New Colored Carbon Fiber Fabric Now Available in the Market

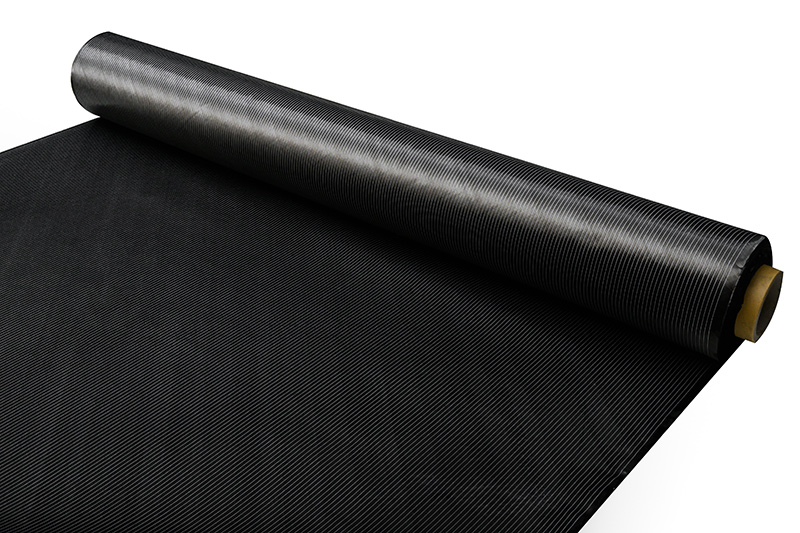

Colored carbon fiber fabric takes the textile world by stormThe textile industry, like many other sectors, constantly seeks to innovate and incorporate new materials into their portfolio. One such industry that has experienced a significant shift is the carbon fiber fabric market. Carbon fiber fabrics are widely used in several industries, including aerospace, automotive, and sporting goods. They have gained popularity due to their amazing attributes, such as lightweight, high tensile strength, stiffness, and chemical resistance, making them ideal for various applications.A few years ago, colored carbon fiber fabric entered the market, marking the onset of a new era. Unlike traditional carbon fiber, which has a dark black hue, colored carbon fiber is vibrant and captivating. The new fabric has been warmly embraced as it offers a wide range of aesthetically pleasing possibilities. The fabrics are a favorite of high-end fashion designers and luxury brands who have incorporated it into their collections, giving their products a sophisticated look. One company that has excelled in producing the colored carbon fiber fabric is the {remove brand name} firm. They have made a significant impact in the market due to their unmatched flair and creativity in the production process. According to Tim Smith, the company's COO, the colored carbon fiber fabric is achieved by introducing colored films in the weaving process that gives the fiber added color. The result is a weave of colored carbon fiber textiles that match the color scheme of a customer's specification.The new fabric has found its way into numerous industries and applications, as companies seek to augment their products with a touch of elegance and class. For example, car enthusiasts can use the colored carbon fiber to indulge in their car's customization, giving it a personal flair that catches the eye. As for sports enthusiasts, brands use the carbon fiber fabric to produce superior quality sports equipment that is both lightweight and durable.One crucial benefit of this new fabric is the wide range of design options available. The carbon fiber fabric can be further enhanced with added patterns and textures to create more complex structures. This versatility in design vastly expands the range of applications the carbon fiber fabric can be used in, making it a top choice in the market. But it's not all about aesthetics; the colored carbon fiber fabric holds immense value in various applications that require durable materials. The colored carbon fiber fabric has extensive use in the aerospace industry as it is lightweight, yet strong enough to meet the high safety standards required. Since the fabric's introduction into the market, the aerospace industry has embraced it as the go-to material for a variety of applications. Another industry that has reaped the benefits of the new fabric is the marine industry. The colored carbon fiber fabric's unique properties make it the ideal material for boat-building as it offers durability and high-performance capabilities in harsh environments. Furthermore, the fabric's moisture-resistant properties prolong its lifespan, making it a sound investment for boat owners. In the medical industry, the colored carbon fiber fabric has found even more applications. The material is ideal for making prosthetics as it is lightweight and durable. It can be used in artificial limbs to provide amputees with a more comfortable and mobile life. The colored carbon fiber fabric in prosthetics has also found application in the entertainment industry, where it is used to create realistic-looking props and costumes. The colored carbon fiber fabric has created a whole new world of possibilities for the textile industry. It offers both elegance and functionality, combining aesthetics and durability. The fabric's range of applications and design options has made it a top choice in many industries, and its future only seems to shine brighter. According to {remove brand name}'s Tim Smith, with the increased focus on sustainability and eco-friendliness, they have embarked on developing eco-friendly colored carbon fiber fabric. This move is aimed at ensuring that the company conforms to the industry's sustainability guidelines and reduces its carbon footprint. The company plans to introduce this new material in the market soon, and the textile industry is eagerly waiting for it. In conclusion, the colored carbon fiber fabric is an exceptional innovation that has transformed the textile industry. Its lightweight, strong, and aesthetically appealing properties make it diverse, resulting in its extensive application in various sectors. With the development of eco-friendly materials, the colored carbon fiber industry is well-positioned to pave the way for a more sustainable future.

Read More

New Carbon Fiber Cloth Technology: Stronger and more flexible than traditional materials

Cloth Carbon Fiber: A Game-Changer in the World of TextilesCarbon fiber has been steadily gaining popularity over the last few years, and for good reason. This durable, lightweight material has revolutionized many industries, including automotive, aerospace, and sports equipment. However, the world of textiles has been slower to adopt carbon fiber, due to the high cost and difficulty in manufacturing. That’s where Cloth Carbon Fiber comes in.Cloth Carbon Fiber is a company that specializes in producing high-quality carbon fiber textiles. Founded in 2010, the company has quickly become a leader in the industry, thanks to its innovative production methods and commitment to quality.One of the key features of Cloth Carbon Fiber’s textiles is their strength-to-weight ratio. Carbon fiber is incredibly strong, yet lightweight, making it an ideal material for textiles. This means that Cloth Carbon Fiber textiles are not only durable, but also very lightweight, making them perfect for a wide range of applications.The manufacturing process used by Cloth Carbon Fiber is also worth noting. Traditional carbon fiber production methods involve laying individual carbon fibers by hand, which is time-consuming and expensive. Cloth Carbon Fiber, on the other hand, uses an automated process that weaves the fibers together, greatly reducing production time and costs. This means that their carbon fiber textiles are more affordable and can be produced in larger quantities, making them more accessible to a wider range of customers.Cloth Carbon Fiber’s textiles have already made waves in the world of fashion and sportswear. Their carbon fiber fabrics have been used by designers to create unique, high-tech fashion pieces, and by athletic brands to create performance-enhancing clothing.But the applications for Cloth Carbon Fiber’s textiles extend far beyond fashion and sports. Carbon fiber’s strength, durability, and lightweight properties make it ideal for a wide range of applications, including construction, aerospace, and automotive.In the construction industry, Cloth Carbon Fiber’s textiles could be used to reinforce concrete structures, making them more resistant to earthquakes and other natural disasters. In the aerospace industry, carbon fiber is already widely used to make lightweight, yet strong components for planes and spacecraft. Cloth Carbon Fiber’s textiles could be used to create even more advanced components, helping to make space travel safer and more efficient.In the automotive industry, Cloth Carbon Fiber’s textiles could potentially revolutionize the way cars are made. Carbon fiber is already used in high-performance sports cars, but its high cost has made it impractical for mass-produced vehicles. However, Cloth Carbon Fiber’s more affordable textiles could change that, making it possible to create lightweight, fuel-efficient cars that are also durable and safe.Overall, the potential applications for Cloth Carbon Fiber’s textiles are vast and varied. Their innovative manufacturing process and commitment to quality have already established them as a leader in the industry, and their continued growth and expansion are sure to have a major impact on the world of textiles and beyond.

Read More

High-Quality Carbon Fiber Cloth for Various Applications - Product Information

Read More

Explore the Versatility of Fiberglass Mat and Woven Roving for Various Applications

[Company Name], a leading manufacturer specializing in fiberglass composite materials, has recently introduced a new product called Fiberglass Mat Woven Roving. This innovative material is set to revolutionize various industries with its exceptional strength, durability, and versatility.Fiberglass Mat Woven Roving is a high-performance composite fabric made by interweaving fine fiberglass rovings and a layer of chopped strand mat. This unique combination creates a fabric that offers exceptional properties for a wide range of applications. The material is widely used in the automotive, marine, construction, and aerospace industries due to its outstanding strength-to-weight ratio and resistance to corrosion and fire.With continuously advancing technology and increasing demand for lightweight and high-performance materials, Fiberglass Mat Woven Roving stands out as a remarkable solution. It offers excellent dimensional stability, ensuring optimal shape retention under various environmental conditions. This is particularly crucial in the marine industry, where the material is extensively used in boat building and repair.The automotive industry can also benefit greatly from Fiberglass Mat Woven Roving. Its exceptional strength makes it ideal for reinforcing body panels, frames, and internal structures, providing added safety without compromising weight. Additionally, the material's resistance to chemicals and high temperatures makes it suitable for numerous components and under-the-hood applications.In the construction industry, Fiberglass Mat Woven Roving is highly preferred for its durability and resistance to moisture and weathering. It is commonly utilized in the construction of pipelines, storage tanks, and infrastructure projects, ensuring long-lasting and reliable structures. The material's fire resistance further adds to its appeal, making it an essential choice for fireproofing applications.Aerospace and defense industries also find Fiberglass Mat Woven Roving invaluable. It is widely incorporated into aircraft structures, satellites, and other aerospace components due to its high strength and excellent thermal and electrical insulation properties. Moreover, its lightweight nature contributes to significant fuel savings and overall cost reduction.With its unparalleled versatility, Fiberglass Mat Woven Roving offers endless possibilities for various other applications, including wind turbine blades, sporting goods, and even art and design. Its ease of handling and compatibility with different resin systems make it a preferred choice for manufacturers seeking to enhance their products' mechanical properties.[Company Name], as a trusted leader in the fiberglass composite materials industry, ensures that all its products, including Fiberglass Mat Woven Roving, are manufactured with the highest quality standards. Their state-of-the-art production facilities and rigorous quality control processes guarantee consistent performance and reliability.In addition to providing exceptional products, [Company Name] also prioritizes customer satisfaction by offering excellent customer service and technical support. Their team of experts is readily available to provide guidance and assistance, ensuring that customers can fully maximize the benefits of Fiberglass Mat Woven Roving in their respective applications.As a result of their commitment to innovation and customer-centric approach, [Company Name] has garnered a strong reputation in the market. Their products are trusted by industry professionals worldwide, and their continual investment in research and development ensures that they stay at the forefront of the fiberglass composite materials industry.In conclusion, [Company Name]'s introduction of Fiberglass Mat Woven Roving is set to revolutionize a multitude of industries. This high-performance material offers exceptional strength, durability, and versatility, serving as a game-changer for manufacturers in the automotive, marine, construction, and aerospace sectors. With a commitment to quality and customer satisfaction, [Company Name] continues to shape the future of fiberglass composite materials.

Read More

High-Quality 1/2 oz Fiberglass Cloth - 38 Inches Wide - 3m Long

Read More

High-Quality Fiberglass Woven Fabrics for Marine and Industrial Use

Fiberglass Release Fabric: The Key to Easy Release of Composite MaterialsIn the world of composites, fiberglass fabrics play a crucial role. Fiberglass fabrics are widely used for their outstanding temperature and strength properties, as well as their resistance to rot and mildew. Fiberglass fabrics are commonly used in applications such as marine, aerospace, automotive, and industrial processes.However, the biggest challenge that comes with using fiberglass fabrics is the issue of release. Fiberglass fabrics tend to stick to the composite materials, making it difficult to separate them. This issue can lead to increased production time and waste of materials, which can ultimately affect the profitability of your business.The solution to this problem is the use of fiberglass release fabric. Fiberglass release fabric is designed to prevent fiberglass fabrics from sticking to composite materials. The fabric is coated with a special release agent that prevents adhesion, making it easy to release the composite part from the mold.Fiberglass release fabric is an essential tool for manufacturers who need to produce high-quality composite parts efficiently. Using fiberglass release fabric not only saves time and materials but also ensures the integrity of the finished product.At (need remove brand name), we offer a wide range of fiberglass release fabrics designed to meet the needs of different industries. Our high-quality release fabrics are made from premium fiberglass materials that are asbestos-free and do not harm health. Our products provide an excellent release effect, reduce cycle time and increase productivity; this will help your business improve profitability!Our fiberglass release fabrics are available in various sizes, widths, and thicknesses, and we can customize our fabrics to meet our customer's specific needs. We also offer various coatings to suit different production processes and part geometries.In summary, fiberglass release fabric is a game-changer for manufacturers who use fiberglass fabrics in composite production processes. The use of fiberglass release fabric reduces production time, reduces material waste, and ensures high-quality finished products. At (need remove brand name), we offer high-quality fiberglass release fabrics that will improve production efficiency and ultimately improve your bottom line! So, try our products today and experience the difference!

Read More

Fiberglass Cloth: The Top Choice for Strengthening Materials

Title: Cloth for Fiberglass: A Revolutionary Innovation in the Composite IndustryIntroduction:In an era driven by innovation, the integration of advanced materials and revolutionary techniques is crucial in various sectors. In the field of composites, a recent breakthrough has been achieved with the development of Cloth for Fiberglass. This cutting-edge product has revolutionized the composite industry, enabling enhanced strength and durability across a wide range of applications. This news article aims to explore the features, benefits, and applications of Cloth for Fiberglass, while shedding light on the pioneering company behind this game-changing invention.Company Introduction:Owned and operated by a team of dedicated professionals, the company behind the development of Cloth for Fiberglass is committed to pushing the boundaries of composite materials. With decades of experience in the industry, their expertise has allowed them to engineer an innovative product that surpasses traditional fiberglass cloth. Leveraging their state-of-the-art facilities, the company has successfully manufactured Cloth for Fiberglass, catering to the growing demands and requirements of various sectors.Features of Cloth for Fiberglass:Cloth for Fiberglass boasts several key features that differentiate it from conventional materials. Firstly, its molecular structure has been meticulously designed to offer exceptional strength and sturdiness, making it resistant to impact and external forces. This remarkable strength not only improves the lifespan of the end products but also enhances their structural integrity. Additionally, Cloth for Fiberglass is lightweight and flexible, facilitating ease of use during manufacturing processes. Furthermore, it exhibits exceptional resistance to corrosion, chemicals, and extreme temperatures, making it an ideal choice for harsh environments.Benefits of Cloth for Fiberglass:The introduction of Cloth for Fiberglass provides numerous benefits across various industries. One of its primary advantages is its versatility, allowing its application in numerous sectors, including aerospace, automotive, marine, and construction. By using this innovative material, manufacturers can achieve the perfect balance between strength, weight reduction, and cost-effectiveness. Moreover, the inherent dimensional stability of Cloth for Fiberglass ensures that the end products retain their shape even under extreme conditions. This stability further contributes to the longevity of the final product, reducing maintenance and replacement costs.Applications of Cloth for Fiberglass:The revolutionary Cloth for Fiberglass has found applications across a wide range of sectors, with its unparalleled benefits making it an ideal choice for composite manufacturers. In the aerospace industry, it is utilized for the construction of aircraft components, providing lightweight and durable alternatives. In the automotive sector, it offers solutions for high-performance vehicles, allowing manufacturers to enhance fuel efficiency while maintaining safety standards. Furthermore, Cloth for Fiberglass finds extensive use in the marine industry, contributing to the design and production of sturdy and seaworthy vessels. Its resistance to corrosion and moisture make it particularly suitable for marine applications. Finally, in the construction industry, the cloth is extensively employed to produce durable and strong composite materials for infrastructure projects.Conclusion:The development of Cloth for Fiberglass marks a significant milestone in the composite industry, bringing forth a groundbreaking material that surpasses traditional alternatives. The company behind this innovative product continues to drive the industry forward by harnessing the endless potential of composites. With its remarkable strength, versatility, and resistance to various environmental factors, Cloth for Fiberglass is revolutionizing the way industries design and manufacture their products. As manufacturers increasingly adopt this game-changing cloth, we can expect a paradigm shift in the utilization of composites, opening avenues for enhanced performance, sustainability, and cost-effectiveness.

Read More

Discover the Revolutionary World of Glass Fibre Textiles: Unleash the Potential of High-Performance Materials

In today's fast-paced world, people are constantly seeking out innovative materials that can address their needs. One such material that is gaining popularity is Glass Fibre Textiles. This is a high-performance material that is made from a combination of glass and textile fibers. Glass Fibre Textiles are being used in a wide range of applications across various industries. From construction to textiles, and from aerospace to consumer goods, Glass Fibre Textiles have become a trend setter due to their unique qualities and features.Glass Fibre Textiles are manufactured using different methods, but the most common one is the continuous filament process. In this process, glass fibers are drawn out from molten glass through small orifices. These fibers are then combined with textile materials such as nylon, polyester, or aramid fibers to create the final product. The result is a material that is strong, flexible, and lightweight.One of the key advantages of Glass Fibre Textiles is their high strength-to-weight ratio. This means that they are much stronger than other conventional materials such as steel, while they are also much lighter in weight. This makes Glass Fibre Textiles especially useful in applications where weight is a critical factor, such as in aerospace and automotive industries. Another advantage of Glass Fibre Textiles is their ability to resist high temperatures. They are highly heat-resistant and can withstand temperatures of up to 400°C. This makes them ideal for use in applications where high temperatures are present, such as in the manufacturing and processing of chemicals and in engine components.In addition, Glass Fibre Textiles are also highly abrasion-resistant, making them ideal for use in the construction industry. They can withstand heavy wear and tear, and they are often used as a reinforcement material in concrete structures. Furthermore, Glass Fibre Textiles have excellent electrical insulation properties, which make them ideal for use in electrical and electronic applications.Glass Fibre Textiles have found a wide range of applications in the textile industry. They are incorporated into high-performance fabrics such as fire-resistant fabrics and bullet-proof vests. This is because of their ability to provide excellent protection against heat, abrasion, and impacts.Glass Fibre Textiles are also widely used in the automotive industry. They are used to manufacture body panels, engine components, and suspension components. The high strength-to-weight ratio of Glass Fibre Textiles makes them an ideal material for use in the automobile industry, where weight reduction is a critical factor.Another sector that has seen significant growth in its use of Glass Fibre Textiles is the wind turbine industry. Glass Fibre Textiles are used to manufacture the blades of the wind turbines. The lightweight and durable nature of Glass Fibre Textiles makes it an ideal material for use in this application.In conclusion, Glass Fibre Textiles have become a popular material for use in various industries due to their unique properties. They are strong, lightweight, and durable, making them ideal for use in applications where weight is a critical factor. Glass Fibre Textiles are also highly heat-resistant and abrasion-resistant, making them suitable for use in harsh environments. With the increased demand for high-performance materials that offer excellent protection, Glass Fibre Textiles are expected to continue growing in popularity across various industries.

Read More

Prominent Fiberglass Fabric Manufacturer in China - High-Quality and Durable Fiberglass Fabrics Available

Read More