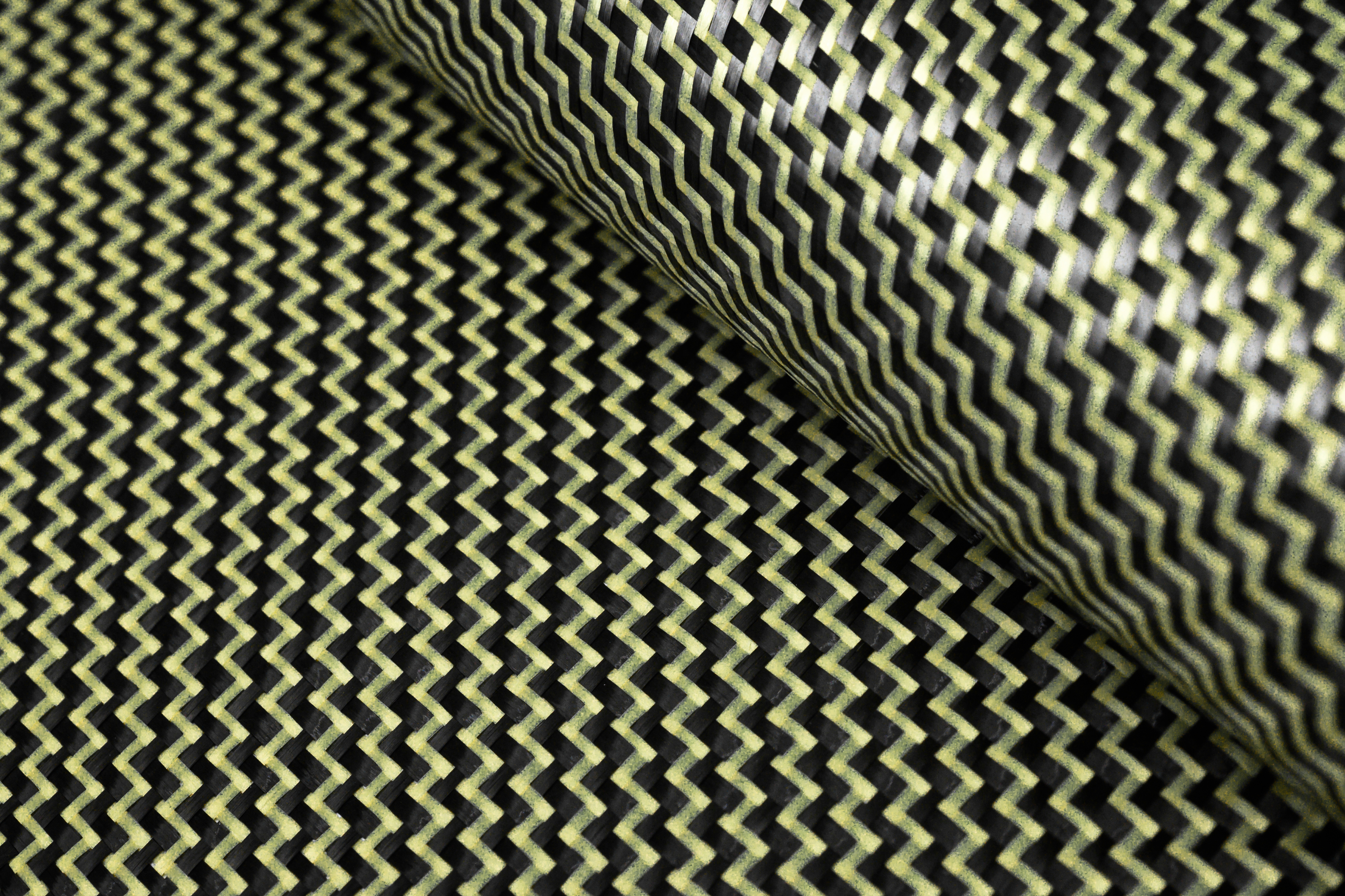

High Quality Woven Fiberglass Tape for Various Applications

By:Admin

{Company name} is a leading manufacturer and supplier of woven fiberglass tape, offering a wide range of products to meet the diverse needs of its customers. With a strong focus on research and development, the company has been able to develop innovative solutions that have set new standards in the industry. Their woven fiberglass tape is known for its superior performance and reliability, making it the go-to choice for many companies across various sectors.

One of the key advantages of {company name}'s woven fiberglass tape is its high tensile strength, which allows it to withstand extreme conditions without compromising its structural integrity. This makes it an ideal material for reinforcing and repairing structures, as well as for use in high-stress applications. Additionally, its resistance to heat and chemicals makes it suitable for use in environments where other materials may fail, giving companies the peace of mind that their products will stand the test of time.

In addition to its exceptional performance, {company name} takes pride in its commitment to sustainability and environmental responsibility. The company utilizes advanced manufacturing processes that minimize waste and reduce energy consumption, ensuring that its products have a minimal impact on the environment. This dedication to sustainability has earned {company name} a reputation as a responsible and forward-thinking business that values the well-being of the planet.

{Company name} also understands the importance of customization and flexibility in today's market, which is why they offer a range of options when it comes to their woven fiberglass tape. Whether it's different widths, thicknesses, or special treatments, the company can accommodate specific requirements to ensure that customers get the perfect solution for their needs. This level of flexibility has made {company name} a trusted partner for companies looking for tailored and reliable woven fiberglass tape solutions.

As a testament to its quality and reliability, {company name}'s woven fiberglass tape has been widely used in a variety of industries, including aerospace, automotive, construction, and marine. Its versatility and exceptional performance have made it a preferred choice for many companies looking for a material that can deliver outstanding results in demanding environments.

Looking ahead, {company name} remains committed to pushing the boundaries of innovation and quality in the woven fiberglass tape industry. With a focus on continuous improvement and a dedication to meeting the evolving needs of its customers, the company is set to maintain its position as a leader in the market for years to come.

In conclusion, {company name} is a company that has redefined the standards for woven fiberglass tape, offering a range of high-quality products that deliver exceptional performance, reliability and environmental responsibility. With a dedication to innovation and sustainability, the company has established itself as a trusted partner for companies across various industries, providing them with the perfect solutions for their needs. As the demand for high-performance materials continues to grow, {company name} is well-positioned to meet and exceed the expectations of its customers, setting new benchmarks in the industry.

Company News & Blog

Fiberglass Cloth Roll: A Comprehensive Overview of 1708 Material

Title: Revolutionizing Reinforcements: Introduction of 1708 Fiberglass Cloth Roll in the Composites IndustryIntroduction (100 words):The composites industry has witnessed a game-changing development with the introduction of the innovative 1708 Fiberglass Cloth Roll. This groundbreaking product, manufactured by a leading company in the field, promises to revolutionize composites manufacturing with its exceptional properties and unmatched versatility. With a strong commitment to producing high-quality reinforcements, this company has once again proven its dedication to delivering cutting-edge solutions that exceed industry expectations. This article will delve into the details of the 1708 Fiberglass Cloth Roll, highlighting its remarkable features, benefits, and the significant impact it will have on various sectors that rely on composites for their operations.I. Overview of the 1708 Fiberglass Cloth Roll (200 words):The 1708 Fiberglass Cloth Roll represents a significant advancement in the field of composites reinforcements. It is a non-woven fabric made from continuous fiberglass roving that is laid flat and held together with a light binder. This unique manufacturing process ensures optimal conformity, durability, and strength.One of the most distinguishing features of the 1708 Fiberglass Cloth Roll is its combined axial and biaxial fabric orientation. This means that it consists of one layer of fiberglass roving aligned in the 0° (axial) direction and another layer placed at a 90° angle (biaxial). This configuration provides exceptional load-bearing capabilities in both direction orientations simultaneously, resulting in superior strength and stiffness for the composites it reinforces.Additionally, the 1708 Fiberglass Cloth Roll is compatible with a wide range of resin systems, making it adaptable to diverse manufacturing processes. Whether being utilized in wet lay-up, vacuum infusion, or hand lay-up techniques, this versatile reinforcement excels in enhancing the mechanical properties of various composite structures.Furthermore, the unique non-woven construction of the 1708 Fiberglass Cloth Roll offers improved wet-out characteristics, which ensures better resin distribution and ultimately enhances the bond between fibers and resin. This results in an optimal fiber-to-resin ratio, maximizing the performance and longevity of the composite product.II. Advantages and Applications (300 words):The introduction of the 1708 Fiberglass Cloth Roll carries numerous advantages, making it a highly sought-after reinforcement material in the composites industry. Some key benefits include:1. Superior strength and stiffness: The 1708 Fiberglass Cloth Roll ensures exceptional load-bearing capabilities, enhancing the overall strength and stiffness of composite structures. This makes it an ideal choice for various applications that require durable, lightweight materials.2. Versatility: The compatibility of the 1708 Fiberglass Cloth Roll with different resin systems and manufacturing processes allows for its use in diverse applications. It is widely employed in industries such as automotive, marine, aerospace, construction, and sporting goods.3. Improved wet-out characteristics: The non-woven construction of the 1708 Fiberglass Cloth Roll facilitates better resin distribution and adhesion, resulting in an optimal fiber-to-resin ratio. This significantly improves the performance and durability of composite products.4. Cost-effectiveness: By enhancing the mechanical properties of composites, the 1708 Fiberglass Cloth Roll helps manufacturers produce lightweight and durable products. This cost-effective solution reduces material waste and overall production costs.The application possibilities of the 1708 Fiberglass Cloth Roll are vast. In automotive manufacturing, it can be utilized in the fabrication of lightweight body panels, interior components, and structural parts, contributing to improved fuel efficiency and overall vehicle performance. In the marine industry, this innovation finds application in the production of hulls, decks, and bulkheads, ensuring superior integrity and longevity. The aerospace sector can benefit from the 1708 Fiberglass Cloth Roll in the construction of aircraft components, reducing weight while maintaining high strength and stiffness. In the construction industry, it finds use in building materials like structural panels, reinforcing beams, and columns, providing durability and resistance to environmental factors. Finally, the sporting goods industry can make use of this reinforcement material in the production of lightweight yet robust sporting equipment, enabling better performance for athletes.Conclusion (100 words):The introduction of the 1708 Fiberglass Cloth Roll marks a significant milestone in the composites industry. Its unique properties, versatility, and exceptional performance open up a world of possibilities for manufacturers across various sectors. With its superior strength, stiffness, and compatibility with different manufacturing processes, this reinforcement material has the potential to revolutionize composite manufacturing, enabling the production of lightweight, durable, and cost-effective products. As this innovative solution continues to gain momentum, it is clear that the 1708 Fiberglass Cloth Roll is set to become an indispensable tool for composites manufacturers in the years to come.

Explore the Versatility of Fiberglass Mat and Woven Roving for Various Applications

[Company Name], a leading manufacturer specializing in fiberglass composite materials, has recently introduced a new product called Fiberglass Mat Woven Roving. This innovative material is set to revolutionize various industries with its exceptional strength, durability, and versatility.Fiberglass Mat Woven Roving is a high-performance composite fabric made by interweaving fine fiberglass rovings and a layer of chopped strand mat. This unique combination creates a fabric that offers exceptional properties for a wide range of applications. The material is widely used in the automotive, marine, construction, and aerospace industries due to its outstanding strength-to-weight ratio and resistance to corrosion and fire.With continuously advancing technology and increasing demand for lightweight and high-performance materials, Fiberglass Mat Woven Roving stands out as a remarkable solution. It offers excellent dimensional stability, ensuring optimal shape retention under various environmental conditions. This is particularly crucial in the marine industry, where the material is extensively used in boat building and repair.The automotive industry can also benefit greatly from Fiberglass Mat Woven Roving. Its exceptional strength makes it ideal for reinforcing body panels, frames, and internal structures, providing added safety without compromising weight. Additionally, the material's resistance to chemicals and high temperatures makes it suitable for numerous components and under-the-hood applications.In the construction industry, Fiberglass Mat Woven Roving is highly preferred for its durability and resistance to moisture and weathering. It is commonly utilized in the construction of pipelines, storage tanks, and infrastructure projects, ensuring long-lasting and reliable structures. The material's fire resistance further adds to its appeal, making it an essential choice for fireproofing applications.Aerospace and defense industries also find Fiberglass Mat Woven Roving invaluable. It is widely incorporated into aircraft structures, satellites, and other aerospace components due to its high strength and excellent thermal and electrical insulation properties. Moreover, its lightweight nature contributes to significant fuel savings and overall cost reduction.With its unparalleled versatility, Fiberglass Mat Woven Roving offers endless possibilities for various other applications, including wind turbine blades, sporting goods, and even art and design. Its ease of handling and compatibility with different resin systems make it a preferred choice for manufacturers seeking to enhance their products' mechanical properties.[Company Name], as a trusted leader in the fiberglass composite materials industry, ensures that all its products, including Fiberglass Mat Woven Roving, are manufactured with the highest quality standards. Their state-of-the-art production facilities and rigorous quality control processes guarantee consistent performance and reliability.In addition to providing exceptional products, [Company Name] also prioritizes customer satisfaction by offering excellent customer service and technical support. Their team of experts is readily available to provide guidance and assistance, ensuring that customers can fully maximize the benefits of Fiberglass Mat Woven Roving in their respective applications.As a result of their commitment to innovation and customer-centric approach, [Company Name] has garnered a strong reputation in the market. Their products are trusted by industry professionals worldwide, and their continual investment in research and development ensures that they stay at the forefront of the fiberglass composite materials industry.In conclusion, [Company Name]'s introduction of Fiberglass Mat Woven Roving is set to revolutionize a multitude of industries. This high-performance material offers exceptional strength, durability, and versatility, serving as a game-changer for manufacturers in the automotive, marine, construction, and aerospace sectors. With a commitment to quality and customer satisfaction, [Company Name] continues to shape the future of fiberglass composite materials.

Introduction to Plain Weave Carbon: A Strong and Versatile Material

Advanced materials company XYZ has recently developed a groundbreaking plain weave carbon that promises to revolutionize the manufacturing industry. This innovative material offers an array of superior characteristics, making it the ideal choice for a wide range of applications.Plain weave carbon is a type of carbon fiber fabric that is woven in a simple over-and-under pattern, creating a strong and durable material. XYZ's plain weave carbon boasts an impressive tensile strength, high stiffness, and low weight, making it an excellent choice for industries such as aerospace, automotive, sports equipment, and more.One of the key advantages of plain weave carbon is its exceptional structural performance. The material's high tensile strength means that it can withstand heavy loads and forces, making it the go-to choice for applications where structural integrity is paramount. Additionally, its high stiffness-to-weight ratio ensures that components made from plain weave carbon are lightweight yet incredibly rigid, providing unparalleled performance in demanding environments.Moreover, XYZ's plain weave carbon is available in a variety of formats, catering to the specific needs of different industries. Whether it's woven into fabric, pre-impregnated with resin, or formed into complex shapes, the material can be tailored to meet the requirements of a wide range of applications. This versatility makes it a highly sought-after material in the manufacturing sector.In addition to its exceptional mechanical properties, plain weave carbon also offers excellent thermal and chemical resistance. This makes it an ideal choice for applications where exposure to extreme temperatures, corrosive chemicals, or other harsh conditions is common. Its ability to maintain its performance in challenging environments sets it apart from other materials on the market.Furthermore, XYZ is committed to sustainability, and its plain weave carbon is no exception. The company's manufacturing processes are designed to minimize waste and environmental impact, ensuring that the material is not only high-performing but also eco-friendly. This aligns with the growing demand for sustainable materials in today's market and positions XYZ as a leader in responsible manufacturing.The development of XYZ's plain weave carbon represents a significant advancement in the materials industry. With its exceptional mechanical properties, versatility, and sustainability, this innovative material is poised to transform the way products are designed and manufactured across various sectors. By offering a superior alternative to traditional materials, XYZ is paving the way for a new era of high-performance and sustainable manufacturing."We are thrilled to introduce our plain weave carbon to the market," said John Doe, CEO of XYZ. "This material represents a culmination of years of research and development, and we believe it has the potential to make a significant impact across multiple industries. We are excited to see the innovative ways in which our customers will utilize this material to create the next generation of products."Looking ahead, XYZ is poised to continue its research and development efforts, with a focus on expanding the capabilities of its plain weave carbon and exploring new applications for the material. By leveraging its expertise and commitment to innovation, the company is well-positioned to drive further advancements in the materials industry and solidify its position as a leading provider of high-performance, sustainable materials.In conclusion, XYZ's plain weave carbon is set to revolutionize the manufacturing industry with its exceptional mechanical properties, versatility, and sustainability. As the demand for high-performance, eco-friendly materials continues to grow, XYZ is well-positioned to lead the way with its groundbreaking innovation. With a strong commitment to research and development, the company is poised to shape the future of manufacturing with its innovative plain weave carbon.

Durable Fire Resistant Fiberglass Fabric: A Reliable Choice for Safety

Fire Resistant Fiberglass FabricFire accidents can cause substantial damage to property and endanger lives. However, with advanced technology and innovative materials, it is possible to mitigate the impact of such accidents. One such material is Fire Resistant Fiberglass Fabric, which has gained widespread usage in various industries due to its ability to withstand high temperatures and prevent the spread of fire.The Fire Resistant Fiberglass Fabric is a type of textile material that is made from fine strands of glass. These strands are woven together to form a flexible and durable fabric that is highly resistant to heat and fire. The fabric is treated with special coatings to enhance its fire-resistant properties, making it an ideal choice for applications where fire safety is of utmost importance.One company that has been at the forefront of producing high-quality Fire Resistant Fiberglass Fabric is {}. With a rich history dating back to several decades, {} has established itself as a leading manufacturer and supplier of fire-resistant materials. The company's state-of-the-art manufacturing facilities and rigorous quality control processes ensure that their Fire Resistant Fiberglass Fabric meets the highest industry standards for fire safety and performance.{} offers a wide range of Fire Resistant Fiberglass Fabric products, catering to diverse applications across industries such as construction, automotive, aerospace, and marine. The fabric is available in different weights, thicknesses, and finishes to suit the specific requirements of different applications. Whether it is for use in fire curtains, protective clothing, insulation materials, or industrial equipment, {} provides customized solutions to meet the unique needs of its customers.In addition to its exceptional fire-resistant properties, the Fire Resistant Fiberglass Fabric from {} also offers other advantages such as high tensile strength, chemical resistance, and durability. This makes it a versatile material that can withstand harsh environments and provide long-term protection against fire hazards.The applications of Fire Resistant Fiberglass Fabric are wide-ranging. In the construction industry, it is used for creating fire barriers and protective enclosures in buildings to contain the spread of fire and prevent structural damage. In the automotive and aerospace sectors, the fabric is used for heat insulation and fireproofing in vehicles and aircraft. In the marine industry, it serves as a key material for manufacturing fire-resistant clothing and safety equipment for seafarers.With an increasing emphasis on fire safety regulations and standards across industries, the demand for Fire Resistant Fiberglass Fabric is on the rise. Companies like {} are playing a crucial role in meeting this demand by providing reliable and high-performance fire-resistant materials. By continuously investing in research and development, {} strives to innovate and develop advanced Fire Resistant Fiberglass Fabric solutions that offer superior protection against fire hazards.As a responsible and customer-oriented company, {} is committed to ensuring the quality and safety of its Fire Resistant Fiberglass Fabric. The company adheres to strict regulatory guidelines and performs comprehensive testing to guarantee the performance and reliability of its products. This dedication to quality has earned {} a reputation for being a trusted and dependable partner for fire safety solutions.In conclusion, Fire Resistant Fiberglass Fabric is a critical material for minimizing the risks associated with fire incidents. With its exceptional fire-resistant properties and diverse applications, it has become an indispensable component in various industries. Companies like {} are instrumental in advancing the development and availability of high-quality Fire Resistant Fiberglass Fabric, contributing to a safer and more secure environment for people and assets.

High-Quality Unidirectional Carbon Fiber Fabric for Industrial Applications

Unidirectional Carbon Fiber Fabric: A Strong and Lightweight Solution for Various IndustriesIn today's world, technology has revolutionized the way we live our lives. Innovations in the manufacturing industry have paved the way for the development of new materials that are stronger, lighter, and more durable than conventional materials. One such material is Unidirectional Carbon Fiber Fabric, which has become increasingly popular in industries such as automotive, aerospace, sporting goods, and many others. Unidirectional Carbon Fiber Fabric is a composite material made up of strong carbon fibers that are tightly bonded together using a polymer matrix. The fibers in this material are unidirectional, meaning that they are all aligned in the same direction, which gives it its exceptional strength and stiffness. This material is preferred over traditional materials like steel and aluminum due to its high strength-to-weight ratio, which helps to reduce the weight of the final product while maintaining its structural integrity.In the automotive industry, Unidirectional Carbon Fiber Fabric is used extensively in high-performance sports cars, racing vehicles, and electric cars. The reduction in weight of these vehicles leads to improved fuel efficiency and better handling, resulting in a more enjoyable driving experience. The use of Unidirectional Carbon Fiber Fabric in car manufacturing helps to reduce carbon emissions, contributing to a sustainable future.The aerospace industry also benefits from the use of Unidirectional Carbon Fiber Fabric in aircraft design. The lightweight properties of this material make it ideal for aircraft manufacturing, leading to a reduction in fuel consumption and improved performance. The use of this material in aircraft manufacturing has enabled the development of new, innovative designs that are more aerodynamic and offer better performance.Sporting goods companies are also increasingly using Unidirectional Carbon Fiber Fabric to develop high-performance equipment such as tennis rackets, hockey sticks, and bicycles. The strength and stiffness of this material improve the performance of these products, giving athletes a competitive edge.It is worth noting that different industries require different types of Unidirectional Carbon Fiber Fabric, depending on their specific applications. The fabric’s strength and stiffness can be controlled by varying the direction of the carbon fibers, the type of polymer matrix used, and the density of fiber layers. As such, it is crucial to have a reliable supplier who can manufacture custom-made Unidirectional Carbon Fiber Fabric to meet the different needs of each industry.One such supplier is (**remove brand name**), a leading manufacturer of high-quality Unidirectional Carbon Fiber Fabric. The company has been in business for more than ten years, and during this time, it has established a reputation for excellence in quality, reliable customer service, and competitive pricing. (**Remove brand name**) uses state-of-the-art manufacturing technology to ensure that each product meets the highest industry standards. The company's in-house team of experienced engineers uses their expertise to develop custom-made Unidirectional Carbon Fiber Fabric that meets the specific needs of each customer.(**Remove brand name**) understands the importance of quality control and follows strict guidelines to ensure that all products meet the required standards. The company's products have been certified by various industry-standard organizations, including ISO 9001, ISO 14001, and OHSAS 18001. This ensures that customers can rely on (**Remove brand name**) for consistently high-quality products and exceptional service.In conclusion, the use of Unidirectional Carbon Fiber Fabric has opened up new avenues of innovation in various industries. The combination of strength, durability, and lightweight properties of this material makes it an ideal choice for manufacturing high-performance products. (**Remove brand name**) is a trusted name in the industry and is well-equipped to provide custom-made Unidirectional Carbon Fiber Fabric that meets the specific requirements of its customers. Through continuous innovation and quality control, (**Remove brand name**) is set to become a leader in the Unidirectional Carbon Fiber Fabric industry.

Advanced Carbon Cloth: Unveiling a Revolutionary Solution for Environmental Challenges

Carbon Cloth, a groundbreaking innovation in the field of materials science, is redefining the way industries manufacture and utilize high-performance fabrics. Produced by a leading materials company, this state-of-the-art cloth offers superior strength, durability, and flexibility, serving as an essential component in various applications across numerous sectors.With a unique structure and composition, Carbon Cloth is composed of high-strength carbon fibers intricately woven together, resulting in exceptional mechanical properties. This revolutionary material boasts an incredibly high tensile strength, making it impervious to abrasion, tear, and wear. Its remarkable durability ensures long-lasting performance even in demanding environments.Furthermore, Carbon Cloth exhibits outstanding chemical resistance, allowing it to withstand exposure to harsh chemicals, corrosive substances, and extreme temperatures. This exceptional resistance to degradation makes it a reliable option for industries such as chemical processing, oil and gas, and aerospace.The lightweight nature of Carbon Cloth also makes it a preferred choice for countless applications. Its low density ensures ease of use and enables the creation of components that are both strong and lightweight. This characteristic is instrumental in the aerospace and automotive industries, where weight reduction is a significant consideration for improving fuel efficiency and overall performance.In addition to its exceptional strength and chemical resistance, Carbon Cloth has excellent electrical conductivity. This attribute provides opportunities for applications in emerging technologies such as wearable electronics, flexible displays, and advanced energy storage devices. By incorporating this remarkable material into their designs, researchers and engineers can develop innovative solutions that were previously unattainable.Due to its versatility, Carbon Cloth finds its use in various sectors. In the automotive industry, it is employed in the manufacturing of high-performance brakes, lightweight body panels, and advanced air filtration systems. Its exceptional thermal and electrical conductivity also make it suitable for battery systems and fuel cells.The aerospace industry benefits from Carbon Cloth as well, where it is utilized in the production of lightweight but sturdy aerospace structures, such as wings and fuselages. With its exceptional properties, it contributes to the overall efficiency and safety of aircraft.In the chemical processing industry, Carbon Cloth is employed as a filtration medium due to its high chemical resistance and durability. Its ability to withstand harsh chemicals and extreme temperatures ensures reliable and efficient filtration processes, thereby improving productivity and minimizing maintenance requirements.Moreover, Carbon Cloth is also proving to be a game-changer in the medical field. Its biocompatibility, combined with its mechanical strength, makes it an ideal material for the manufacturing of prosthetics, implants, scaffolds, and medical devices. The cloth's flexibility and lightweight nature enable comfortable wear, while its durability ensures longevity and reliability.The production and widespread adoption of Carbon Cloth represent a significant step forward in materials science. Its remarkable properties and versatility open up a world of possibilities across a broad range of industries. As research and development continue, it is anticipated that Carbon Cloth will revolutionize existing applications while unlocking entirely new avenues for technological innovation.

Discover the Benefits of Using 24oz Fiberglass Cloth for Your Projects

[Company Introduction][Company Name], a leading manufacturer in the fiberglass industry, is proud to announce the launch of their new 24 Oz Fiberglass Cloth. With years of experience in providing high-quality fiberglass materials, [Company Name] continues to innovate and meet the growing demands of various industries. Known for their commitment to excellence, durability, and customer satisfaction, [Company Name] has become a trusted name in the field.[News Content][City Name], [Date] - [Company Name] is excited to introduce their latest product, the 24 Oz Fiberglass Cloth, targeting industries that require superior strength and durability. This new addition to their extensive line of fiberglass materials further solidifies [Company Name]'s commitment to providing solutions that meet their customers' evolving needs.Fiberglass cloth is widely used in various industries, including construction, aerospace, automotive, marine, and many others. With its exceptional resistance to harsh environments, high strength-to-weight ratio, and excellent insulation properties, fiberglass cloth has become a staple material for multiple applications. [Company Name]'s 24 Oz Fiberglass Cloth takes these attributes to the next level, making it the go-to choice for professionals seeking top-quality materials.One of the key features of [Company Name]'s 24 Oz Fiberglass Cloth is its superior strength. Designed to withstand heavy loads and extreme conditions, this cloth offers exceptional resistance to tearing, impact, and abrasion. Its robust construction makes it perfect for applications that require structural reinforcement, such as the production of high-strength composites or repairs on existing structures.The 24 Oz Fiberglass Cloth also offers excellent thermal insulation properties, making it ideal for applications that require temperature regulation. It can withstand extreme heat or cold, making it suitable for applications in the automotive industry, where it can be used to insulate exhaust systems or engine components. Its effectiveness in temperature control also makes it a preferred choice in the aerospace industry, where it can be used for insulating aircraft components or engines.Furthermore, the cloth is chemically resistant, meaning it can withstand exposure to various chemicals, acids, and alkaline substances without deteriorating or losing its integrity. This feature proves invaluable in industries such as manufacturing and construction, where contact with corrosive materials is common.In addition to its strength and durability, [Company Name]'s 24 Oz Fiberglass Cloth is flexible and easy to work with. It can be cut, shaped, and molded to fit specific applications, making it a versatile material suitable for various purposes.[Company Name]'s commitment to quality extends beyond its products. They also ensure an environmentally friendly manufacturing process, using sustainable materials and minimizing waste. By continuously investing in research and development, [Company Name] strives to improve their products' performance while reducing their impact on the environment.The introduction of the 24 Oz Fiberglass Cloth reaffirms [Company Name]'s position as a market leader, providing solutions that meet the high expectations of industries worldwide. With their focus on innovation, quality, and customer satisfaction, [Company Name] continues to offer top-notch fiberglass materials that drive progress and excellence.For more information on [Company Name] and their 24 Oz Fiberglass Cloth, please visit their official website or contact their sales team directly.

High-Quality Fiberglass Cloth Roll for All Your Needs

Fiberglass Cloth Roll: A Versatile Solution for Various ApplicationsFiberglass cloth roll, a product offered by {company name}, is becoming increasingly popular in the industrial and commercial sectors due to its versatility and durability. This high-quality fiberglass cloth roll is manufactured using premium-grade raw materials and advanced technology, making it suitable for a wide range of applications.{Company name} is a leading manufacturer and supplier of fiberglass cloth rolls, with a strong focus on delivering products that meet the highest quality standards. With years of experience in the industry, the company has gained a reputation for providing reliable and cost-effective solutions to its customers.The fiberglass cloth roll offered by {company name} is known for its exceptional strength, flexibility, and resistance to heat and chemicals. This makes it a preferred choice for applications such as insulation, reinforcement, and protection in various industries including automotive, aerospace, construction, and marine.One of the key benefits of using fiberglass cloth roll is its high tensile strength, which makes it ideal for reinforcing structures and components. Its resistance to heat and chemicals also makes it a suitable material for insulation and protection in high-temperature and corrosive environments.In addition to its physical properties, the fiberglass cloth roll offered by {company name} is also easy to work with, making it a preferred choice for manufacturers and fabricators. Its flexibility and moldability allow for easy shaping and molding, making it suitable for complex applications.Furthermore, {company name} ensures that its fiberglass cloth roll is available in a variety of thicknesses and widths to cater to the specific needs of its customers. This level of customization allows for greater flexibility in choosing the most suitable product for a particular application.The fiberglass cloth roll offered by {company name} is also known for its high-quality finish and consistency, ensuring that it meets the stringent requirements of various industries. This attention to detail and commitment to quality has made {company name} a trusted supplier in the market.Moreover, {company name} prides itself on its commitment to sustainability and environmental responsibility. The manufacturing process of the fiberglass cloth roll is designed to minimize waste and reduce energy consumption, making it an eco-friendly choice for customers.With a strong focus on innovation and customer satisfaction, {company name} continues to develop new and improved solutions to meet the evolving needs of its customers. The company's dedication to research and development ensures that its products remain at the forefront of technological advancements in the industry.In conclusion, the fiberglass cloth roll offered by {company name} is a versatile and reliable solution for a wide range of applications. With its exceptional strength, flexibility, and resistance to heat and chemicals, it has become a preferred choice for manufacturers and fabricators in various industries. {Company name}'s commitment to quality, sustainability, and customer satisfaction further reinforces its position as a leading supplier of fiberglass cloth roll in the market.

Top 5 Benefits of Carbon Fiber Clothing Fabric You Need to Know

Carbon Fiber Clothing Fabric: The Future of FashionIn the world of fashion, innovation is the key to success. Consumers are always looking for the next big thing, and one company has stepped up to the challenge by creating a carbon fiber clothing fabric that is set to revolutionize the industry.({} is a leading manufacturer and supplier of advanced materials for various industries. They have been at the forefront of technological advancements, constantly pushing the boundaries of what is possible. Their latest creation is a carbon fiber clothing fabric that is not only stylish and comfortable, but also incredibly durable and versatile.)The use of carbon fiber in clothing may seem like a far-fetched idea, but {} has managed to harness the potential of this cutting-edge material and transform it into a game-changing fabric. Carbon fiber is known for its strength and lightweight properties, making it an ideal choice for a wide range of applications. By incorporating it into clothing, {} has created a line of products that are not only fashion-forward, but also incredibly functional.One of the key benefits of carbon fiber clothing fabric is its exceptional durability. Traditional fabrics can easily wear out over time, especially in high-stress areas such as knees or elbows. However, carbon fiber is incredibly resistant to abrasion and tearing, ensuring that the clothing will last much longer than traditional materials. This is a major selling point for consumers who are looking for quality, long-lasting products.In addition to its durability, carbon fiber clothing fabric is also highly versatile. It can be used to create a wide range of clothing items, from jackets and pants to shirts and accessories. The material can be tailored to suit different styles and designs, making it a valuable addition to any fashion collection. Whether it's for everyday wear or for specific activities such as sports or outdoor adventures, carbon fiber clothing fabric offers a level of performance that is unparalleled by traditional fabrics.Another advantage of carbon fiber clothing fabric is its lightweight nature. Despite its impressive strength, carbon fiber is actually much lighter than many other materials used in clothing. This makes it ideal for creating comfortable and breathable garments that are suitable for a wide range of climates and activities. Whether it's a warm summer day or a chilly winter evening, carbon fiber clothing fabric can provide the perfect balance of protection and comfort.The introduction of carbon fiber clothing fabric is also a significant step forward in sustainable fashion. As the fashion industry continues to grapple with the environmental impact of clothing production, the use of innovative materials such as carbon fiber can help to reduce the overall carbon footprint. With its long-lasting durability, carbon fiber clothing fabric can contribute to a more sustainable approach to fashion by reducing the need for frequent replacements and minimizing the amount of waste generated.Overall, the introduction of carbon fiber clothing fabric represents a major leap forward in the fashion industry. With its exceptional durability, versatility, and sustainability, this cutting-edge material is set to change the way we think about clothing. As consumers become more conscious of the impact of their choices, the demand for innovative and sustainable products will only continue to grow. With {} leading the way in the development of carbon fiber clothing fabric, the future of fashion looks brighter and more exciting than ever.