at varying temperatures.4. Application in Automotive Engineering: Automotive manufacturers are eagerly embracing the potential of Carbon Quadraxial Fabric for its ability to enhance vehicle performance and fuel efficiency. Lightweight components made with CQF allow designers to reduce vehicle weight while maintaining structural integrity, leading to improved handling, reduced emissions, and increased overall energy efficiency. Additionally, CQF's impact resistance properties contribute to increased passenger safety.5. Impacting Sporting and Recreational Industries: Sports and recreational equipment manufacturers are also recognizing the tremendous advantages of Carbon Quadraxial Fabric. From high-performance bicycles and tennis rackets to skis and golf clubs, CQF's exceptional strength and stiffness provide athletes with a competitive edge. Its lightweight nature also enables enthusiasts to enjoy more comfortable and energy-efficient experiences.Conclusion:The introduction of Carbon Quadraxial Fabric onto the market represents a significant watershed moment in the composite material industry. This cutting-edge technology promises to revolutionize various sectors, offering unparalleled strength, versatility, and durability. As CQF gains widespread adoption, industries can expect to witness exponential advancements in product performance, design, and sustainability. With limitless possibilities in fields ranging from aerospace and automotive engineering to sports and recreation, Carbon Quadraxial Fabric is poised to redefine the future of advanced materials.

Carbon fiber is one of the most popular materials used in various industries because of its distinct features. It is known to have high strength-to-weight ratio, which makes it an ideal material for various applications like aerospace, defense, and sports equipment. Another benefit of carbon fiber is its versatility, making it possible to be formed into different shapes and sizes.One of the most important processes in manufacturing carbon fiber products is cutting and marking. With the help of laser technology, cutting and marking carbon fiber have become more accurate, fast, and efficient. Here are some of the benefits of using laser cutting and marking for carbon fiber:Precision and AccuracyLaser technology offers high precision and accuracy when it comes to cutting and marking carbon fiber. It ensures that the fabric is cut or marked according to the exact specifications needed for a specific product. With the precision offered by laser cutting and marking, there is limited room for errors, making the process more efficient and resulting in better quality products.Speed and EfficiencyLaser cutting and marking carbon fiber is also fast and efficient compared to traditional methods. The laser equipment is computer-controlled, which means that it can make precise cuts and marks in a shorter time than manual processes. This allows for faster production times, enabling manufacturers to produce more products in a shorter amount of time.Clean and Smooth FinishLaser cutting and marking carbon fiber also offer a clean and smooth finish, which is critical in the production of carbon fiber products. The laser technology ensures that the edges of the fabric are smooth and clean, which reduces the risk of fraying or unraveling. Moreover, the precision of the laser ensures that a high-quality finish is achieved every time, providing consistency in the manufacturing process.VersatilityLaser cutting and marking machines are versatile and can be used on different types of carbon fiber cloth fabric. This means that they can be used for various products, regardless of the shape and size of the material. Additionally, laser technology allows for the customization of the cutting and marking process, ensuring that specific products are created according to individual needs.Cost-EffectiveUsing laser cutting and marking for carbon fiber is cost-effective in the long run. It reduces the need for manual labor, which in turn reduces the costs associated with human labor. Additionally, the precision and accuracy of laser cutting and marking result in a reduction of material waste, which also saves on production costs.ConclusionLaser cutting and marking carbon fiber offer several benefits that make the manufacture of carbon fiber products more efficient, accurate, and cost-effective. The precision, speed, and versatility of laser technology allow manufacturers to create products that meet specific needs while also maintaining consistency in the manufacturing process. Furthermore, the clean and smooth finish of the material ensures that the final product is of high quality, providing an excellent user experience. By taking advantages of the benefits of laser technology, manufacturers can produce high-quality carbon fiber products that meet the varied needs of different industries and consumers.

High-quality Mesh Tape for Glass Repairs: A Must-Have for DIY Enthusiasts

[Company Name] Introduces Innovative Glass Mesh Tape for Superior Strength and Durability[City, State] – [Company Name], a leading manufacturer of construction materials, has introduced a new and innovative product to their line-up – Glass Mesh Tape. This tape is designed to provide superior strength and durability to various construction and renovation projects, making it an ideal choice for both professional contractors and DIY enthusiasts.The Glass Mesh Tape is made from high-quality fiberglass mesh, which provides exceptional tensile strength and resistance to tearing and cracking. This makes it an ideal choice for reinforcing joints and corners in drywall installation, as well as for repairing cracks and holes in walls and ceilings. The tape is also coated with a high-quality adhesive that ensures a strong and long-lasting bond, making it suitable for use in both indoor and outdoor applications.One of the key features of [Company Name]'s Glass Mesh Tape is its self-adhesive property, which eliminates the need for additional adhesives or compounds during installation. This not only speeds up the installation process but also results in a cleaner and more professional finish. Additionally, the tape is highly flexible and easy to cut, allowing for seamless application around corners and curves.In addition to its exceptional strength and durability, the Glass Mesh Tape is also resistant to mold and mildew, making it an ideal choice for use in damp or humid environments such as bathrooms, kitchens, and basements. This adds an extra layer of protection and longevity to the finished walls and ceilings, ensuring that they remain in top condition for years to come."We are thrilled to introduce our Glass Mesh Tape to the market," said [Spokesperson Name], spokesperson for [Company Name]. "We have always been committed to providing innovative and high-quality products to our customers, and this tape is a testament to that commitment. Whether you are a professional contractor or a DIY enthusiast, our Glass Mesh Tape is sure to meet and exceed your expectations in terms of strength, durability, and ease of use."[Company Name] has a long-standing reputation for delivering top-of-the-line construction materials, and their Glass Mesh Tape is just the latest addition to their impressive product line. With a focus on innovation, quality, and customer satisfaction, the company has become a trusted name in the construction industry, known for providing reliable and high-performance products that professionals and homeowners can rely on.The Glass Mesh Tape is now available for purchase through [Company Name]'s extensive network of distributors and retailers, as well as online through their website. With its exceptional strength, durability, and ease of use, this tape is set to revolutionize the way construction and renovation projects are approached, providing a reliable and efficient solution for reinforcing joints and repairing cracks and holes with ease.For more information about [Company Name] and their innovative Glass Mesh Tape, visit [Company Website] or contact their customer service team at [Phone Number].

24oz Vermiculite Coated Fiberglass Cloth: A Fire and Chemical Resistant Solution for High Temperature Insulation and Welding Applications

Acmetex Inc Launches Revolutionary 24oz Vermiculite Coated Fiberglass ClothAcmetex Inc, a leading manufacturer of high-performance fiberglass cloth and textile products, has announced the launch of its latest innovation, the 24oz Vermiculite Coated Fiberglass Cloth. This new product brings cutting-edge technology and design to the market, providing customers with an advanced and reliable solution for their high-temperature insulation and fire-resistant needs.Acmetex's 24oz Vermiculite Coated Fiberglass Cloth is made from continuous texturized E-fiberglass yarns, which offer exceptional strength and durability. These yarns are woven together to create a tight, dense fabric that can withstand high temperatures and harsh conditions. Vermiculite coating is added to the cloth to improve abrasion resistance and add an extra layer of protection against direct flame.Heat travels across the fabric, not through it, making this product an excellent choice for high-temperature insulation and heat shield applications. It provides superior thermal insulation, keeping heat from escaping and cold from seeping in, making it ideal for use in welding blankets, curtains, and expansion joints. The vermiculite coating also improves the cloth's strength and resistance to tearing, making it a great option for high-stress applications.Acmetex Inc has been a leading manufacturer of fiberglass cloth and textile products for over 20 years. The company has a proven track record of providing high-quality solutions to customers across a wide range of industries, including automotive, aerospace, marine, and construction. Acmetex's commitment to innovation and quality has made it a trusted partner for many leading companies in these industries."We are excited to launch our latest innovation, the 24oz Vermiculite Coated Fiberglass Cloth," said a spokesperson for Acmetex Inc. "This new product is a testament to our commitment to providing our customers with the highest quality solutions for their needs. We believe that this product will be a game-changer in the market, and we are confident that it will be very well received by our customers."Acmetex's 24oz Vermiculite Coated Fiberglass Cloth is available in a variety of widths and lengths, making it suitable for a wide range of applications. It is also customizable, allowing customers to tailor the fabric to meet their specific needs. The product is expected to be available for purchase on Acmetex's website and through its authorized distributors in the coming weeks.In conclusion, Acmetex Inc's 24oz Vermiculite Coated Fiberglass Cloth is a breakthrough product that offers exceptional strength, durability, and fire-resistant properties. It is a testament to the company's commitment to innovation and quality and a clear demonstration of its ability to bring cutting-edge solutions to the market. This product is sure to be a game-changer and a valuable asset for customers across a wide range of industries.

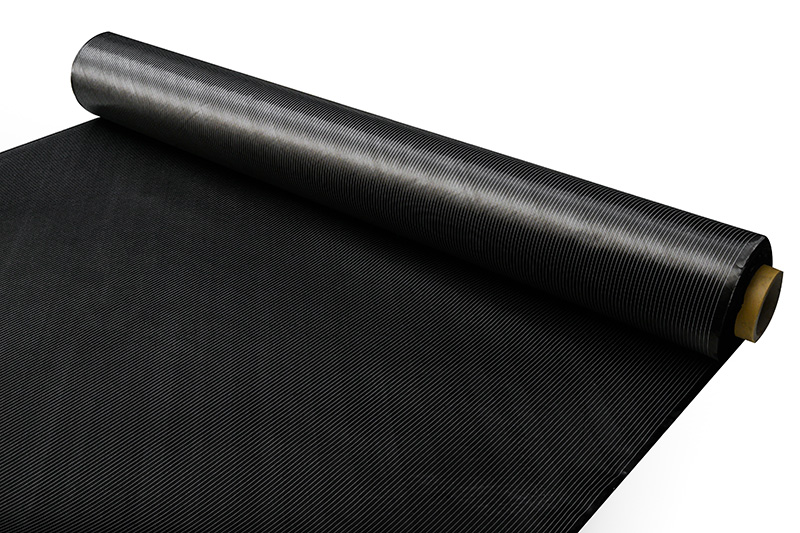

Durable and Versatile Black Fiberglass Fabric: A Must-Have Material for Your Project

Black Fiberglass Fabric, offered by the leading company in the industry, is making waves in the world of manufacturing. This innovative material is being praised for its exceptional properties which make it ideal for various applications across many different industries.The company, with its extensive experience and expertise in the production of high-quality and reliable fiberglass fabrics, has established itself as a reputable and trusted supplier of this cutting-edge material. With a strong commitment to delivering top-notch products and superior customer service, the company has earned the trust and loyalty of its clients from around the world.The Black Fiberglass Fabric offered by the company is designed to meet the diverse needs of its customers. This versatile material is known for its outstanding strength, flexibility, and durability. Its high tensile strength and excellent resistance to chemicals, heat, and moisture make it an ideal choice for a wide range of applications.In the automotive industry, Black Fiberglass Fabric is used for manufacturing components such as body panels, engine covers, and interior trims. Its exceptional thermal insulation properties and lightweight nature make it perfect for reducing vehicle weight and improving fuel efficiency. Additionally, its resistance to corrosion and high temperature makes it a popular choice for the construction of exhaust systems and other engine components.In the construction industry, the Black Fiberglass Fabric is widely used for reinforcing concrete and plaster, providing added strength and stability to structures. Its resistance to weather, fire, and chemicals makes it an excellent material for building facades, insulation, and roofing materials. The fabric's ability to withstand harsh environmental conditions has made it a preferred choice for construction projects in various locations around the world.The aerospace industry also benefits from the exceptional properties of Black Fiberglass Fabric. Its high strength-to-weight ratio and resistance to extreme temperatures make it an essential material for the production of aircraft components, such as wings, fuselage, and interior panels. Its flexibility and ease of molding allow for the creation of complex shapes and forms, contributing to the efficiency and performance of aircraft designs.Moreover, Black Fiberglass Fabric has found applications in the marine industry, where its resistance to saltwater, UV rays, and harsh weather conditions make it an ideal choice for boat building and marine equipment. Its ability to endure the challenging marine environment while maintaining its structural integrity has made it a preferred material for the construction of boat hulls, decks, and superstructures.With its wide range of applications and exceptional properties, Black Fiberglass Fabric continues to gain popularity across various industries. The company's commitment to delivering high-quality products and its dedication to meeting the needs of its customers have positioned it as a leader in the fiberglass fabric industry.The company's state-of-the-art manufacturing facilities, advanced production techniques, and stringent quality control processes ensure that the Black Fiberglass Fabric meets the highest industry standards. Furthermore, the company's experienced team of professionals provides technical support and expertise to assist customers in choosing the right material for their specific applications and requirements.As the demand for high-performance and reliable materials continues to grow, the Black Fiberglass Fabric offered by the company is set to play an even more significant role in shaping the future of manufacturing across various industries. With its exceptional properties and the company's strong commitment to excellence, the Black Fiberglass Fabric is poised to make a lasting impact and solidify its position as the material of choice for a wide range of applications.

High-Quality Fiberglass Cloth for Improved Strength and Durability

article, addressing the following:1. Briefly explain what fiberglass cloth 1708 is and its main uses.2. Discuss the unique features of fiberglass cloth 1708 that set it apart from other materials.3. Highlight the benefits that users can expect to enjoy when using fiberglass cloth 1708.4. Provide examples of companies that have used fiberglass cloth 1708 to achieve their objectives.5. Articulate the company's commitment to quality and customer satisfaction.6. Discuss the future of fiberglass cloth 1708 and the company's plans to improve its product offeringFiberglass Cloth 1708: An All-Round Reinforcement Solution Fiberglass cloth is known for its ability to resist moisture, fire, and corrosion while providing excellent adhesive properties and high tensile strength. It's extensively used in construction, automotive, marine, and aerospace industries. Fiberglass cloth 1708, in particular, is known for its incredible strength and versatility. It's considered one of the best all-round reinforcement fabrics thanks to its unique features.What is Fiberglass Cloth 1708?Fiberglass cloth 1708 comprises two layers of fiberglass fabric: one layer of biaxial reinforcement and another of chopped strand. The biaxial reinforcement layer reinforces the fabric in two directions, providing superior strength, while the chopped strand layer provides extra durability, making the fabric easy to handle. Unique Features of Fiberglass Cloth 1708Fiberglass cloth 1708 boasts unique features that set it apart from other materials in the market. Among these features is its high-resistance to water, chemicals, and UV radiation. The unique combining of the chopped strand and biaxial fabrics offers exceptional coverage, with the chopped strand layer preventing fraying, making it extremely easy to work with. The high strength and flexibility of fiberglass cloth 1708 make it a preferred material for use in applications with curves and edges. What's more, it's lightweight, which makes it ideal for transportation, facilitating handling of large structures. Benefits of Fiberglass Cloth 1708 Thanks to its unique features, users can enjoy various benefits when using fiberglass cloth 1708. The material offers excellent bonding properties, saving on adhesives, hence reducing overall production costs. Fiberglass cloth 1708 is also incredibly stiff and flexible, allowing the material to conform to various shapes and objects. Additionally, the cloth is non-porous, which ensures that it remains water-resistant, enhancing its lifespan and durability. Companies' Applications of Fiberglass Cloth 1708Fiberglass cloth 1708 has been used in a variety of applications across different industries. For example, the aviation industry uses the material to repair damage to the aircraft's fiberglass body parts. Fiberglass cloth 1708 has also been used in the marine industry for boat repairs, construction of boats, and various other marine applications such as wind turbine blades. In the automotive industry, fiberglass cloth 1708 is used for mold making, repairing old cars, and fixing fiberglass car parts. Company's Approach to Quality and Customer Satisfaction At our company, quality and customer satisfaction are among our primary objectives. We strive to ensure that we consistently produce high-quality products. We achieve this by maintaining a highly-skilled workforce that uses the latest technologies and processes to produce and test our fiberglass cloth 1708 products. The Future of Fiberglass Cloth 1708 and Its Product Offering Our company is committed to consistently improving our products to meet your ever-changing needs. To this end, we are continually adopting new technologies and processes to produce the best fiberglass cloth 1708. We're confident that our ongoing efforts will ensure that we remain leaders in the production of high-quality fiberglass cloth 1708 for years to come. Conclusion Fiberglass cloth 1708 is an incredible material known for its versatility and exceptional strength. It is no wonder that it's a reliable reinforcement solution for many companies across various industrial sectors such as marine, aerospace, and automotive, among others. Our company remains committed to producing high-quality products that meet your every need. Contact us today for all your fiberglass cloth 1708 needs!

New Carbon Fiber Cloth Technology: Stronger and more flexible than traditional materials

Cloth Carbon Fiber: A Game-Changer in the World of TextilesCarbon fiber has been steadily gaining popularity over the last few years, and for good reason. This durable, lightweight material has revolutionized many industries, including automotive, aerospace, and sports equipment. However, the world of textiles has been slower to adopt carbon fiber, due to the high cost and difficulty in manufacturing. That’s where Cloth Carbon Fiber comes in.Cloth Carbon Fiber is a company that specializes in producing high-quality carbon fiber textiles. Founded in 2010, the company has quickly become a leader in the industry, thanks to its innovative production methods and commitment to quality.One of the key features of Cloth Carbon Fiber’s textiles is their strength-to-weight ratio. Carbon fiber is incredibly strong, yet lightweight, making it an ideal material for textiles. This means that Cloth Carbon Fiber textiles are not only durable, but also very lightweight, making them perfect for a wide range of applications.The manufacturing process used by Cloth Carbon Fiber is also worth noting. Traditional carbon fiber production methods involve laying individual carbon fibers by hand, which is time-consuming and expensive. Cloth Carbon Fiber, on the other hand, uses an automated process that weaves the fibers together, greatly reducing production time and costs. This means that their carbon fiber textiles are more affordable and can be produced in larger quantities, making them more accessible to a wider range of customers.Cloth Carbon Fiber’s textiles have already made waves in the world of fashion and sportswear. Their carbon fiber fabrics have been used by designers to create unique, high-tech fashion pieces, and by athletic brands to create performance-enhancing clothing.But the applications for Cloth Carbon Fiber’s textiles extend far beyond fashion and sports. Carbon fiber’s strength, durability, and lightweight properties make it ideal for a wide range of applications, including construction, aerospace, and automotive.In the construction industry, Cloth Carbon Fiber’s textiles could be used to reinforce concrete structures, making them more resistant to earthquakes and other natural disasters. In the aerospace industry, carbon fiber is already widely used to make lightweight, yet strong components for planes and spacecraft. Cloth Carbon Fiber’s textiles could be used to create even more advanced components, helping to make space travel safer and more efficient.In the automotive industry, Cloth Carbon Fiber’s textiles could potentially revolutionize the way cars are made. Carbon fiber is already used in high-performance sports cars, but its high cost has made it impractical for mass-produced vehicles. However, Cloth Carbon Fiber’s more affordable textiles could change that, making it possible to create lightweight, fuel-efficient cars that are also durable and safe.Overall, the potential applications for Cloth Carbon Fiber’s textiles are vast and varied. Their innovative manufacturing process and commitment to quality have already established them as a leader in the industry, and their continued growth and expansion are sure to have a major impact on the world of textiles and beyond.

Fiberglass Cloth Roll and Resin: The Ultimate Guide for High-Quality Materials

Title: Advanced Fiberglass Cloth Roll and Resin for Enhanced Manufacturing ProcessesIntroduction:In the realm of manufacturing, the demand for reliable and high-quality materials is ever-increasing. Fiberglass has emerged as a crucial component in several industries, owing to its exceptional strength, durability, and versatility. Combining the robust properties of fiberglass cloth roll and resin, one company has emerged as a leading provider, delivering innovative solutions to meet the evolving needs of various sectors.Company Background:With over two decades of experience in the industry, {Company Name} has become a reputable and reliable supplier of fiberglass cloth roll and resin. Based on the principles of quality, innovation, and customer satisfaction, they have consistently proven their commitment to excellence. Their extensive range of top-notch fiberglass products has garnered them a loyal customer base.Advanced Fiberglass Cloth Roll:Fiberglass cloth roll is an integral component in manufacturing processes that require strength and flexibility. {Company Name}, through its relentless research and development efforts, has successfully developed an advanced fiberglass cloth roll that offers enhanced performance. The new fiberglass cloth roll boasts higher tensile strength, improved flame resistance, and increased resistance to chemical degradation.The company understands the significance of diverse application requirements, and hence, offers a wide range of options in terms of thickness, weave patterns, and styles, ensuring compatibility with various manufacturing processes. Industries such as automotive, aerospace, construction, and marine extensively benefit from the utilization of this advanced fiberglass cloth roll.High-Quality Resin:When it comes to ensuring the integrity and longevity of fiberglass-based products, the role of resin cannot be undermined. {Company Name} has strived to overcome the limitations of conventional resins by formulating a high-quality resin that complements their advanced fiberglass cloth roll. This resin excels in its ability to bond with the fiberglass cloth, providing excellent adhesion and increasing structural integrity.The improved resin combines ease of handling with rapid curing, thereby reducing production time and costs. Furthermore, its compatibility with various manufacturing processes, such as hand lay-up, vacuum infusion, and resin transfer molding, makes it a versatile choice for a multitude of industries.Applications and Benefits:The combination of advanced fiberglass cloth roll and high-quality resin has revolutionized manufacturing in numerous sectors. Some key applications and benefits of this innovation include:1. Automotive Industry: Fiberglass cloth roll and resin find applications in the production of lightweight body panels, reducing overall vehicle weight and enhancing fuel efficiency.2. Aerospace Industry: Utilizing advanced fiberglass cloth roll and resin in the fabrication of aircraft components results in improved strength-to-weight ratios, leading to enhanced performance and reduced maintenance costs.3. Construction Industry: The combination of these materials enables the production of durable and weather-resistant construction panels, ensuring longevity and reduced repair and replacement expenses.4. Marine Industry: Fiberglass cloth roll and resin allow the construction of robust boat hulls, resistant to water penetration and damage from UV radiation, contributing to extended vessel lifespans.Conclusion:Driven by their commitment to quality and innovation, {Company Name} has successfully produced advanced fiberglass cloth roll and resin, catering to diverse industry requirements. Their state-of-the-art materials offer improved strength, durability, and compatibility with a range of manufacturing processes. As various sectors continue to rely on fiberglass-based products, the combination of advanced fiberglass cloth roll and high-quality resin remains indispensable in achieving superior manufacturing outcomes.

Carbon Fiber Style Fabric: The Ultimate Guide

Carbon Fiber Look Alike Fabric Revolutionizes the Textile IndustryIn recent years, the demand for high-performance and lightweight materials has been steadily increasing in various industries, from automotive to aerospace. As a response to this demand, a cutting-edge company specializing in advanced textiles has developed a groundbreaking Carbon Fiber Look Alike Fabric that is set to revolutionize the industry.The Carbon Fiber Look Alike Fabric, developed by [company name], is a game-changing material that combines the high-performance properties of carbon fiber with the versatility and cost-effectiveness of fabric. This innovative fabric is engineered to mimic the appearance and functionality of traditional carbon fiber, making it a highly sought-after alternative in industries where lightweight and durable materials are essential.One of the key advantages of the Carbon Fiber Look Alike Fabric is its remarkable strength-to-weight ratio. While traditional carbon fiber is known for its exceptional strength and stiffness, it can be costly and difficult to work with. In contrast, the Carbon Fiber Look Alike Fabric offers similar strength and stiffness properties, while being more flexible and easier to handle. This makes it an ideal choice for applications where both performance and ease of use are paramount.Additionally, the Carbon Fiber Look Alike Fabric is highly customizable, allowing for a wide range of finishes and weave patterns to be achieved. This level of customization is a significant advantage for designers and engineers, as it enables them to tailor the fabric to their specific requirements and aesthetic preferences. Whether it's for automotive interiors, sporting goods, or aerospace components, the Carbon Fiber Look Alike Fabric offers endless possibilities for innovation and creativity.Furthermore, the Carbon Fiber Look Alike Fabric is engineered to be more environmentally friendly than traditional carbon fiber. By utilizing alternative materials and manufacturing processes, [company name] has developed a fabric that minimizes the environmental impact without compromising on performance. This aligns with the company's commitment to sustainability and responsible manufacturing practices, making the Carbon Fiber Look Alike Fabric a forward-thinking choice for eco-conscious industries.[Company name] has a track record of delivering high-quality, innovative textiles to a wide range of industries, and the development of the Carbon Fiber Look Alike Fabric is a testament to their dedication to pushing the boundaries of textile technology. With state-of-the-art manufacturing facilities and a team of experienced engineers and designers, the company is well-positioned to meet the growing demand for advanced materials in today's competitive market.The introduction of the Carbon Fiber Look Alike Fabric has been met with widespread anticipation and enthusiasm from industry professionals. Companies across various sectors are eagerly awaiting the opportunity to incorporate this groundbreaking material into their products, with the potential to enhance performance and efficiency across the board.In conclusion, the development of the Carbon Fiber Look Alike Fabric by [company name] marks a significant milestone in the textile industry. With its exceptional strength, versatility, and sustainability, this innovative fabric is poised to transform the way high-performance materials are utilized in a multitude of applications. As the demand for lightweight and durable materials continues to grow, the Carbon Fiber Look Alike Fabric stands out as a game-changing solution with the potential to shape the future of advanced textiles.