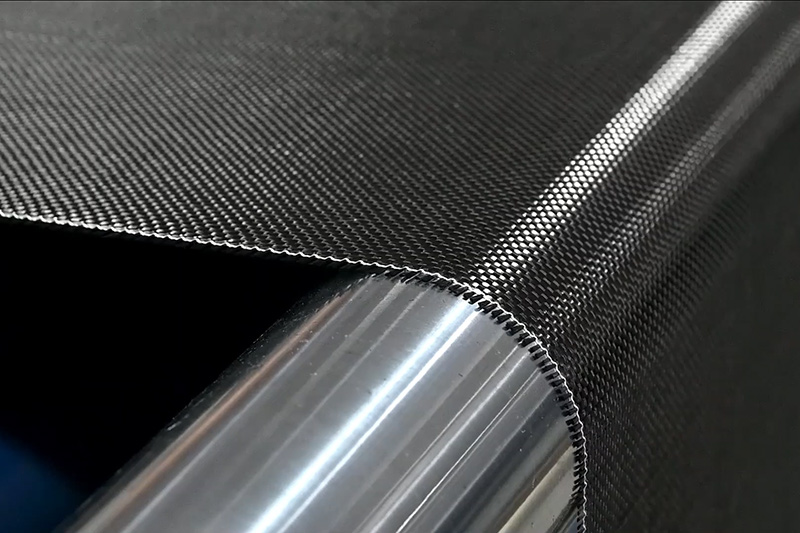

New Carbon Fiber Cloth Technology: Stronger and more flexible than traditional materials

By:Admin

Carbon fiber has been steadily gaining popularity over the last few years, and for good reason. This durable, lightweight material has revolutionized many industries, including automotive, aerospace, and sports equipment. However, the world of textiles has been slower to adopt carbon fiber, due to the high cost and difficulty in manufacturing. That’s where Cloth Carbon Fiber comes in.

Cloth Carbon Fiber is a company that specializes in producing high-quality carbon fiber textiles. Founded in 2010, the company has quickly become a leader in the industry, thanks to its innovative production methods and commitment to quality.

One of the key features of Cloth Carbon Fiber’s textiles is their strength-to-weight ratio. Carbon fiber is incredibly strong, yet lightweight, making it an ideal material for textiles. This means that Cloth Carbon Fiber textiles are not only durable, but also very lightweight, making them perfect for a wide range of applications.

The manufacturing process used by Cloth Carbon Fiber is also worth noting. Traditional carbon fiber production methods involve laying individual carbon fibers by hand, which is time-consuming and expensive. Cloth Carbon Fiber, on the other hand, uses an automated process that weaves the fibers together, greatly reducing production time and costs. This means that their carbon fiber textiles are more affordable and can be produced in larger quantities, making them more accessible to a wider range of customers.

Cloth Carbon Fiber’s textiles have already made waves in the world of fashion and sportswear. Their carbon fiber fabrics have been used by designers to create unique, high-tech fashion pieces, and by athletic brands to create performance-enhancing clothing.

But the applications for Cloth Carbon Fiber’s textiles extend far beyond fashion and sports. Carbon fiber’s strength, durability, and lightweight properties make it ideal for a wide range of applications, including construction, aerospace, and automotive.

In the construction industry, Cloth Carbon Fiber’s textiles could be used to reinforce concrete structures, making them more resistant to earthquakes and other natural disasters. In the aerospace industry, carbon fiber is already widely used to make lightweight, yet strong components for planes and spacecraft. Cloth Carbon Fiber’s textiles could be used to create even more advanced components, helping to make space travel safer and more efficient.

In the automotive industry, Cloth Carbon Fiber’s textiles could potentially revolutionize the way cars are made. Carbon fiber is already used in high-performance sports cars, but its high cost has made it impractical for mass-produced vehicles. However, Cloth Carbon Fiber’s more affordable textiles could change that, making it possible to create lightweight, fuel-efficient cars that are also durable and safe.

Overall, the potential applications for Cloth Carbon Fiber’s textiles are vast and varied. Their innovative manufacturing process and commitment to quality have already established them as a leader in the industry, and their continued growth and expansion are sure to have a major impact on the world of textiles and beyond.

Company News & Blog

High-quality Fiberglass Mesh Cloth: All You Need to Know

Fiberglass Mesh Cloth Helps Improve Building Integrity and LongevityIn today's construction industry, it's essential to prioritize building integrity and longevity by using high-quality materials and equipment. Fiberglass mesh cloth is one such material that can help improve the quality of buildings and other structures.{Company Name} has been at the forefront of manufacturing top-quality fiberglass mesh cloth for the construction industry. We specialize in producing a range of high-performance fiberglass mesh cloth that is designed to meet the diverse needs of our clients.Our fiberglass mesh cloth is made from high-quality fiberglass yarn and woven into a fine mesh fabric. This material is then coated with a high-quality alkaline-resistant emulsion to make it even more durable and long-lasting. This coating makes the mesh cloth resistant to harsh weather conditions, UV rays, and chemicals that can cause it to deteriorate over time.At {Company Name}, we offer a range of fiberglass mesh cloth products that are designed to meet the specific needs of various construction projects. We produce different types of fiberglass mesh cloth, including the standard mesh, reinforced mesh, self-adhesive mesh, and drywall tape. Each product is designed to meet specific construction needs and demands.One of the primary advantages of using fiberglass mesh cloth is that it provides structural reinforcement for buildings and walls. When applied correctly, it improves the tensile strength of the wall, making it more resistant to cracking and other forms of structural damage.Our fiberglass mesh cloth helps improve the overall durability of buildings by preventing the formation of cracks. It also enhances the stability of plaster and other wall coatings by reducing the likelihood of cracking and peeling. This quality makes our fiberglass mesh cloth a popular choice for those who prefer an aesthetically appealing building.Another critical benefit of our fiberglass mesh cloth is that it makes construction faster and more manageable. Because our mesh cloth is self-adhesive, it can be quickly and easily applied to walls, which helps save time and minimizes labor costs. Our mesh cloth also provides excellent coverage, making it ideal for use in large commercial buildings, residential homes, and other types of construction projects.Our fiberglass mesh cloth products are also eco-friendly, which means they are safe for the environment. Unlike traditional building materials that can cause pollution or harm to the environment, our fiberglass mesh cloth is entirely safe and poses no risk to the environment.In conclusion, the use of fiberglass mesh cloth in construction projects is essential for improving building integrity, longevity, and enhancing overall performance. {Company Name} specializes in manufacturing top-quality fiberglass mesh cloth products that have been tested and approved by industry experts. Our products are durable, long-lasting, eco-friendly, and cost-effective, making them an ideal choice for construction projects of all sizes and types. Contact us today to discuss your specific fiberglass mesh cloth needs.

Fiberglass Mat Woven Roving: The Versatile and Durable Reinforcement Material" can be rewritten as "Discover the Benefits of Woven Roving Fiberglass Mat as Your Reinforcement Material".

Fiberglass Mat Woven Roving - The Ultimate Solution in Reinforcement MaterialsIn the modern world, composite materials have gained significant traction in various industries, including aerospace, automotive, marine, and architecture, to name a few. Among the various types of composite materials, fiberglass-based products are some of the most popular ones. One of the vital components of fiberglass composites is the reinforcement material - the fiberglass mat woven roving. This material provides strength and durability to the composite, making it suitable for a wide range of applications.One of the leading manufacturers of fiberglass mat woven roving is the unnamed company, which has been in the industry for several decades. Over the years, the company has established itself as a reliable supplier of high-quality fiberglass-based products, catering to diverse industries worldwide. Their products are known for their consistency, durability, and versatility, making them the preferred choice for many customers.The fiberglass mat woven roving from the unnamed company is designed to meet the requirements of various composite applications. This material is made from high-quality fiberglass strands, which are woven together using advanced weaving techniques. The resulting product is a highly-dense, uniform, and strong material that is ideal for reinforcing composites.Some of the key features of the fiberglass mat woven roving from the unnamed company include superior strength, high flexibility, and excellent resin compatibility. These features allow the material to withstand high-stress loads, resist impacts and abrasions, and conform to different shapes and sizes.Furthermore, the fiberglass mat woven roving from the unnamed company is available in various thicknesses, widths, and styles, making it suitable for different applications. For instance, the company offers plain and biaxial woven roving, which can be used for various reinforcement needs. They also manufacture chopped strand mat, which is ideal for use with resin infusion and vacuum bagging processes.In addition to standard products, the unnamed company also offers customized solutions to meet specific customer requirements. They work closely with customers to understand their needs, suggest the best possible solutions, and deliver products that exceed expectations. Their team of experts has a deep understanding of the composite industry and can provide valuable insights and recommendations to customers.Apart from producing high-quality products, the unnamed company is also committed to sustainable practices. They strive to minimize their environmental impact by reducing waste, conserving energy and resources, and recycling materials wherever possible. Their products are also designed to be eco-friendly, ensuring that they meet the highest ethical and environmental standards.In conclusion, fiberglass mat woven roving from the unnamed company is the ultimate solution in reinforcement materials. Their products are designed to meet the toughest industry requirements, providing strength, resilience, and durability to composite materials. With their commitment to quality, sustainability, and customer satisfaction, the unnamed company is a reliable partner that customers can trust.

Revolutionize Your Wardrobe with Cutting-Edge Carbon Fiber Clothing Fabric

Carbon Fiber Clothing Fabric: Revolutionizing the Future of FashionIn recent years, a remarkable breakthrough in the fashion industry has captivated the attention of both fashion enthusiasts and technology enthusiasts alike. Carbon Fiber Clothing Fabric, a cutting-edge innovation, has emerged as a game-changer that combines style and functionality. With its unique properties and endless possibilities, this fabric has the potential to revolutionize the future of fashion.As a leading research and development company in advanced textiles, {Company Name} has been at the forefront of this groundbreaking technology. With their expertise in material science and commitment to sustainability, they have successfully created a carbon fiber clothing fabric that is both lightweight and incredibly strong. This fabric opens up a world of opportunities for designers, athletes, and everyday consumers.One of the most notable features of carbon fiber clothing fabric is its exceptional strength-to-weight ratio. Thanks to the inherent properties of carbon fibers, garments made from this fabric are incredibly robust while remaining lightweight. This revolutionary fabric can withstand rigorous activities, making it an ideal choice for athletes, adventurers, and outdoor enthusiasts.The durability of carbon fiber clothing fabric is nothing short of impressive. Unlike conventional fabrics, it resists wear and tear, making it long-lasting and ensuring that the garments maintain their shape and appearance over time. This durability translates to a reduction in the environmental impact of the fashion industry, as fewer garments need to be produced and discarded.Moreover, carbon fiber clothing fabric is highly breathable and moisture-wicking, enabling optimal comfort in various climates and physical activities. Its ability to regulate body temperature is essential for athletes and individuals engaging in intense workouts. This exceptional fabric also provides UV protection, safeguarding the wearer from harmful rays. With these functional attributes, carbon fiber clothing fabric is an ideal choice for both performance wear and daily attire.Beyond its functional properties, carbon fiber clothing fabric also offers endless design possibilities. Its sleek and futuristic aesthetic adds a touch of modernity to any garment. Designers can experiment with various cuts, shapes, and textures, enabling them to create unique and avant-garde pieces that stand out in the fashion industry. The versatility of this fabric makes it suitable for both high-end fashion collections and everyday wear.Furthermore, the production of carbon fiber clothing fabric aligns with {Company Name}'s commitment to sustainability and environmental responsibility. The manufacturing process of this fabric uses significantly fewer resources compared to traditional textiles. With a lower carbon footprint and reduced waste generation, carbon fiber clothing fabric is a step forward in creating a more sustainable fashion industry.{Company Name} aims to make carbon fiber clothing fabric accessible to a wider audience by collaborating with renowned fashion brands and retailers. This partnership will ensure that consumers have the opportunity to experience the unparalleled benefits of this fabric in their everyday lives. The company also actively promotes education and awareness regarding the environmental impact of the fashion industry, striving to inspire positive change in consumer behavior.In conclusion, Carbon Fiber Clothing Fabric represents a significant breakthrough in the fashion industry, blending style, performance, and sustainability. Thanks to innovative companies like {Company Name}, this fabric is on the cusp of transforming the way we think about clothing. From durable sportswear to high-end fashion creations, the possibilities are endless. By embracing carbon fiber clothing fabric, we are embracing a future where fashion and functionality go hand in hand.

Revolutionary Carbon Kevlar Fabric is Changing the Future of Materials" could be rewritten as "Innovative Carbon Kevlar Fabric is Transforming Material Development.

Title: Revolutionary Carbon Kevlar Fabric Promises Unparalleled Strength and DurabilityIntroduction:In a groundbreaking development, a leading company in the textile industry has unveiled an innovative Carbon Kevlar Fabric (Please note: brand name omitted) that is set to revolutionize various sectors, including automotive, aerospace, technology, and sporting goods. Engineered to provide unparalleled strength and exceptional durability, this cutting-edge fabric is poised to pave the way for new advancements in material science and product innovation.Unmatched Resilience:The Carbon Kevlar Fabric is the result of extensive research and development by a team of expert engineers. By combining the remarkable properties of carbon fiber and Kevlar, the fabric delivers a myriad of benefits, making it an ideal choice for numerous applications.One of the key features of this groundbreaking fabric is its exceptional strength-to-weight ratio. Due to the unique combination of materials, it boasts incredible tensile strength while remaining lightweight. This characteristic makes it an excellent choice for industries seeking to enhance performance, increase fuel efficiency, and reduce overall weight.Versatile Applications:The Carbon Kevlar Fabric's versatility extends across a wide range of industries. In the automotive sector, it can be used in the manufacturing of high-performance vehicle components, such as body panels, chassis reinforcements, and interior trims. Its exceptional strength and durability can significantly increase driver safety while reducing vehicle weight, thereby improving fuel efficiency.Furthermore, in the aerospace industry, this fabric can offer an alternative to conventional materials, contributing to lighter aircraft designs and reduced emissions. Additionally, its ability to withstand extreme temperatures and resist corrosion make it an ideal choice for the construction of spacecraft and satellites.In the realm of technology, the Carbon Kevlar Fabric could find applications in the production of smartphones, laptops, and wearable devices. Its strength and durability ensure that these products remain resilient and functional, even in demanding environments. This fabric's ability to protect against impacts and withstand harsh conditions could prove instrumental in enhancing the longevity of technology devices.Sporting Goods Innovation:Athletic equipment manufacturers are also expected to benefit from the advent of Carbon Kevlar Fabric. With its remarkable strength, this fabric holds the potential to revolutionize sporting goods, including helmets, paddles, and body armor. By utilizing the fabric's incredible resistance to impact, manufacturers could develop products that offer superior safety and performance to athletes.Environmental Impact:With sustainability being a critical concern today, the Carbon Kevlar Fabric offers significant advantages over traditional materials. Its strength and longevity ensure reduced maintenance needs and longer product lifespans, ultimately resulting in less waste and lower carbon emissions. Additionally, its lightweight nature contributes to fuel efficiency and reduced energy consumption.Conclusion:The introduction of the Carbon Kevlar Fabric has marked a major milestone in material science and product innovation. Its unparalleled strength, durability, and versatility make it an attractive choice for various industries, from automotive and aerospace to technology and sporting goods. As this remarkable fabric gains widespread adoption, we can expect substantial advancements in safety, performance, and environmental sustainability across numerous sectors.

Triaxial Fiberglass Fabric for Pultrusion: A Guide to Fiber Architectures and Weights

Changzhou Utek Composite Co., Ltd. is a renowned manufacturer of composite materials, based in China. Established in the year 2001, the company has grown to become a leading supplier of fiberglass fabrics, carbon fiber fabrics, and other composite materials.The company boasts of modern production facilities, state-of-the-art equipment, and a team of highly experienced professionals. It is committed to providing clients with high-quality and innovative products that meet their specific needs.One of the latest products from Changzhou Utek Composite Co., Ltd. is the Dbt480 Triaxial Fiberglass Fabric for Pultrusion Fiberglass. This product is designed to provide excellent mechanical properties, high strength, and durability, making it ideal for a wide range of applications.The Dbt480 Triaxial Fiberglass Fabric for Pultrusion Fiberglass is available in a wide variety of weights and fiber architectures from unidirectional to quadraxial. The fabric is made using high-quality fiberglass yarns that are carefully woven together to produce a strong, durable, and lightweight material.This product is designed specifically for pultrusion fiberglass applications. Pultrusion is a continuous manufacturing process that involves pulling reinforcement materials, such as fiberglass, through a resin bath, and then through a heated die. The process produces a strong and durable composite material that is widely used in various industries.The Dbt480 Triaxial Fiberglass Fabric for Pultrusion Fiberglass is an excellent choice for use in pultrusion applications due to its excellent mechanical properties and high strength. The fabric is also resistant to chemicals, UV light, and heat, making it suitable for use in harsh environments.Changzhou Utek Composite Co., Ltd. is committed to providing high-quality products that meet the needs of its customers. The company has invested heavily in research and development to ensure that its products meet the highest quality standards.Whether you are looking for fiberglass fabrics, carbon fiber fabrics, or other composite materials, Changzhou Utek Composite Co., Ltd. has the expertise and resources to deliver high-quality and innovative products that meet your specific needs.In conclusion, the Dbt480 Triaxial Fiberglass Fabric for Pultrusion Fiberglass from Changzhou Utek Composite Co., Ltd. is a high-quality and innovative product that is designed to meet the needs of the pultrusion industry. With its excellent mechanical properties, high strength, and durability, this product is an excellent choice for use in various applications.

New Carbon Fiber Cotton Fabric Revolutionizes Textile Industry

Carbon Fiber Print Cotton Fabric: A Revolutionary Innovation in Textile TechnologyIn the ever-evolving world of textile technology, the introduction of Carbon Fiber Print Cotton Fabric is a groundbreaking innovation that is set to revolutionize the industry. This unique fabric combines the strength and durability of carbon fiber with the comfort and versatility of cotton, resulting in a fabric that offers exceptional performance and style.Carbon fiber is known for its impressive strength-to-weight ratio, making it an ideal material for applications that require high strength and lightweight properties. However, traditional carbon fiber fabrics have limited flexibility and can be uncomfortable to wear for extended periods. By integrating carbon fiber into cotton fabric, this new development bridges the gap between performance and comfort, offering a fabric that is both functional and wearable.The incorporation of carbon fiber into cotton fabric is achieved using advanced printing techniques. The carbon fiber print is applied to the cotton fabric in a way that maintains the fabric's soft and comfortable texture, while also adding an additional layer of strength and durability. This unique combination not only enhances the fabric's performance but also opens up a whole new range of possibilities for its application in various industries.One of the key advantages of Carbon Fiber Print Cotton Fabric is its exceptional strength. The carbon fiber reinforcement provides superior tensile strength to the fabric, making it highly resistant to tearing and fraying. This attribute makes it an excellent choice for applications that require high-stress resistance, such as athletic wear, outdoor gear, and industrial protective clothing. Additionally, the fabric's lightweight nature ensures that it does not compromise on comfort, making it suitable for everyday wear.Another notable feature of Carbon Fiber Print Cotton Fabric is its enhanced thermal regulation properties. The carbon fiber component helps to regulate body temperature by effectively managing heat and moisture. This makes the fabric highly breathable and moisture-wicking, allowing for improved comfort, especially during intense physical activities. Whether it's for sports enthusiasts or individuals in hot and humid climates, this fabric offers a significant advantage over traditional cotton fabrics.Furthermore, Carbon Fiber Print Cotton Fabric exhibits excellent anti-microbial properties. The integration of carbon fiber into the fabric inhibits the growth of odor-causing bacteria, keeping the wearer feeling fresh and odor-free for extended periods. This characteristic makes the fabric particularly suitable for applications in the healthcare and sports industries, where hygiene and long-lasting freshness are paramount.The versatility of Carbon Fiber Print Cotton Fabric extends beyond its protective and functional attributes. Due to its unique visual appeal, the fabric can also be used for various fashion and design purposes. The carbon fiber print adds a modern and futuristic touch to any garment, making it a popular choice for designers looking to create innovative and eye-catching clothing. From sophisticated activewear to cutting-edge fashion collections, the possibilities are endless when it comes to utilizing this fabric in the world of fashion.In conclusion, the introduction of Carbon Fiber Print Cotton Fabric marks a remarkable advancement in textile technology. By combining the strength and durability of carbon fiber with the comfort and versatility of cotton, this fabric offers a groundbreaking solution that caters to the needs of multiple industries. With exceptional strength, thermal regulation properties, and anti-microbial attributes, this fabric outperforms traditional cotton fabrics in terms of functionality and performance. Additionally, its unique visual appeal opens up exciting opportunities for its use in the fashion and design world. As the textile industry continues to evolve, Carbon Fiber Print Cotton Fabric is certainly at the forefront of innovation.

The Advantages and Differences of Carbon Fiber and Kevlar in Protective Gear

Kevlar is a brand name for a type of para-aramid fiber that is often used in the production of bulletproof vests, helmets, and other protective gear. It was first developed by DuPont in the 1960s, and has since become one of the most widely-used materials in the field of ballistic protection.Kevlar is incredibly strong and lightweight, which makes it ideal for use in protective gear. It is five times stronger than steel on an equal weight basis, and has a high tensile strength that makes it resistant to penetration from bullets, knives, and other sharp objects. Kevlar is also heat-resistant and can withstand temperatures as high as 500 degrees Fahrenheit.One of the main advantages of Kevlar is its flexibility. It can be woven into a variety of different fabrics, including ballistic fabrics, which are designed to stop bullets and other high-speed projectiles. Kevlar is also resistant to abrasion and tearing, which makes it ideal for use in heavy-duty applications such as ropes and cables.Carbon FiberCarbon fiber is another popular material that is used in the production of ballistic protection gear. Unlike Kevlar, which is a type of para-aramid fiber, carbon fiber is a type of graphite-based fiber that is composed of thin, tightly-woven strands.Carbon fiber is known for its exceptional strength and rigidity, which makes it popular for use in aerospace, automotive, and sporting applications. It is also lightweight and highly resistant to corrosion and other types of environmental damage.When used in the production of ballistic gear, carbon fiber is typically combined with other materials such as Kevlar or aramid fibers to create composite materials that offer superior protection against bullets and other threats.Carbon Kevlar FabricOne of the most popular composites that is used for making ballistic gear is carbon Kevlar fabric. This material is a combination of carbon fiber and Kevlar, which creates a fabric that is both strong and flexible.Carbon Kevlar fabric is widely used in the production of body armor, helmets, and other protective gear. It is known for its ability to stop high-speed projectiles such as bullets and shrapnel, and is also highly resistant to cutting, tearing, and other types of damage.In addition to its ballistic properties, carbon Kevlar fabric is also popular for use in automotive and sporting applications. It can be woven into a variety of different shapes and sizes, and is often used to reinforced key areas of high-performance vehicles and equipment.ConclusionIn summary, Kevlar and carbon fiber are two of the most popular materials that are used in the production of ballistic gear. While they are similar in many ways, they differ in their composition and properties, and are often combined to create composite materials that offer superior protection and performance. Carbon Kevlar fabric is one example of such a composite, and is widely used in a variety of different applications where strength, flexibility, and protection are key concerns.

Shop for Fiberglass Fabric, Weave & Cloth in Various Lengths, Sizes & Styles - In Stock & Ready to Ship.

Fiberglass Fabric: A Versatile Solution for a Variety of ApplicationsFiberglass fabric is a woven material that is often used in applications that require high strength and durability. This versatile material is made by combining glass fibers with a polymer resin, resulting in a material that is strong, lightweight, and heat-resistant. Fiberglass fabric is available in a variety of styles, sizes, and lengths, making it an ideal solution for a wide range of applications in industries such as aerospace, automotive, marine, and construction.One of the key benefits of fiberglass fabric is its excellent strength-to-weight ratio. This property makes it an ideal material for applications where weight is a concern, such as aerospace and automotive engineering. Fiberglass fabric is also highly resistant to heat, making it a popular choice for applications that involve high temperatures, such as insulation for furnaces and ovens.In addition to its strength and heat resistance, fiberglass fabric is also highly resistant to chemicals and moisture. This makes it an ideal material for use in the marine industry, where it can be used to fabricate components such as boat hulls, decks, and bulkheads. Fiberglass fabric can also be used in a variety of construction applications, from reinforcing concrete to creating lightweight composite panels.At (brand name removed), we offer a wide selection of fiberglass fabrics, weaves, and cloths to meet the needs of our customers. Our fiberglass fabrics are available in a range of styles and sizes, including plain weave, twill weave, and satin weave options. We carry both E-glass and S-glass fabrics, allowing our customers to choose the material that is best suited for their specific application.Our fiberglass fabrics are available in a variety of lengths, ranging from small rolls to large bolts, and we can also custom cut our fabrics to meet our customers' specific needs. All of our fiberglass fabrics are of the highest quality, and we take great care to ensure that they meet the strictest industry standards for strength, durability, and performance.In addition to our selection of fiberglass fabrics, we also offer aluminized fiberglass fabrics, which are coated with a layer of aluminum to provide additional heat resistance and reflectivity. Aluminized fiberglass fabrics are often used in applications such as furnace curtains, welding blankets, and fire barriers.At (brand name removed), we pride ourselves on our commitment to providing our customers with the highest-quality fiberglass fabrics, weaves, and cloths in the industry. We understand that every application is unique, and we work closely with our customers to ensure that they have the right materials to meet their specific needs. With our extensive selection, competitive pricing, and unparalleled customer service, we are the go-to source for fiberglass fabrics for customers across a wide range of industries.In conclusion, fiberglass fabric is a versatile material that offers a range of benefits for a variety of applications. At (brand name removed), we are proud to offer a wide selection of fiberglass fabrics, weaves, and cloths to meet the needs of our customers. Whether you are working on an aerospace project, automotive application, marine fabrication, or construction project, we have the right materials to meet your needs. Contact us today to learn more about our fiberglass fabrics and how they can benefit your application.

New lightweight material made of carbon kevlar hybrid fabric is set to revolutionize the aerospace industry

Title: Innovative Carbon Kevlar Hybrid Fabric Revolutionizes the Textile IndustryIntroduction:In a groundbreaking development, an industry-leading company has introduced a cutting-edge Carbon Kevlar Hybrid Fabric, emerging as a game-changer in the textile world. Embracing advanced technologies, this revolutionary fabric combines the remarkable properties of carbon fiber and Kevlar, offering unprecedented strength, durability, and versatility. With its wide range of applications, this innovative fabric is set to reshape industries such as aerospace, automotive, sports, and defense.1. The Unparalleled Strength of Carbon Kevlar Hybrid Fabric:The Carbon Kevlar Hybrid Fabric incorporates the best qualities of both carbon fiber and Kevlar. Carbon fiber is renowned for its exceptional strength-to-weight ratio, making it a preferred choice in industries where lightweight yet robust materials are required. On the other hand, Kevlar is famous for its outstanding resistance to impact and abrasion, making it an ideal choice for ballistic protection and structural reinforcement. By combining these two fibers, this hybrid fabric transcends the limitations of conventional materials, ensuring enhanced performance in a variety of applications.2. Aerospace Industry: Empowering High-performance StructuresThe aerospace industry stands to benefit immensely from the introduction of Carbon Kevlar Hybrid Fabric. Due to its lightweight nature and superior strength, the fabric can be incorporated into the manufacture of aircraft components, including fuselages, wings, and engine parts. By utilizing this innovative fabric, manufacturers can significantly reduce the weight of aircraft, contributing to improved fuel efficiency and lower operating costs. Moreover, the exceptional fatigue resistance of the hybrid fabric enhances the durability and longevity of key structural elements, ensuring increased safety for passengers and crew.3. Automotive Industry: Paving the Way for Safer VehiclesIn the automotive sector, the integration of Carbon Kevlar Hybrid Fabric presents significant advancements in safety and performance. By utilizing this fabric for manufacturing body panels, car manufacturers can enhance crashworthiness while reducing overall vehicle weight. The superior impact resistance of the fabric combined with its lightweight attributes makes it a valuable asset in protecting passengers during collisions. As a result, vehicles can achieve better fuel efficiency while offering enhanced safety to occupants.4. Sports Industry: Elevating Performance EquipmentThe sports industry is no stranger to materials that offer exceptional strength and durability. The Carbon Kevlar Hybrid Fabric is set to revolutionize sports equipment, enabling athletes to reach new heights of performance. Sports gear, such as helmets, paddles, and protective gear, created using this hybrid fabric will offer unrivaled protection without compromising agility. The lightweight nature of the fabric will facilitate better maneuverability, giving athletes a competitive edge in various sports.5. Defense Industry: Reinforcing Military ApplicationsThe defense sector, where protection and reliability are paramount, can greatly benefit from the introduction of Carbon Kevlar Hybrid Fabric. The fabric's exceptional resistance to extreme temperatures and impact makes it an ideal choice for the manufacture of protective clothing and equipment for military personnel. As a result, soldiers will experience significantly improved protection without being encumbered by heavy gear.Conclusion:The introduction of Carbon Kevlar Hybrid Fabric represents an exciting milestone in the textile industry. This innovative fabric's ability to combine the extraordinary properties of carbon fiber and Kevlar opens up endless possibilities across various sectors. From aerospace to sports, and automotive to defense, this versatile fabric promises to redefine the standards of strength, durability, and performance. With its numerous benefits, the adoption of Carbon Kevlar Hybrid Fabric is set to revolutionize manufacturing processes and shape the future of the textile industry.

High Quality 3k 5.8oz Carbon Fiber Fabric - Ideal for Composites

and Toray T300.Carbon fiber is a revolutionary material that is changing the way modern industries design and manufacture products. Carbon fiber twill cloth, or Toray T300 carbon fiber fabric, is a high-quality material that is sought after for its strength and lightweight properties.The Toray T300 carbon fiber is a popular choice in the composite industry due to its exceptional balance of strength, stiffness, and toughness. The fabric boasts remarkable mechanical properties that are ideal for a wide range of applications, including aerospace, automotive, marine, and sports equipment.The carbon fiber twill cloth features a 2x2 twill weave that provides excellent drapability and conformability. The fabric is lightweight, weighing only 5.8oz/196gsm, making it ideal for weight-sensitive applications. The fabric has a thickness of .010", making it easy to handle and manipulate.To use the raw fabric, it must be hardened into a usable form using an appropriate resin or epoxy. The fabric can be hand-laid or vacuum infused with the resin to create composite parts that are lightweight, high-strength, and durable.The carbon fiber twill cloth is a versatile material that can be used for various applications. It is commonly used to manufacture aircraft components, automobile parts, bicycle frames, and sports equipment. The fabric is also used in the fashion industry to create high-tech, lightweight clothing.In conclusion, Toray T300 carbon fiber fabric is an exceptional material that offers unmatched strength, stiffness, and toughness. The 2x2 twill weave provides excellent drapability, allowing it to conform to complex shapes. The fabric is lightweight, easy to handle, and perfect for weight-sensitive applications. When combined with the proper resin or epoxy, the fabric can be used to create high-strength composite parts that are ideal for a wide range of applications.